Preparation method of high-nickel positive electrode material of lithium secondary battery

A lithium secondary battery and positive electrode material technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of difficult doping process, complicated preparation process, and difficult application process, and achieve the control of depth and content , The production process is flexible, and the effect of avoiding aggravation and destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Preparation of Li 0.2 Ni0.8 co 0.1 mn 0.1 o 2 Oxide

[0035] Lithium carbonate, nano manganese dioxide and Ni 0.8 co 0.1 (OH) 2 Mixing was carried out in a molar ratio of 0.1:0.1:1. The mixed raw materials were heated from room temperature to 350°C at a heating rate of 2°C / min in an air atmosphere, and then heated to 950°C for 5 hours after holding for 3 hours, and then cooled naturally to room temperature to obtain doped Li 0.2 Ni 0.8 co 0.1 mn 0.1 o 2 Oxide intermediates with a median particle size of about 10 μm.

[0036] 2) Preparation of LiNi 0.8 co 0.1 mn 0.1 o 2 Cathode material

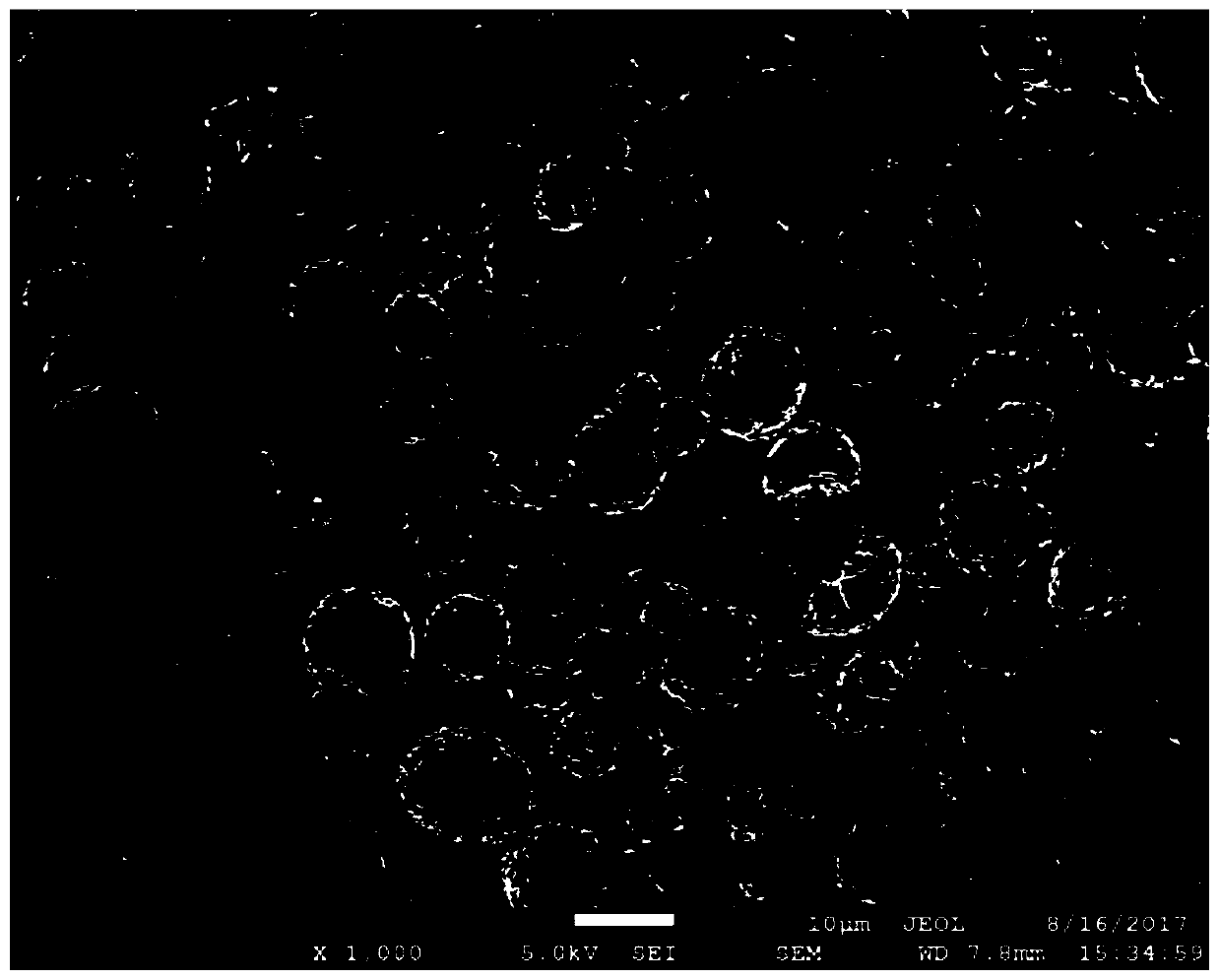

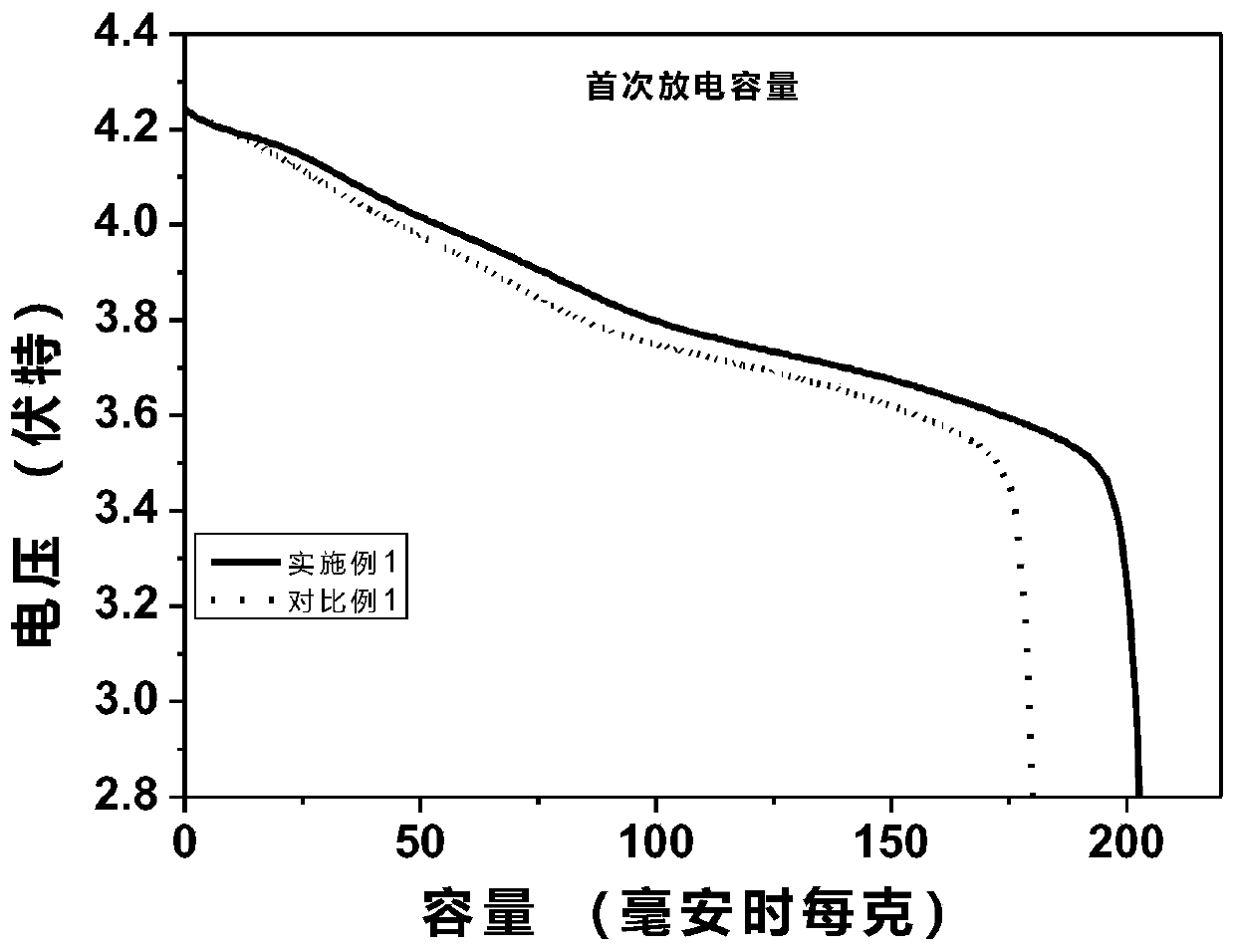

