Building station type production line for simultaneous production of sand and aggregate

A production line and building station technology, applied in chemical instruments and methods, mixing plants, clay preparation equipment, etc., can solve the problems of high particle size requirements, easy resonance, and high cost of dust removal, and achieve control of sand and gravel content. The effect of powder quantity and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

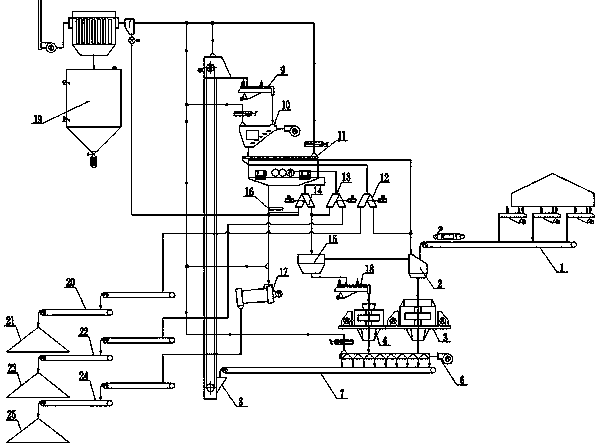

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

[0026] Such as figure 1 As shown, a floor-standing production line capable of producing sand and aggregates at the same time includes a multi-layer vertically arranged steel structure frame, and dual-main crushing equipment connected by a PLC control system, two Wind separation equipment, finished sand fineness modulus control device 16, humidifier 17 and dust collection equipment 19 are installed at the first stage, and the dust collection equipment 19 is connected to the dust outlet of each equipment through dust collection pipes.

[0027] The dual-host crushing equipment includes a shaping machine 3, a sand making machine 4 and a vibrating screening mechanism. The shaping machine 3 is a constant-speed shaping vertical shaft crusher with overflow; the sand mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com