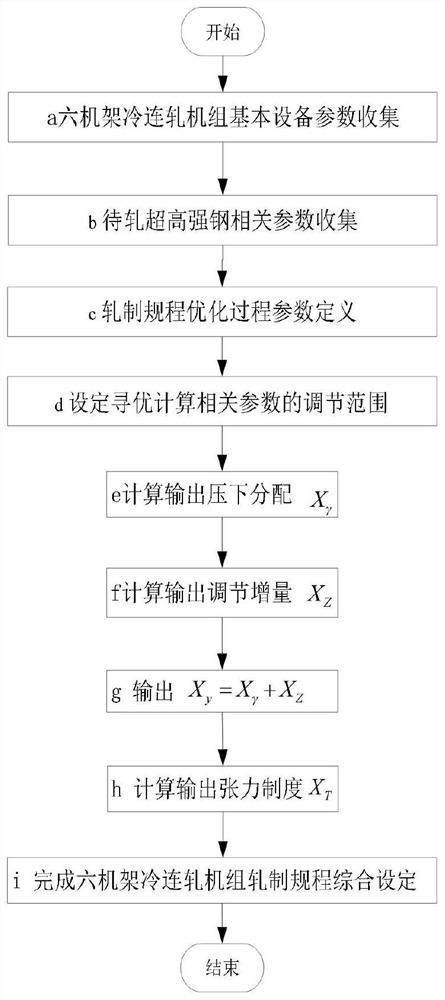

Comprehensive optimization setting method for rolling schedule of ultrahigh-strength steel of six-rack cold continuous rolling unit

A cold tandem rolling unit and ultra-high-strength steel technology, which is applied in the field of cold rolling, can solve the problems of affecting comprehensive rolling capacity and different comprehensive rolling capacity, so as to achieve uniform investment in rolling mill equipment capacity, ensure rolling stability, and ensure rolling stability. The effect of manufacturing stability and finished product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

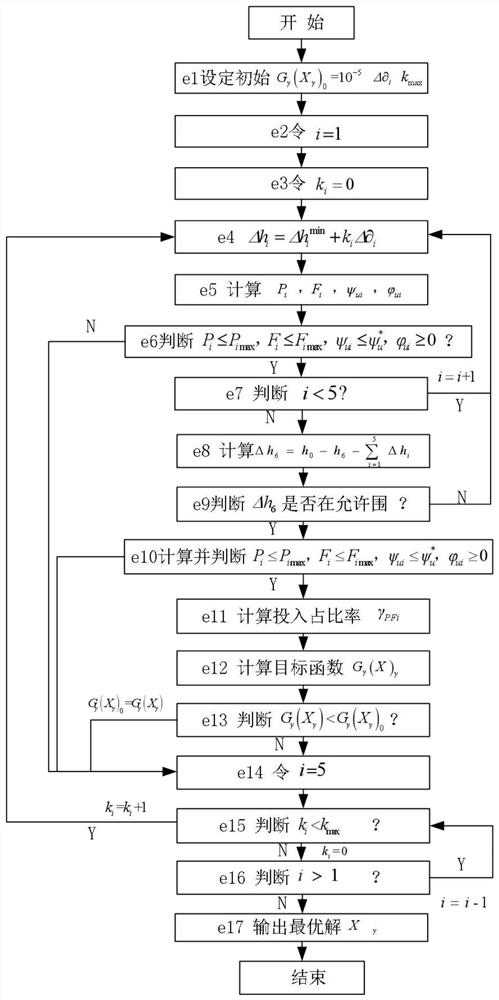

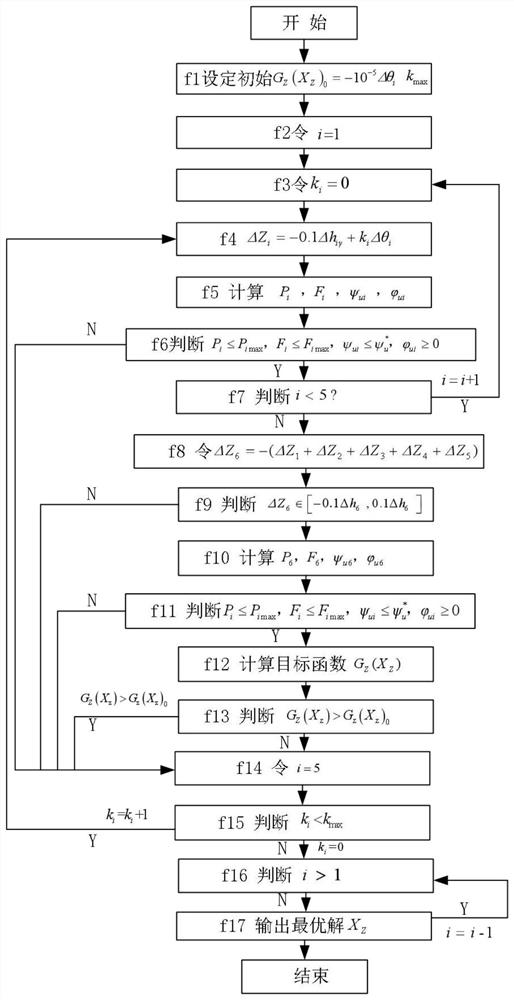

Method used

Image

Examples

Embodiment 1

[0087] First, the basic equipment parameters of the six-frame cold rolling unit, including: a conventional rolling mill (first, 2, 3, 5, 6 rack) and a small roller rolling mill (fourth rack) work roller The roller diameter is shown in Table 1, the maximum rolling pressure allows value

[0088] {P 1max , P 2max , P 3max , P 4max , P 5max , P 6max } = {27000, 27000, 27000, 27000, 27000, 27000} KN, maximum rolling power allowable value

[0089] {F 1max , F 2max , F 3max , F 4max , F 5max , F 6max } = {4200, 6000, 6000, 6400, 6000, 6000} KW The maximum allowable value and minimum allowable value of the tension of the i-1 rack

[0090] {T 1,2max , T 2,3max , T 3,4max , T 4,5max , T 5,6max } = {600, 600, 600, 600, 600} KN

[0091] {T 1,2min , T 2,3min , T 3,4min , T 4,5min , T 5,6min } = {58, 58, 58, 58, 58} KN

[0092] Table 1

[0093]

[0094] In step (b), the collected parameters to be rolled, high-stroke, including: collecting steel material thickness h 0 = 3.025mm, steel finished...

Embodiment 2

[0158] First, the basic equipment parameters of the six-frame cold rolling unit, including: a conventional rolling mill (first, 2, 3, 5, 6 rack) and a small roller rolling mill (fourth rack) work roller Roller diameter is as shown in Table 1, the maximum rolling pressure allowable value

[0159] {P 1max , P 2max , P 3max , P 4max , P 5max , P 6max } = {27000, 27000, 27000, 27000, 27000, 27000} KN, maximum rolling power allowable value

[0160] {F 1max , F 2max , F 3max , F 4max , F 5max , F 6max } = {4200, 6000, 6000, 6400, 6000, 6000} KW The maximum allowable value and minimum allowable value of the tension of the i-1 rack

[0161] {T 1,2max , T 2,3max , T 3,4max , T 4,5max , T 5,6max } = {600, 600, 600, 600, 600} KN

[0162] {T1,2min , T 2,3min , T 3,4min , T 4,5min , T 5,6min } = {58, 58, 58, 58, 58} KN

[0163] Table 1

[0164]

[0165] In step (b), the collected parameters to be rolled, high-stroke, including: collecting steel material thickness h 0 = 2.925mm, steel finishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com