Method for preparing biodiesel by directly using cellulose through mixed fermentation

A mixed fermentation and biodiesel technology, which is applied in the direction of fermentation and biofuels, can solve the problems that cannot be used to produce biodiesel, high-yielding microbial bacteria cannot use cellulose, etc., to achieve abundant raw materials, solve energy shortages, and rapid regeneration cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

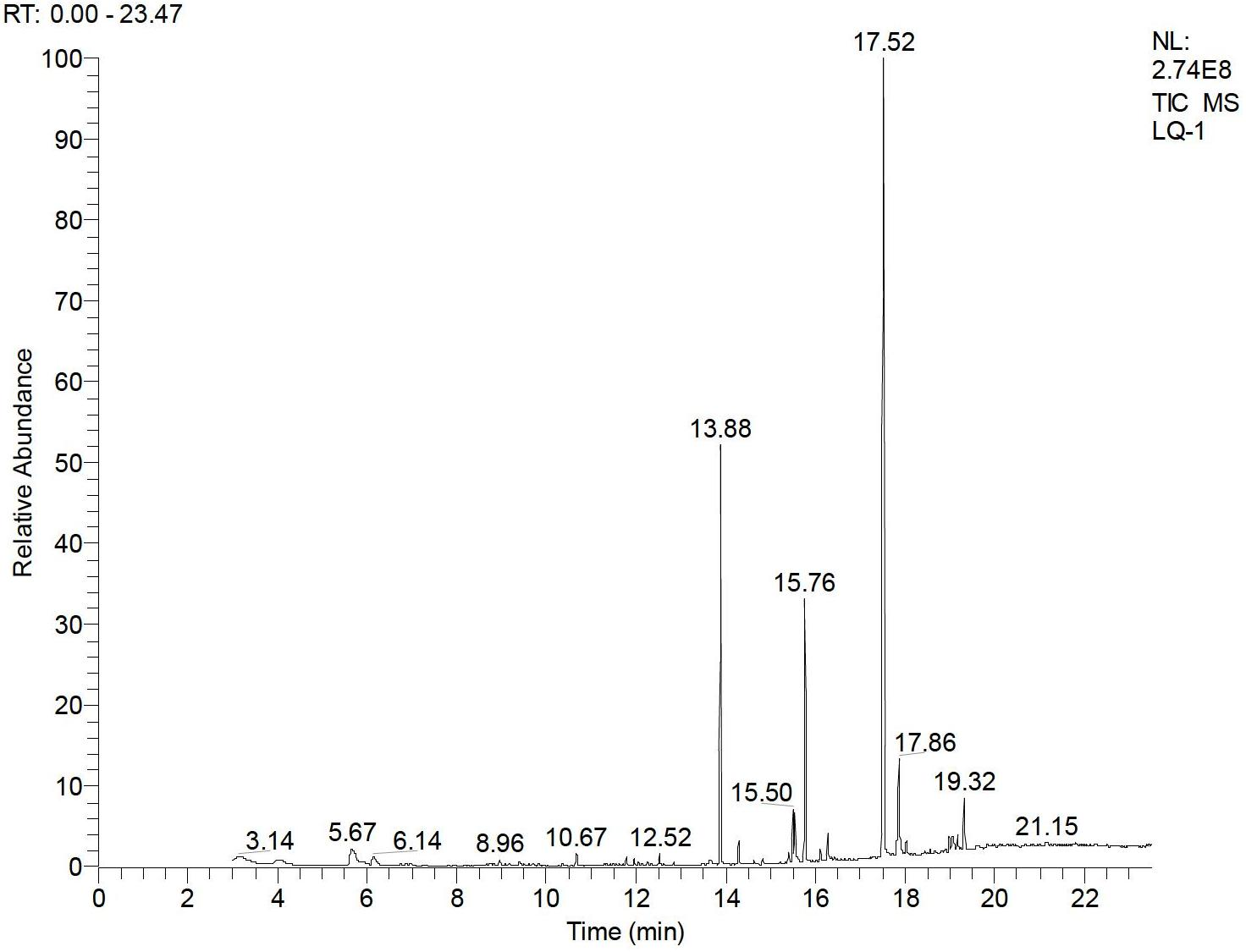

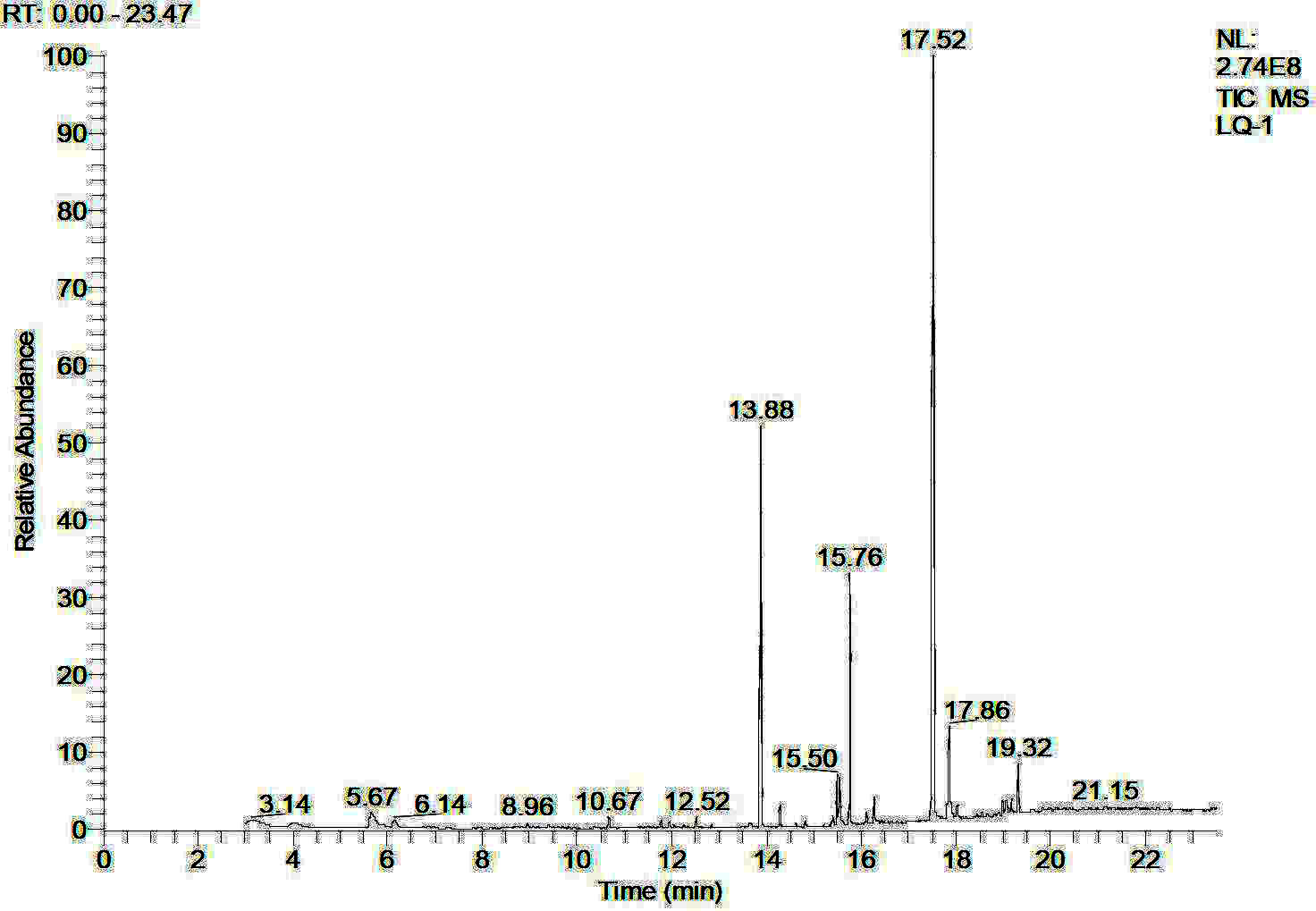

Image

Examples

Embodiment 1

[0037] Determination of medium for mixed fermentation:

