Patents

Literature

91results about How to "Reduce bacterial contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formulations containing propofol and a sulfoalkyl ether cyclodextrin

InactiveUS7034013B2Reduce bacterial contaminationHigh photochemical stabilityBiocideHydroxy compound active ingredientsEmulsionAllergic response

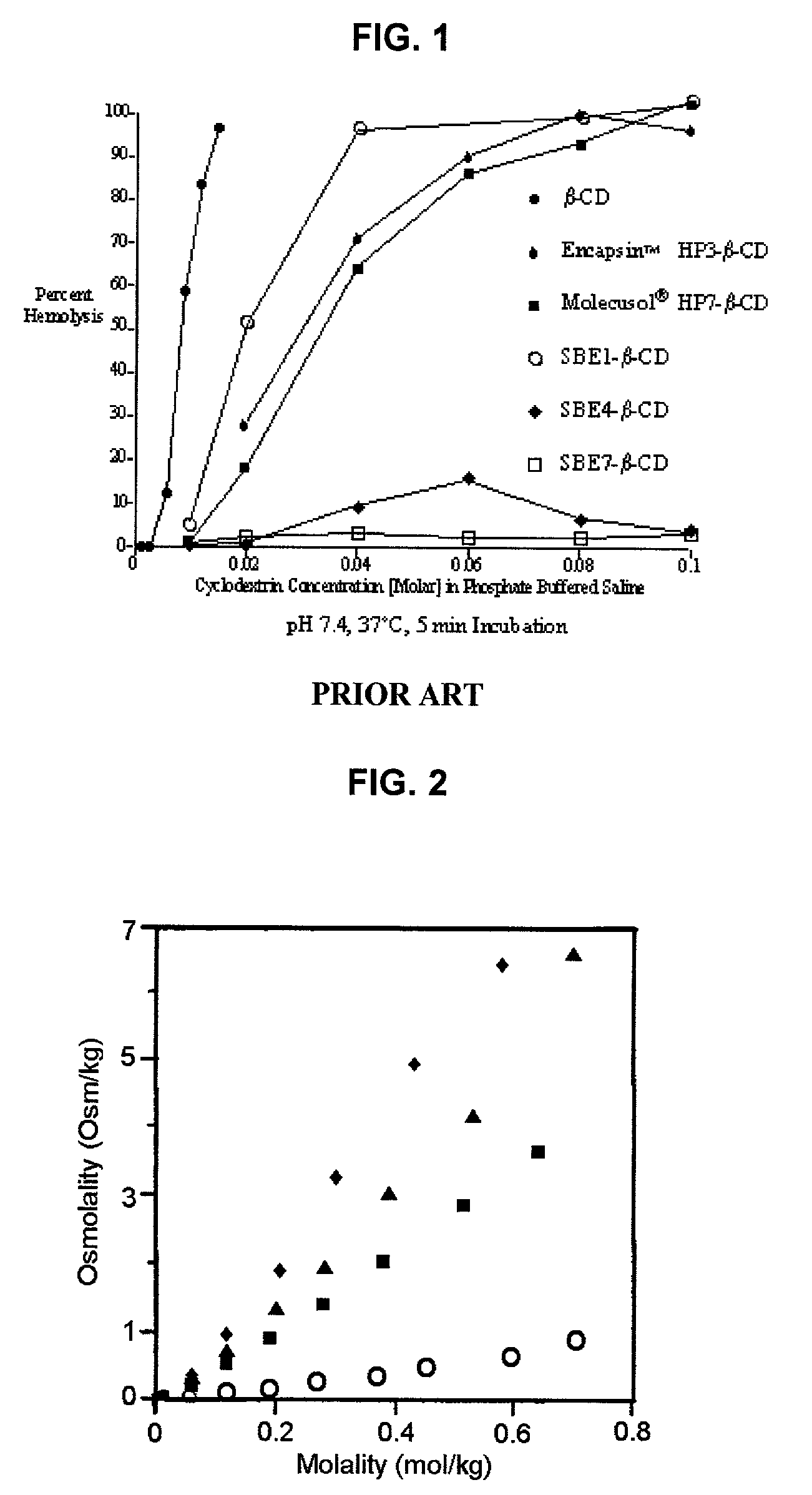

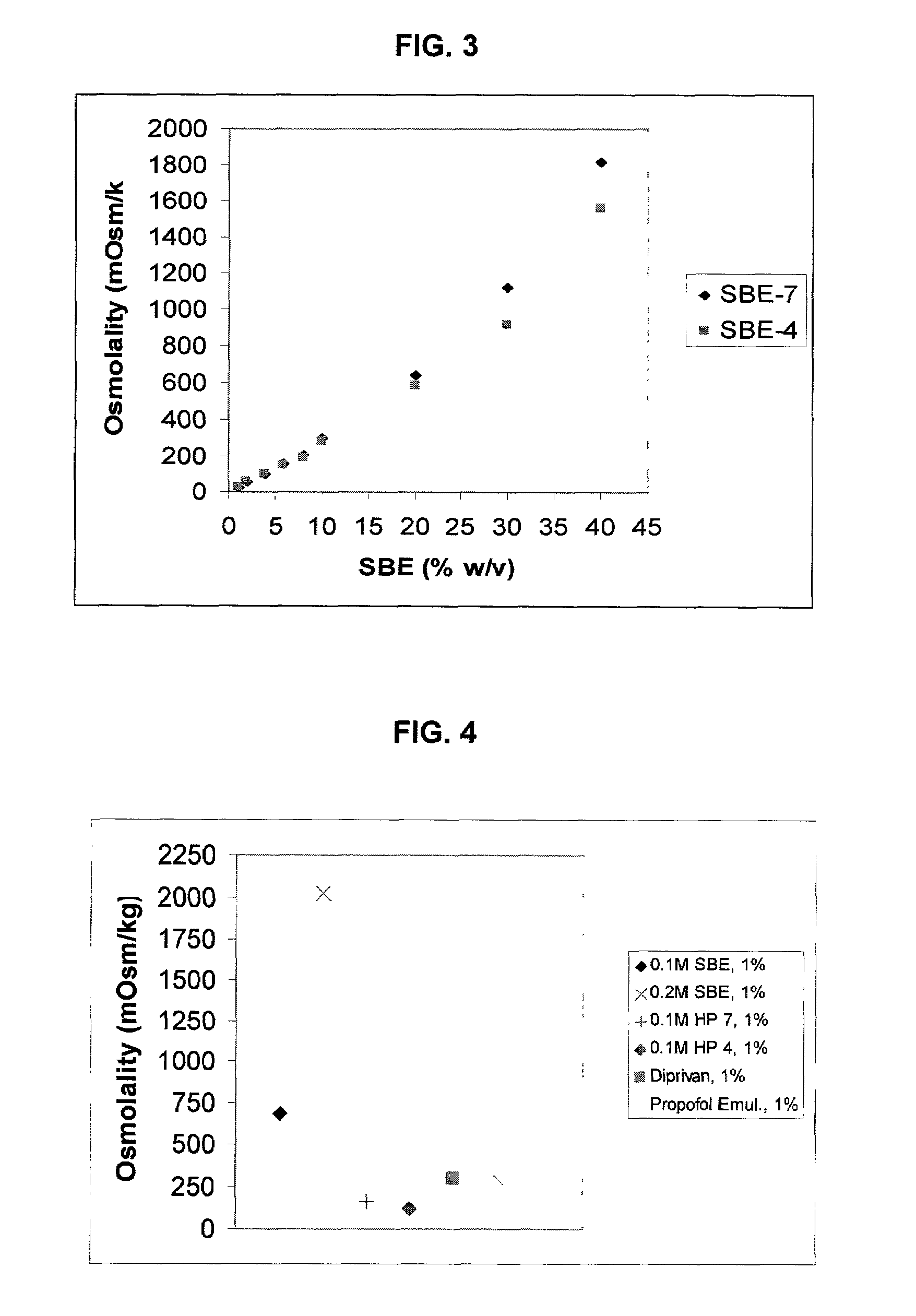

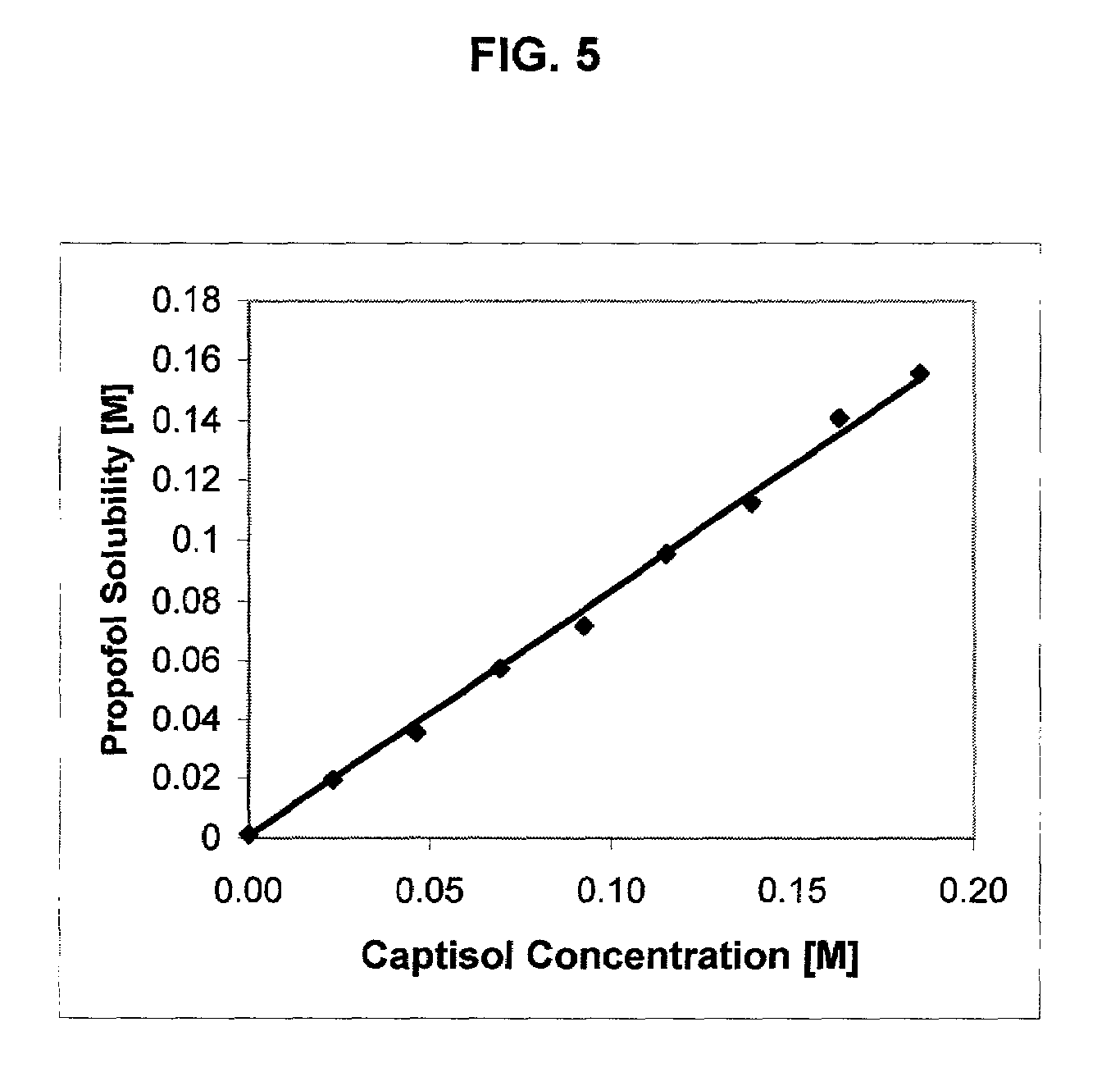

An injectable formulation of a sedative hypnotic drug, such as the anesthetic drug propofol, that is pharmaceutically stable and demonstrates a reduced incidence of pain upon injection. The formulation of the present invention employs a sulfoalkyl ether cyclodextrin solubilizing and complexing excipient, such as CAPTISOL® cyclodextrin (sulfobutyl ether β-cyclodextrin) to form a true aqueous solution and not a suspension. This formulation minimizes the allergic response and microbial contamination issues typically associated with propofol parenteral formulations. The present formulation may also reduce pain on injection as compared to the known emulsion type propofol formulations. The liquid formulation can be sterile filtered unlike emulsion-type formulations of sedative hypnotics. The liquid formulation can be lyophilized or otherwise dried to yield a solid formulation.

