Patents

Literature

55results about How to "Release feedback inhibition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

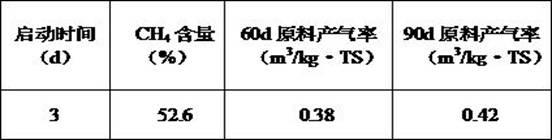

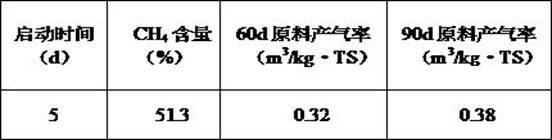

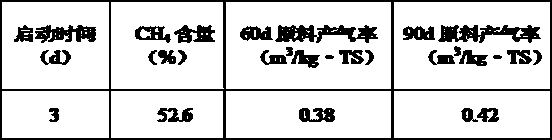

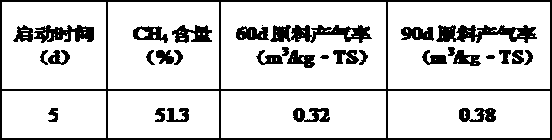

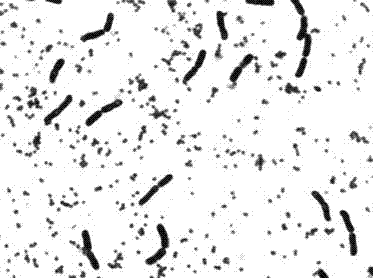

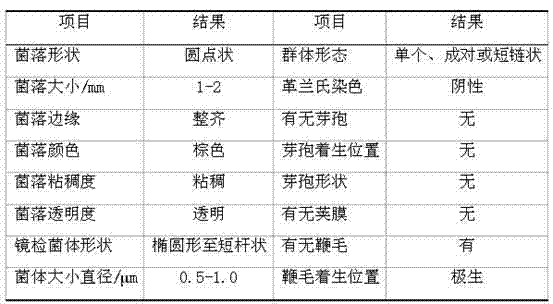

Preparation method of methane dry fermentation compound bacterial preparation

InactiveCN102559499AReduce volumeLow costBacteriaMicroorganism based processesBiotechnologyCellulose

The invention discloses a preparation method of a methane dry fermentation compound bacterial preparation, which comprises the following steps: mixing fermentation substrate with an inoculum which is compound bacteria composed of cellulose decomposing bacteria, proteolytic bacteria, fat decomposing bacteria, hydrogen-producing aceogenic bacteria, sulfate reducing bacteria and methanogenic archaea, adjusting the water content and pH of the mixed materials to 70-80% and 7.0 respectively, performing anaerobic fermentation under the condition of 35 DEG C plus or minus 2 DEG C for 60-90 days to obtain methane dry fermentation compound bacterial preparation. The preparation method of the invention can prepare compound bacterial preparation with a relatively complete methane fermentation function, and the total number of microbial cells and methanogenic archaea cells in the bacterial preparation are at least 10*10<10> / g and 1.0*10<8> / g respectively. Using the compound bacterial preparation as an inoculum of methane dry fermentation can reduce the starting time, and the fermentation process is stable and easy to control.

Owner:BIOGAS SCI RES INST MIN OF AGRI

Method for improving forage nutritional value of cottonseed meal through microbial fermentation

InactiveCN104186957AImprove the nutritional value of feedHigh protein contentAnimal feeding stuffBiotechnologyCellulose

The invention utilizes a microbial fermentation technology to improve the forage nutritional value of the cottonseed meal, so as to improve the forage quality of the cottonseed meal, increase the addition proportion in the forage and realize the promotion of the protein nutritional value and the feeding value of the cottonseed meal, aiming at the disadvantages that cottonseed meal is rich in antinutritional factors of free gossypol, cellulose, oligosaccharide, phytic acid and the like, the protein quality is relatively poor and the content of essential amino acids of methionine and the like is low and unbalanced, so that the large-scale forage of cottonseed meal is restricted. The method for improving forage nutritional value of cottonseed meal through the microbial fermentation adopts the technology of 'composite enzymatic hydrolysis and multi-strain three-step solid-state fermentation', so as to prepare the fermented cottonseed meal product that is high in the free gossypol, cellulose degradation degree and the protein content; the cottonseed meal product is rich in nutritional ingredients of probiotics, vitamins, enzyme, amino acid, short peptide, high-grade protein and the like; the method for improving the forage nutritional value of cottonseed meal through the microbial fermentation has the advantages of prompting growth and development, improving the utilization ratio of the forage, enhancing immunization, improving intestinal micro ecology, preventing diseases and the like. The method for improving forage nutritional value of cottonseed meal through the microbial fermentation adopts the solid-state fermentation; the manufacturing technology is simple; the energy consumption is low; zero environmental pollution is generated; and the investment is small. Therefore, mass production is easy.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

