Fermentation device and method for efficiently fermenting and producing bacteriocin

A fermentation device and a bacteriocin technology are applied in the field of fermentation separation coupling process for producing bacteriocin, which can solve the problems of inability to influence the yield of Nisin, difficulty in realizing industrialized production, and high separation cost, so as to relieve the feedback inhibition of bacterial production and metabolism, Improve application efficiency and simplify the effect of downstream purification processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

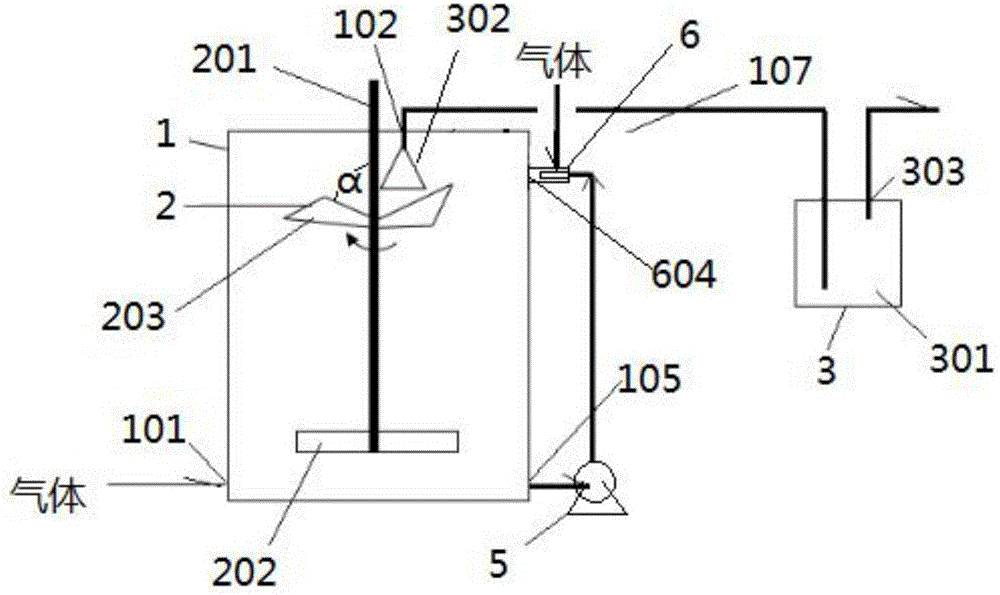

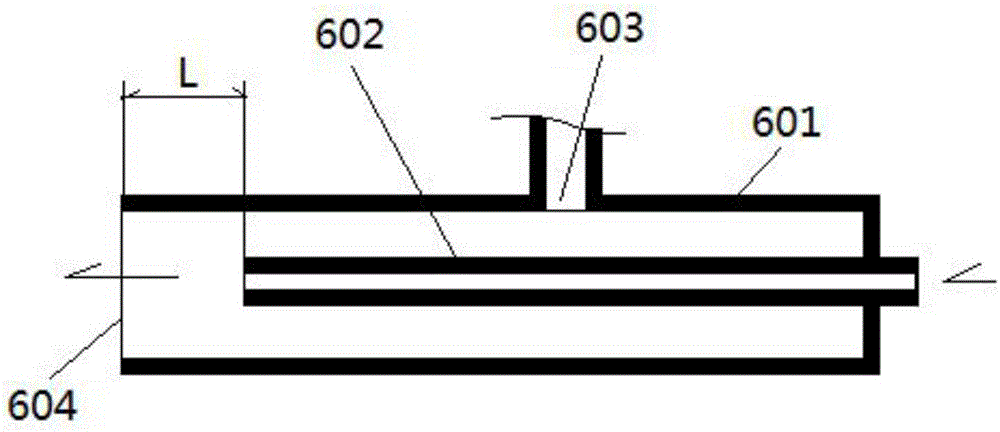

[0075] use figure 1 with figure 2 s installation. Wherein, the fermentation broth circulation device is not used.