Owner:CUDA PHARMA LLC

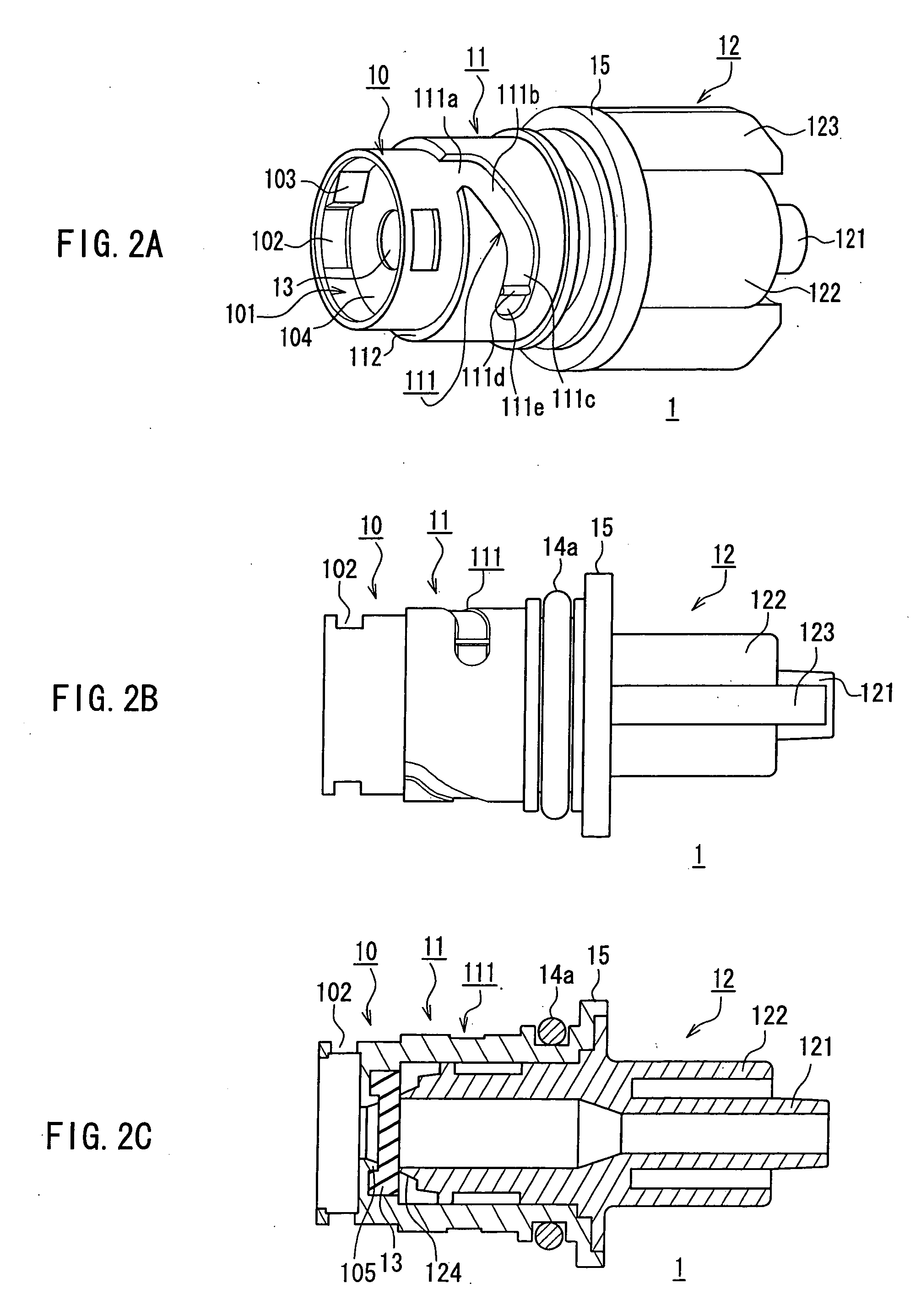

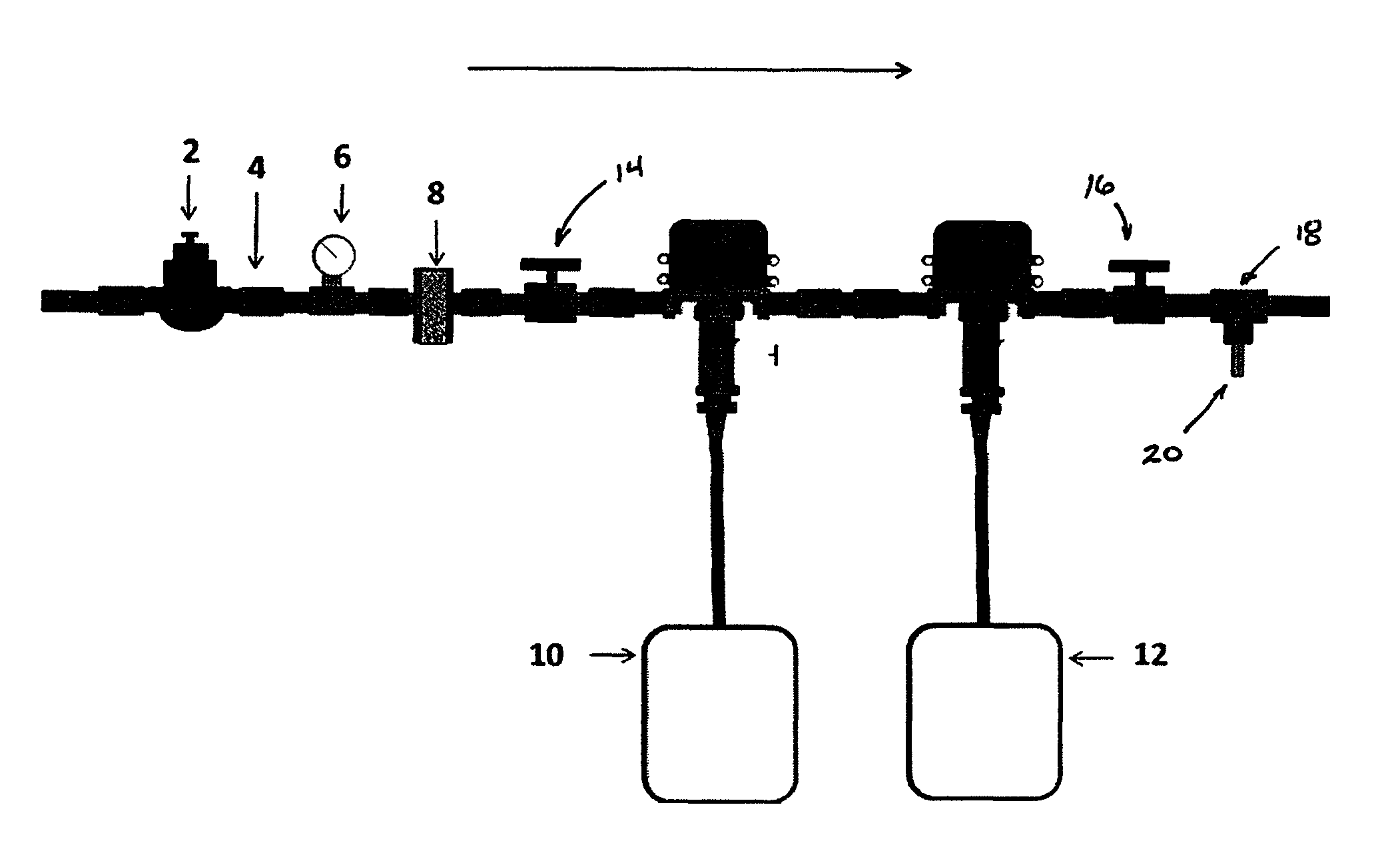

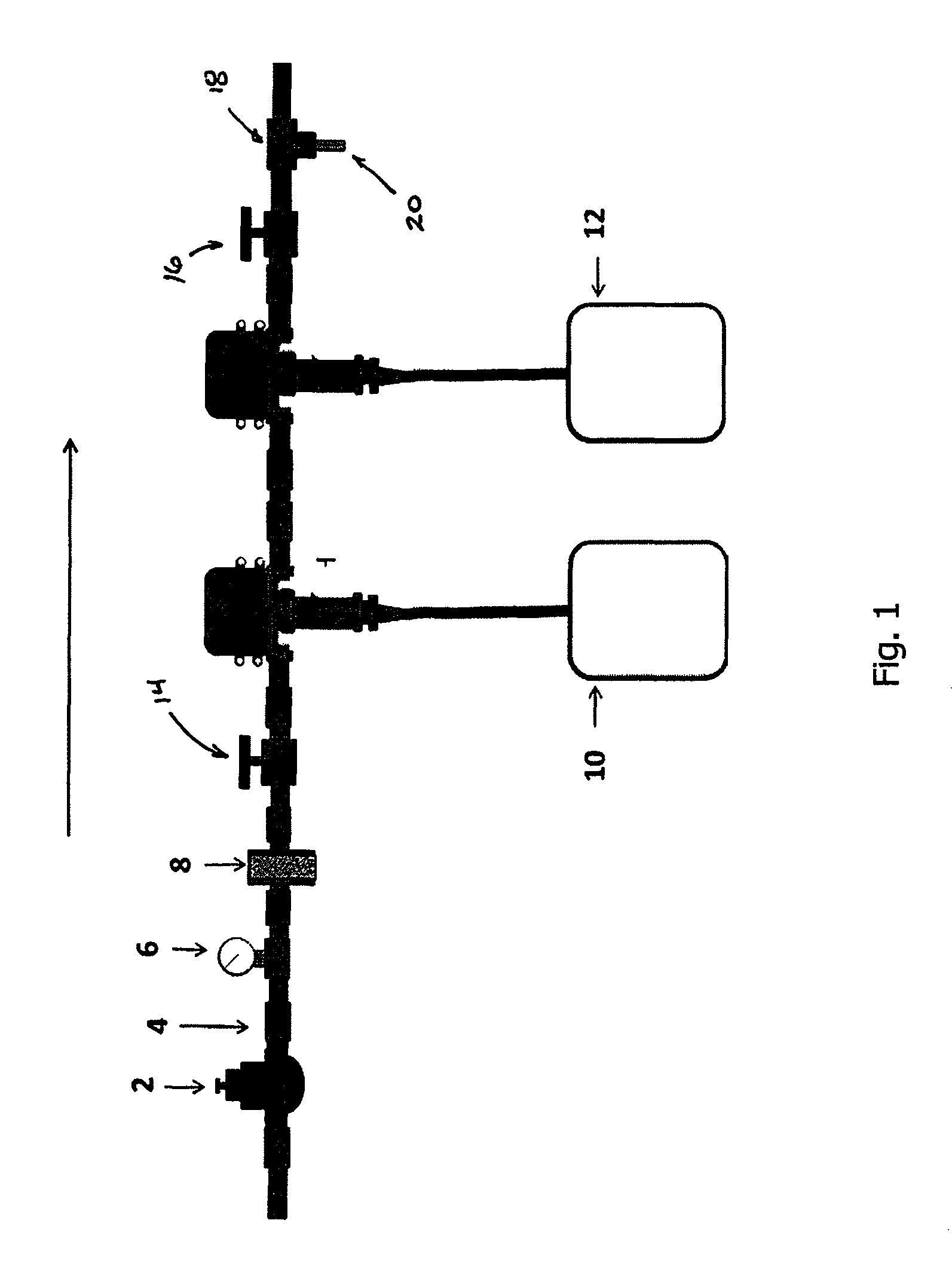

Medical connector system

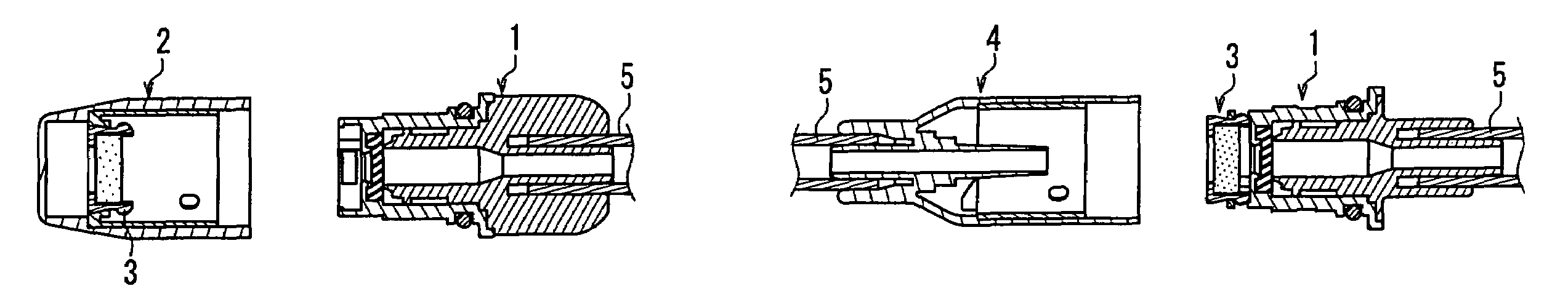

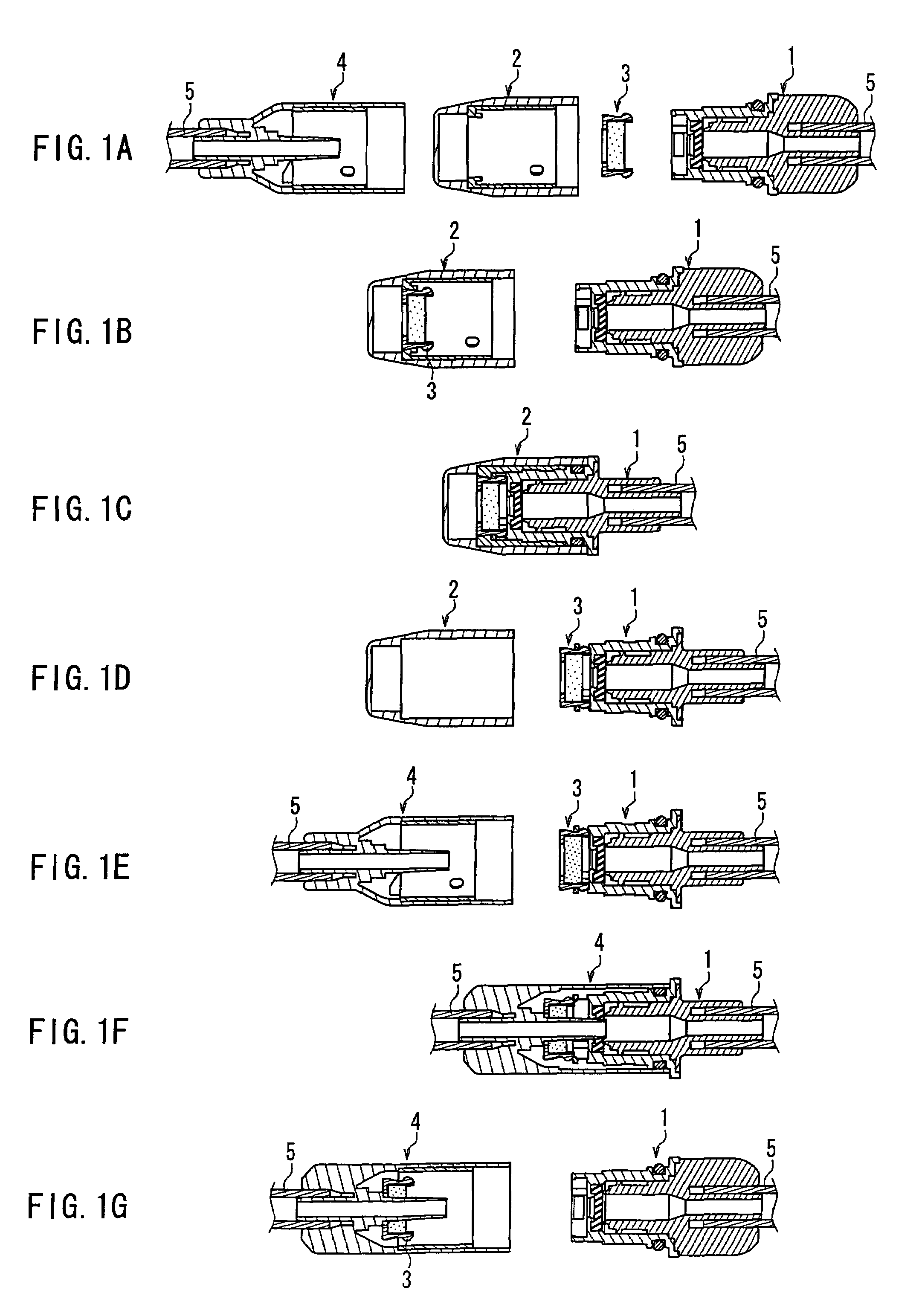

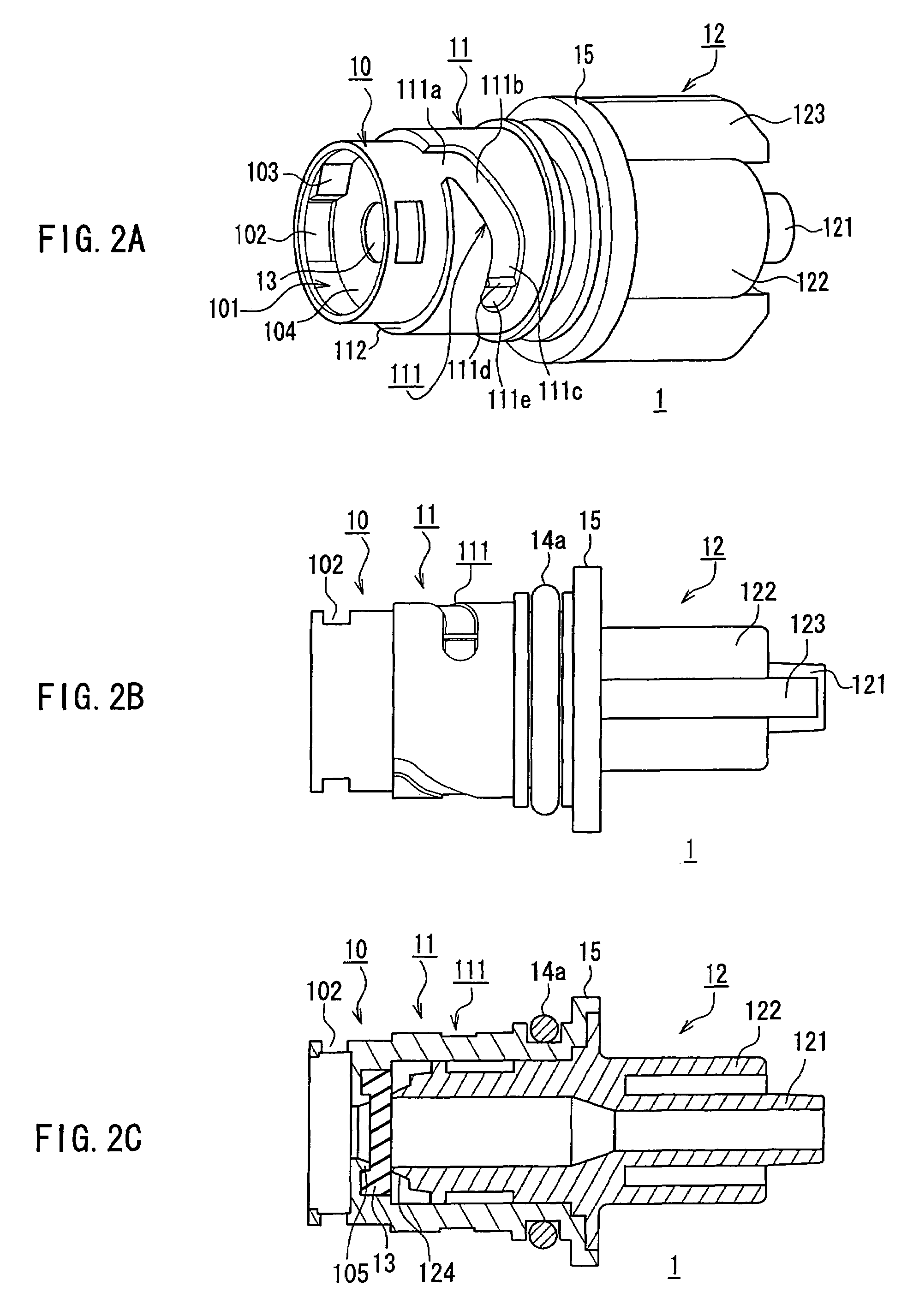

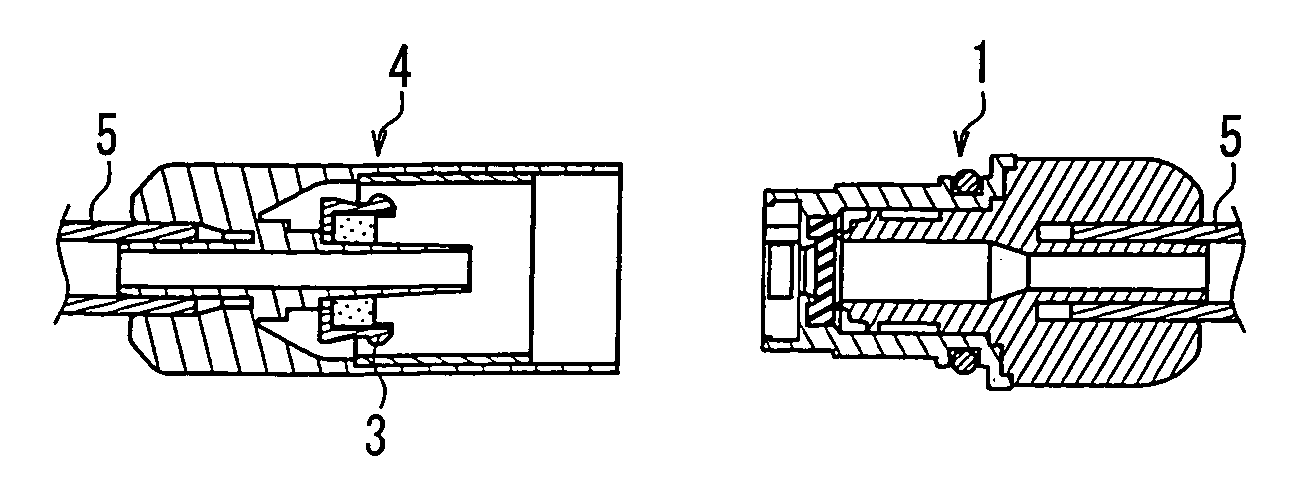

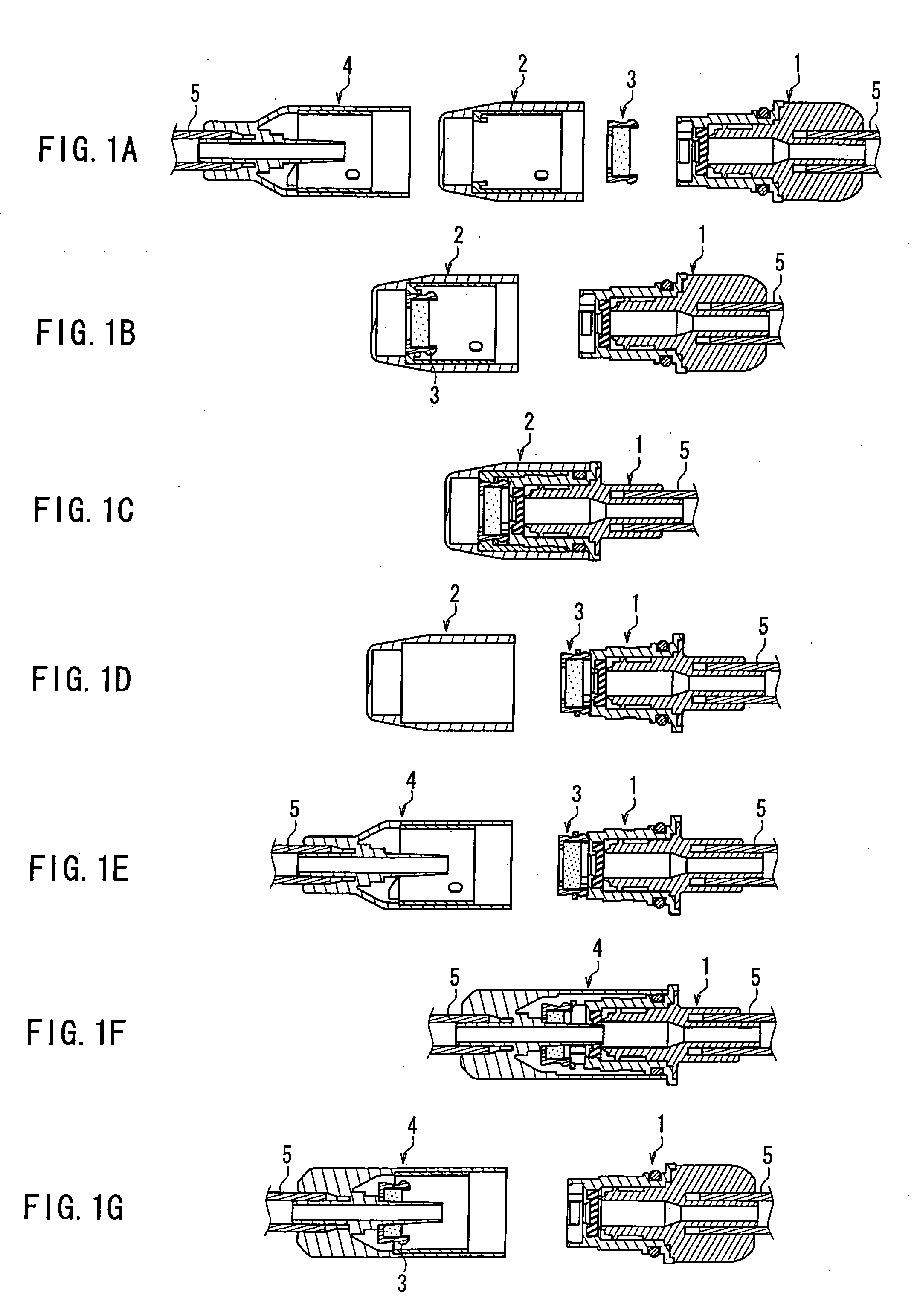

There are provided a male type connector (1), a protective cap (2), an inner cap (3) that supports a disinfectant-impregnated member therein and is retained in the protective cap, and a female type connector (4) in which an inner cylinder is fixed at an end of an outer cylinder, the inner cylinder including an internal end portion located inside the outer cylinder and an exposed external end portion. The inner cap includes engaging legs at each of