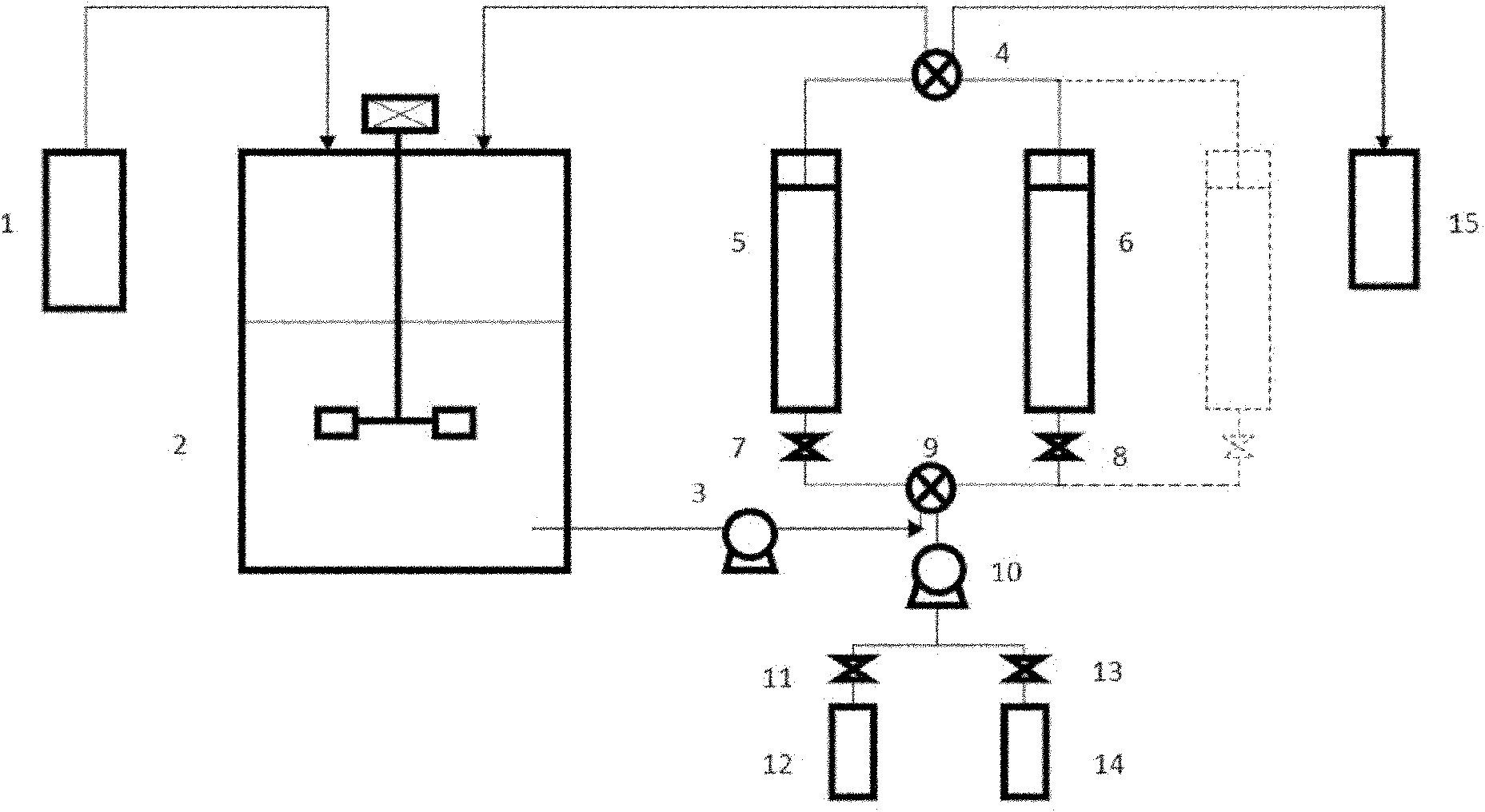

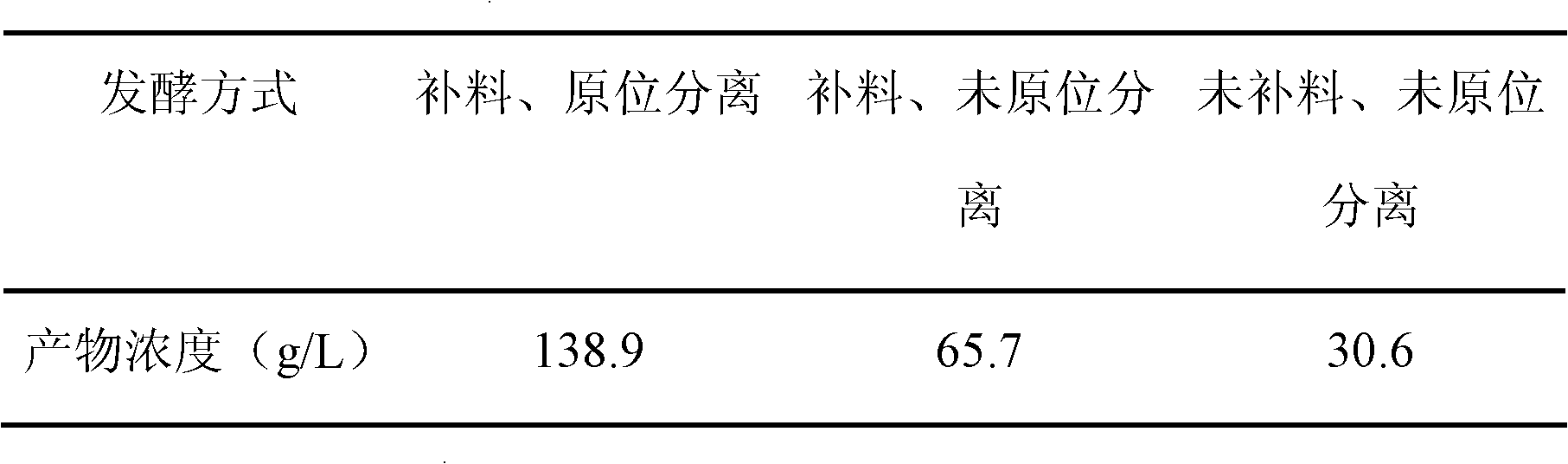

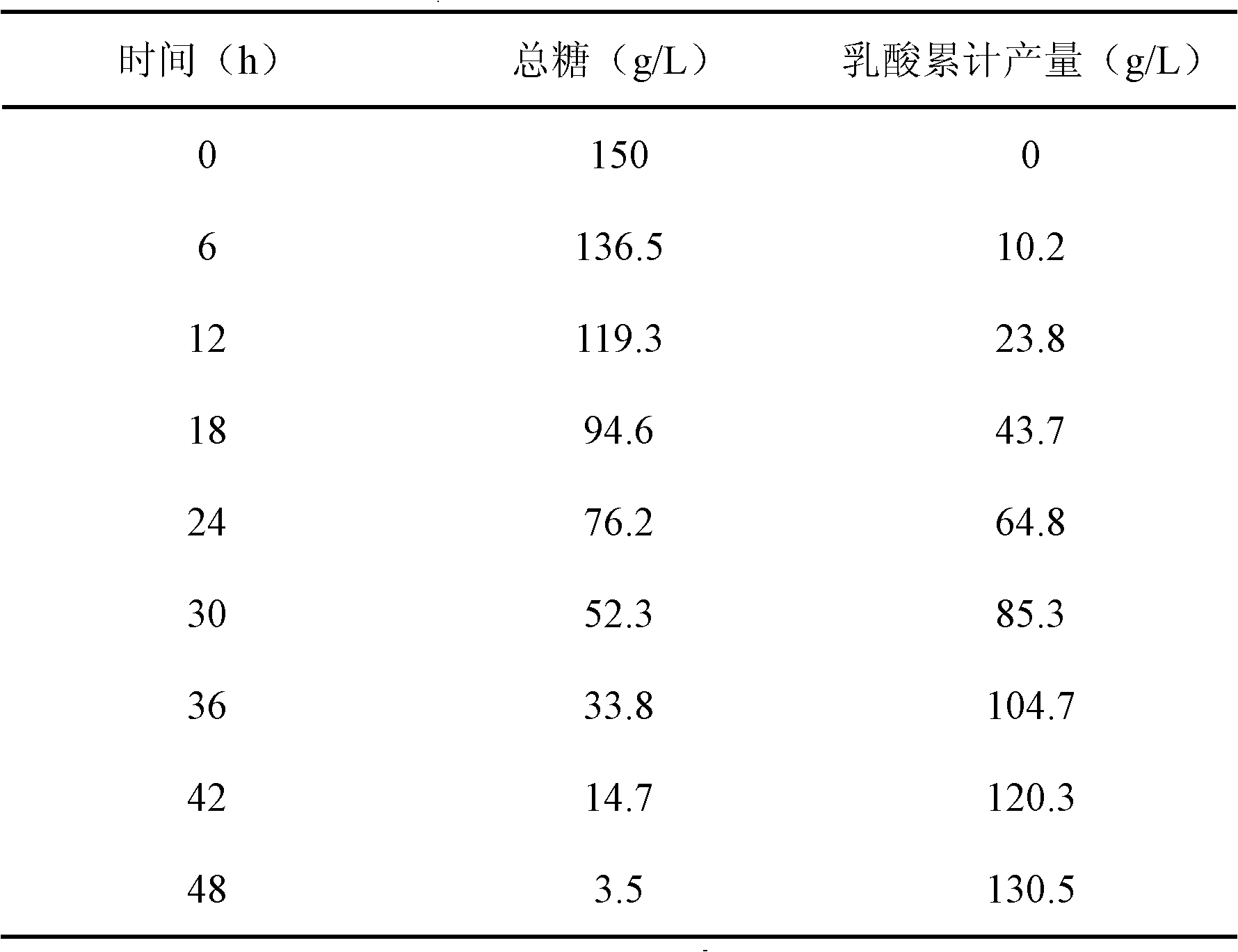

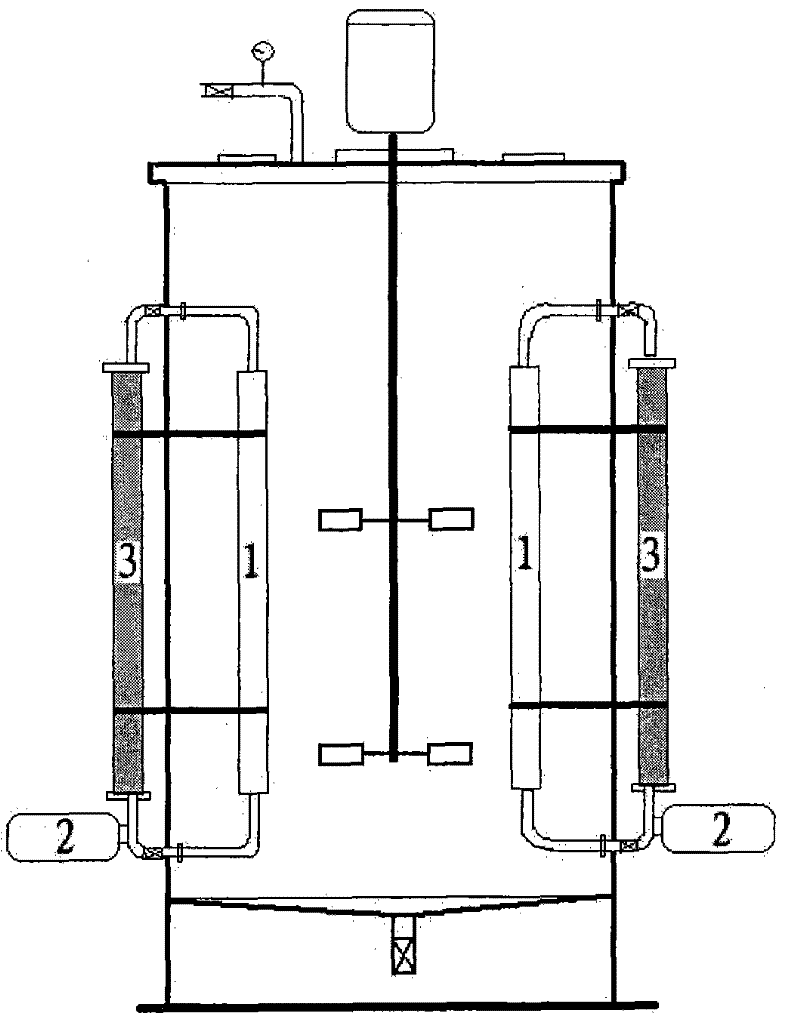

Lactic acid production process with fermentation and expanded bed for in-situ adsorption coupling

InactiveCN101914433AAvoid cloggingNo cloggingBioreactor/fermenter combinationsBiological substance pretreatmentsCouplingFixed bed

The invention discloses a lactic acid production device for fermentation and separation coupling and a lactic acid fermentation process using expanded bed in-situ adsorption to realize online separation. In the invention, an expanded bed and a fermentation tank are coupled, the online separation of lactic acid fermentation is realized by using the expanded bed method, so that the feedback inhibition of lactic acid is relieved, the yield and the conversion rate of the lactic acid fermentation are increased, and meanwhile, the problem of bed blockage by thalli when a fixed bed is used for absorbing the lactic acid in the prior art. Untreated fermentation liquor is permitted to directly enter a chromatographic column. Because the synchronization of fermentation and separation is realized, the cost of downstream extraction and separation in the prior art is greatly reduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Compound type biological flocculating agent two-stage fermentation method

InactiveCN1597571AAvoid partial lossShort processBacteriaWater/sewage treatment by flocculation/precipitationCelluloseFiber

A two-stage fermenting process for preparing composite biologic flocculant includes such steps as physically and chemically pretreating cellulose, preparing culture liquid, adding inorganic salt, regulating pH value, sterilizing, adding cellulose gradating bacteria to convert cellulose to glucose and cellodiase, and adding flocculant generating bacteria.

Owner:哈尔滨益生环境技术有限公司

Methane dry fermentation compound bacteria

InactiveCN102533609AHigh yieldEnergy optimizationBacteriaMicroorganism based processesCelluloseMicroorganism

The invention discloses methane dry fermentation compound bacteria, which comprise 25% to 45% of cellulose decomposing bacteria, 9% to 15% of protein decomposing bacteria, 8% to 15% of fat decomposing bacteria, 8% to 12% of hydrogen-producing acetogenic bacteria, 18% to 31% of sulfate reducing bacteria and 2.5% to 9.5% of methanogenic archaea according to bacterium number percentages. The compound bacteria of microorganisms with a complete methane fermentation function are capable of processing methane dry fermentation raw materials with TS content as 20% to 30% and stable in methane production effect and apt to control methane production.

Owner:BIOGAS SCI RES INST MIN OF AGRI

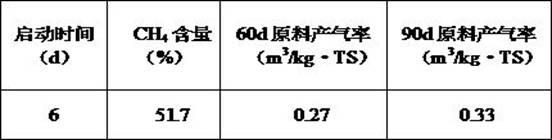

Method for improving percent conversion of tylosin component A

ActiveCN102703549AImprove permeabilityFacilitated releaseMicroorganism based processesFermentationMicrobiologyMethyltransferase

The invention relates to a method for improving the percent conversion of a tylosin component A. With the method, streptomyces fradiae is used as a producing strain and is fermented to produce the tylosin by first-level seed tank fermentation culture, second-level seed tank fermentation culture and fermentation tank fermentation culture. The method is characterized in that nonionic surfactant of which the mass concentration is 0.5-2.5% is added into a fermentation culture medium after the fermentation tank fermentation culture enters a stable period after a logarithmic growth phase is finished. The nonionic surfactant is added into the culture medium during a fermentation culture period to the stable period so as to enhance the permeability of a mycelium cell, so that a metabolin in a cell is accelerated to quickly release out of the cell to relieve the feedback inhibition of macrosin methyltransferase and improve the enzyme activity, and finally, a tylosin component C is accelerated to quickly covert into the tylosin component A. The tylosin component A in the current industrial production generally accounts for 80-85%, and the content of the tylosin component A can finally achieve 90-94% according to the method disclosed by the invention.

Owner:宁夏泰瑞制药股份有限公司

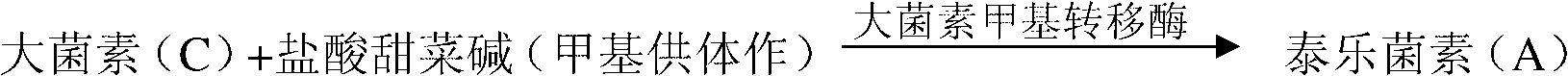

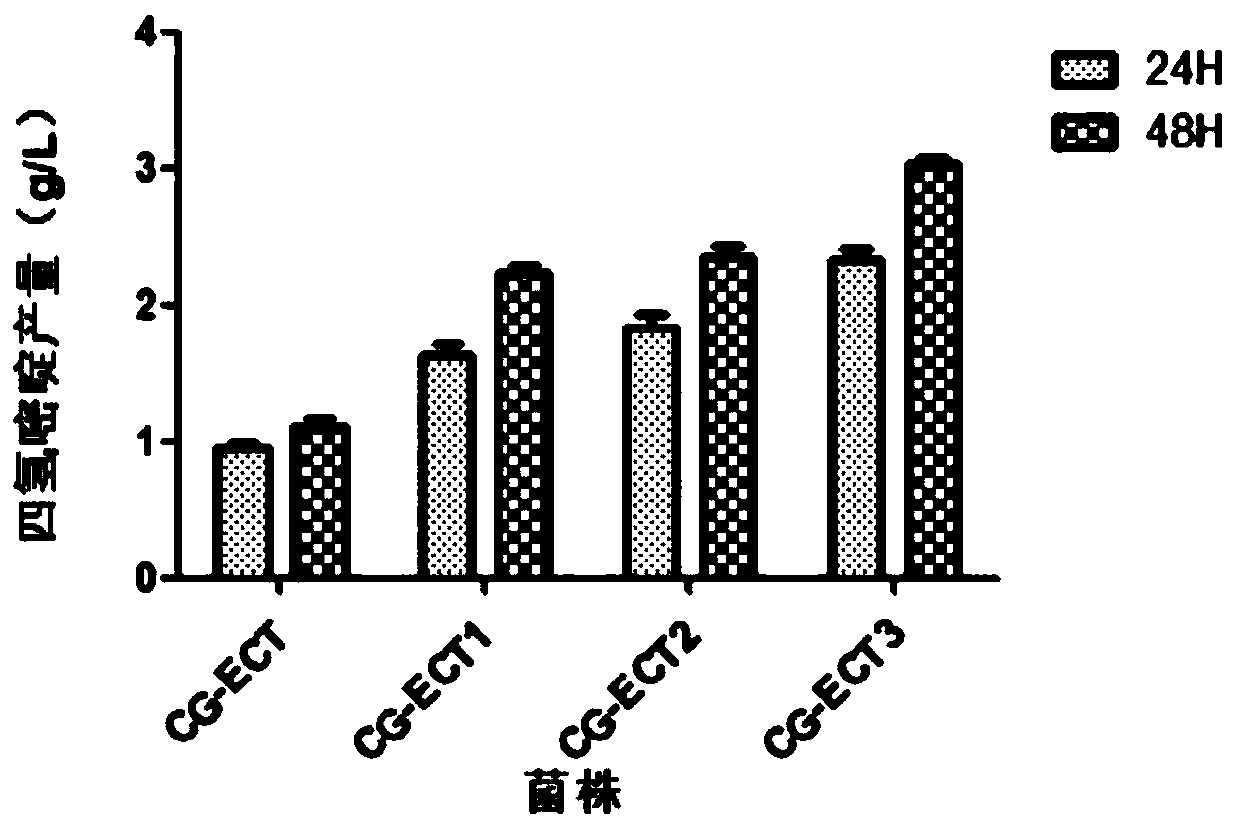

Tetrahydropyridine high-yield Corynebacterium glutamicum and application thereof

ActiveCN110699310APromote accumulationIncrease productionBacteriaTransferasesBacilliBiological safety

The invention discloses tetrahydropyridine high-yield Corynebacterium glutamicum and application thereof and belongs to the field of bioengineering. Feedback inhibition is relieved through site-directed mutagenesis of Corynebacterium glutamicum aspartokinase gene lysC, and expression of mutational LysC is intensified through promoter replacement. Further, pentose phosphate pathway of host bacteriais further intensified through promoter replacement to meet needs on reducing power NADPH in efficient synthesis of tetrahydropyridine. Finally, tetrahydropyridine high-yield Corynebacterium glutamicum is obtained by transferring tetrahydropyridine synthetic gene cluster ectABC of P. stutzeri into recombinant bacteria. By recombinant Corynebacterium glutamicum, tetrahydropyridine can be efficiently synthesized by utilizing cheap raw materials like glucose and maize plasm; compared with recombinant Escherichia coli produced strains, tetrahydropyridine high-yield Corynebacterium glutamicum hasbetter bio-safety and is of great significance to industrial production and large-scale application of tetrahydropyridine.

