Structure for encapsulating multichip LED

A technology of LED packaging and packaging structure, applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve problems such as LED damage, affecting reliability and life, and achieve expanded contact, increased working voltage, and anti-electricity high impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Embodiment 1 Encapsulation of a single high-power LED chip.

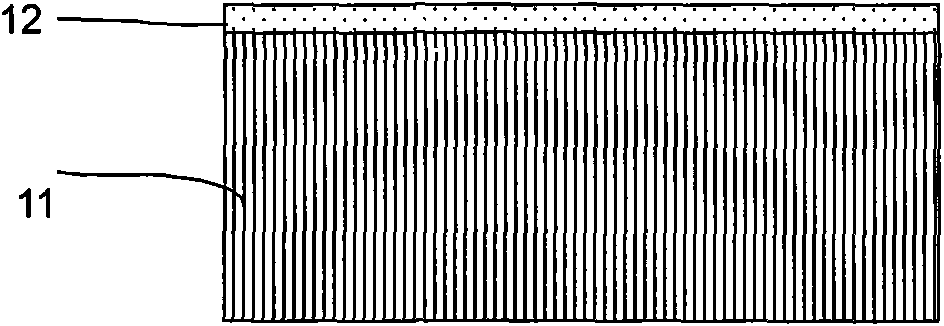

[0036] figure 1 is the structure of the substrate 10 . Its lower layer 11 is a metal with good heat dissipation, and the first choice is light in weight, high in thermal conductivity, and easy to process aluminum and becomes the first choice. The upper layer 12 is a film grown by sputtering, preferably AlN and SiC.

