Production method for rolling production of thin-gauge low-carbon steel from ferrite on CSP production line

A production method and ferrite technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of high pass reduction, poor formability, and high yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with specific embodiments, so that those skilled in the art can understand.

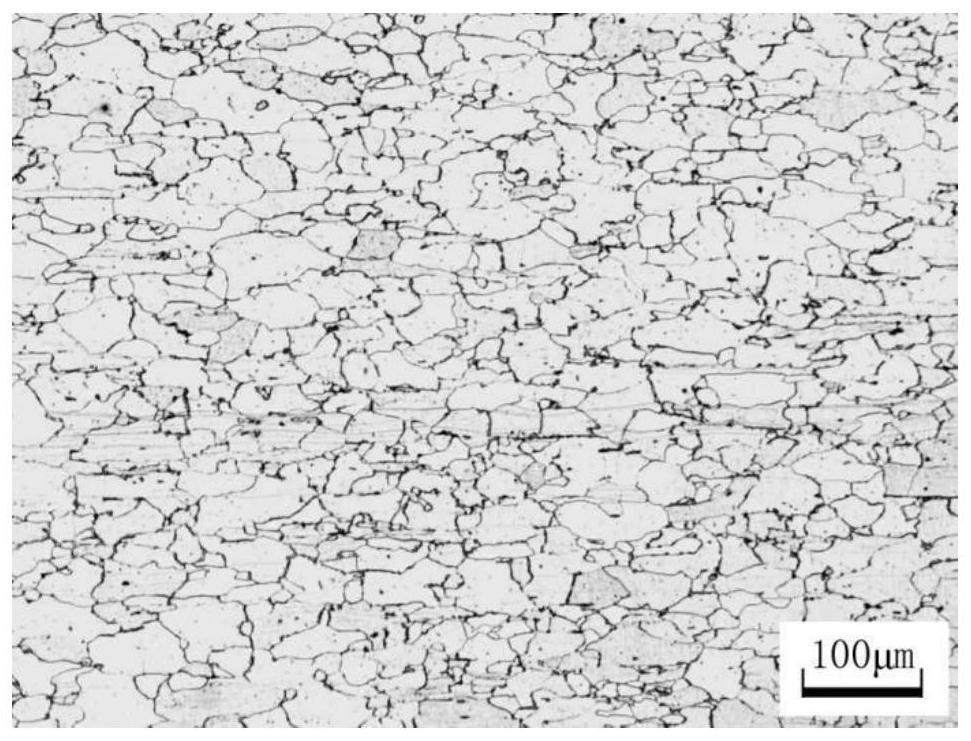

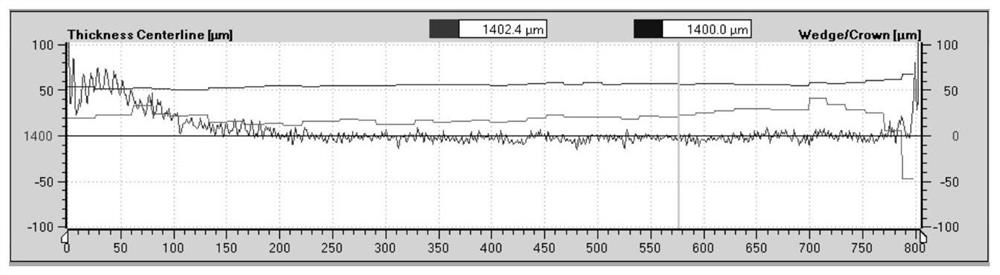

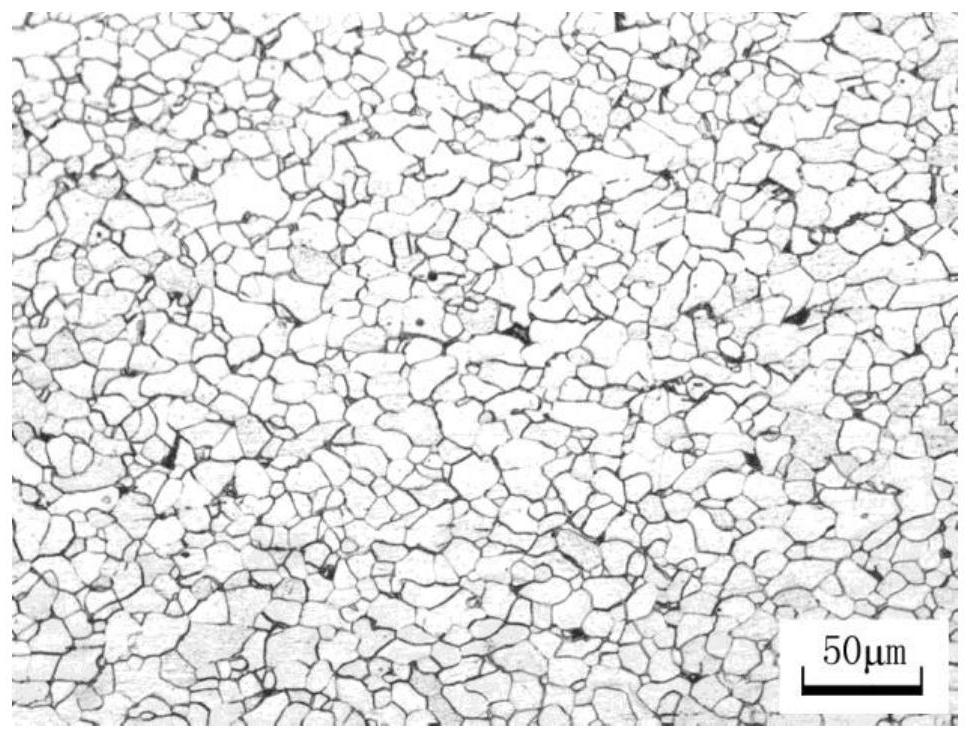

[0043] In the CSP production line, ferrite rolling is used to produce thin-gauge low-carbon steel production methods. This method includes five major steps: soaking, phosphorus removal, finish rolling, coiling, and slow cooling under heat preservation covers. Among them:

[0044] 1) Soaking: the thickness of the slab is 50-60mm, the temperature of the slab out of the furnace is controlled at 990-1030°C, and the excess air coefficient is 1.2-1.4; 2) Phosphorus removal: the pressure of phosphorus removal is controlled at 30-40MPa;

[0045] 3) Finish rolling: finish rolling is rolling with 6 to 7 stands (the stands are F1 to F7 respectively), the starting temperature of finish rolling is 900 to 950°C, and the reduction ratios of F1 and F2 stands are controlled to be 50-60%, the average reduction rate of F3 frame and F4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com