Owner:无锡晶扬生物科技有限公司

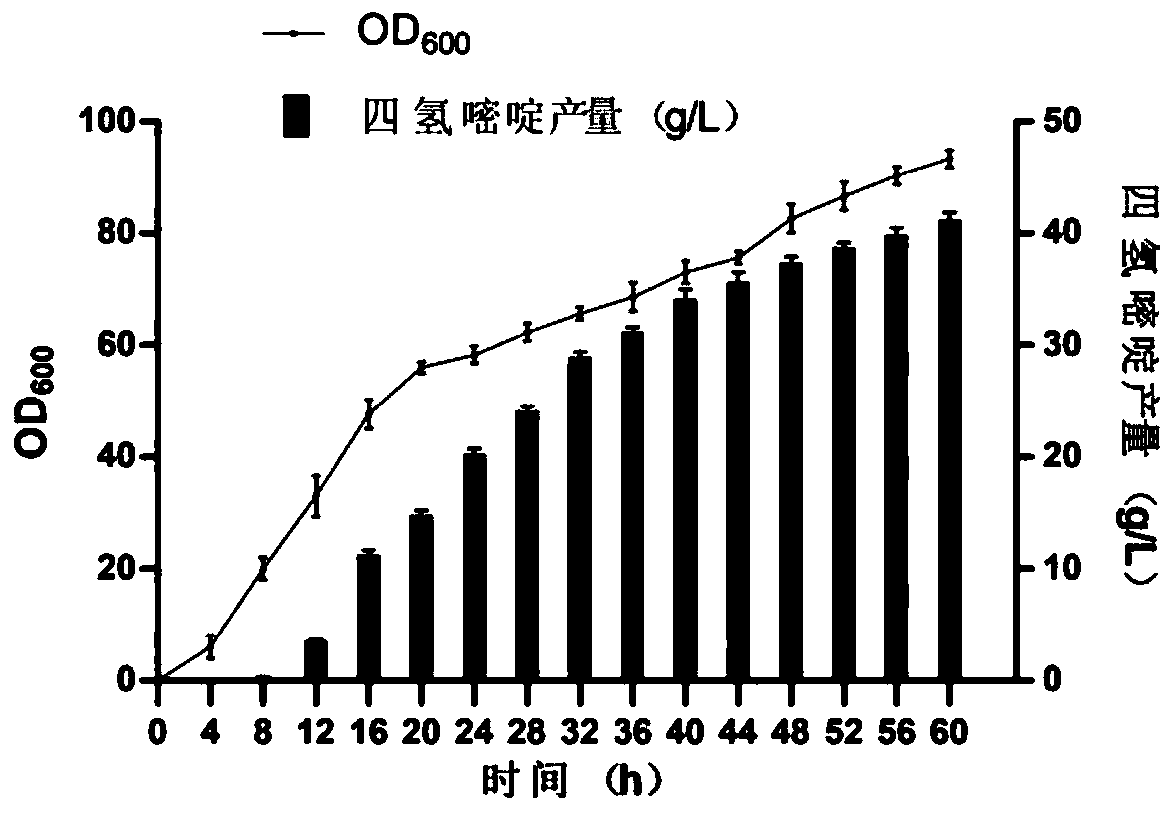

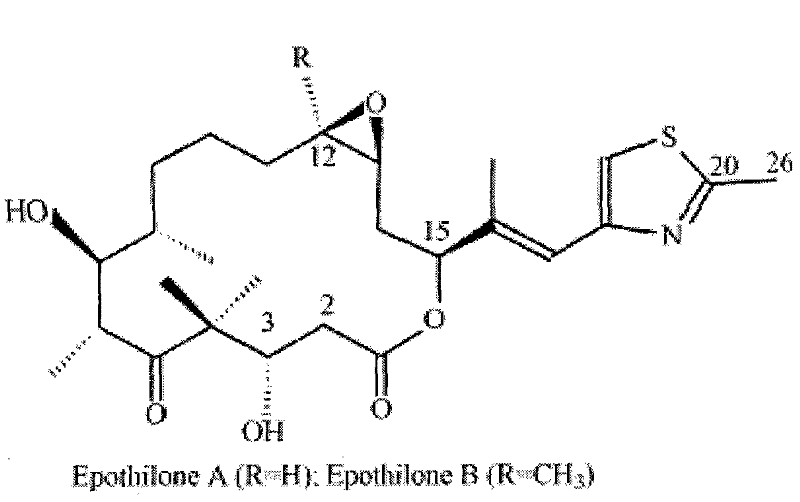

Production process for high-density fermentation of sprangium cellulosum and separation coupling of epothilone product

InactiveCN102174426AAchieve high density fermentationHigh yieldOrganic chemistryBacteriaFiberHigh density

The invention discloses a production process for high-density fermentation of sprangium cellulosum and separation coupling of an epothilone product. In the invention, the high-density fermentation of the sprangium cellulosum is realized by feeding carbon and nitrogen source substances and precursors; and at the same time, a polymeric adsorbent which can be repeatedly used can be used for separating the epothilone product and the high-density fermentation and product separation coupling are realized, thus feedback inhibition of the epothilone on the sprangium cellulosum is removed and output of the epothilone is increased. The invention has the technical characteristics of cost conservation, simple process, convenience in operation and high production efficiency.

Owner:QILU UNIV OF TECH

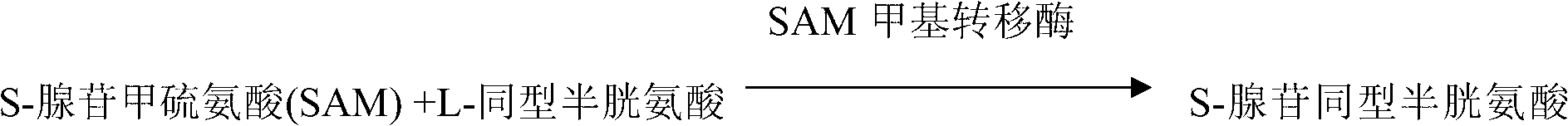

Determination method for S-adenosylmethionine methyltransferase and kit thereof

ActiveCN102703576AEliminate distractionsEfficient responseMicrobiological testing/measurementS-Adenosyl methionineS-Adenosyl-l-methionine

The invention discloses a determination method for S-adenosylmethionine methyltransferase and a kit thereof. The determination method for S-adenosylmethionine methyltransferase comprises the step of detecting SAM methyltransferase through the enzyme coupling reaction between S-adenosylhomocysteine hydrolase and adenosine deaminase. The detection technique relieves feedback inhibition of products,has stable results and accurate quantitative reaction, and effectively overcomes the problem of radioactive pollution of the radioactive marking method. With double reagents in the kit, detection canbe carried out manually or through a full automatic biochemical analyzer within the visible range, and therefore the use and the fast detection of a plurality of samples are convenient. The determination method is also suitable for detection of the enzyme coupling reaction between S-adenosylhomocysteine hydrolase and adenosine deaminase.

Owner:NINGBO MEDICAL SYSTEM BIOTECHNOLOGY CO LTD

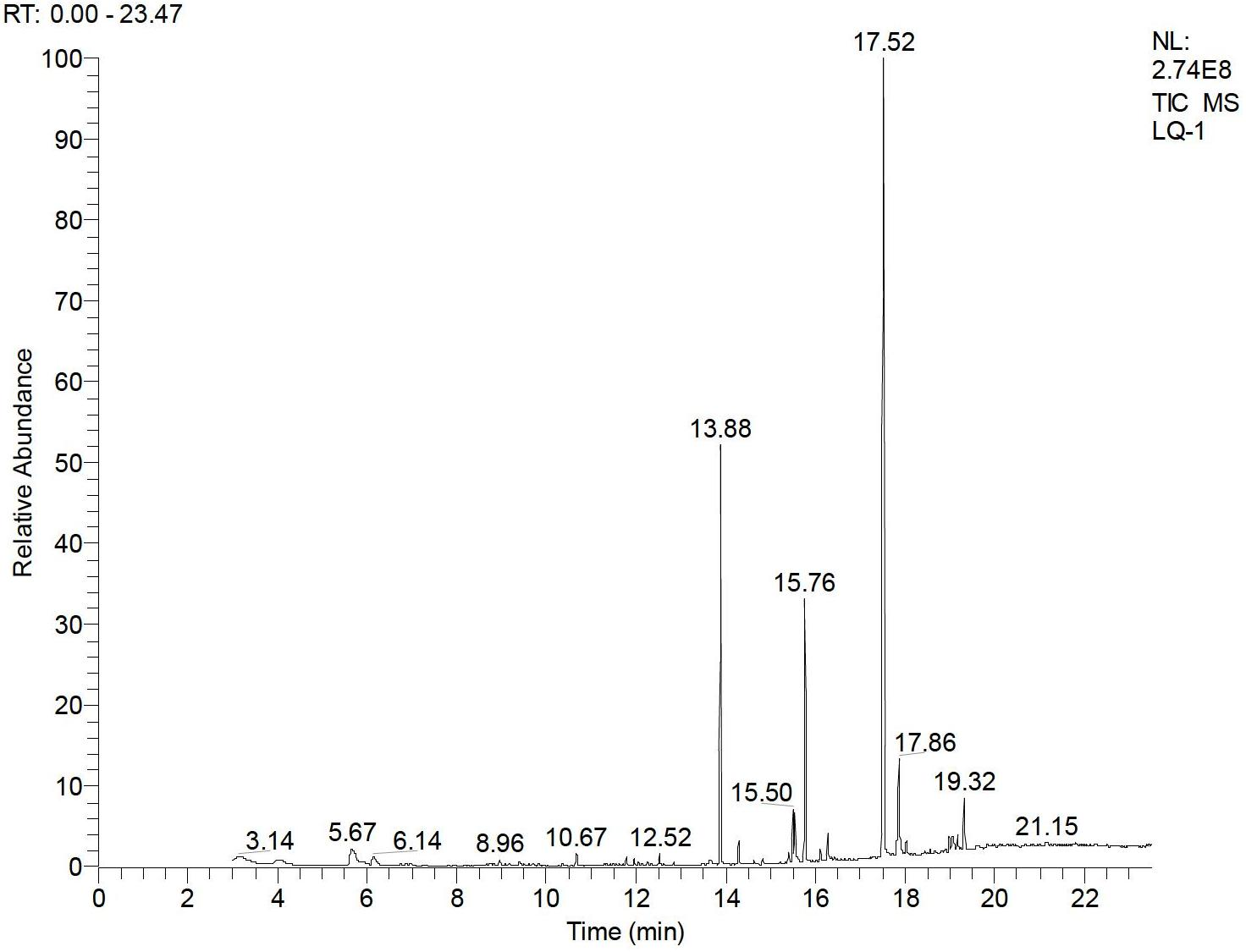

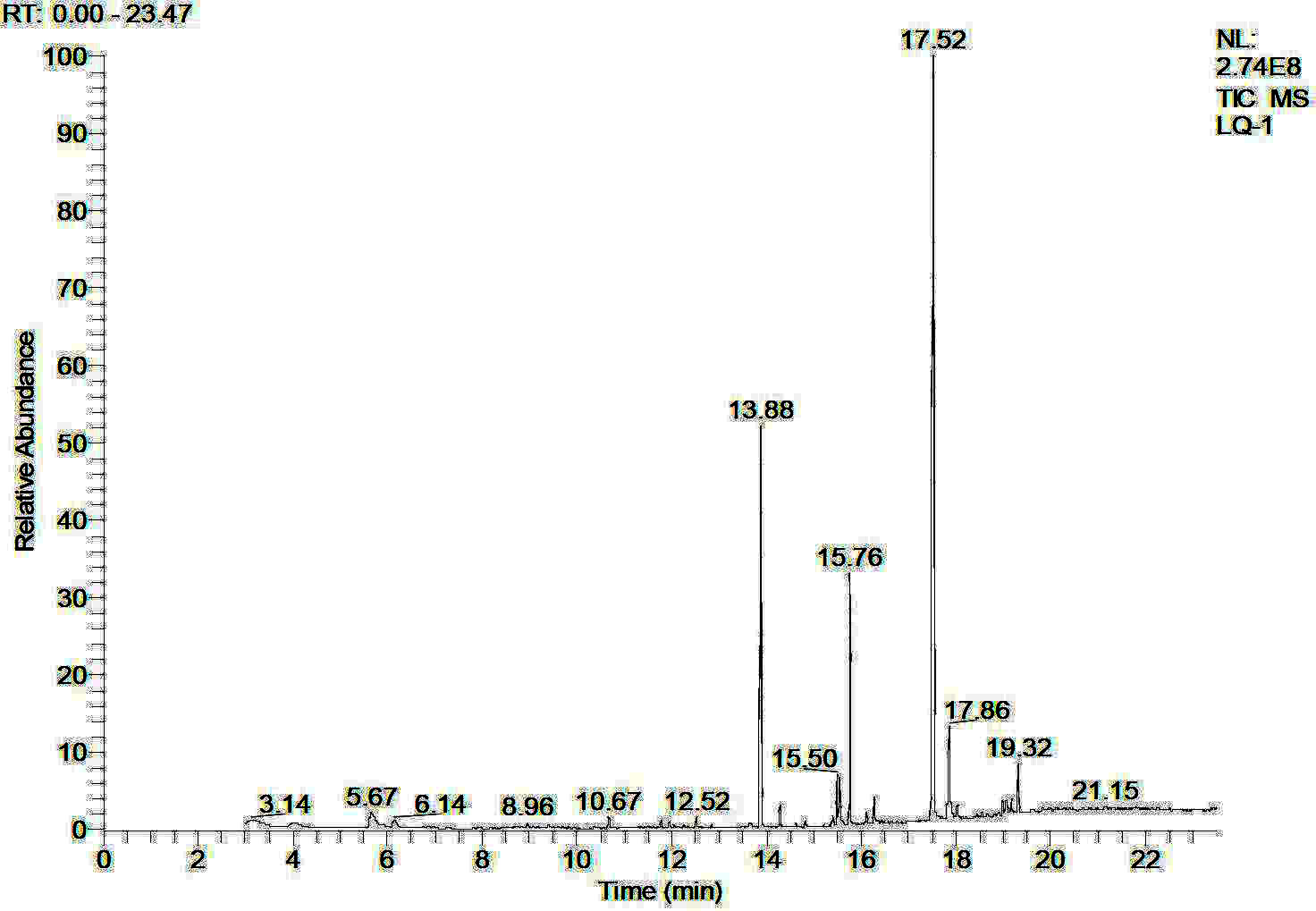

A novel isopropylmalate synthase variant and a method of producing l-leucine using the same

A novel modified polypeptide having an isopropylmalate synthase activity, a polynucleotide encoding the same, a microorganism comprising the polypeptide, and a method of producing L-leucine by culturing the microorganism.

