Method for producing Chlamydosporium crassicarpa granule by solid state fermentation of silkworm excrement

A solid-state fermentation and Verticillium spore technology, applied in the biological field, can solve the problems of unstable control effect, low bacterial cell survival rate, and great influence of inoculants, and achieves the advantages of eliminating the granulation process, high survival rate and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method for producing Verticillium chlamydospora granules by solid-state fermentation of silkworm excrement of the present embodiment comprises the following steps:

[0032] a. Bacteria activation:

[0033] Prepare PDA slant medium and inoculate Pochonia chamydosporia=Verticillium chlamydosporium CGMCC 14131, cultivate at room temperature for 5 days, then wash the conidia of Trichoderma harzianum on the PDA slant medium with sterile water, and prepare a concentration of for 10 8 spores / mL of spore suspension;

[0034]Weigh 10 parts of silkworm excrement and 10 parts of water in parts by weight, mix well and balance the water for 60 minutes, stir well and put it into a 500mL Erlenmeyer flask, each bottle is filled with 250g, sealed with a breathable film, sterilized at 121°C for 120min, and cooled After reaching room temperature, inoculate 10 mL / bottle of Verticillium chlamydospore spore suspension, and culture at 26°C until the mycelium is covered with silkworm exc...

Embodiment 2

[0041] The method for producing Verticillium chlamydospora granules by solid-state fermentation of silkworm excrement of the present embodiment comprises the following steps:

[0042] a. Bacteria activation:

[0043] Prepare PDA slant medium and inoculate Pochonia chamydosporia=Verticillium chlamydosporium CGMCC 14131, cultivate at room temperature for 5 days, then wash the conidia of Trichoderma harzianum on the PDA slant medium with sterile water, and prepare a concentration of for 10 8 spores / mL of spore suspension;

[0044] Weigh 10 parts of silkworm excrement and 6 parts of water in parts by weight, mix well and balance the water for 60 minutes, stir well and put it into a 500mL Erlenmeyer flask with 250g of material in each bottle, seal it with a gas-permeable film, sterilize at 121°C for 120min, cool After reaching room temperature, inoculate 20 mL / bottle of Verticillium chlamydospore spore suspension, and culture at 26°C until the mycelium is covered with silkworm ex...

Embodiment 3-10

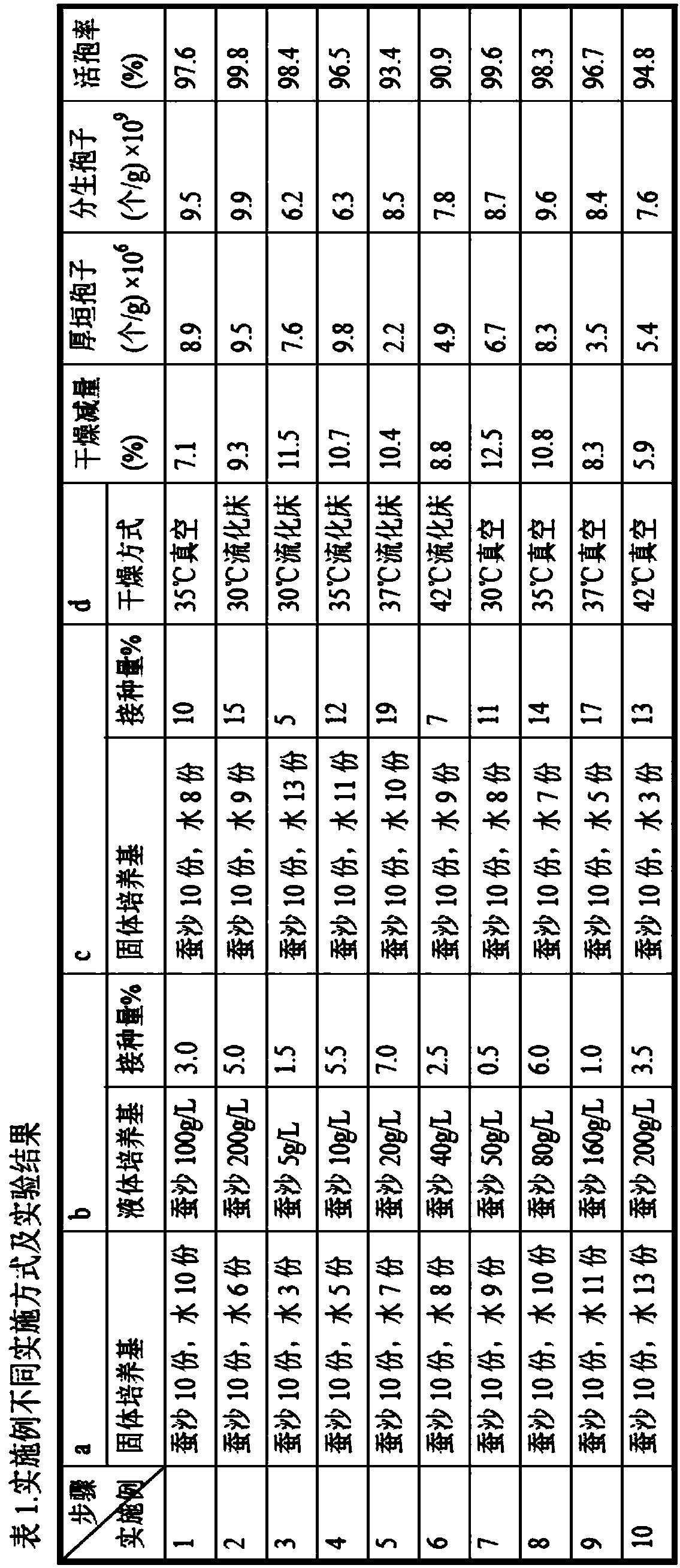

[0051] The different implementations of Examples 3-10 are shown in Table 1, and the rest of the operations are the same as in Example 1.

[0052] After implementation according to different examples, sampling is carried out according to the method of 5.3.3 "solid preparation sampling" in GB / T 1605-2001, and the drying loss is determined according to the pesticide drying loss method specified in GB / T 30361-2003. The number of chlamydospores, the number of conidia and the rate of viable spores (%) of Verticillium chlamydospore granules were determined. The detection method of Chlamydosporum is one-by-one counting method under the microscope, conidia are counted by hemocytometer plate counting method, and the viable spore rate is by the spore germination rate method on 0.5% malt extract medium. The results are shown in Table 1. After testing, the chlamydospores in the final product can reach 9.8×10 6 individual / g, conidia up to 9.9×10 9 pcs / g. From the detailed description of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com