Tetrahydropyridine high-yield Corynebacterium glutamicum and application thereof

A technology of Corynebacterium glutamicum and ectoine, applied in the field of bioengineering, can solve problems such as endotoxin and bacteriophage pollution, and achieve the effect of strengthening accumulation and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

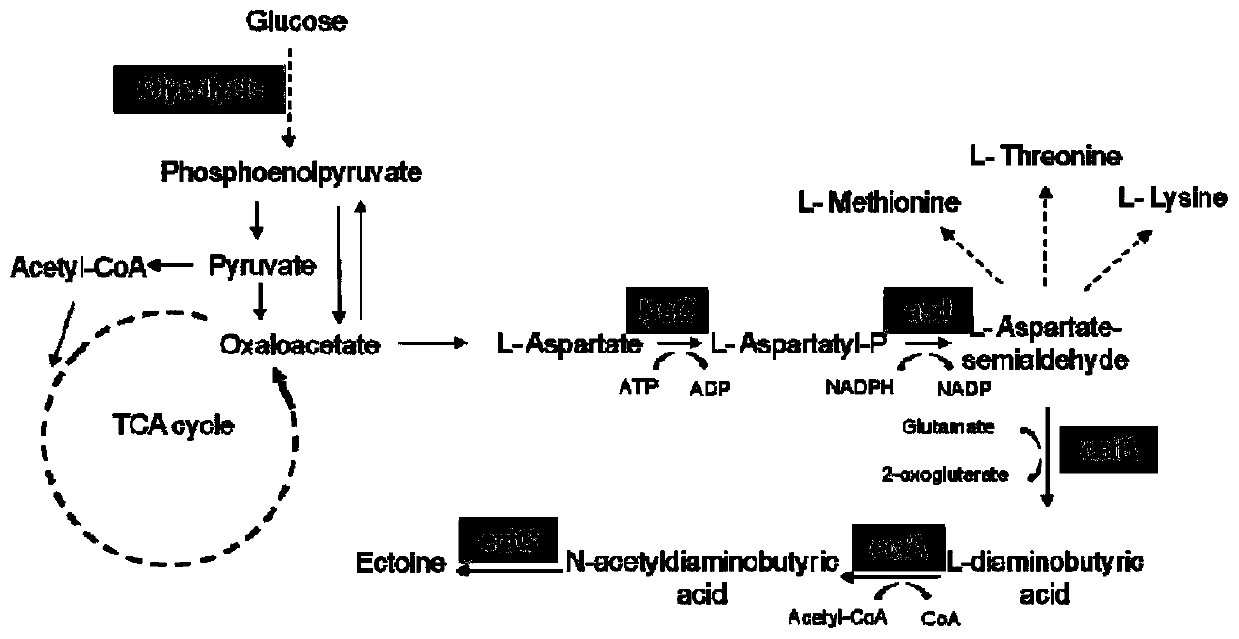

Method used

Image

Examples

Embodiment 1

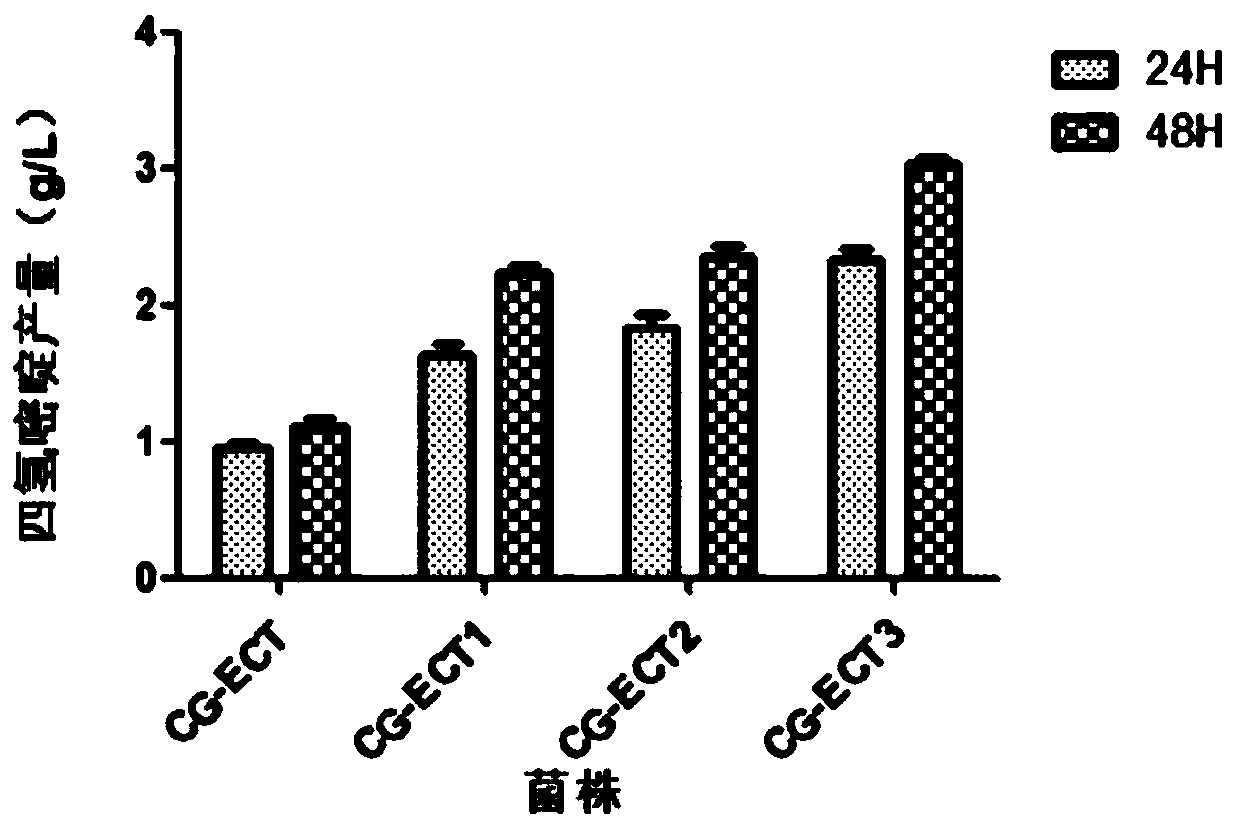

[0044] Embodiment 1: Construction and transformation of recombinant Corynebacterium glutamicum ectoine high-yielding strain

[0045] (1) Construction of ectoine expression plasmid

[0046] Primers ect-PF and ect-PR were designed according to the ectopyrimidine synthesis gene cluster ectABC in Pseudomonas stutzeri (Pseudomonas stutzeri A1501), and the 5' end was amplified by PCR using the genomic DNA of Pseudomonas stutzeri A1501 as a template The ectABC gene with the artificially designed RBS (the nucleotide sequence of the ectABC gene with the artificially designed RBS is shown in SEQID NO.1, wherein 1 to 26bp is the artificially designed RBS), and an approximately 2.3kb Gene fragments and purification of PCR products.

[0047] Primers:

[0048] ect-PF: acagaattaattaagcttgtttaactttaagaaggagatataccatgcctaccctaaaaaggaattcaatcaac, SEQ ID NO. 2,

[0049] ect-PR: agctcggtacccggggatcctcagacggtttcggcctccagagga, SEQ ID NO.3.

[0050] Using the commercial expression plasmid pXMJ19...