Owner:CJ CHEILJEDANG CORP

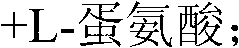

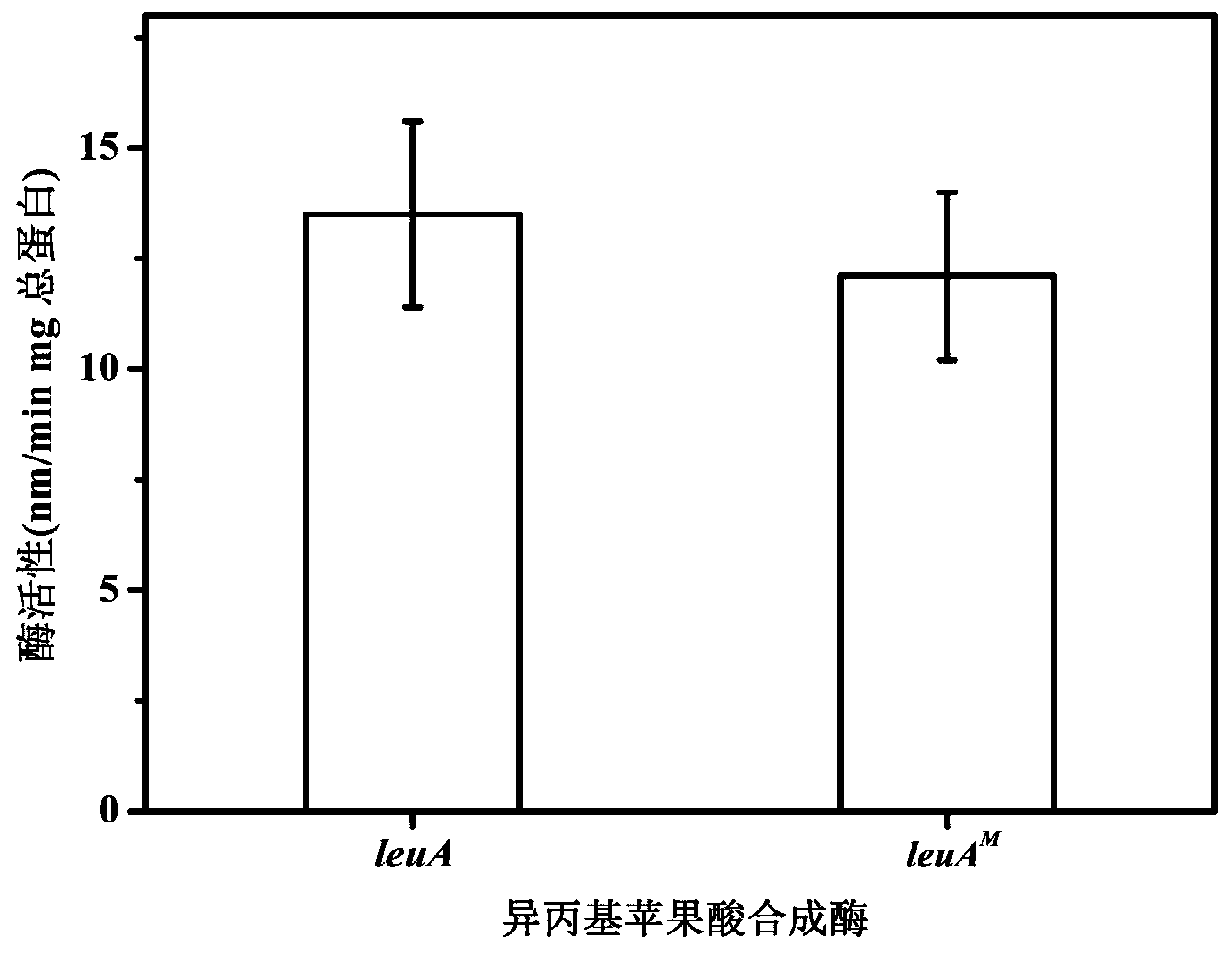

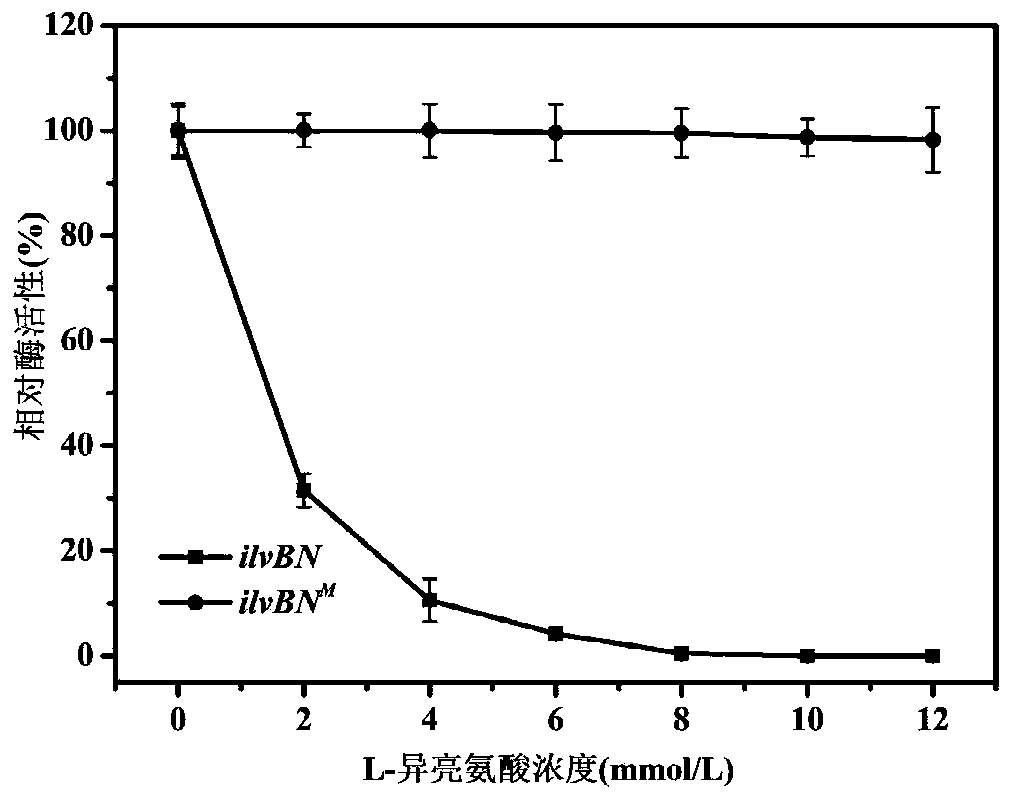

Genetic engineering bacterium for producing L-leucine, and application of genetic engineering bacterium

ActiveCN110551670AGrow fastShort fermentation cycleBacteriaMicroorganism based processesGenetic engineeringAcetolactate synthase

The invention relates to a genetic engineering bacterium for producing L-leucine, and application of the genetic engineering bacterium, and belongs to the field of metabolic engineering. The genetic engineering bacterium is obtained by an isopropylmalate synthetase encoding gene leuA[M] capable of relieving L-leucine feedback inhibition through overexpression in a host cell, an acetolactate synthase encoding gene ilvBN[M] capable of relieving L-leucine feedback inhibition, a 3-isopropylmalate dehydrogenase encoding gene leuB and a 3-isopropylmalate dehydratase encoding gene leuCD. Acetohydroxyacid synthase encoded by the leuA[M] relieves the feedback inhibition function of the L-leucine for the acetohydroxyacid synthase, in addition, the activity of the acetohydroxyacid synthase is not obviously lowered than wild leuA encoded isopropylmalate synthetase. The L-leucine genetic engineering bacterium does not have nutritional deficiencies, is quick in growth, and has a short fermentation period, a high yield and a high conversion rate. After fermentation is conducted for 40-44h, the concentration of the L-leucine in fermentation liquor achieves 60.5-69.6g / L.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

