Anti-rolling-fracture roller of hot rolling temper mill and application method of anti-rolling-fracture roller

An anti-coil and unit technology, which is used in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of inability to guarantee the surface quality and performance of strip steel, poor wear resistance of the tempering unit, and unstable structure. The effect of being pulled off, improving the surface quality and performance of the strip, and structurally reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

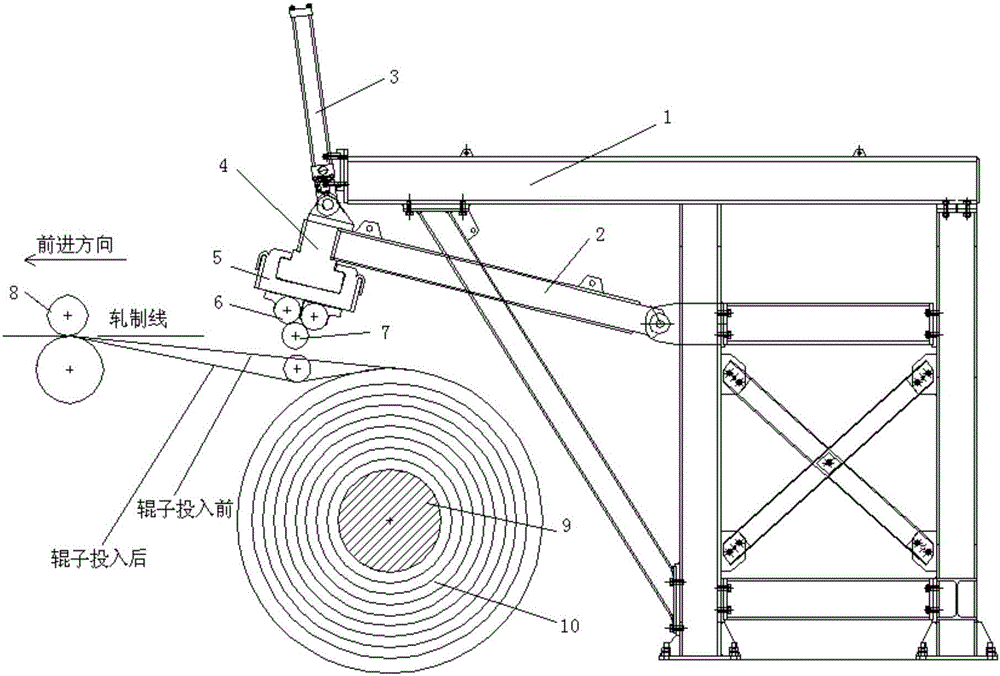

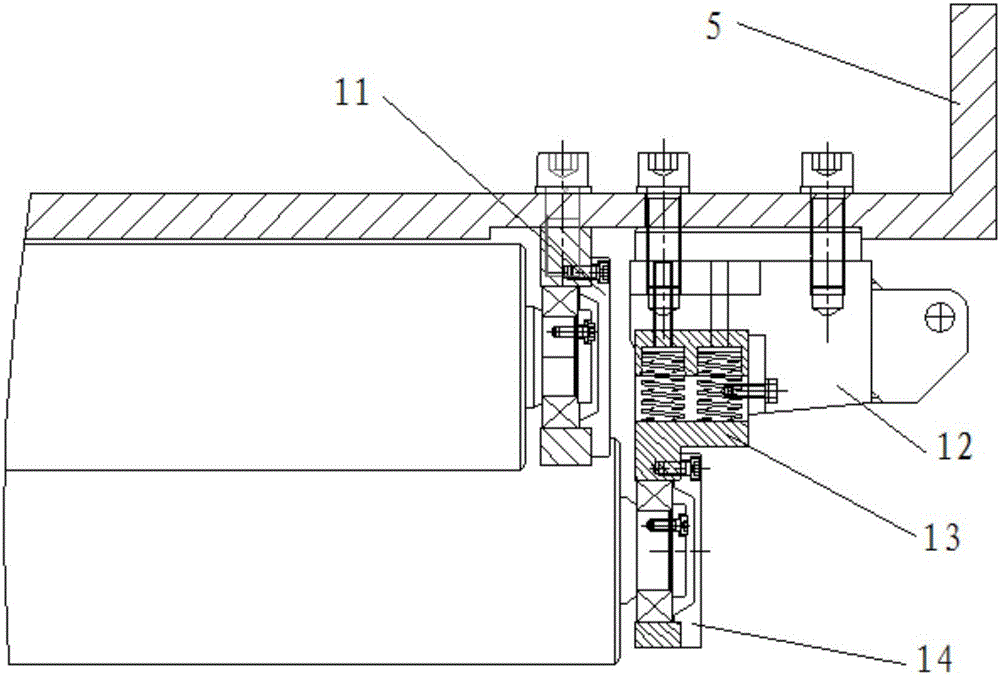

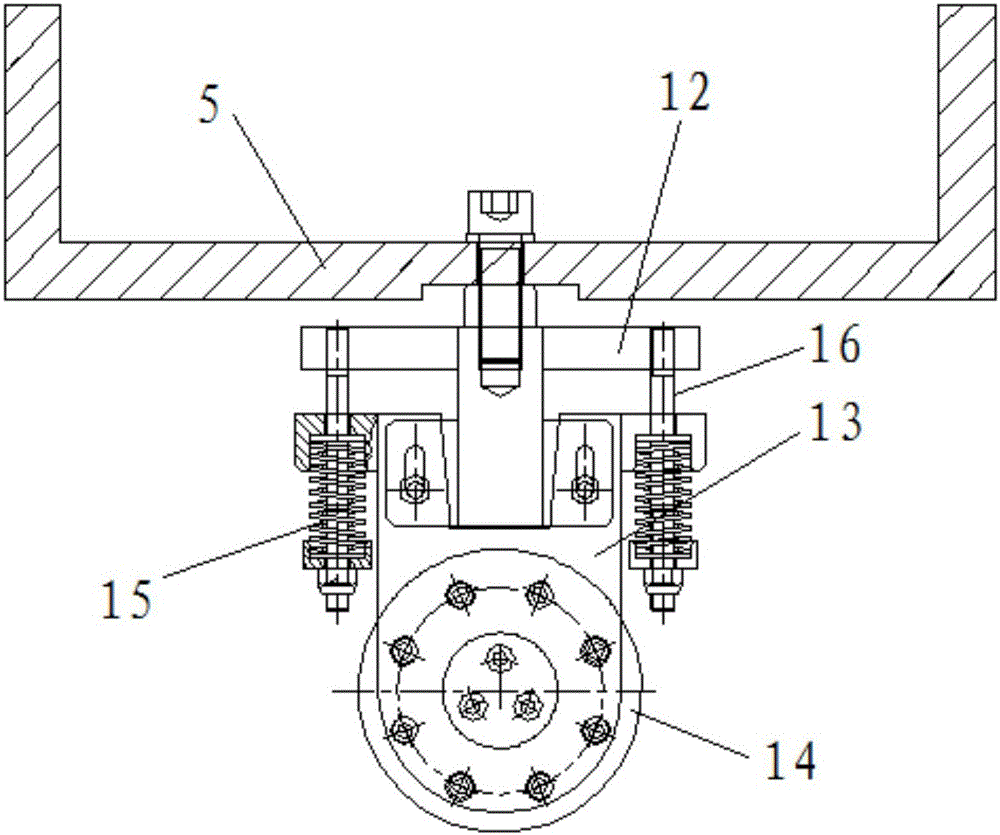

[0072] The structure of the anti-rolling and breaking rolls of the hot-rolling and skin-passing unit is as follows:

[0073] 4 back-up rolls 6 and 1 work roll 7 are arranged in reverse order; the back-up roll 6 and work roll 7 are solid structures with a diameter of 200mm and a hardness of 58HRC; self-lubricating bearing 14 type BS2-2214-2CS / VT134; The first bearing assembly includes: a common type bearing housing 11, a self-lubricating bearing, a gland, an end cover, and bolts. The first bearing assembly includes: a wing-shaped support 12 , a figure-shaped support 13 , a self-lubricating bearing 14 , an end cover, bolts, studs 16 , and a spring 15 . The length of spring 15 is 102mm, the outer diameter is 38mm, and the inner diameter is 20mm.

[0074] An anti-roll breaking roller is installed between the reel of the uncoiler 9 and the entrance pinch roller 8 . Wherein, a fixed frame 1 is set on the foundation on the right side of the reel of the uncoiler 9, and the lifting h...

Embodiment 2

[0082] The structure of the anti-rolling and breaking rolls of the hot-rolling and skin-passing unit is as follows:

[0083] 4 back-up rolls 6 and 1 work roll 7 are arranged in reverse order; the back-up roll 6 and work roll 7 are solid structures with a diameter of 200mm and a hardness of 58HRC; self-lubricating bearing 14 type BS2-2214-2CS / VT134; The first bearing assembly includes: a common type bearing housing 11, a self-lubricating bearing, a gland, an end cover, and bolts. The first bearing assembly includes: a wing-shaped support 12 , a figure-shaped support 13 , a self-lubricating bearing 14 , an end cover, bolts, studs 16 , and a spring 15 . The length of spring 15 is 102mm, the outer diameter is 38mm, and the inner diameter is 20mm.

[0084] An anti-roll breaking roller is installed between the reel of the uncoiler 9 and the entrance pinch roller 8 . Wherein, a fixed frame 1 is set on the foundation on the right side of the reel of the uncoiler 9, and the lifting h...

Embodiment 3

[0092] The structure of the anti-rolling and breaking rolls of the hot-rolling and skin-passing unit is as follows:

[0093] 4 back-up rolls 6 and 1 work roll 7 are arranged in reverse order; the back-up roll 6 and work roll 7 are solid structures with a diameter of 200mm and a hardness of 58HRC; self-lubricating bearing 14 type BS2-2214-2CS / VT134; The first bearing assembly includes: a common type bearing housing 11, a self-lubricating bearing, a gland, an end cover, and bolts. The first bearing assembly includes: a wing-shaped support 12 , a figure-shaped support 13 , a self-lubricating bearing 14 , an end cover, bolts, studs 16 , and a spring 15 . The length of spring 15 is 102mm, the outer diameter is 38mm, and the inner diameter is 20mm.

[0094] An anti-roll breaking roller is installed between the reel of the uncoiler 9 and the entrance pinch roller 8 . Wherein, a fixed frame 1 is set on the foundation on the right side of the reel of the uncoiler 9, and the lifting h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com