Production method of thin gauge low carbon steel by ferritic rolling in csp production line

A production method and ferrite technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of high yield ratio, high yield strength, and high pass reduction ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with specific embodiments, so that those skilled in the art can understand.

[0043] In the CSP production line, ferrite rolling is used to produce thin-gauge low-carbon steel production methods. This method includes five major steps: soaking, phosphorus removal, finish rolling, coiling, and slow cooling under heat preservation covers. Among them:

[0044] 1) Soaking: the thickness of the slab is 50-60mm, the temperature of the slab out of the furnace is controlled at 990-1030°C, and the excess air coefficient is 1.2-1.4; 2) Phosphorus removal: the pressure of phosphorus removal is controlled at 30-40MPa;

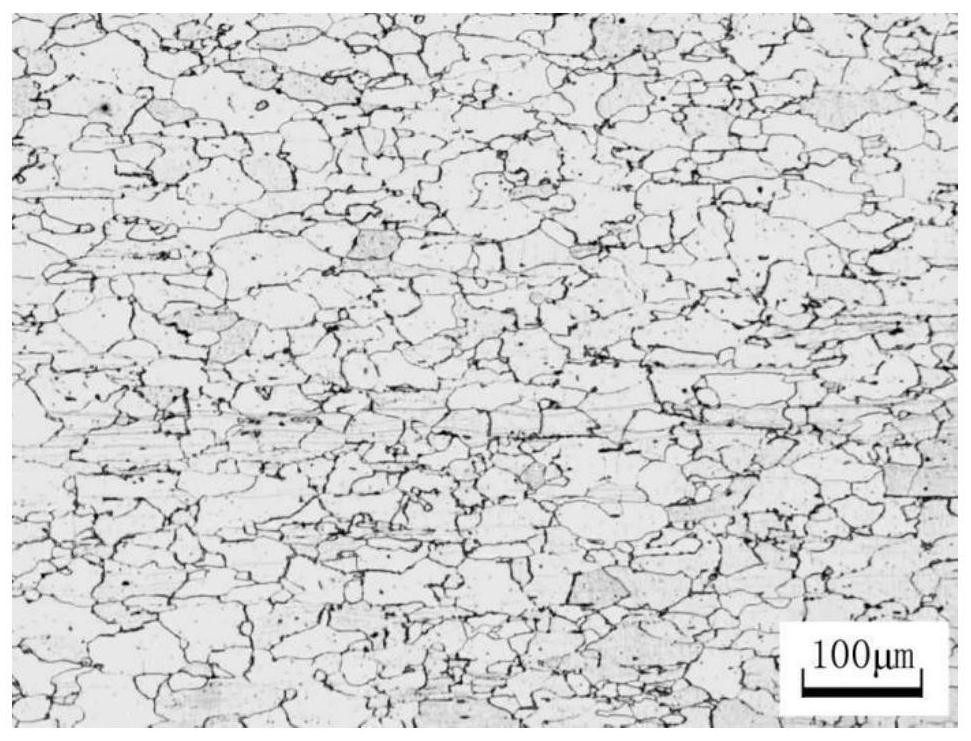

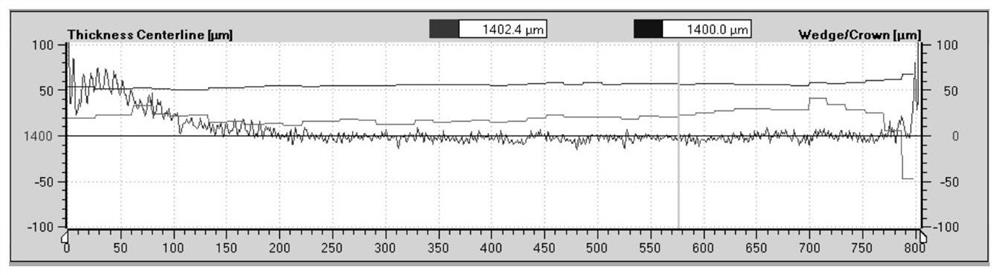

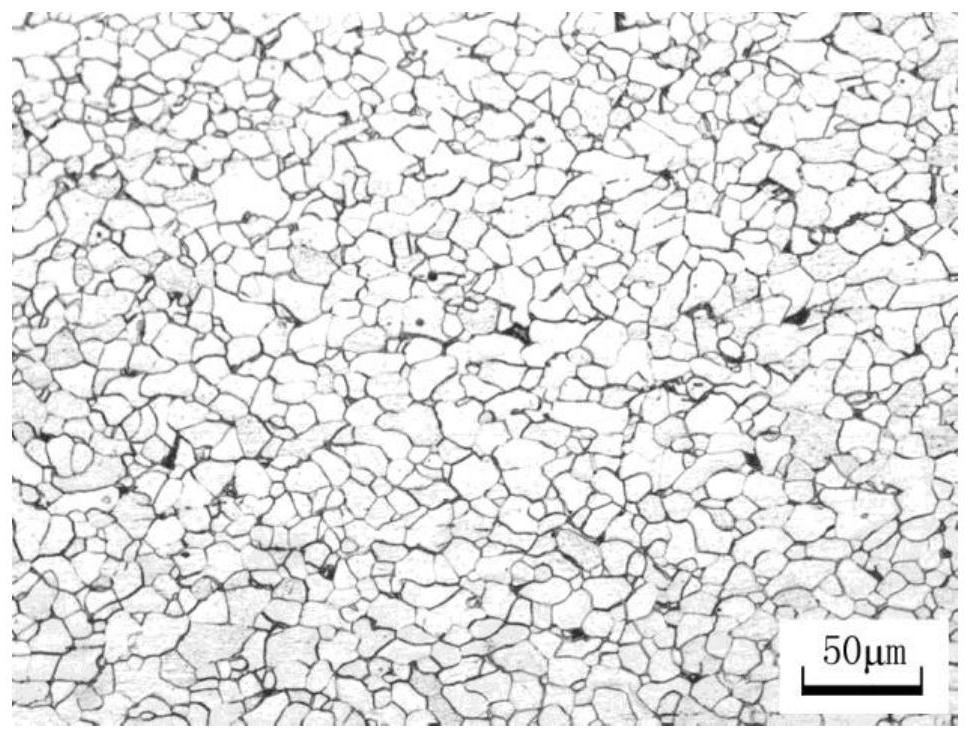

[0045] 3) Finish rolling: finish rolling is rolling with 6 to 7 stands (the stands are F1 to F7 respectively), the starting temperature of finish rolling is 900 to 950°C, and the reduction ratios of F1 and F2 stands are controlled to be 50-60%, the average reduction rate of F3 frame and F4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com