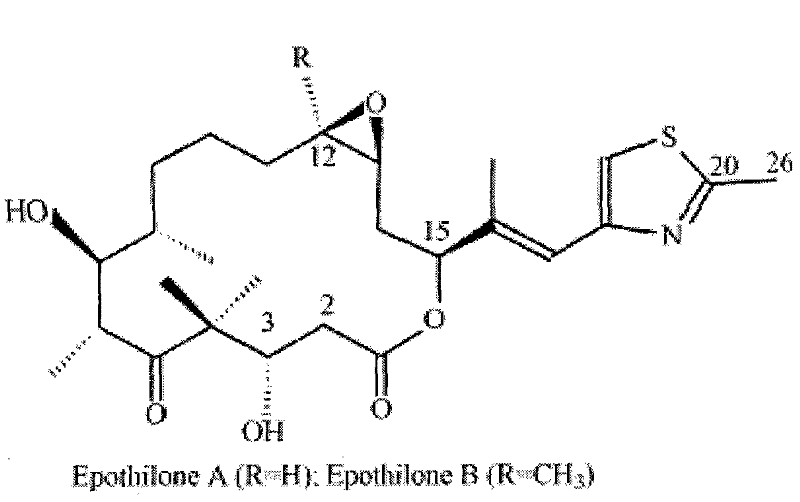

Production process for high-density fermentation of sprangium cellulosum and separation coupling of epothilone product

A technology of high-density fermentation and S. cellulosus, applied in the direction of fermentation, microbial-based methods, bacteria, etc., to achieve high production efficiency, convenient operation, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

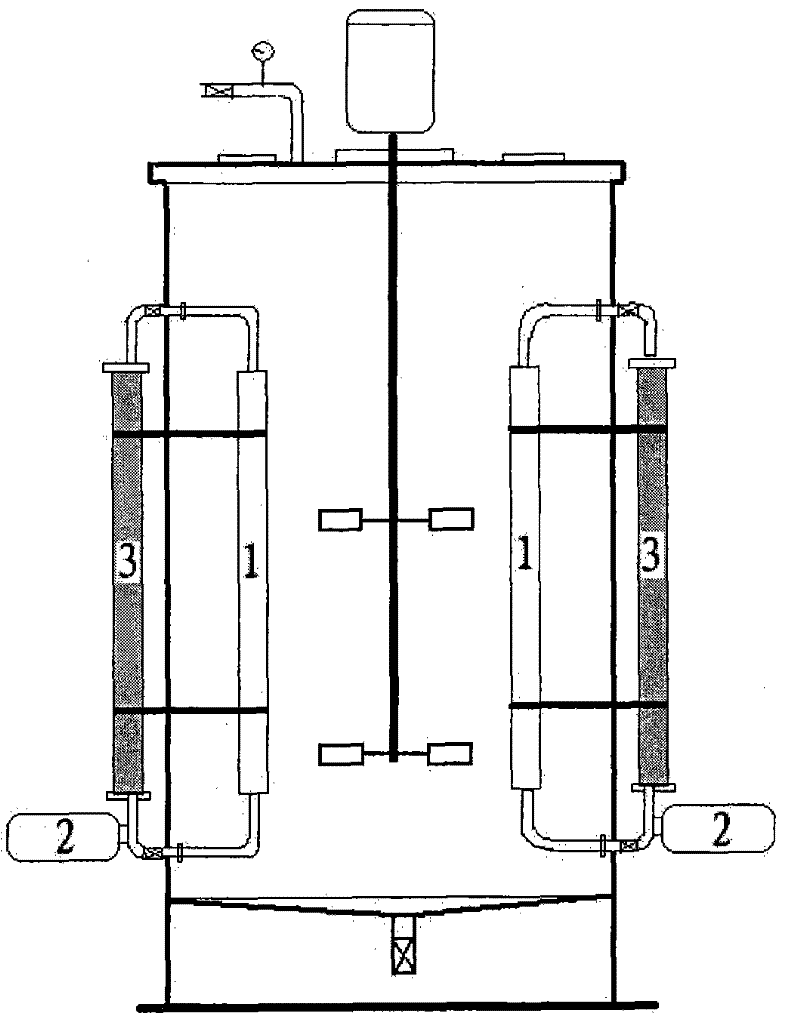

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of S. cellulosus strain: Epothilone production strain S. cellulosus So0157-2, preserved in China Center for Typical Microorganisms Collection, No. M208078. Before use, the strains were activated by culturing in solid activation medium at 28°C for 5 days, and in liquid seed medium at 30°C for 3 days, and the cell volume reached 10 10 When inoculating the fermentation medium, the filling coefficient of the fermentation tank is 70%, the inoculum size is 5% (V / V), and the fermentation period is 7 days.

[0025] The solid activation medium as described in 1 is: 0.5% potato starch, 1% soybean peptone, 1% glucose, 0.5% yeast extract, MgSO 4 0.5%, CaCl 2 0.5%; TE 1.0ml / L; pH7.0. Add 0.8% agar and sterilize at 121°C for 20 minutes before use.

[0026] The liquid seed medium as described in 1 is: 0.5% potato starch, 1% soybean peptone, 1% glucose, 0.5% yeast extract, MgSO 4 0.5%, CaCl 2 0.5%; TE 1.0ml / L; pH7.0. Sterilize at 121°C for 20 minutes before use.

...

Embodiment 2

[0034] 1. Preparation of S. cellulosus strain: Epothilone production strain S. cellulosus So0157-2, preserved in China Center for Typical Microorganisms Collection, No. M208078. Before use, the strains were activated by culturing solid activation medium at 30°C for 6 days, and culturing liquid seed medium at 31°C for 4 days, and the cell volume reached 10 10 When inoculating the fermentation medium, the filling coefficient of the fermentation tank is 70%, the inoculum size is 10% (V / V), and the fermentation period is 8 days.

[0035] The solid-state activation medium as described in 1 is: 1% potato starch, 1.5% soybean peptone, 1.5% glucose, 0.8% yeast extract, MgSO 4 0.7%, CaCl 2 0.7%; TE 1.5ml / L; pH7.5. Add 1% agar and sterilize at 121°C for 20 minutes before use.

[0036] The liquid seed medium as described in 1 is: 2% potato starch, 1.5% soybean peptone, 1.5% glucose, 0.8% yeast extract, MgSO 4 0.7%, CaCl 2 0.7%; TE 1.5ml / L; pH7.5. Sterilize at 121°C for 20 minutes be...

Embodiment 3

[0044] 1. Preparation of S. cellulosus strain: Epothilone production strain S. cellulosus So0157-2, preserved in China Center for Typical Microorganisms Collection, No. M208078. Before use, the strains were activated by culturing in solid activation medium at 32°C for 7 days, and in liquid seed medium for 5 days at 32°C, and the cell volume reached 10 10 When inoculating the fermentation medium, the filling coefficient of the fermentation tank is 70%, the inoculum size is 5% (V / V), and the fermentation period is 9 days.

[0045] The solid activation medium as described in 1 is: 3% potato starch, 2% soybean peptone, 2% glucose, 1% yeast extract, MgSO 4 1%, CaCl 2 1%; TE 2.0ml / L; pH8.0. Add 1.5% agar, and sterilize at 121°C for 20 minutes before use.

[0046] The liquid seed medium as described in 1 is: 3% potato starch, 2% soybean peptone, 2% glucose, 1% yeast extract, MgSO 4 1%, CaCl 2 1%; TE 2.0ml / L; pH8.0. Sterilized at 121°C for 20 minutes before use.

[0047] The fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com