which an engaging convexity is formed. A front end portion of the male type connector allows the engaging convexities at the engaging legs to engage therewith from inside. An inner cap retaining portion is formed on an inner wall surface of the protective cap, and a force exerted by the engagement between the inner cap and the male type connector is larger than a force exerted by the inner cap retaining portion to retain the inner cap. When the protective cap with the inner cap retained therein is fitted with the male type connector, and then is removed from the male type connector, the inner cap is retained in the male type connector and is detached from the protective cap. When the male type connector is connected with the female type connector, the internal end portion of the inner cylinder penetrates through the disinfectant-impregnated member, so that a channel is opened. When the connecting and detaching are repeated, the bacterial contamination can be reduced with a simple operation.

Owner:JMS CO LTD

Connector system for medical use

There are provided a male type connector (1), a protective cap (2), an inner cap (3) that supports a disinfectant-impregnated member therein and is retained in the protective cap, and a female type connector (4) in which an inner cylinder is fixed at an end of an outer cylinder, the inner cylinder including an internal end portion located inside the outer cylinder and an exposed external end portion. The inner cap includes engaging legs at each of which an engaging convexity is formed. A front end portion of the male type connector allows the engaging convexities at the engaging legs to engage therewith from inside. An inner cap retaining portion is formed on an inner wall surface of the protective cap, and a force exerted by the engagement between the inner cap and the male type connector is larger than a force exerted by the inner cap retaining portion to retain the inner cap. When the protective cap with the inner cap retained therein is fitted with the male type connector, and then is removed from the male type connector, the inner cap is retained in the male type connector and is detached from the protective cap. When the male type connector is connected with the female type connector, the internal end portion of the inner cylinder penetrates through the disinfectant-impregnated member, so that a channel is opened. When the connecting and detaching are repeated, the bacterial contamination can be reduced with a simple operation.