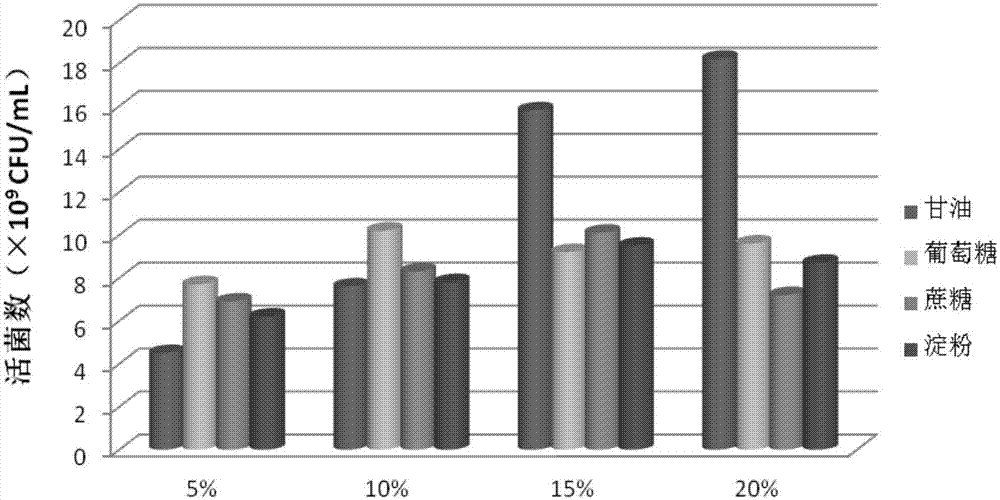

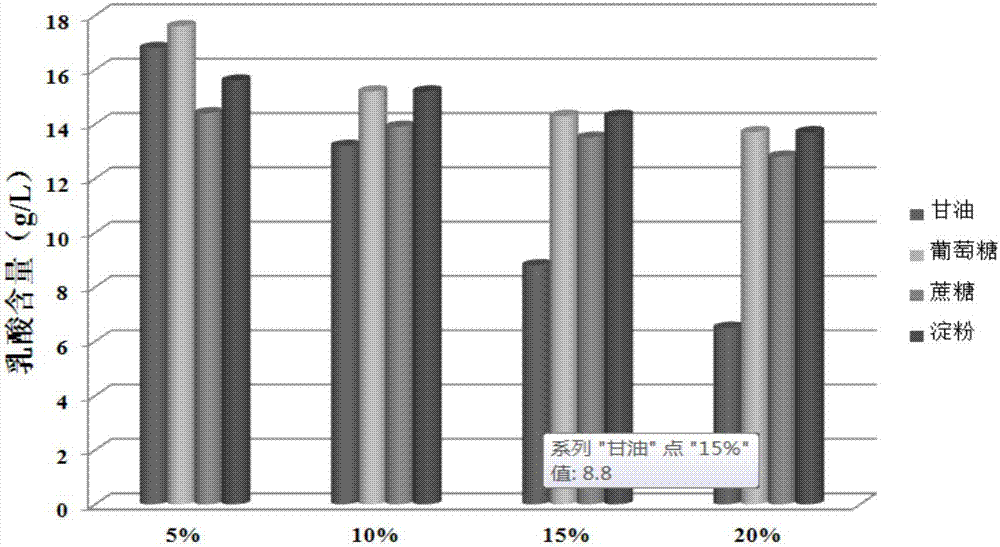

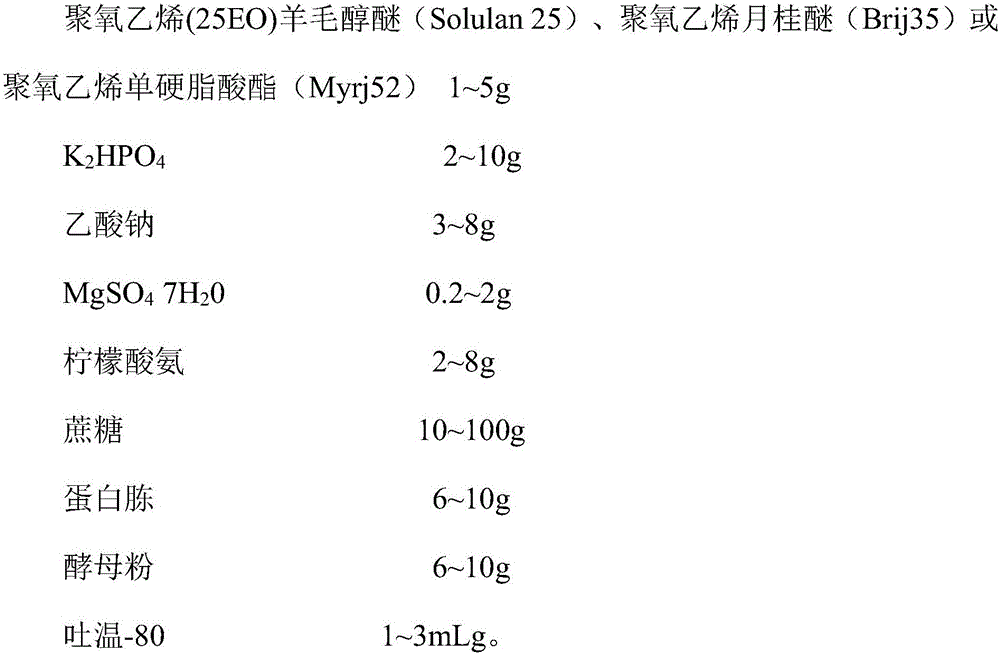

High-density fermentation medium for enterococcus faecalis for feed and fermentation method of medium

InactiveCN106148212AReduce concentrationRelease feedback inhibitionBacteriaMicroorganism based processesSucroseHigh density

The invention belongs to the technical field of culture of enterococcus faecalis and relates to a high-density fermentation medium for the enterococcus faecalis for feed and a fermentation method of the medium. The strategy that addition of sucrose is controlled according to pH feedback is adopted, and meanwhile, the concentration of lactic acid in fermentation broth is reduced, so that the feedback inhibition effect of lactic acid is relieved; the bacterium density of the enterococcus faecalis fermented by the aid of the high-density fermentation medium with the fermentation method of the medium is remarkably higher than that of enterococcus faecalis fermented with a common fermentation method, the number of living bacteria is not less than 10<10> cfu / mL and is 40 times or more that of enterococcus faecalis cultured by the aid of a common MRS medium, and high-density fermentation of the enterococcus faecalis is realized; thus, the separation cost of biomass can be reduced, the production cycle can be shortened, the production cost can be reduced, and the production efficiency can be improved.

Owner:JIANGXI KENUO BIOTECH

Method for preparing biodiesel by directly using cellulose through mixed fermentation

The invention discloses a method for preparing biodiesel by directly using cellulose through mixed fermentation. The mixed fermentation is performed by using a plant fiber degrading strain and a grease producing strain, and ethanol is produced by directly using natural plant fiber such as straws. The method comprises the following steps of: designing a culture medium for the mixed fermentation by optimization methods such as a response surface method, and optimizing to obtain the fermentation conditions such as the optimum temperature of mixed fermentation, optimum mixing proportion of strains and optimum mixing time of the strains by utilizing the methods such as orthogonal test and response surface methodology; according to the optimized fermentation conditions, by using the plant fiber as a carbon source, degrading the cellulose into fermentable sugar by using a cellulase producing strain, and adding grease-producing microorganisms into the culture system for the mixed fermentation; and by using the sugar which is produced by the constant enzymolysis of the plant fiber as the carbon source, fermenting to produce grease by using the grease producing strain, and performing methyl esterification reaction of the microbial grease to obtain the biodiesel.

Owner:JIANGSU UNIV OF SCI & TECH

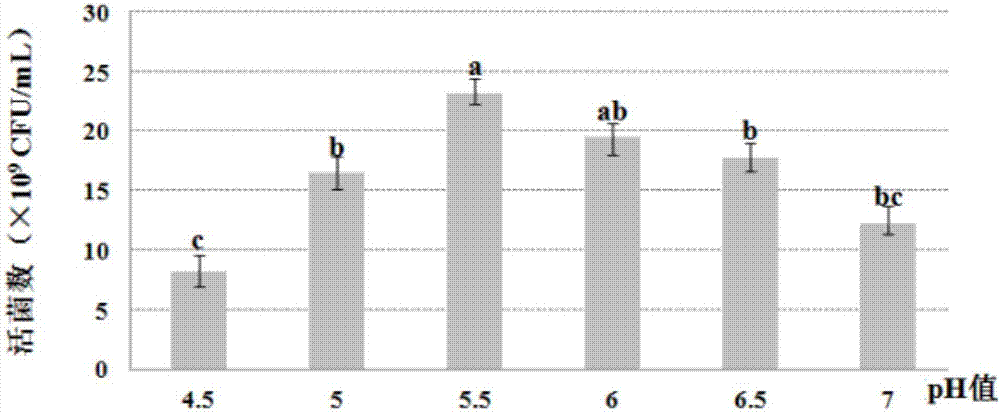

High-density enterococcus faecalis fermentation culture medium and fermentation process thereof

ActiveCN107034165AAchieve high density fermentationRelease feedback inhibitionBacteriaMicroorganism based processesBiotechnologySodium acetate

The invention relates to a high-density enterococcus faecalis fermentation culture medium and a fermentation process thereof. The fermentation culture medium is prepared from 20-30 g / L of glycerol, 10-15 g / L of soybean meal, 1-3 g / L of ammonium sulfate, 2-3 g / L of potassium hydrogen phosphate, 3-8 g / L of sodium acetate trihydrate, 2-4 g / L of trisodium citrate dihydrate, 0.3-0.8g / L of magnesium sulfate heptahydrate and 0.1-0.3 g / L of manganese sulfate monohydrate. The fermentation process comprises the steps that high dissolved oxygen (25%) is adopted and combined with glycerin to serve as a fermentation carbon source, the pH value of the constant sodium carbonate fermentation liquid is 5.5, the glycerol concentration is controlled to 10 g / L by adding a supplementary material in the fermentation process in a flowing mode, culture is performed for 16 hours, and then the fermentation is completed when OD (600 nm) is greater than 35, wherein the viable count of the enterococcus faecalis contained in the fermentation liquid can be up to 8*1010 CFU / mL or above. In the fermentation mode that the high dissolved oxygen is combined with the glycerin to serve as the carbon source, the lactic acid concentration in the fermentation liquid is reduced, the enterococcus faecalis contained in the fermentation liquid can be up to 8*1010 CFU / mL or above, the biomass separation cost is reduced, a production cycle is shortened, the production cost is reduced, and the production efficiency is improved.

Owner:INST OF MICROBIOLOGY JIANGXI ACADEMY OF SCI +1

Methane dry fermentation compound bacteria

InactiveCN102533609BHigh yieldEnergy optimizationBacteriaMicroorganism based processesCelluloseMicroorganism

Owner:BIOGAS SCI RES INST MIN OF AGRI

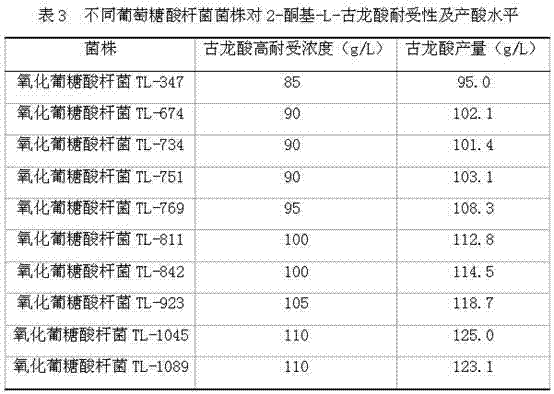

2-keto-L-gulonic acid high tolerance type gluconobacteroxydans and application thereof in vitamin C fermentation production

ActiveCN102757928AImprove fermentation production efficiencyRelease feedback inhibitionBacteriaMicroorganism based processesThallusBiotechnology

The invention discloses 2-keto-L-gulonic acid high tolerance type gluconobacteroxydans TL-1045 and also provides application of the bacterial strain in vitamin C fermentation production. The gluconobacteroxydans TL-1045 can tolerate the 2-keto-L-gulonic acid which has high concentration, the feedback inhibition of a product for a thallus in a second step during vitamin C fermentation production is eliminated, the output of 2-keto-L-gulonic acid can reach above 125g / L, the production efficiency of the vitamin C is improved remarkably and the production cost of the vitamin C is reduced effectively.

Owner:SHANDONG TIANLI PHARMA

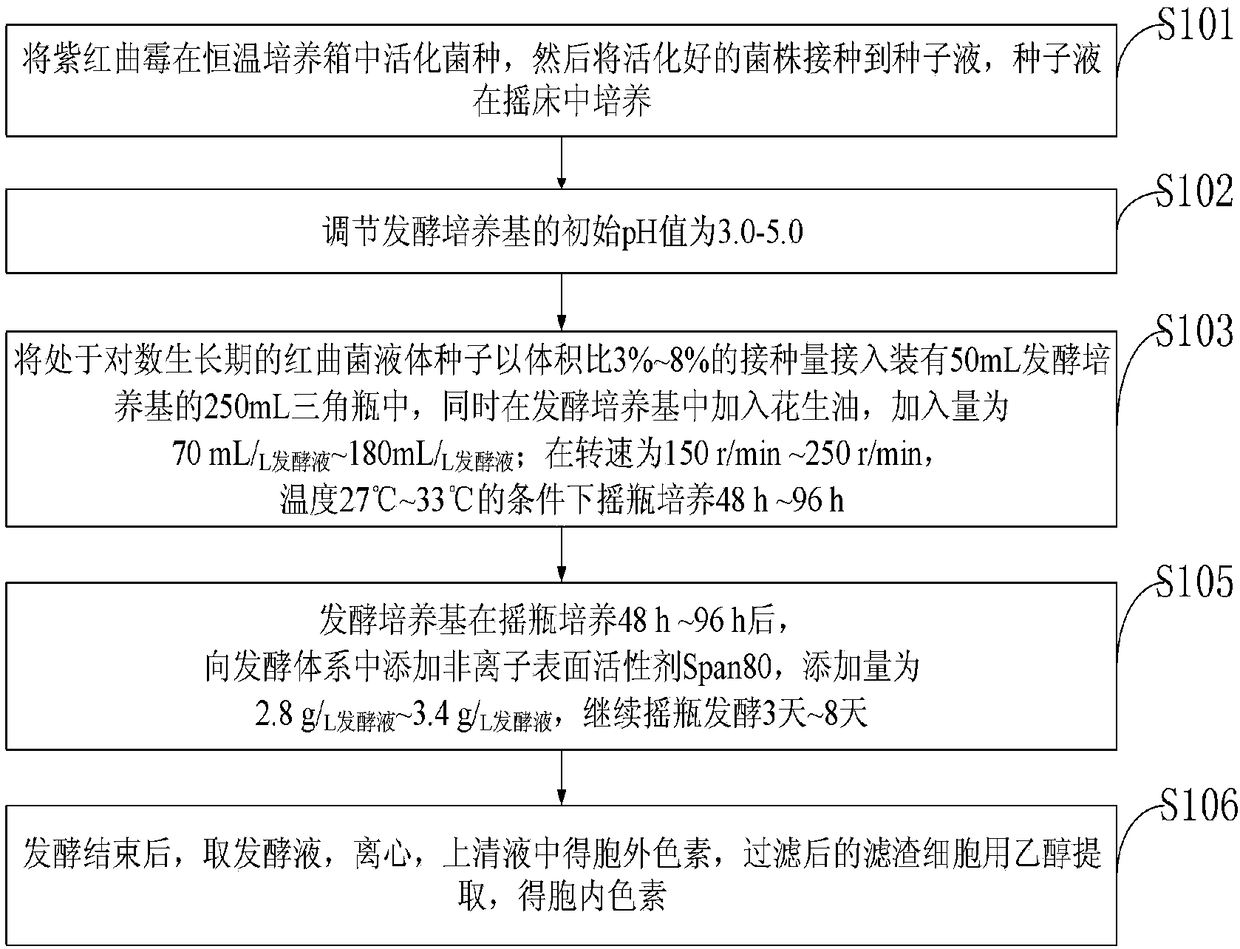

Composite extracting agent and method for promoting production of monascus pigments by using of composite extracting agent

InactiveCN108251457AHigh pigment yieldImprove economic efficiencyMicroorganismsMicroorganism based processesChemistryShake-Flask Culture

The invention belongs to the field of fermentation engineering, and discloses a composite extracting agent and a method for promoting production of monascus pigments by using of the composite extracting agent, wherein the method comprises the steps of: inoculating a monascus liquid seed in the logarithmic growth phase into a fermentation medium according to the inoculum size of 3%-8% by volume, adding peanut oil into the fermentation medium according to the amount of 70 mL / L fermentation liquid to 180 mL / L fermentation liquid; performing shake-flask culture at temperature of 27 DEG C to 33 DEGC; adding non-ionic surfactant Span80 into the fermentation system containing the Monascus liquid seed and the peanut oil according to the amount of 2.8 g / L fermentation liquid to 3.4 g / L fermentation liquid, performing shake-flask culture again, and the like. The final yields of red, orange and yellow pigments in the fermentation liquid with the composite extracting agent added are increased by76%, 85% and 89%, respectively, compared with the control group.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

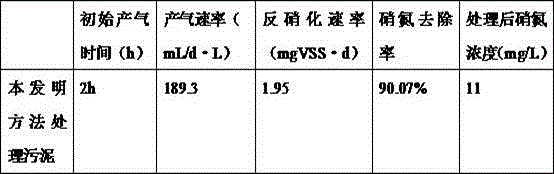

Microbial preparation for sludge anaerobic fermentation

InactiveCN106754543ALower initial costAdaptableBacteriaMicroorganism based processesBacillus amyloliquefaciensSludge

The present invention belongs to the field of microbial technology and discloses a microbial preparation for sludge anaerobic fermentation. The microbial preparation comprises a mixed bacteria liquid and a carrier, wherein the mixed bacteria liquid is prepared from Bacillus pumilus, enterobacter cloacae, denitrifying bacteria, paracoccus denitrificans, bacillus amyloliquefaciens, and lactococcus lactis. The microbial preparation can greatly increase the amount of methane generated by sludge, increase the utilization rate of the sludge, and recycle the sludge.