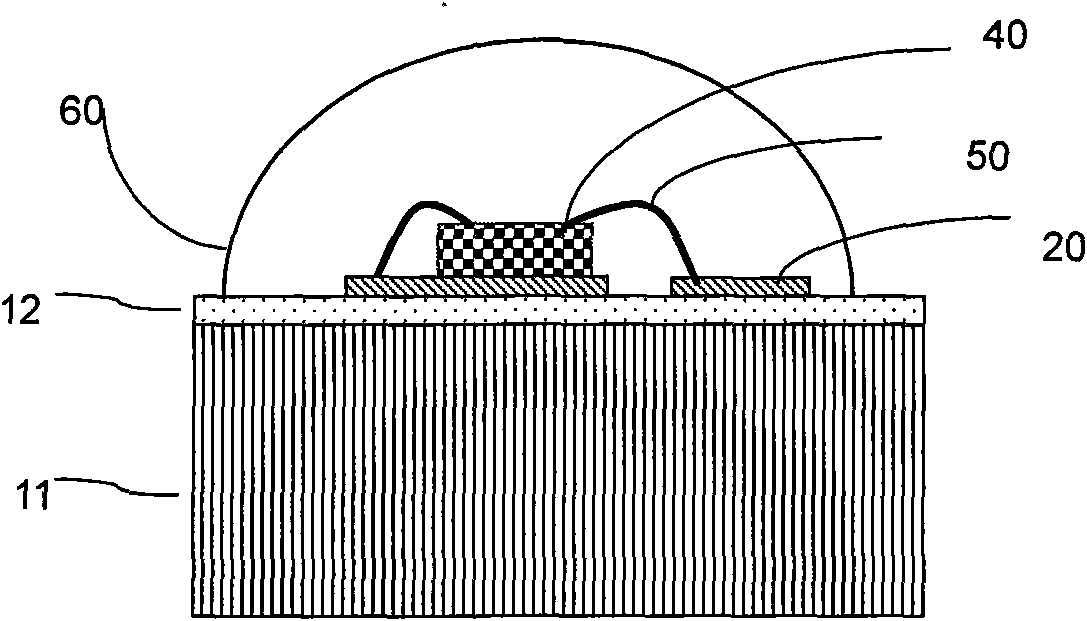

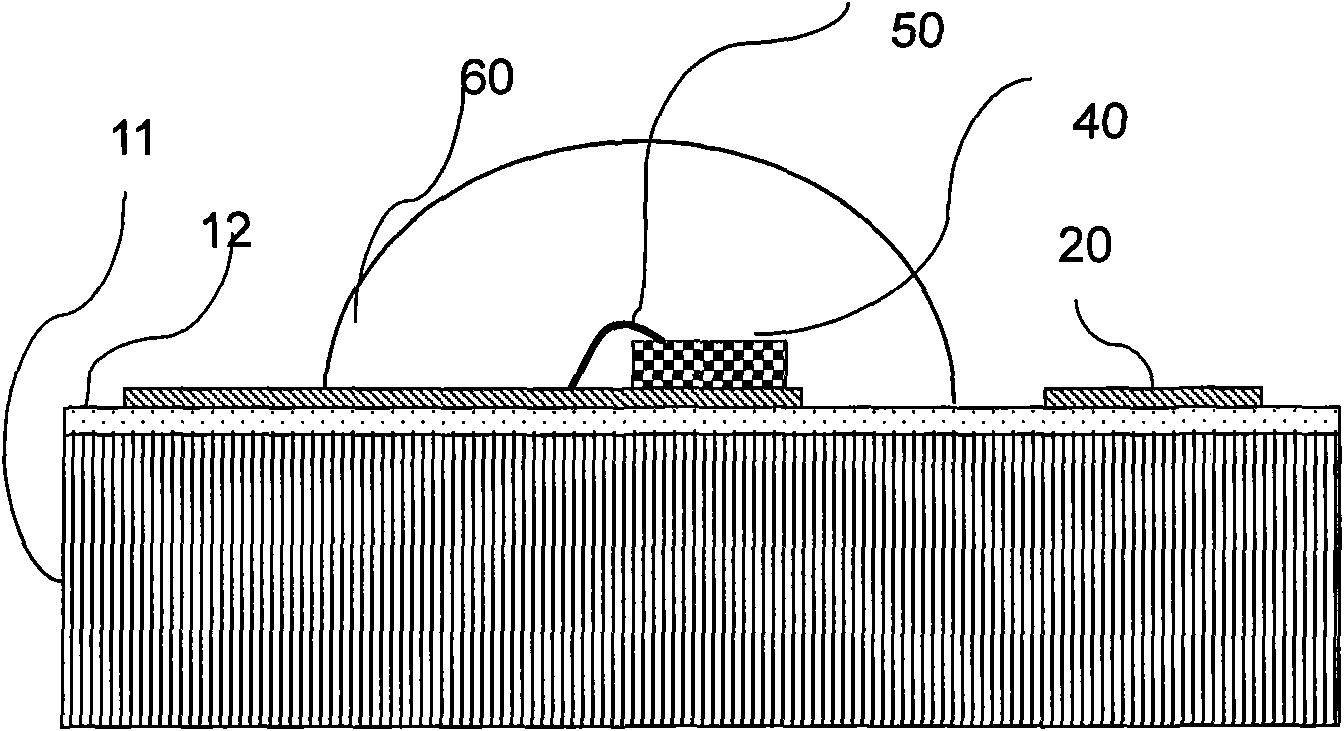

[0037] figure 2 , 3, 4, is a structure in which a single high-power LED chip 40 and a transient protection diode 30 are packaged together. The bracket 20 is prefabricated in a certain shape, and its material is preferably copper, on which tin is plated as required. The LED and the transient protection chip are bonded on the bracket 20 with an adhesive, such as silver paste. After baking and fixing, use a bonding machine to make connecting wires 50, mainly gold wires here, and weld the positive and negative electrodes of the chips 30 and 40 to the bracket 20 respectively. Evenly spread a thi...

Embodiment 2

[0038] Embodiment 2 Packaging of Multi-chip Parallel LEDs

[0039] Using the same production method as in Embodiment 1, changing the shape of the support 20 can produce high-power LEDs formed by parallel connection of smaller power chips. Figure 5 A method of connecting 16 low-power LED chips 40 and a protection chip 30 in parallel to form a 1W power LED is shown. This method not only reduces the thermal resistance between different layers, but also increases the heat dissipation area of the LED chip, so the resistance of the system is reduced by about 30% compared with the conventional packaging method.

Embodiment 3

[0040] Embodiment 3 Packaging of multi-chip series-parallel LEDs

[0041] Figure 6 16 LED chips 40 and one protection chip 30 are packaged in series and parallel. The feature of this packaging method is that it can change the driving voltage of the finished LED product and improve the energy replacement efficiency of the power supply. Although LED is a light source with high energy efficiency, its final power conversion efficiency is also affected by power conversion efficiency. As we all know, LED is a low-voltage current-driven device. In order to make it work stably and reliably, it is necessary to change the power supply voltage, such as replacing AC with DC, and replacing high-voltage DC with low-voltage DC. Constant current, and these conversions will lose some energy. If the working conditions of the LED can be made as close as possible to the voltage conditions of the power supply, this part of energy loss can be reduced and the overall energy conversion efficiency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com