High-temperature-resistant high-yield cellulase bacillus subtilis and application thereof

A technology of Bacillus subtilis and Bacillus, applied in the direction of enzymes, bacteria, enzymes, etc., can solve the problems of high production cost of cellulase, long production cycle of fungi, and long time consumption, and achieve a wide range of temperature and pH stability, easy to use The effect of pure culture and stable fermentation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Enrichment culture:

[0042] Add 1g of soil sample to 50ml enrichment medium, the composition of enrichment medium is: 1-2.5g / L KH 2 PO 4 , 1.2-1.8g / L (NH4) 2 SO 4 , 0.3-0.6g / L MgSO 4 .7H 2 O, 0.1-0.4g / L CaCl 2 , 0.001-0.005g / LFeSO 4 .7H 2 O, 0.5-1.5g / L tryptone, 5-10g / L CMC-Na. Cultivate at 37° C. and 200 rpm for 48 hours. After the end of the cultivation, take 1 ml of the culture solution and re-cultivate in the same condition in the fresh enrichment medium, and repeat three times.

[0043] Primary screening:

[0044] CMC-Na plate experiment

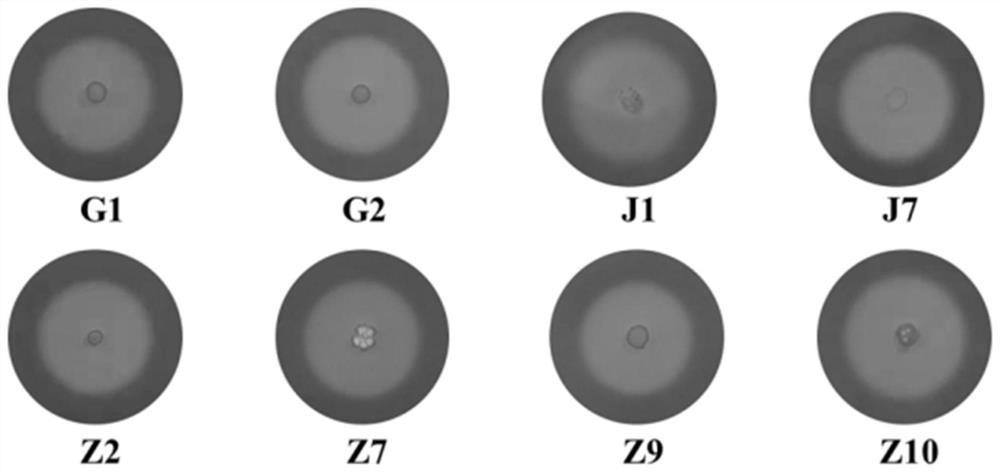

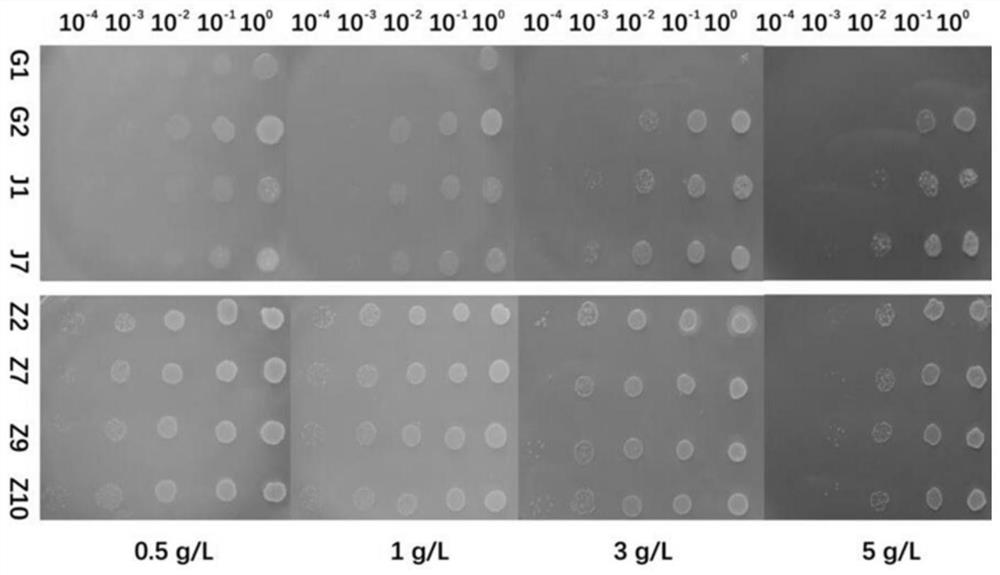

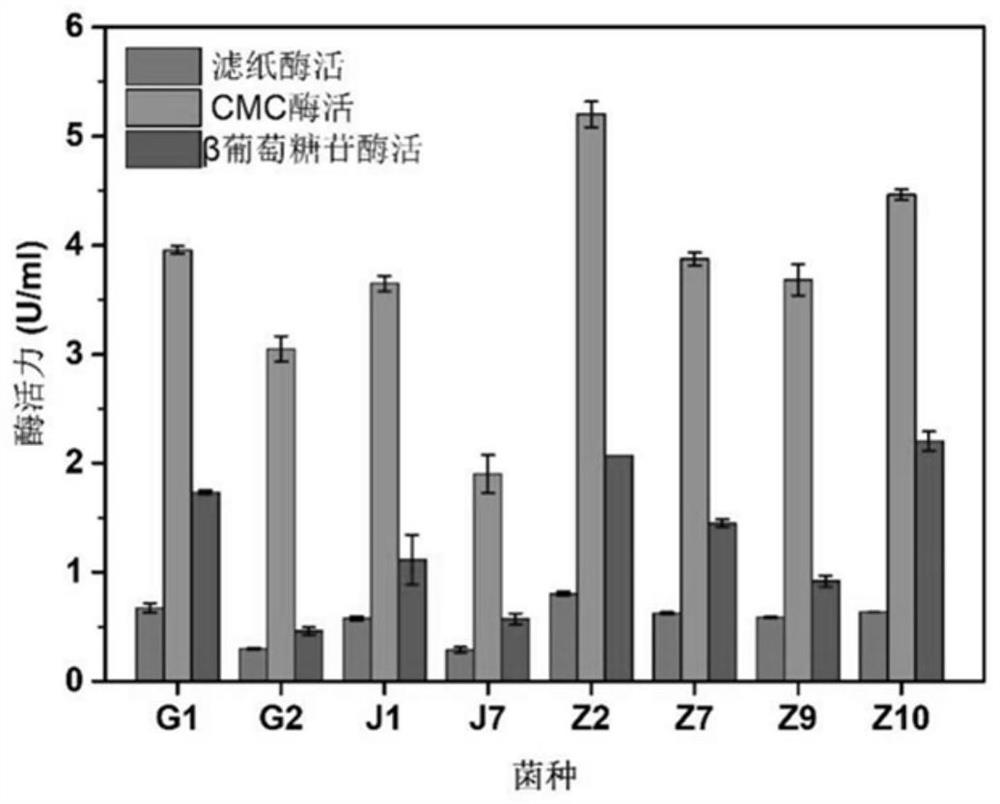

[0045] Take 1ml of the enriched culture solution and spread it on the CMC-Na plate after appropriate dilution. After staining with Congo red and NaCl decolorization, a single colony with a hydrolysis circle is obtained, and the enrichment culture is carried out, and the sample is again spotted on a new CMC-Na plate. To obtain accurate hydrolysis zone diameter / colony diameter data, such as figure 1 shown. The composi...