Embodiment 2

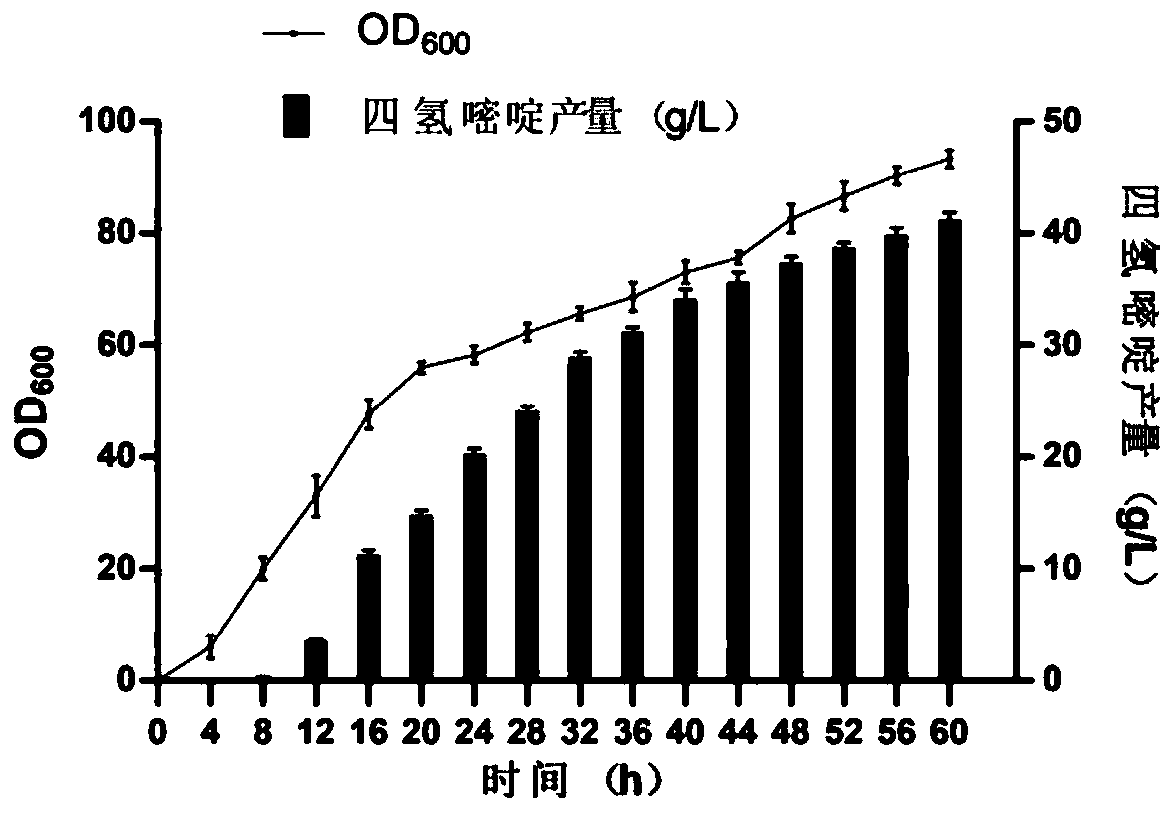

[0092] Embodiment 2: Recombinant Corynebacterium glutamicum fermenter culture synthetic ectoine

[0093] The ectoine synthesis ability of the recombinant Corynebacterium glutamicum high-yielding strain CG-ECT3 was analyzed at the fermenter level by high-density culture.

[0094] Inoculate the seed liquid into a 2.5L fermenter with 1L fermenter medium at an inoculation amount of 10% (volume ratio), control the temperature at 30°C, and maintain the pH at 1vvm by adding 3M phosphoric acid and 3M ammonia water The value is stable at 6.8-7.2. Ferment for about 6 hours, OD 600 At 10 o'clock, add IPTG with a final concentration of 0.5mM; after 16 hours of fermentation, start feeding medium to maintain the glucose concentration in the range of 2-5g / L. The rotational speed was adjusted throughout the fermentation process so that the dissolved oxygen level remained above 10% (the dissolved oxygen before inoculation was calibrated as 100%).

[0095] Fermenter culture medium: every lit...

Embodiment 3

[0098] Embodiment 3: Recombinant Corynebacterium glutamicum fermenter culture synthetic ectoine

[0099] The ectoine synthesis ability of the recombinant Corynebacterium glutamicum high-yielding strain CG-ECT3 was analyzed at the fermenter level by high-density culture.

[0100] Inoculate the seed liquid into a 2.5L fermenter with 1L fermenter medium at an inoculation amount of 10% (volume ratio), control the temperature at 30°C, and maintain the pH at 1vvm by adding 3M phosphoric acid and 3M ammonia water The value is stable at 6.8-7.2. Ferment for about 6 hours, OD 600 At 10 o'clock, add IPTG with a final concentration of 0.5mM; after 16 hours of fermentation, start feeding medium to maintain the glucose concentration in the range of 2-5g / L. The rotational speed was adjusted throughout the fermentation process so that the dissolved oxygen level remained above 10% (the dissolved oxygen before inoculation was calibrated as 100%).

[0101] Fermenter medium: every liter of me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry cell weight | aaaaa | aaaaa |

| Dry cell weight | aaaaa | aaaaa |

| Dry cell weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com