Microbial preparation for sludge anaerobic fermentation

A technology of microbial preparations and mixed bacterial solutions, applied in the direction of microorganism-based methods, microorganisms, sludge treatment, etc., can solve the problems of reduced methane production efficiency and waste of resources, and achieve reduced treatment costs, improved efficiency, and improved nitrogen removal performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

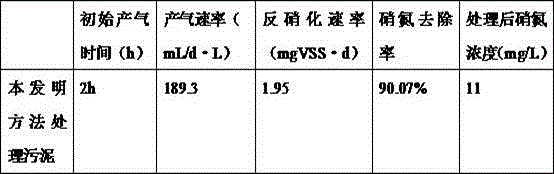

Examples

Embodiment 1

[0033] A microbial preparation is prepared, and the microbial preparation is composed of a mixed bacterial solution and a carrier, and the mixed bacterial solution is prepared from Bacillus pumilus, Enterobacter cloacae, denitrifying bacteria, Paracoccus denitrificans, Bacillus amyloliquefaciens and Lactococcus lactis.

[0034] Described bacillus pumilus is (Bacillus pumilus) ATCC27142;

[0035] The Enterobacter cloacae is ( Enterobacter cloacae ) ATCC 700323;

[0036] The denitrifying bacteria is (Paracoccus pantotrophus) ATCC 35512;

[0037] The paracoccus denitrificans is (Paracoccus denitrificans) ATCC13543;

[0038] The bacillus amyloliquefaciens is ( Bacillus amyloliquefaciens ) ATCC 23843;

[0039]The Lactococcus lactis (Lactococcus lactis) ATCC 11454.

[0040] The carrier is formed by mixing kaolin and chitosan in a weight ratio of 1:3;

[0041] The microbial preparation is prepared by mixing the mixed bacterial liquid and the carrier according to the weight rat...

Embodiment 2

[0046] The sludge samples come from a sewage treatment plant and are processed according to the following steps:

[0047] 1) Adjust the sludge so that the total solid content is 8wt%;

[0048] 2) Add the sludge with a total solid content of 8% obtained in the first step into the anaerobic digestion tank, the amount added is 60% (v / v) of the volume of the digestion tank, and 8% (v / v) of the volume of the digestion tank is added ), add water to 90% of the volume of the digestion tank, and adjust the pH to 7.5-7.7;

[0049] The methanogenic inoculum is biogas fermentation liquid;

[0050] 3) Inoculate microbial preparations, the amount added is 1% (v / v) of the volume of the digestion tank, stir evenly, and cover;

[0051] 4) Keep the reaction temperature at 30°C, stir once every 10 hours, add rare earth nitrate while stirring, and react for 36 hours;

[0052] The addition amount of the rare earth nitrate is 3 μg of rare earth nitrate per gram of volatile solids (VSS) in the sl...

Embodiment 3

[0058] Example 3 Influence of Bacteria Composition on Methane Increment Experiment

[0059] Firstly, take 200kg of sludge from a sewage treatment plant and divide it into five equal parts, each of which is 40kg.

[0060] Five equally divided sludges were placed in five identical airtight reaction containers, respectively marked as the experimental group, control group 1, control group 2, control group 3, and blank control group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com