Owner:JMS CO LTD

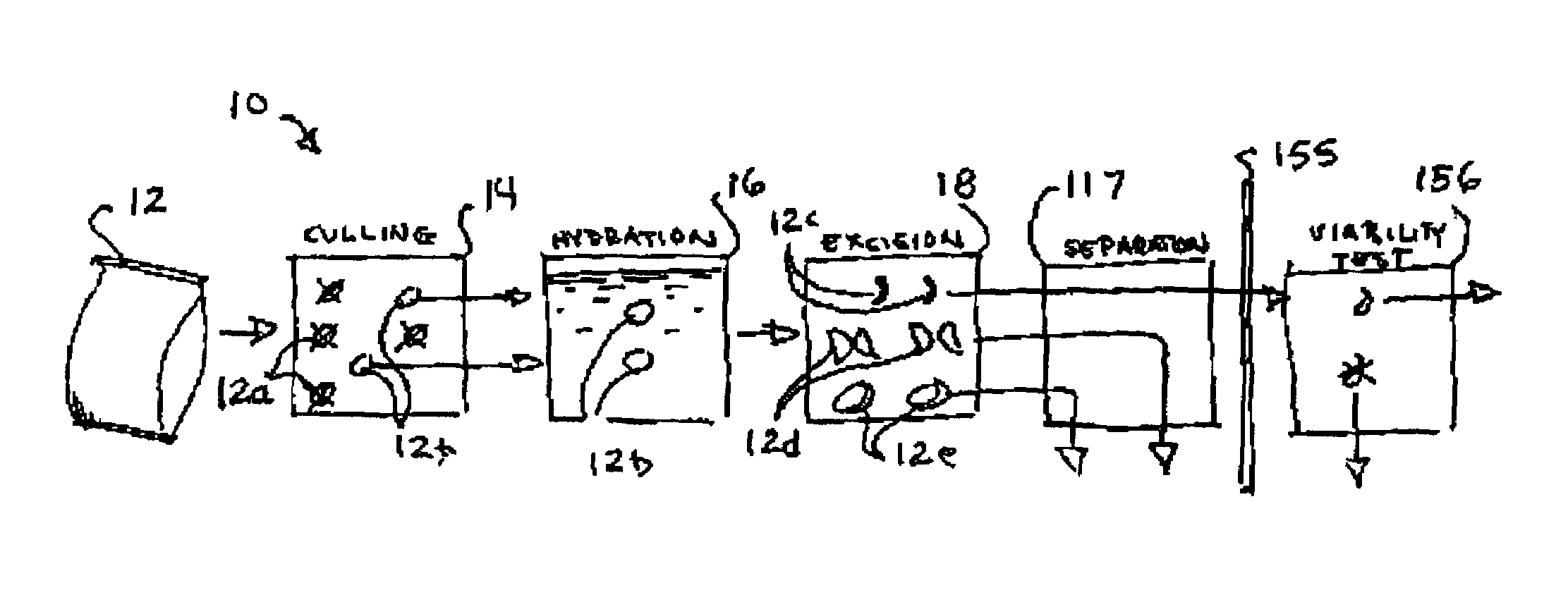

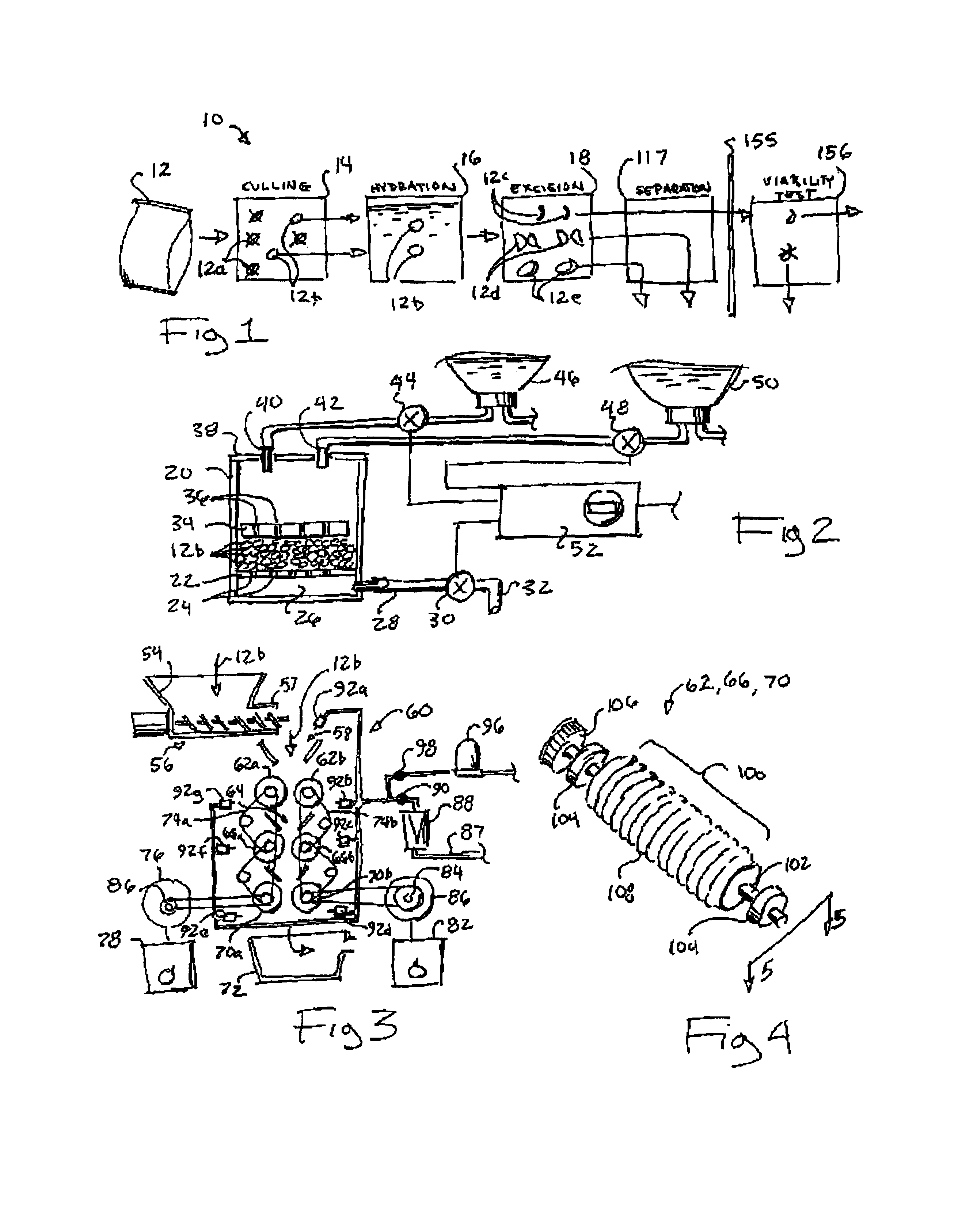

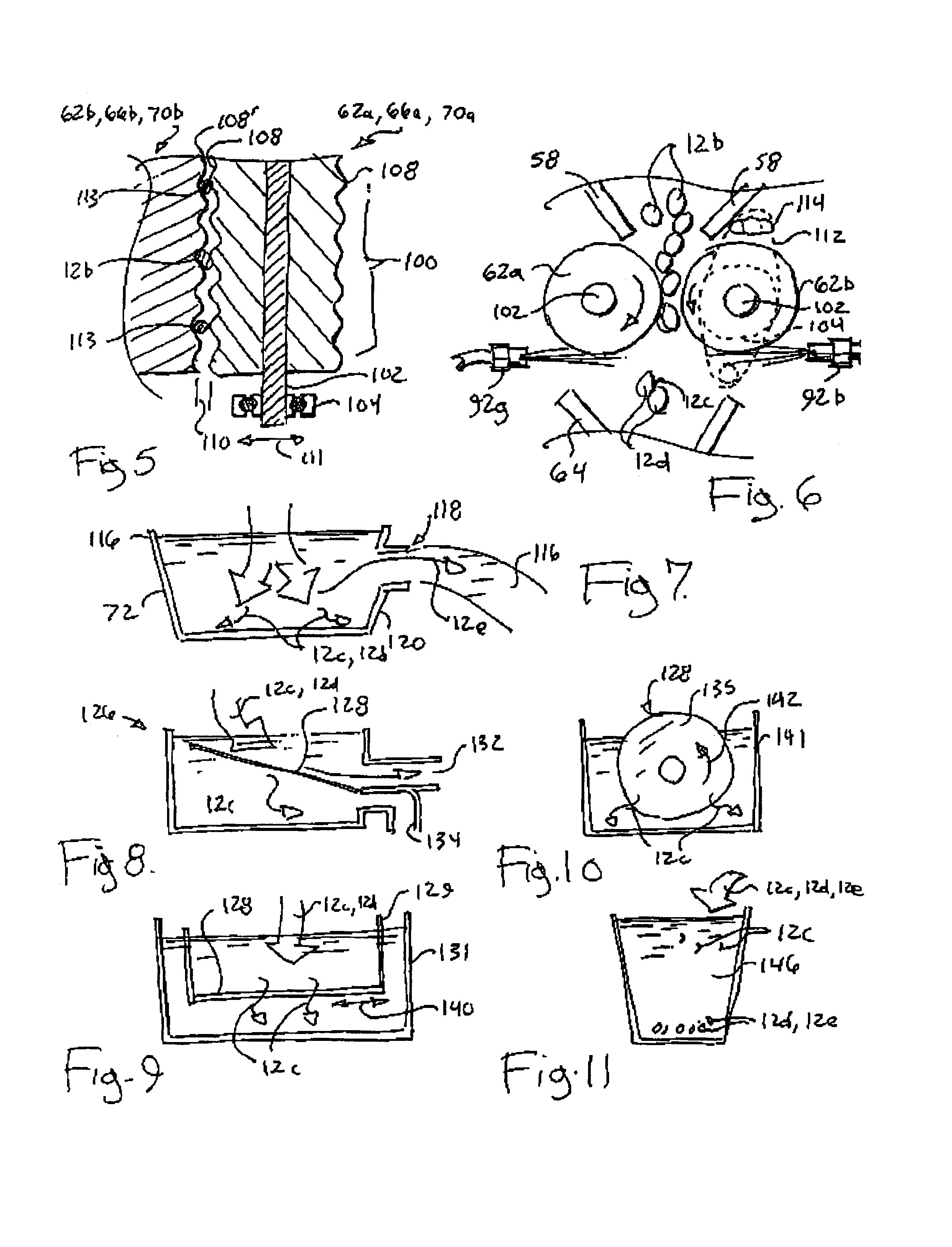

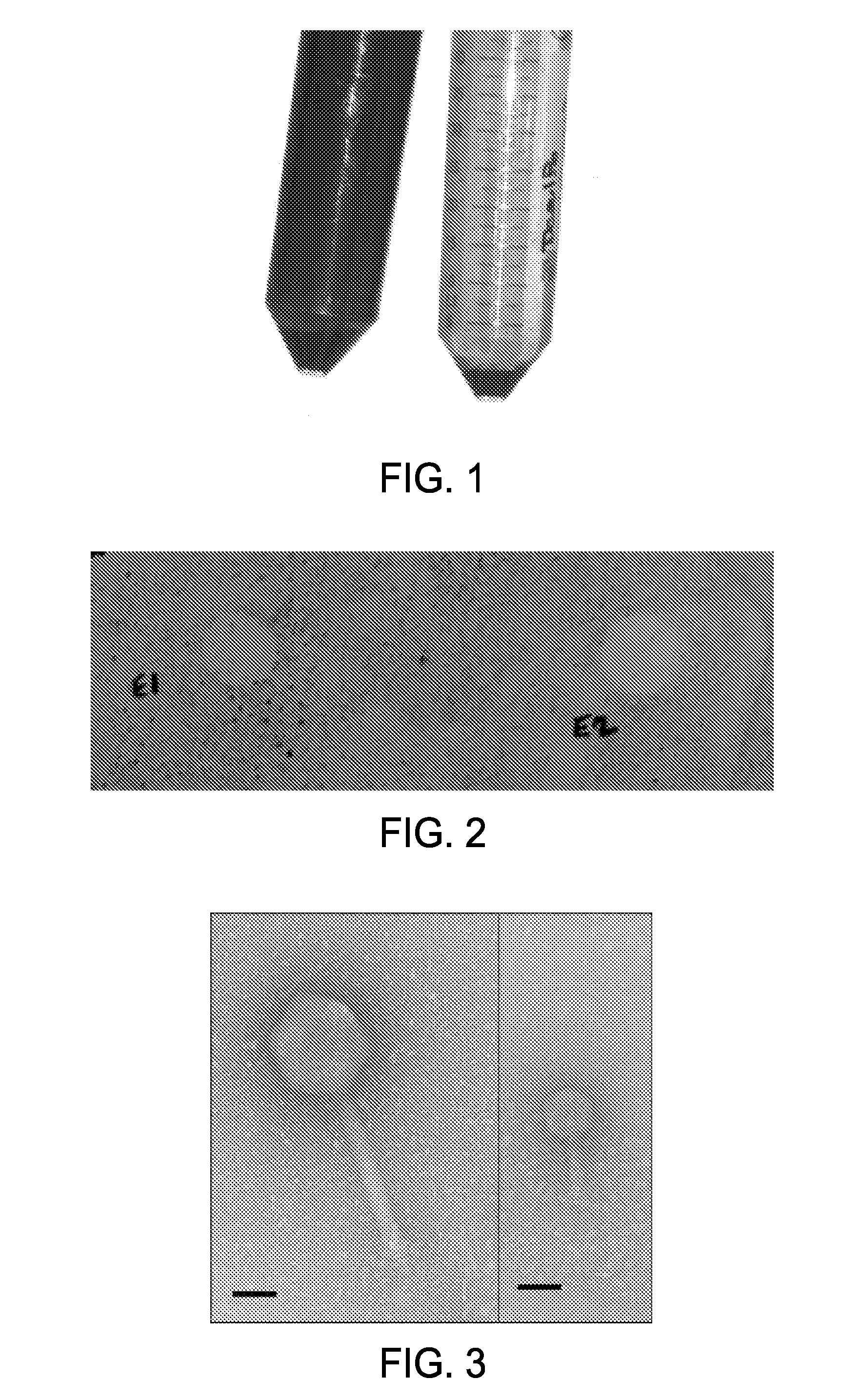

Method and apparatus for preparation of genetically transformable plant tissue

