Fermentation tank system for amino acid production and work method thereof

A working method and fermentation tank technology, applied in the field of fermentation tank systems, can solve the problems of increased workload and labor intensity of workers, large fluctuations in fermentation and bacterial infection parameters, and reduced effective production time, so as to save labor costs and reduce bacterial contamination. and production irregularities, the effect of shortening the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

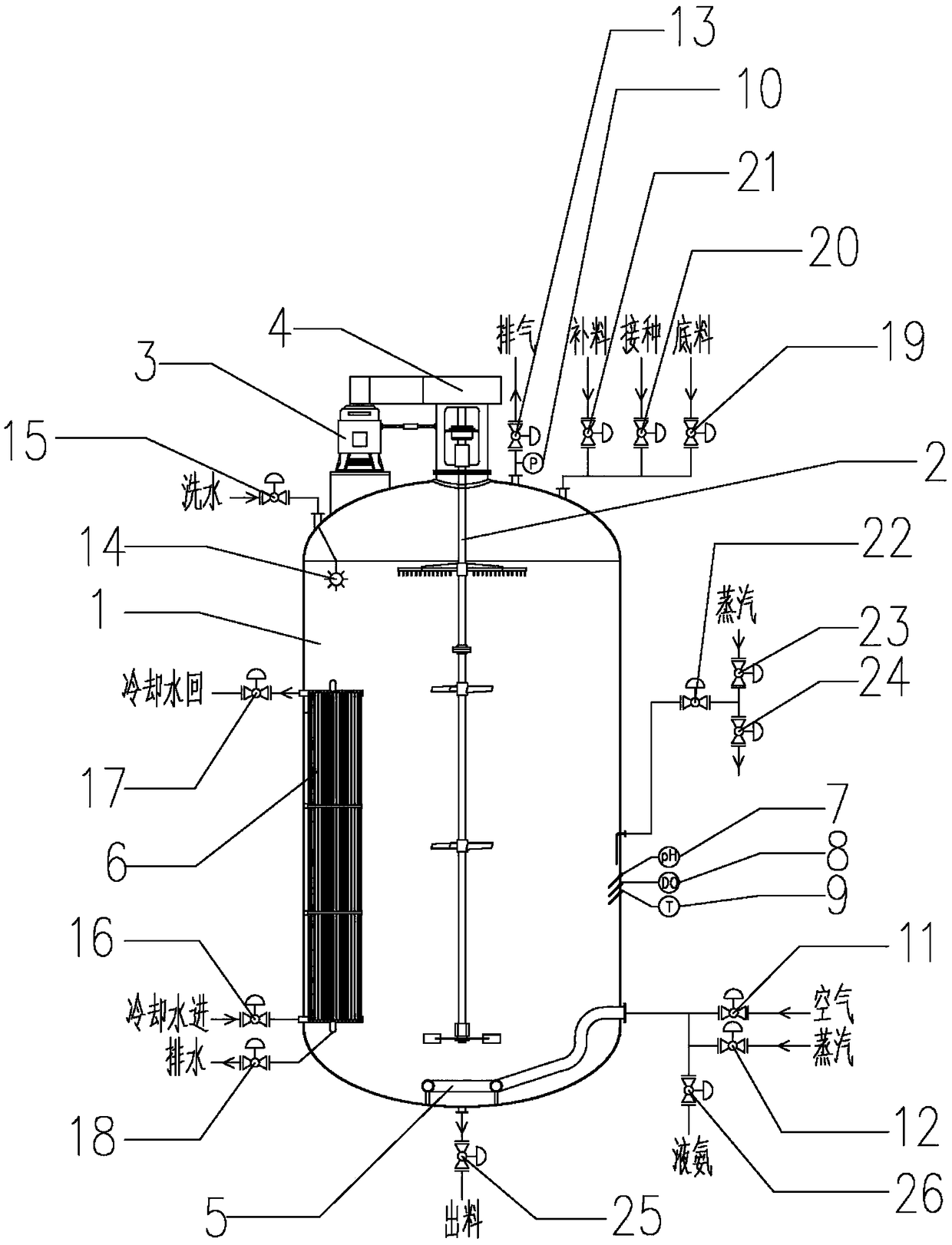

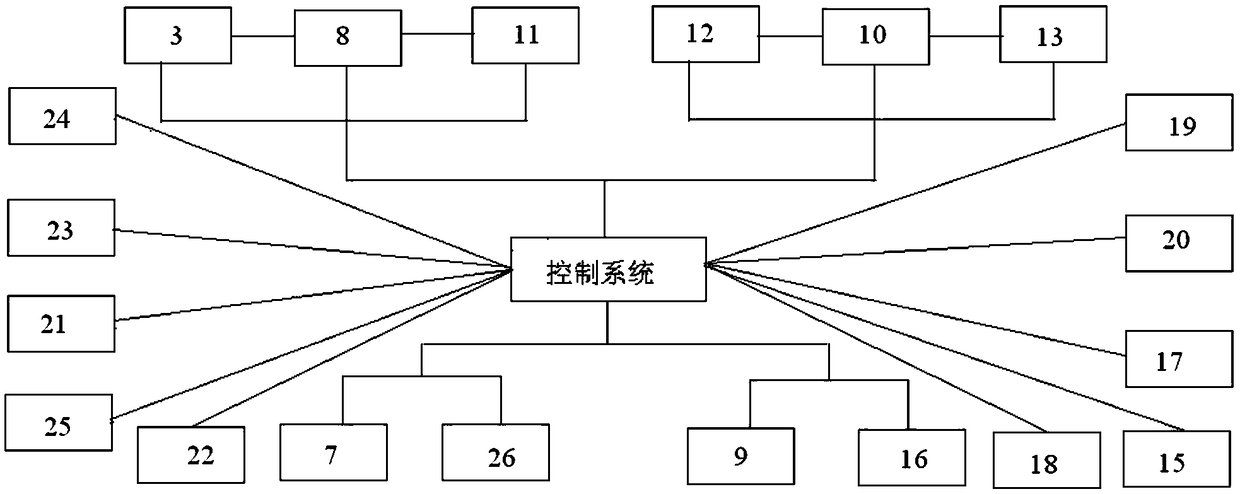

[0032] Such as Figure 1-2 As shown, a fermentation tank system for amino acid production includes a fermentation tank 1, a stirrer 2, a stirring motor 3, a reducer 4, an air distributor 5, a cooling tube 6, and an air inlet pipe Regulating valve 11, inlet steam pipe adjustment valve 12, inlet cooling water pipe adjustment valve 16, return cooling water pipe adjustment valve 17, discharge cooling water pipe adjustment valve 18, inlet bottom material pipe adjustment valve 19, inoculation pipe adjustment valve 20, supplementary Material pipeline regulating valve 21, discharge pipeline regulating valve 25, liquid ammonia pipeline regulating valve 26;

[0033] The top of the fermentation tank 1 is provided with a stirring motor 3, the stirring motor 3 is connected to the reducer 4, and the reducer 4 is connected to the stirrer 2; the bottom of the fermentation tank 1 is provided with an air distributor 5, one end of the air distributor 5 is connected to The three pipes outside the f...

Embodiment 2

[0049] Example 2 The working method of the fermentation tank system for amino acid production is as follows:

[0050] (1) Tank washing: before the empty tank is put into use, the tank washing operation needs to be carried out. The pre-set tank washing program is executed in the automatic control system. The automatic control system automatically checks the status of each automatic regulating valve and sends an instruction: close the air inlet pipe Regulating valve 11, steam inlet pipe regulating valve 12, cooling water pipe regulating valve 16, back cooling water pipe regulating valve 17, bottom feed pipe regulating valve 19, inoculation pipe regulating valve 20, feed pipe regulating valve 21, sampling steam Pipeline regulating valve 23, liquid ammonia pipeline regulating valve 26, open exhaust pipe regulating valve 13 opening degree 10%~100%, discharge cooling water pipeline regulating valve 18 opening degree 50%~100%, discharge pipeline regulating valve 25 degree opening 50%~10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com