[0037] Lithium hydroxide and the oxide intermediate obtained in step 1 were mixed according to a molar ratio of 0.8:1. After the mixed powder was calcined in oxygen at 750 °C for 10 h, LiNi 0.8 co 0.1 mn 0.1 o 2 Lithium-containing oxides, with a median particle size of about 11 μm, such as figure 1 shown.

[0038] Using N-methylpyrrolidone as a solvent, stir th...

Embodiment 2

[0040] 1) Preparation of Li 0.3 Ni 0.8 co 0.1 mn 0.095 Zr 0.005 o 2 Oxide

[0041] Lithium nitrate, nano zirconium dioxide and Ni 0.8 co 0.1 mn 0.095 (OH) 2 Mixing was carried out in a molar ratio of 0.3:0.005:1. The mixed raw materials were heated from room temperature to 350 °C at a heating rate of 1 °C / min in an air atmosphere, and then heated to 1000 °C for 5 h after holding for 3 hours, and then naturally cooled to room temperature to obtain doped Li 0.3 Ni 0.8 co 0.1 mn 0.095 Zr 0.005 o 2 Oxide intermediates, with a median particle size of about 8.5 μm.

[0042] 2) Preparation of LiNi 0.8 co 0.1 mn 0.095 Zr 0.005 o 2 Cathode material

[0043] Lithium hydroxide and the oxide intermediate product obtained in step 1 were mixed according to a molar ratio of 0.7:1. After the mixed powder was calcined in oxygen at 850 °C for 10 h, LiNi 0.8 co 0.1 mn 0.095 Zr 0.005 o 2 Lithium-containing oxide with a median particle size of about 9.5 μm.

[0044] Usi...

Embodiment 3

[0046] 1) Preparation of Li 0.01 Ni 0.8 co 0.1 mn 0.095 Zr 0.005 o 2 Oxide

[0047] Lithium hydroxide, nano zirconium dioxide and Ni 0.8 co 0.1 mn 0.095 (OH) 2 Mixing was carried out in a molar ratio of 0.01:0.005:1. The mixed raw materials were heated from room temperature to 350 °C at a heating rate of 3 °C / min in an air atmosphere, and then heated to 1000 °C for 5 h after holding for 3 hours, and then naturally cooled to room temperature to obtain doped Li 0.01 Ni 0.8 co 0.1 mn 0.095 Zr 0.005 o 2 Oxide intermediates, with a median particle size of about 9 μm.

[0048] 2) Preparation of LiNi 0.8 co 0.1 mn 0.095 Zr 0.005 o 2 Cathode material

[0049] Lithium hydroxide and the oxide intermediate product obtained in step 1 were mixed according to a molar ratio of 0.99:1. After the mixed powder was calcined in oxygen at 820 °C for 10 h, LiNi 0.8 co 0.1 mn 0.095 Zr 0.005 o 2 Lithium-containing oxide with a median particle size of about 10 μm.

[0050] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com