[0038] According to the culture characteristics of cellulolytic microorganisms and oleaginous microorganisms, the medium components described in step (1) were optimized by using single factor experiments, orthogonal experiments, response surface analysis and other methods, and the mixed fermentation medium was screened and designed as follows :

[0039] Medium Ⅰ: 10g cellulose; 9g Na 2 HPO 4 12H 2 O; 1.5 g KH 2 PO 4 ; 1.2mg FeNH 4 -Citrate; 0.34g (NH 4 ) 2 SO 4 ;0.15g Peptone【Peptone】; 0.15g Yeast extract; 0.3g CaCl 2 , 0.3g MgSO 4 , 0.005gFeSO 4 ·7H 2 O; 0.0016g MnSO 4 ·H 2 O; 0.0014g ZnSO 4 ·H 2 O; 0.002g CoCl 2 ; 1000mL H 2 O, the pH is adjusted to a weakly acidic pH of 6.0-6.8.

[0040] Medium Ⅱ: 10g cellulose; 2g KH 2 PO 4 ; 1.4g (NH 4 ) 2 SO 4 ;0.3g MgSO 4 ; 0.3g CaCl 2 ; 0.5g peptone; 0.005g FeSO 4 ·7H 2 O; 0.0016g MnSO 4 ·H 2 O, 0.0014g ZnSO 4 ·H 2 O; 0.002g CoCl 2 , 1000mLH 2 O;...

Embodiment 2

[0058] The oil-producing microorganism Rhodococcus opacus (Rhodococcus opacus ACCC41043) and the cellulose-degrading bacteria Trichoderma reesei (Trichoderma reesei ATCC 26921) were used as mixed strains for mixed fermentation. Mixed fermentation medium adopts medium Ⅰ: 15g cellulose; 9g Na 2 HPO 4 12H 2 O; 1.5 g KH 2 PO 4 ; 1.2mg FeNH 4 -Citrate; 0.34g (NH 4 ) 2 SO 4 ; 0.15g Peptone; 0.15g Yeast extract; 0.3g CaCl 2 , 0.3g MgSO 4 , 0.005g FeSO 4 ·7H 2 O; 0.0016gMnSO 4 ·H 2 O; 0.0014g ZnSO 4 ·H 2 O; 0.002g CoCl 2 ; 1000mL H 2 O, the pH was adjusted to pH 6.8. The fermenter was a 5L fermenter, and the culture temperature was 28°C. Trichoderma reesei was inoculated according to 2% v / v inoculum. After 12 hours of cultivation, Rhodococcus turbide was inoculated into the fermenter according to 2% v / v inoculum for mixed bacteria fermentation.

[0059] Extraction of fatty acids: Ferment for 5 days, take 2L of the bacterial liquid, centrifuge to get the precipitate, ...

Embodiment 3

[0064] The oil-producing microorganism Rhodococcus opacus (Rhodococcus opacus ACCC41043) and the cellulose-degrading bacteria Aspergillus niger (Aspergillus niger DSMZ 821) were used as mixed strains for mixed fermentation. Medium Ⅱ: 18g bagasse; 2g KH 2 PO 4 ; 1.4g (NH 4 ) 2 SO 4 ;0.3g MgSO 4 ; 0.3g CaCl 2 ; 0.5g Peptone; 0.005g FeSO 4 ·7H 2 O; 0.0016gMnSO 4 ·H 2 O, 0.0014g ZnSO 4 ·H 2 O; 0.002g CoCl 2 , 1000mL H 2 O; the pH was adjusted to pH 6.8; the fermentation vessel was a 250mL Erlenmeyer flask, and the culture temperature was 28°C. Aspergillus niger was inoculated according to 2% v / v inoculum, and Rhodococcus turbide was inoculated according to 2% v / v inoculum after 12 hours of cultivation Carry out mixed fermentation.

[0065] Extraction of fatty acids: Ferment for 5 days, take 50mL of the bacterial liquid, centrifuge to get the precipitate, and extract the precipitate with 500mL extractant (volume ratio: chloroform:methanol=2:1) overnight. Centrifuge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com