A kind of preparation method of bimetallic composite finned tube

A finned tube and bimetallic technology, which is applied in the field of composite pipe preparation, can solve the problems of adverse plasticity of bimetallic composite pipes, easy formation of brittle intermetallic compounds, and long bimetallic retention time, achieving large reduction and low cost Low, the effect of improving tissue density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of pure titanium-clad red copper bimetallic composite finned tubes.

[0025] (1) Pretreatment: The specification of pure titanium tube is 70mm in diameter and 5mm in wall thickness; Die steel); use 4% NaOH solution to degrease pure titanium tubes and copper tubes, and use 20% HNO for pure titanium tubes 3 Pickling with +7% HF solution, and pickling the copper tube with 12% HCl solution; then use a wire brush to polish the inner surface of the pure titanium tube and the outer surface of the copper tube to form a fresh metal matrix.

[0026] (2) Sleeve assembly: put the polished copper tube into the pure titanium tube, and insert the mandrel of the planetary rolling mill into the copper tube.

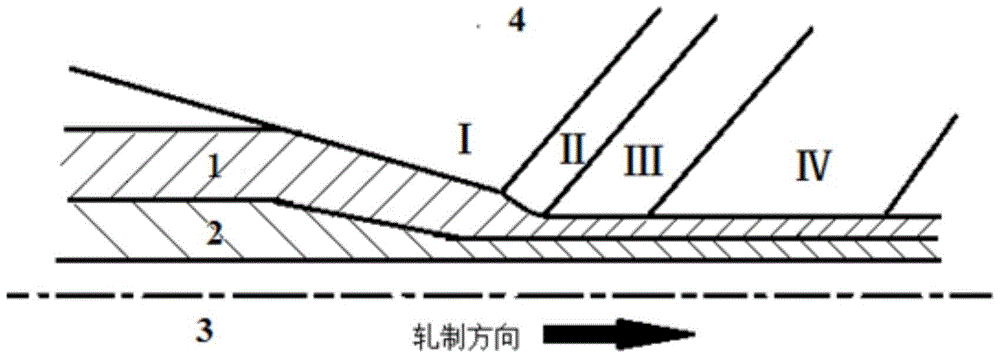

[0027] (3) Rolling composite: use a three-roll planetary rolling mill to roll the inner and outer tubes into a composite smooth tube. During rolling, the pure titanium-clad copper bimetal composite tube is heated by online induction. The heating temperature is 400-450 ...

Embodiment 2

[0031] Preparation of pure titanium clad 20 steel bimetallic composite finned tube.

[0032] (1) Pre-treatment: pure titanium tube is 60mm in diameter, 5mm in wall thickness, 49.5mm in diameter, 5mm in wall thickness in No. 20 steel pipe, 0.5mm in casing gap, 3m in length, and Φ39mm in diameter For die steel), use 4% NaOH solution to degrease pure titanium pipe and No. 20 steel pipe, and use 20% HNO for pure titanium pipe 3 +7% HF solution for pickling, 20 steel pipes with 10% H 2 SO 4 The solution is pickled, and then the inner surface of the pure titanium tube and the outer surface of the 20-gauge steel pipe are ground to a fresh metal matrix with a wire brush.

[0033] (2) Casing assembly: put the polished No. 20 steel pipe into the pure titanium pipe, and insert the mandrel of the planetary rolling mill into the No. 20 steel pipe.

[0034] (3) Rolling composite: use a three-roll planetary rolling mill to roll the inner and outer tubes into a composite smooth tube, and c...

Embodiment 3

[0037] Preparation of pure titanium clad pure aluminum bimetallic composite finned tubes.

[0038] (1) Pre-treatment: The specification of pure titanium tube is 65mm in diameter, 6mm in wall thickness, the specification of pure aluminum tube is 52.5mm in diameter, 6mm in diameter, the casing gap is 0.5mm, the length is 5m, and the mandrel diameter is Φ40mm (the material is mold Steel), use 4% NaOH solution to degrease pure titanium tubes and pure aluminum tubes, use 20% HNO for pure titanium tubes 3 +7% HF solution for pickling, pure aluminum tube for pickling with 5% HCl solution, and then use a wire brush to polish the inner surface of the pure titanium tube and the outer surface of the pure aluminum tube to form a fresh metal matrix.

[0039] (2) Sleeve assembly: put the polished pure aluminum tube into the pure titanium tube, and insert the mandrel of the planetary rolling mill into the pure aluminum tube.

[0040] (3) Rolling composite: use a three-roll planetary rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com