Precise rolling forming method for large Waspaloy alloy casing forge piece

A large, forging technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

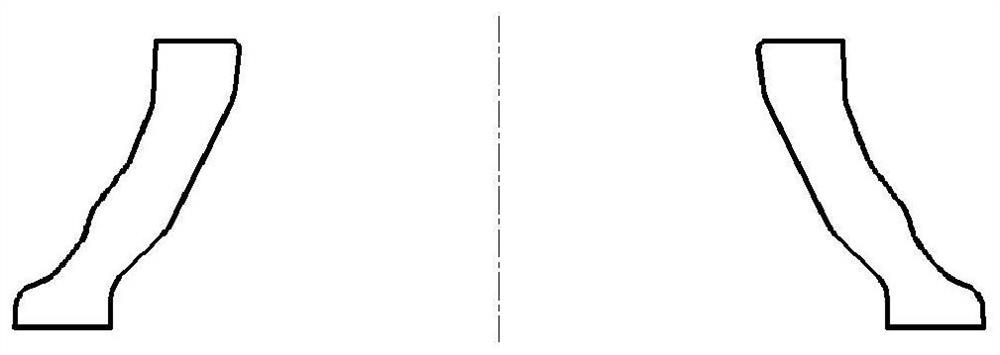

[0016] (1) Preparation of special-shaped intermediate billet: the Waspaloy alloy bar is subjected to blanking, upsetting, punching, horse frame reaming, rectangular pre-rolling and tire mold forming to obtain the required special-shaped intermediate billet, such as figure 1 shown;

[0017] (2) Special-shaped pre-rolling: heat and keep the special-shaped intermediate billet on the Φ3000mm rolling mill for special-shaped pre-rolling, and pre-roll to the design target size.

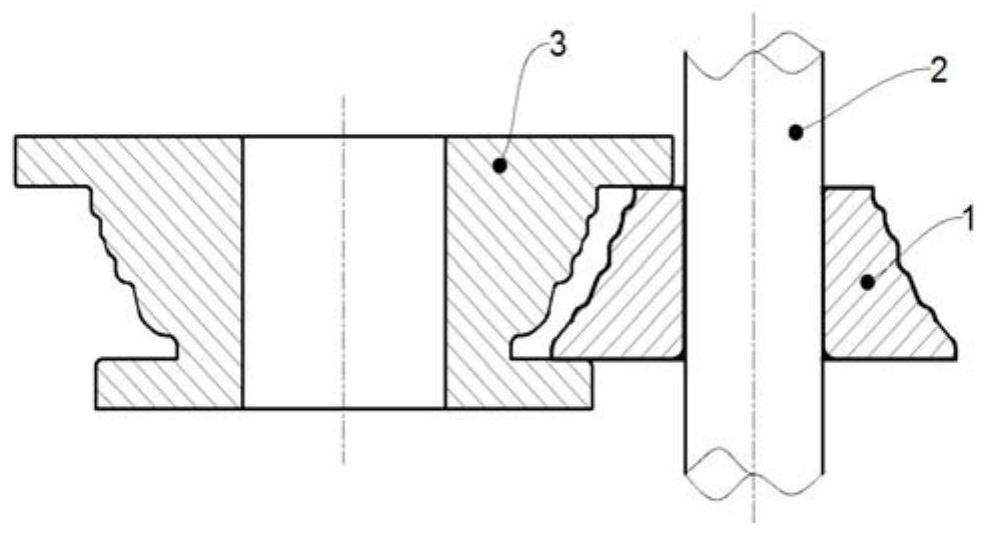

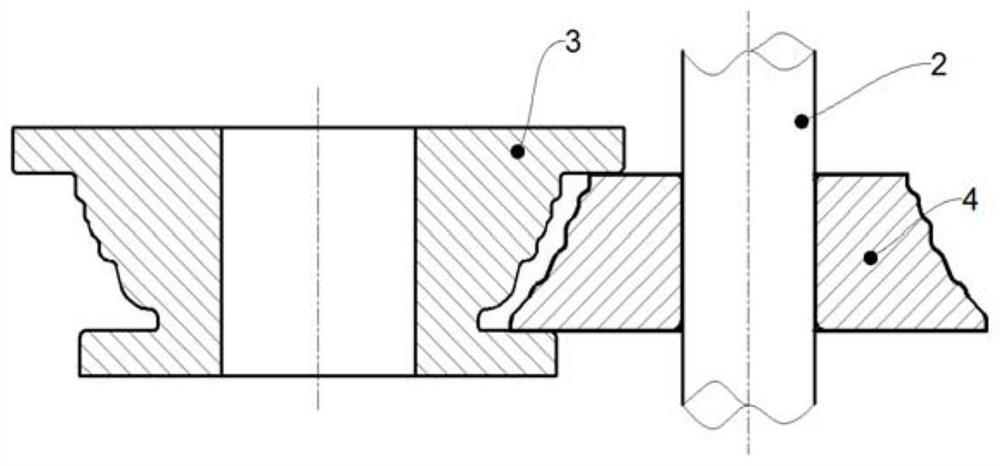

[0018] The special-shaped pre-rolling die such as figure 2 As shown, it includes a pre-rolling mandrel 1, a straight mandrel 2 and a main roll 3; the heated special-shaped intermediate billet is inserted into the pre-rolling mandrel 1, the straight mandrel 2 is inserted into the pre-rolling mandrel 1, and the rolling mill starts rolling. The main roll 3 rotates at an angular speed of 0.5-1.0 rad / s, and the pre-rolling mandrel roll 1 moves toward the main roll 3 at a feed speed of 0.3-2.0 mm / s, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com