Embodiment 2

[0053] Design primers for 16S rRNA sequence amplification, blast Z2 16S rRNA sequence and perform phylogenetic tree analysis, the results show that Z2 is Bacillus subtilis, such as Figure 4 shown.

Embodiment 3

[0055] Effect of pH and temperature on enzyme activity:

[0056] Take an appropriate amount of enzyme solution and the same volume of buffer solution with a pH range between 4.0 and 10.0 and incubate overnight at 50°C, then use 2-5% CMC-Na as a substrate to detect enzyme activity, and obtain the optimal pH of 7 . Among them, Citrate buffer (pH3.0–5.0), Tris-HCl buffer (pH 6.0–8.0) and Glycine-NaOH buffer (pH 9.0–10.0). Adjust the pH to 7, heat in a water bath at 30°C-80°C overnight, and then use 2-5% CMC-Na as a substrate to detect the enzyme activity, and the optimal temperature is 50°C. The effect of pH on CMC enzyme activity is as follows: Figure 5 As shown, the effect of temperature on CMC enzyme activity is as Figure 6 shown.

[0057] Effects of pH and Temperature on Enzyme Activity Stability

[0058] Take an appropriate amount of enzyme solution and the same volume of buffer solution with a pH value ranging from 4.0 to 10.0 and incubate at 50°C for 30 minutes, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com