Owner:王筠涵

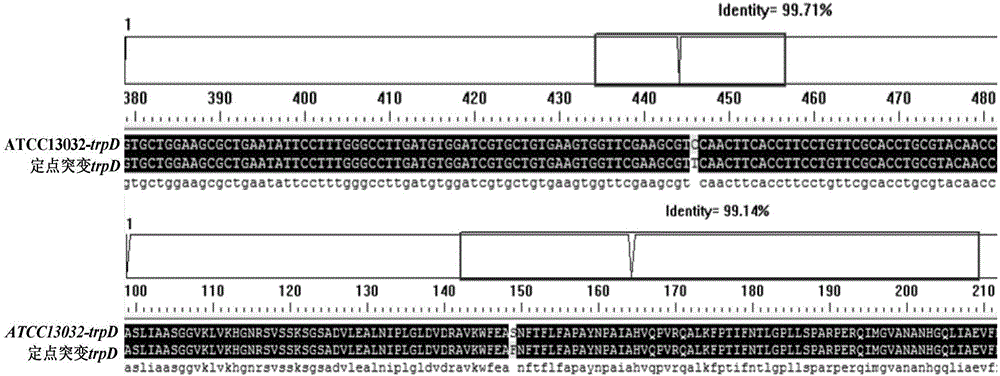

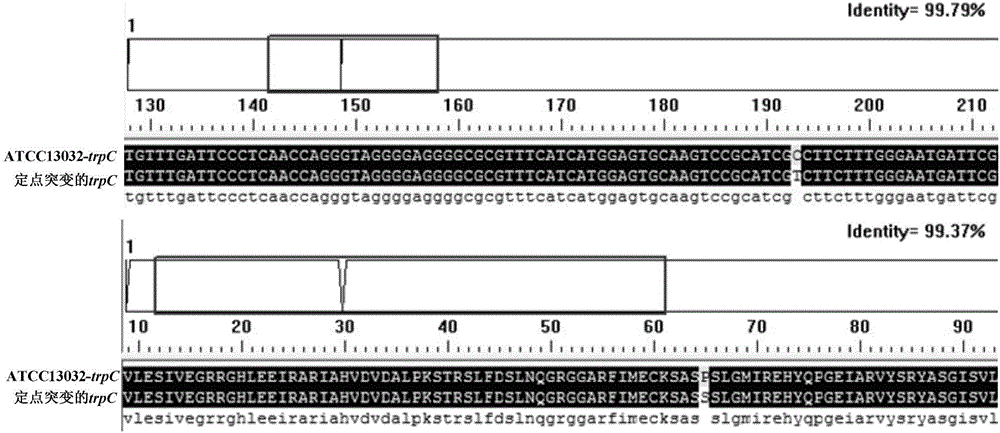

Corynebacterium glutamicum, and key tryptophan synthesis gene thereof

ActiveCN106520652ARelease feedback inhibitionBacteriaMicroorganism based processesTrp operonBiotechnology

The invention belongs to the fields of microorganism breeding and fermentation engineering, and concretely relates to a Corynebacterium glutamicum, and a key tryptophan synthesis gene thereof. The above high-yielding strain is obtained through editing the genome of Corynebacterium glutamicum CGMCC No.12302 through a gene engineering means, and integrating the trpDCB mutation site in a tryptophan operon to the genome of the CGMCC No.12302. The Corynebacterium glutamicum provides a new mutation site for tryptophan synthesis related gene, and provides a new research direction for biosynthesis of the tryptophan; and a shaking bottle fermentation result shows that the tryptophan output of the obtained strain is about 3.4 times original output, so the tryptophan production performance of the strain is greatly improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Production technology for high-density fermentation of lactics and separation coupling of lactic acid by physical method

InactiveCN105296550AHigh selectivityLarge exchange capacityMicroorganism based processesFermentationMetaboliteFreeze-drying

The invention relates to the technical field of inocula preparation, and concretely relates to a production technology for high-density fermentation of lactics and separation coupling of lactic acid by a physical method. Compared with the prior art, through lactics high density fermentation and lactic acid separating by ion exchange resin, feedback inhibition of a lactic acid metabolite can be released, through a high density broth obtained in the technology, bacterium concentration can reach 30g / L, in the prepared freeze-dried powder, live bacteria number is more than 8.0*1011 cfu / g, a culture volume is reduced, a production period is shortened, and a thalline yield and a specific products yield are increased. According to the invention, thalline growth inhibition can be released by employing the ion exchange resin for lactic acid adsorption, and production cost is reduced through subsequent elution and recovery. In addition, the ion exchange resin has the advantages of high selectivity, large exchange capacity, simple operation and easy automation, so that the production technology has the advantages of simpliness, more-convenient operation and high production efficiency.

Owner:BIOGROWING CO LTD

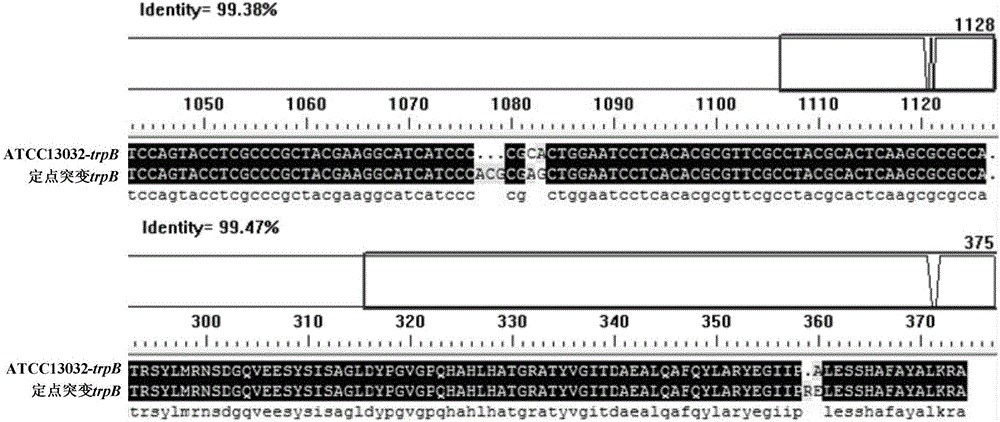

L-histidine high-yielding strain and application thereof

InactiveCN103013876ARelease feedback inhibitionBacteriaMicroorganism based processesCulture mediumsChemistry

The invention provides an L-histidine high-yielding strain and an application thereof, and belongs to the field of a bioengineering technology. The invention provides Serratia marcescens ZJZG25 which is obtained by the following steps of: by taking Serratia marcescens ATCC (American Type Culture Collection) 31026 as a starting strain, carrying out diethyl sulfate (DES), nitrosoguanidine (NTG) and ultraviolet (UV) gradual-grade mutation; and adding analogues of L-histidine including 3-amino-1,2,4-triazole, 6-purinethol, histidine methyl ester, 2-thiouracil, D-histidine and the like into a basic culture medium and screening. The L-histidine is produced by a strain fermentation method; and compared with the starting strain, the capability of the accumulating high-level L-histidine is expressed. The ZJZ 625 is subjected to shake-flask culture for 72 hours and the yield of the L-histidine can reach to 9.7 g / L. The fermentation is a 3-L fermentation tank is carried out for 60 hours and the yield of the L-histidine can reach to 18.1 g / L.

Owner:JIANGNAN UNIV

Method for preparing feed protein from alcohol waste liquid and crop straws

InactiveCN106721054AElimination of repressionEliminate Feedback InhibitionFood processingAnimal feeding stuffLiquid wasteResource utilization

The invention discloses a method for preparing a feed protein from alcohol waste liquid and crop straws, aiming at phenomena that the utilization rate of crops straw feed is not high and alcohol waste liquid pollution is caused, so as to meet straw comprehensive utilization requirements, requirements of animal husbandry feed proteins and objective requirements of alcohol waste liquid harmless treatment and utilization. The method disclosed by the invention mainly comprises the following three steps: ammonifying, carrying out compound enzymatic hydrolysis and carrying out multi-strain three-step solid-state fermentation. The method disclosed by the invention has the advantages of promoting growth and development, improving the feed utilization rate, improving the intestinal micro-ecology, preventing diseases and the like; recycling high-value utilization of the crops straws and harmless treatment and resource utilization of the alcohol waste liquid are realized; healthy, green and scientific development of a feed processing industry is facilitated, and the method has a wide application prospect.

Owner:新昌县拜瑞珂生物技术有限公司

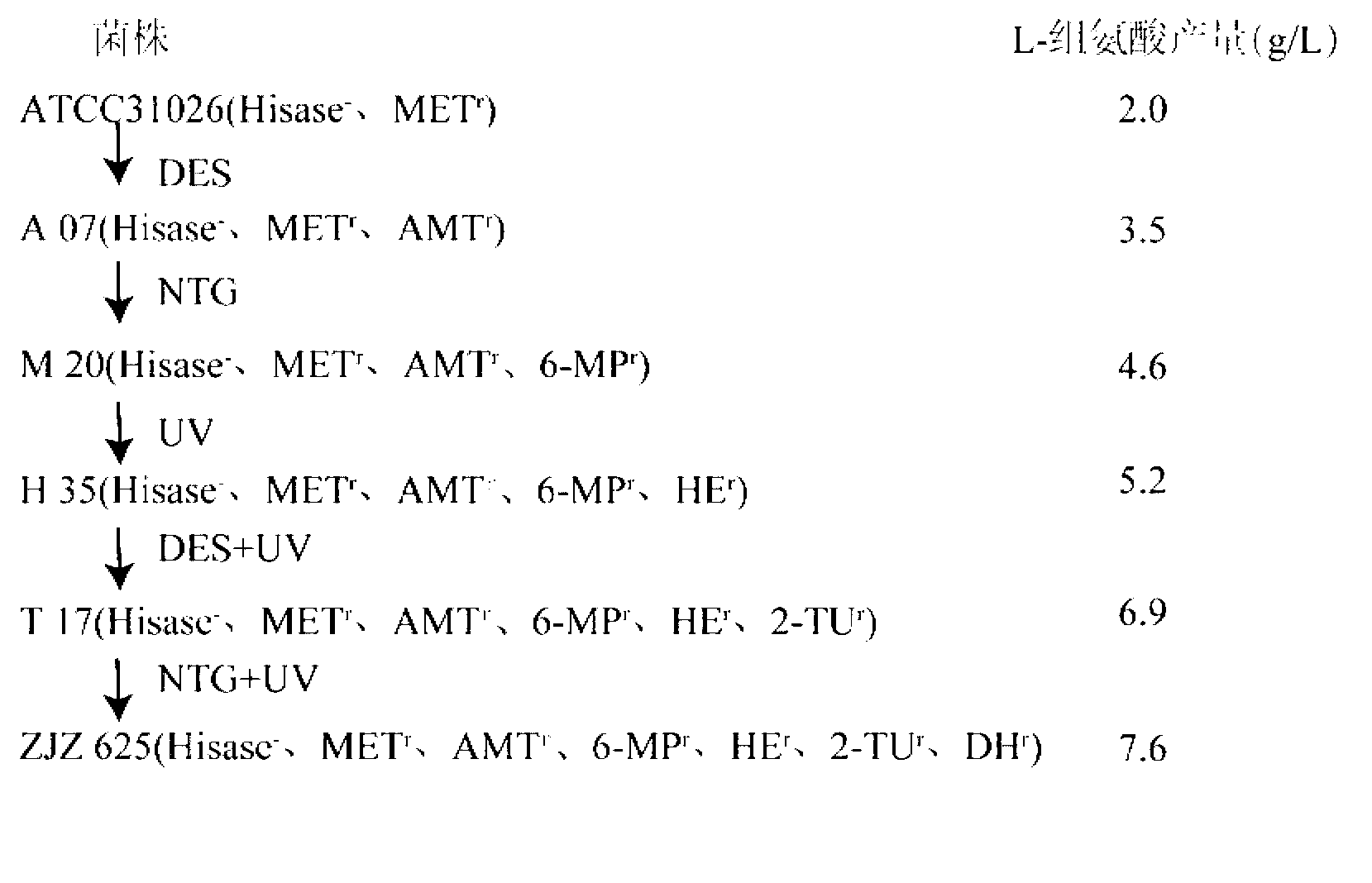

Composite microorganism beta-dextranase and beta-glucosaccharase production method

