2-keto-L-gulonic acid high tolerance type gluconobacteroxydans and application thereof in vitamin C fermentation production

A technology of gluconobacterium oxidizing and gulon acid, which is applied in the direction of microorganism-based methods, fermentation, bacteria, etc., can solve the problems of low fermentation efficiency and poor tolerance, and achieve the goal of improving production efficiency, reducing production costs and increasing production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

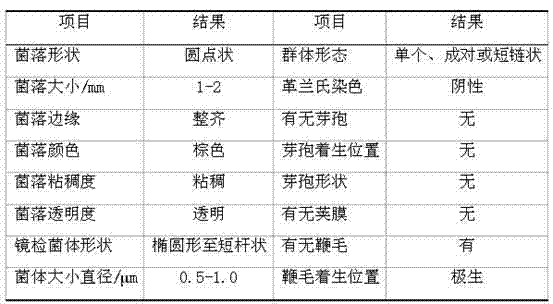

Embodiment 1

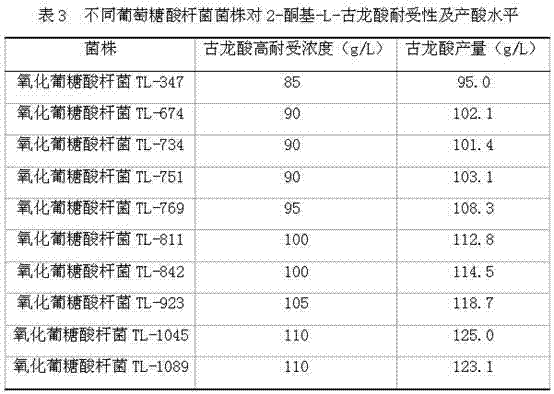

[0044] Mutation Screening of Gluconobacter oxydans TL-1045

[0045] Pick out a single colony of the originating strain Gluconobacter oxydans TL-347, insert it into a sterile Erlenmeyer flask equipped with glass beads, add 30 ml of sterile saline, shake at 150 rpm for 20 min, break up the colony, and prepare bacterial suspension. Take 5 ml of bacterial suspension and add it to a petri dish, and irradiate it at 20-40 cm under a 40-watt ultraviolet lamp for 1 min, 5 min, and 10 min, and then dilute the three treated bacterial suspensions to 10 -3 -10 -5 , coated with selection medium (2-keto-L-gulonic acid 110 g / L, sorbose 15 g / L, tryptone 3 g / L, urea 0.1 g / L, corn steep liquor 4 g / L, beef cream 1.2 g / L, yeast extract 1.2 g / L, potassium dihydrogen phosphate 1 g / L, magnesium sulfate 0.2 g / L, agar powder 17 g / L, pH 6.7), cultured in the dark for 72 h, picked The colonies on the plate were taken and paired with Bacillus megaterium respectively, and then the mixed bacteria were in...

Embodiment 2

[0048] The production of 2-keto-L-gulonic acid by mixed fermentation of Gluconobacter oxydans TL-1045 and Bacillus megaterium comprises the following steps:

[0049] (1) Activation of strains: Wash all the large and small bacteria stored in the eggplant bottle with the activation medium, inoculate them into the activation medium with a liquid volume of 20%, and incubate at 29°C for 24 h; the composition of the activation medium is For: sorbose 5 g / L, glucose 3 g / L, yeast extract 5 g / L, corn steep liquor 5 g / L, urea 0.1 g / L, pH 6.7;

[0050] (2) Separation and purification of strains: Under sterile conditions, use sterile physiological saline to gradiently dilute the strains activated in (1), take 10 -5 Spread 0.1 ml of the dilution on the separation plate, and culture the plate at 29°C for 6 days; the medium composition of the plate is: sorbose 15 g / L, tryptone 3 g / L, urea 0.1 g / L, corn steep liquor 4 g / L, beef extract 1.2 g / L, yeast extract 1.2 g / L, potassium dihydrogen phos...

Embodiment 3

[0056] The production of 2-keto-L-gulonic acid by mixed fermentation of Gluconobacter oxydans TL-1045 and Bacillus megaterium comprises the following steps:

[0057] (1) Activation of strains: Wash all the large and small bacteria stored in the eggplant bottle with the activation medium, inoculate into the activation medium with a liquid volume of 20%, and incubate at 31°C for 22 hours; the composition of the activation medium is For: sorbose 15 g / L, glucose 2 g / L, yeast extract 8 g / L, corn steep liquor 3 g / L, urea 0.05 g / L, pH 7.0;

[0058] (2) Separation and purification of strains: Under sterile conditions, use sterile physiological saline to gradiently dilute the strains activated in (1), take 10 -6 Spread 0.1 ml of the diluent on the separation plate, and culture the plate at 31°C for 4 days; the medium composition of the plate is: sorbose 10 g / L, tryptone 1 g / L, urea 0.2 g / L, corn steep liquor 6 g / L, beef extract 0.6 g / L, yeast extract 0.5 g / L, potassium dihydrogen phosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com