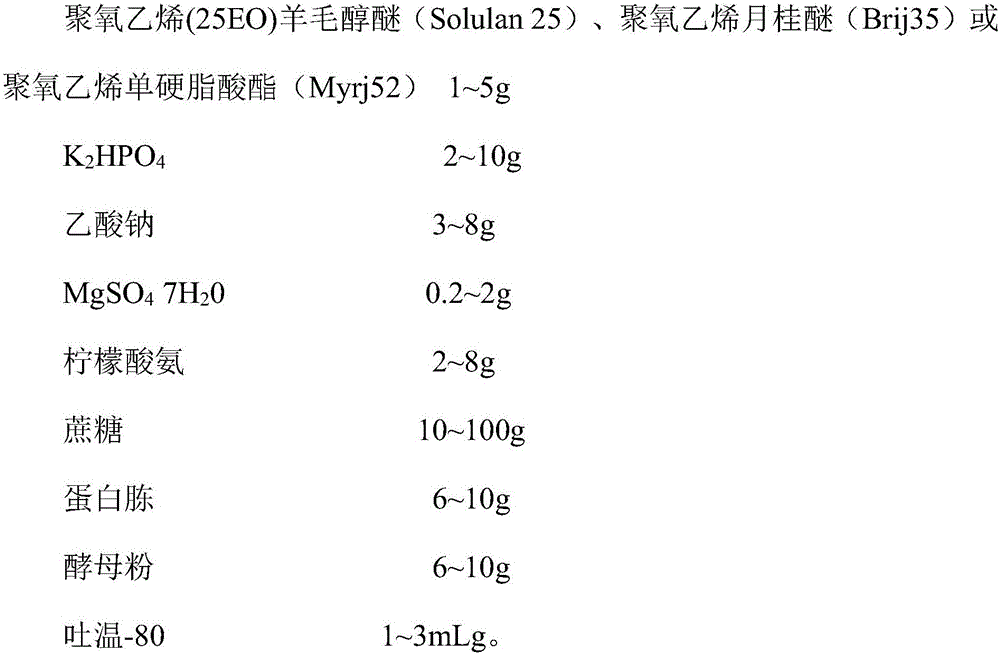

[0076] The foam liquid separation device comprises a 2-leaf oblique impeller at the upper end of the stirring shaft, the width of the blade surface is 0.5cm, and the inclination angle is α10°. This embodiment is based on the food and fermentation industry, volume 26 (5): 19-21 literature The reported production of nisin by fermentation of Lactococcus lactis is an example. The culture medium is: water is used as the carrier, and each 1L of culture medium includes the following components by weight:

[0077]

[0078]

[0079] According to the above ratio, 3 L of culture medium was prepared and placed in a 5 L fermenter 1, and the height of the liquid level of the fermented liquid was adjusted to be 1 cm below the bubble liquid separation device.

[0080] Pour the antifoaming agent polyoxypropylene oxide ethylene glyceryl ether with a weight concentration ...

Embodiment 2

[0091] use figure 1 with figure 2 s installation.

[0092] Take Food and Fermentation Industry, Vol. 26(5): 19-21 as an example of the fermentative production of nisin by Lactococcus lactis.

[0093] The difference from Example 1 is that the fermenter is a 50L stainless steel in-situ sterilized fermenter, the oblique impeller of the bubble liquid separation device is 3 leaves, the leaf width is 10cm, the inclination angle is 25°, and the height is adjusted to be above the fermentation liquid surface 3cm.

[0094] With water as the carrier, according to each L containing polyoxyethylene lauryl ether (Brij35) 5g, K 2 HPO 4 10g, sodium acetate 8g, MgSO 4 7H 2 0 2g, ammonium citrate 8g, sucrose 100g, peptone 10g, yeast powder 10g, Tween-80 3mL ratio to prepare 35L of culture medium, put it in a 50L glass fermentation tank, and the height of the bubble liquid separation device is above the surface of the fermentation liquid 3cm.

[0095] And pour 10% volume of antifoaming...

Embodiment 3

[0108] Adopt the method identical with embodiment 1.

[0109] Taking the food and fermentation industry, volume 26 (5): 19-21, Lactococcus lactis fermented to produce nisin as an example, the difference from Example 1 is that the fermenter is a 500L stainless steel in-situ sterilization fermentation Tank, the oblique impeller of the foam liquid separation device is 6 leaves, the width of the blade surface is 15cm, the inclination angle is 65°, the height is adjusted to 5cm above the fermentation liquid surface, other structures are the same as in Example 1, and its operation steps are:

[0110] With water as the carrier, according to each L containing polyoxyethylene monostearate (Myrj52) 3g, K 2 HPO 4 5g, sodium acetate 4g, MgSO 4 7H 2 0 1g, 4g of ammonium citrate, 40g of sucrose, 8g of peptone, 8g of yeast powder, Tween-80 2mL proportioned and prepared medium 350L, installed in a 500L fermenter, the height of the bubble liquid separation device is 5cm above the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com