InactiveCN1884506ACompatibility scienceCompatibility is reasonableFungiHydrolasesFiltrationDigestion

The invention relates to a method for making composite microbio beta-glucanase and beta-glucosidase. The invention includes mixed fermentation of trichoviridin and aspergillus niger to prepare composite microbio beta-glucanase and beta-glucosidase, preparation of solid enzyme preparation and liquid enzyme preparation, and inclined-plane bacterial, shake flask shake culture, liquid seed tank enrichment culture of the trichoviridin and aspergillus niger, mixed input of the trichoviridin and aspergillus niger after enrichment culture into solid fermentation tank to perform fermentation, after fermentation, by digestion, filtration and ultrafilter membrane concentration, obtaining liquid enzyme preparation after adding protecting agent; obtaining solid enzyme preparation by adding British gum in concentrated enzymatic solution with dehumidification and granulation. The inventiom is of scientific and fair industrial design, the trichoviridin and aspergillus niger obtained by mixed culture and screening of strains of fungus can perform paragenetic mixed culture and mutually have no antagonistic reaction, the cost is low, the energy consumption is small, and the invention is of no devil liquor and waste slag discharge, which has a wide applicability of an invention and fills up our zymin breed margin, and has large market foreground.

Owner:天津科建科技发展有限公司

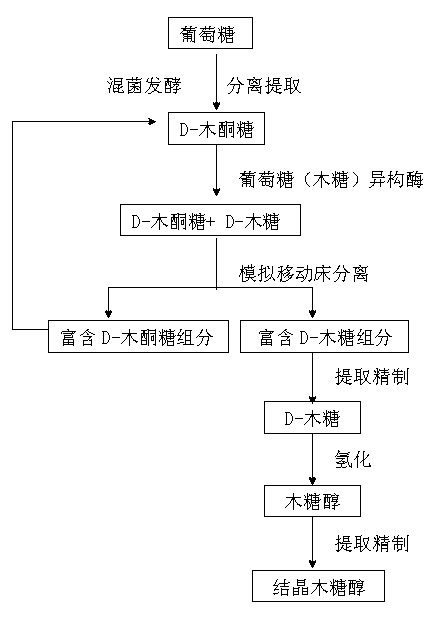

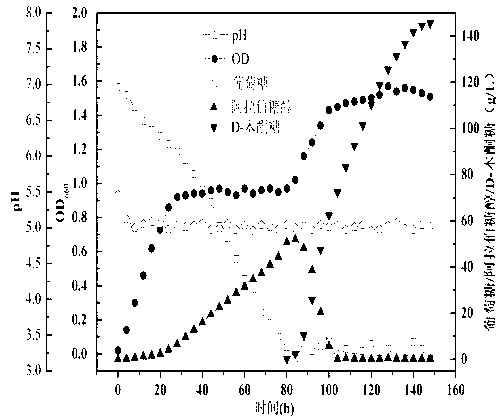

Method for preparing xylitol and its intermediate D-xylosone by microbial transformation of glucose and strain used in the same

ActiveCN102796797AHigh yieldRelease feedback inhibitionFungiMicroorganism based processesBiotechnologyArabitol

The invention discloses a method for preparing D-xylosone by microbial transformation of glucose, comprising the following steps: firstly, respectively preparing an osmophilic yeast seed liquid and a gluconobacter oxydans seed liquid by using glucose as a raw material, then inoculating the osmophilic yeast seed liquid to conduct arabitol fermentation, and then in middle and later stage inoculating the gluconobacter oxydans seed liquid to conduct mixed culture fermentation, simultaneously controlling the glucose content in the broth to be 5-10g / L, and converting arabitol into D-xylosone. According to the method, the feedback inhibition of arabitol is removed, and the efficiency of preparing D-xylosone from glucose is raised. The invention further discloses a method for preparing xylitol by microbial transformation of glucose, comprising the following steps: firstly converting glucose into D-xylosone by the above method, then converting D-xylosone into D-xylose by isomerization of enzyme, extracting and refining, and conducting catalytic hydrogenation to obtain xylitol. According to the method, the production efficiency of xylitol is raised, and the cost of preparing xylitol by biological method is reduced.

Owner:SHANDONG TIANLI PHARMA

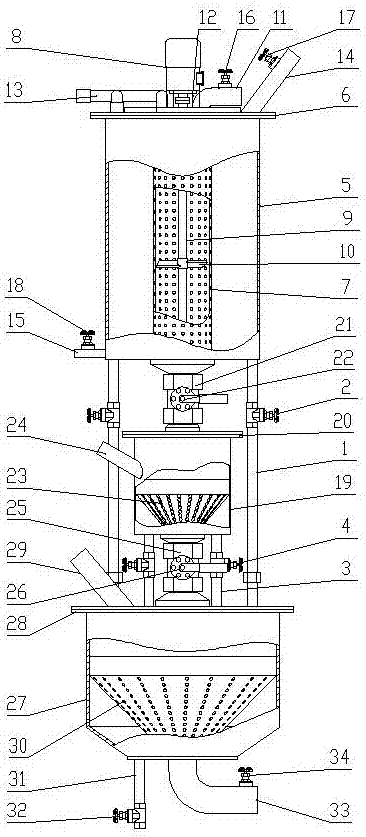

Simultaneous saccharification and fermentation hydrogen-producing reactor accompanied with enzyme recycling and experimental method thereof

ActiveCN107488578AReduce dosageIncrease sugar yieldBioreactor/fermenter combinationsBiological substance pretreatmentsEnzymatic hydrolysisExperimental methods

The invention relates to a simultaneous saccharification and fermentation hydrogen-producing reactor accompanied with enzyme recycling. The reactor comprises an enzymolysis unit, a hydrogen-producing unit, an enzyme desorption unit and an enzyme adsorption unit, wherein the enzymolysis unit is located in the hydrogen-producing unit, and is communicated with the hydrogen-producing unit; the lower end of the enzymolysis unit is connected with a feed inlet in the upper end of the enzyme desorption unit; the bottom part of the hydrogen-producing unit is communicated with the top part of the enzyme adsorption unit through a first support pipeline; a discharge hole in the bottom part of the enzyme desorption unit is communicated with the top part of the enzyme adsorption unit through a second support pipeline. The invention also discloses an experimental method of the simultaneous saccharification and fermentation hydrogen-producing reactor accompanied with enzyme recycling. According to the simultaneous saccharification and fermentation hydrogen-producing reactor accompanied with enzyme recycling and the experimental method of the simultaneous saccharification and fermentation hydrogen-producing reactor accompanied with enzyme recycling provided by the invention, cellulase is recycled after a hydrogen-producing process is finished, and the cellulase subjected to enzymatic hydrolysis can be recycled, so that the residual activity of the cellulase is effectively utilized, the sugar yield of unit enzyme is improved, the dosage of the cellulase is further reduced, the process cost can be greatly reduced, and the industrialization production of straw biomass energy conversion is promoted.

Owner:HENAN AGRICULTURAL UNIVERSITY

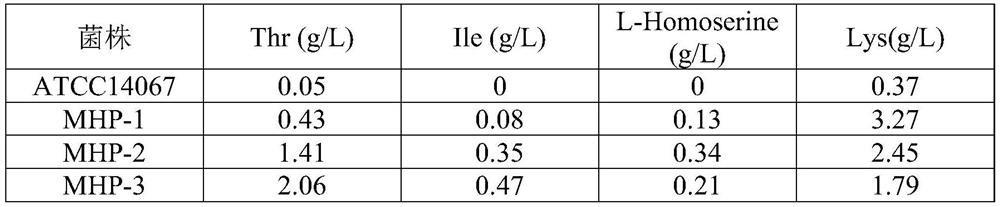

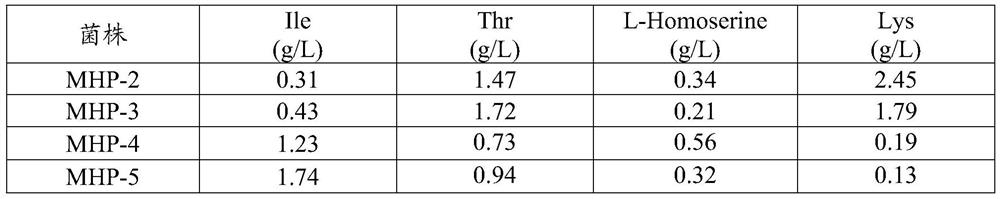

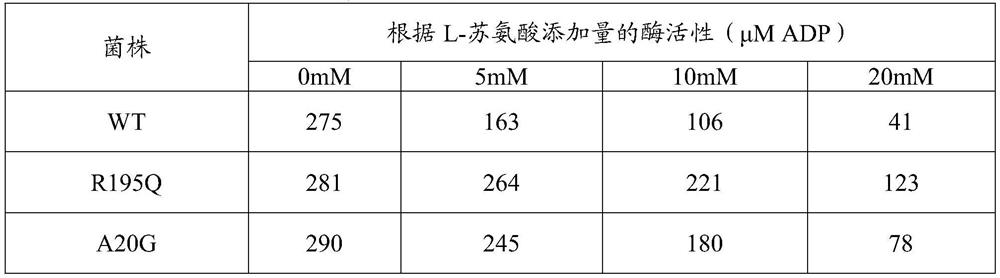

Mutant homoserine kinase and application thereof

The invention relates to the technical field of amino acids, and particularly discloses mutant homoserine kinase and application thereof. The amino acid at the 195th site of the mutated homoserine kinase is mutated. According to the mutant homoserine kinase and the application thereof, a strain with better threonine yield is obtained through mutagenesis screening, a conclusion that homoserine kinase R195Q mutation is an effective site for synthesis of threonine and isoleucine is obtained through verification, the generation capacity of the threonine and the isoleucine in microorganisms with transduced coding genes is remarkably improved, and meanwhile, the feedback inhibition effect of the threonine can be better relieved.

Owner:MEIHUA BIOTECH LANGFANG CO LTD

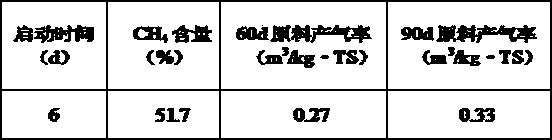

Composite microbial inoculant capable of efficiently producing methane by grease anaerobic degradation, and preparation method and application thereof

ActiveCN104974970ARelease feedback inhibitionGuaranteed stabilityBacteriaMicroorganism based processesStart timeSyntrophomonas

The invention provides a composite microbial inoculant capable of efficiently producing methane by grease anaerobic degradation, which comprises the following strains: Anaerovibrio lipolytica DSM 3074, Syntrophomonas erecta DSM 16215, Syntrophomonas bryantii DSM 3014A, Syntrophomonas palmitatica DSM 18709, Desulfovibrio vulgaris DSM 644, Methanospirillum hungatei DSM 13809, Methanobacterium formicicum DSM 1535, Methanobrevibacter smithii DSM861, and Methanosaeta concilii DSM 2139T. The invention also provides a method for preparing the microbial inoculant and application of the microbial inoculant in producing methane by grease anaerobic degradation. The composite microbial inoculant can obviously shorten the start time, enhance the biogas fermentation efficiency and enhance the stability of the fermentation process. The composite microbial inoculant is suitable for different scales of fermentation systems, and has favorable market value.

Owner:BIOGAS SCI RES INST MIN OF AGRI

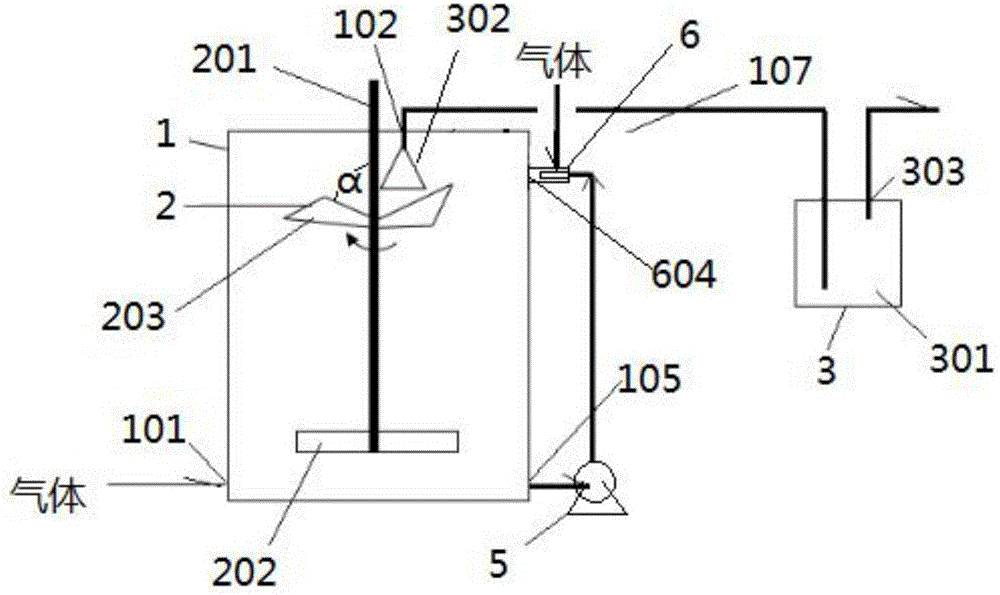

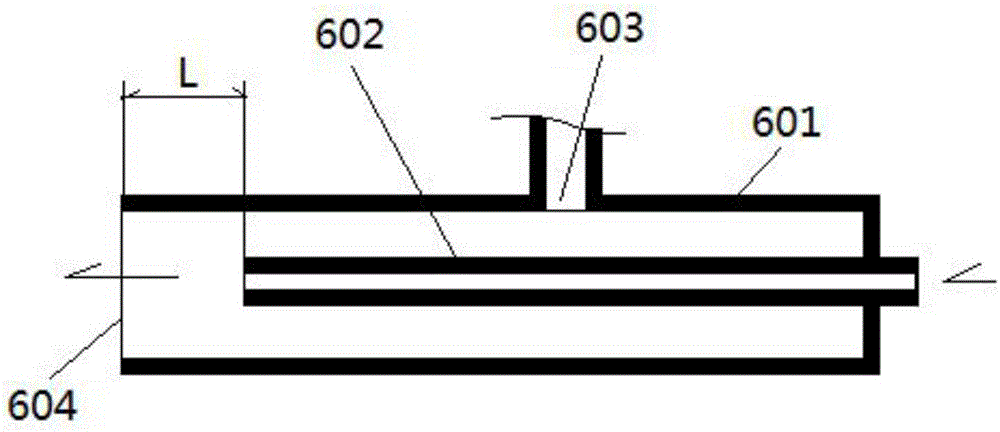

Fermentation device and method for efficiently fermenting and producing bacteriocin

ActiveCN106754296AEfficient collectionEfficient expressionBioreactor/fermenter combinationsBiological substance pretreatmentsFoaming agentHydrogen

The invention discloses a fermentation device and method for efficiently fermenting and producing bacteriocin. The fermentation device comprises a fermentation tank, a foam-liquid separation device and a foam recycling device, wherein the foam-liquid separation device is arranged in the fermentation tank; an inlet of the foam recycling device is connected with a foam outlet at the top of the fermentation tank; a vacuum hole of the foam recycling device is communicated with a vacuum generation device; a gas inlet is formed in the bottom of the fermentation tank. The method for fermenting and producing the bacteriocin comprises the following steps: filling a culture medium containing a foaming catalyst into the fermentation tank; pouring a de-foaming agent into a collection tank; inoculating bacteria into the fermentation tank; ventilating and adjusting the pH (Potential of Hydrogen) to be 6 to 7, and fermenting; starting the vacuum generation device and collecting foam at the upper part of the fermentation tank into the collection tank; decomposing the foam into liquid and collecting a fermentation product from liquid in the collection tank. By adopting the fermentation device and method disclosed by the invention, the feedback inhibition effect, caused by the product, on bacterium production and metabolism, can be effectively eliminated in time, so that a target product is efficiently expressed.

Owner:昆山博青生物科技有限公司

Isopropylmalate synthase variant and a method of producing l-leucine using the same

Owner:CJ CHEILJEDANG CORP

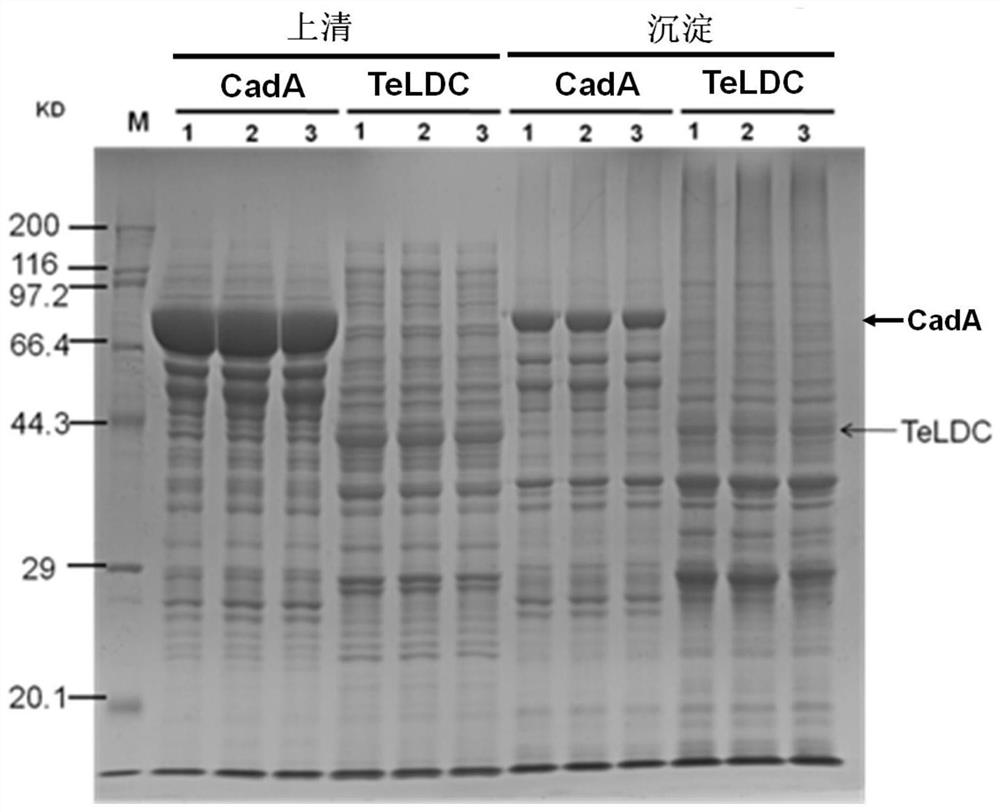

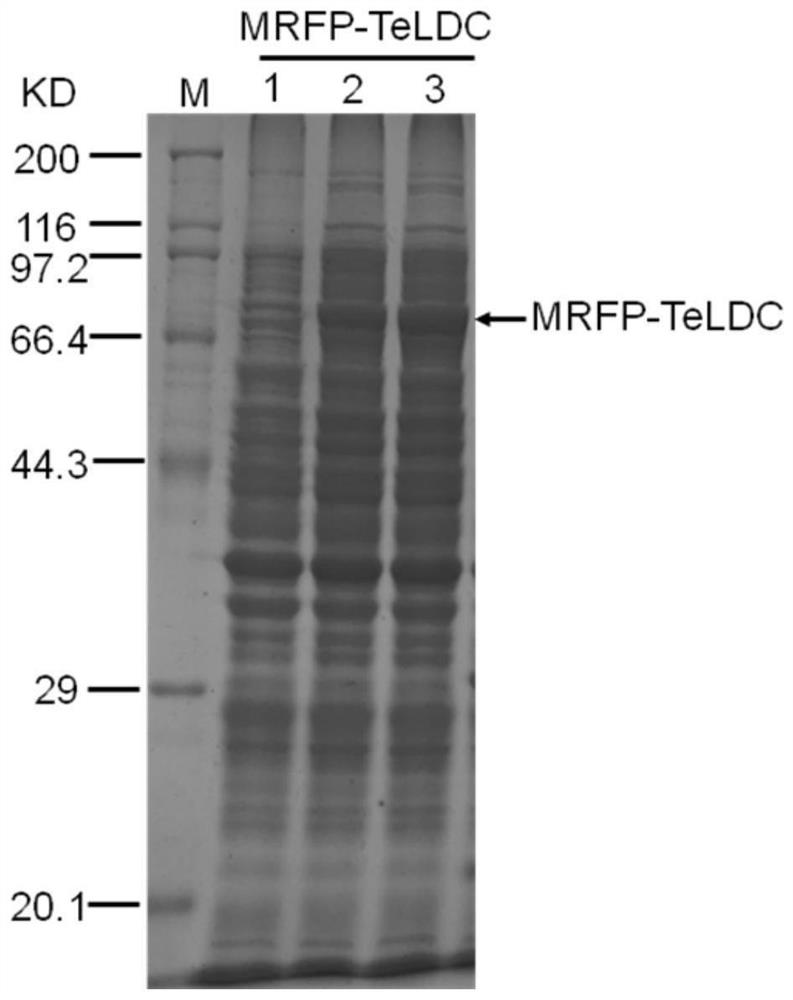

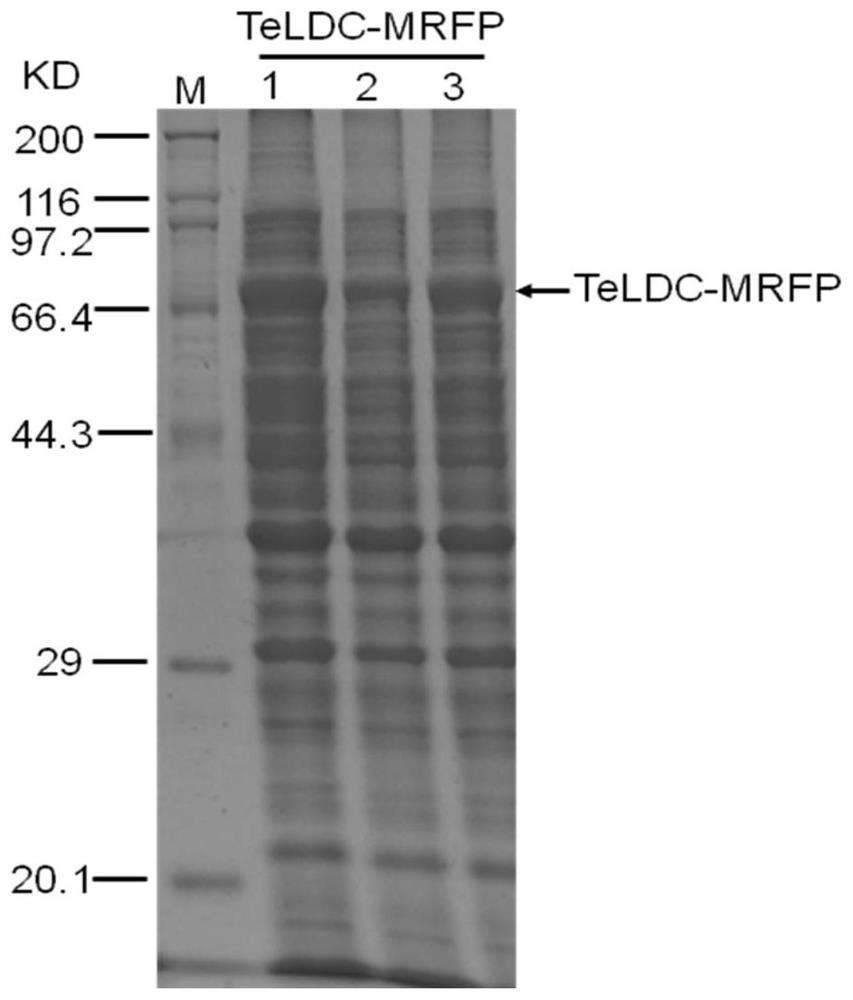

Heterologous expression method and application of L-lysine decarboxylase from thermophilic bacteria

PendingCN111978407ALow cytotoxicityRelease feedback inhibitionBacteriaMicroorganism based processesHeterologousMicrobiology

The invention relates to a heterologous expression method and an application of L-lysine decarboxylase from thermophilic bacteria. L-lysine decarboxylase from a thermophilic strain is screened and isfused and expressed with the thermophilic strain by utilizing a solubilizing tag, and when the L-lysine decarboxylase from the thermophilic strain is connected with the solubilizing tag, the L-lysinedecarboxylase from the thermophilic strain can be helped to exert a lysine decarboxylation function; and in addition, the use of the solubilizing tag may also explicitly indicate a cell expressing thefusion protein. The invention provides a new strategy for fermentation production of high-yield 1, 5-pentanediamine.

Owner:CATHAY R&D CENT CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com