A process of mechanical separation of embryos from seeds for genetic transplantation employs counter-rotating cylinders together with one or more culling, hydration, separation, and viability testing steps to provide high-throughput of viable, transplantable tissue.

Owner:MONSANTO TECH LLC

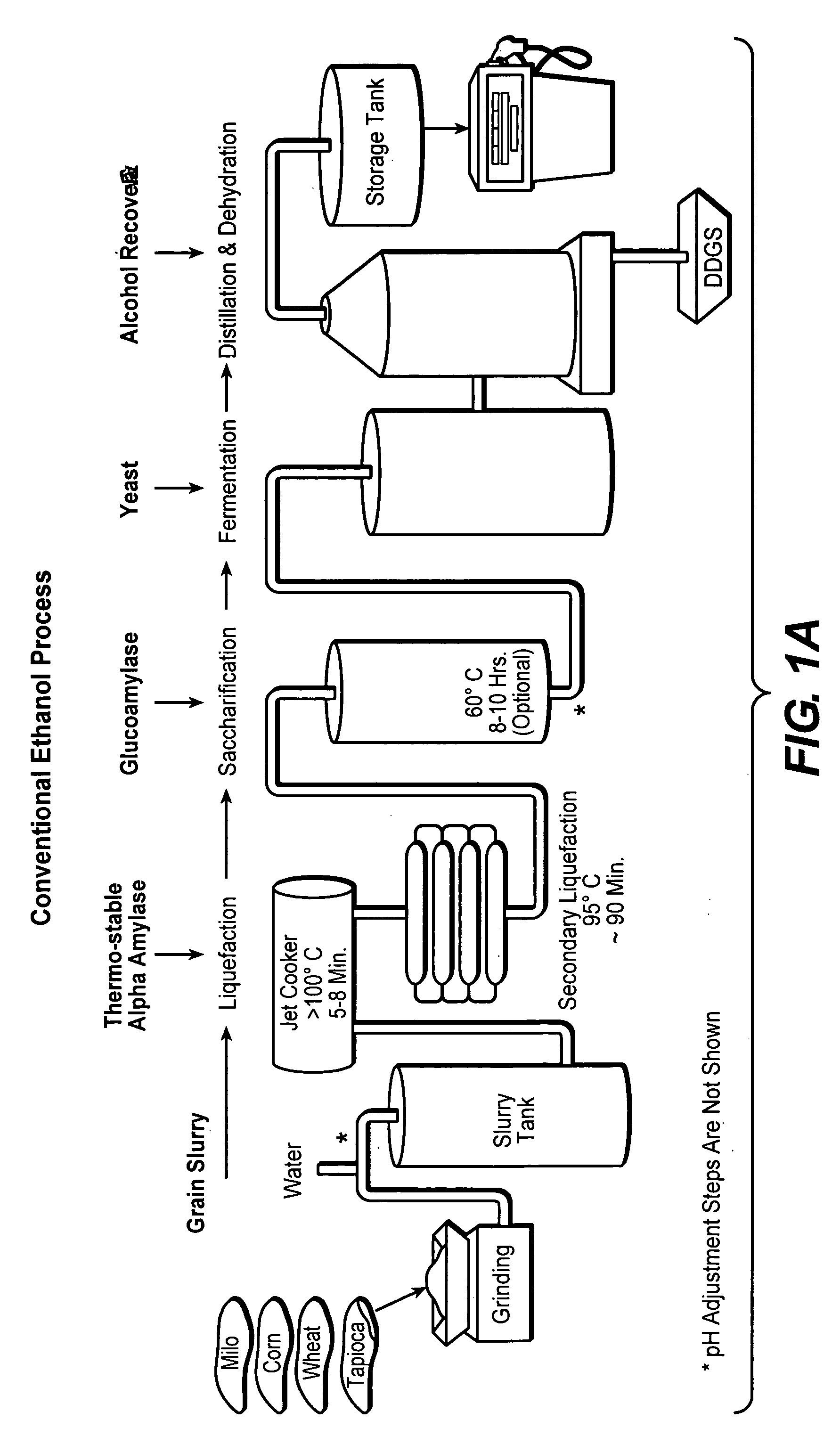

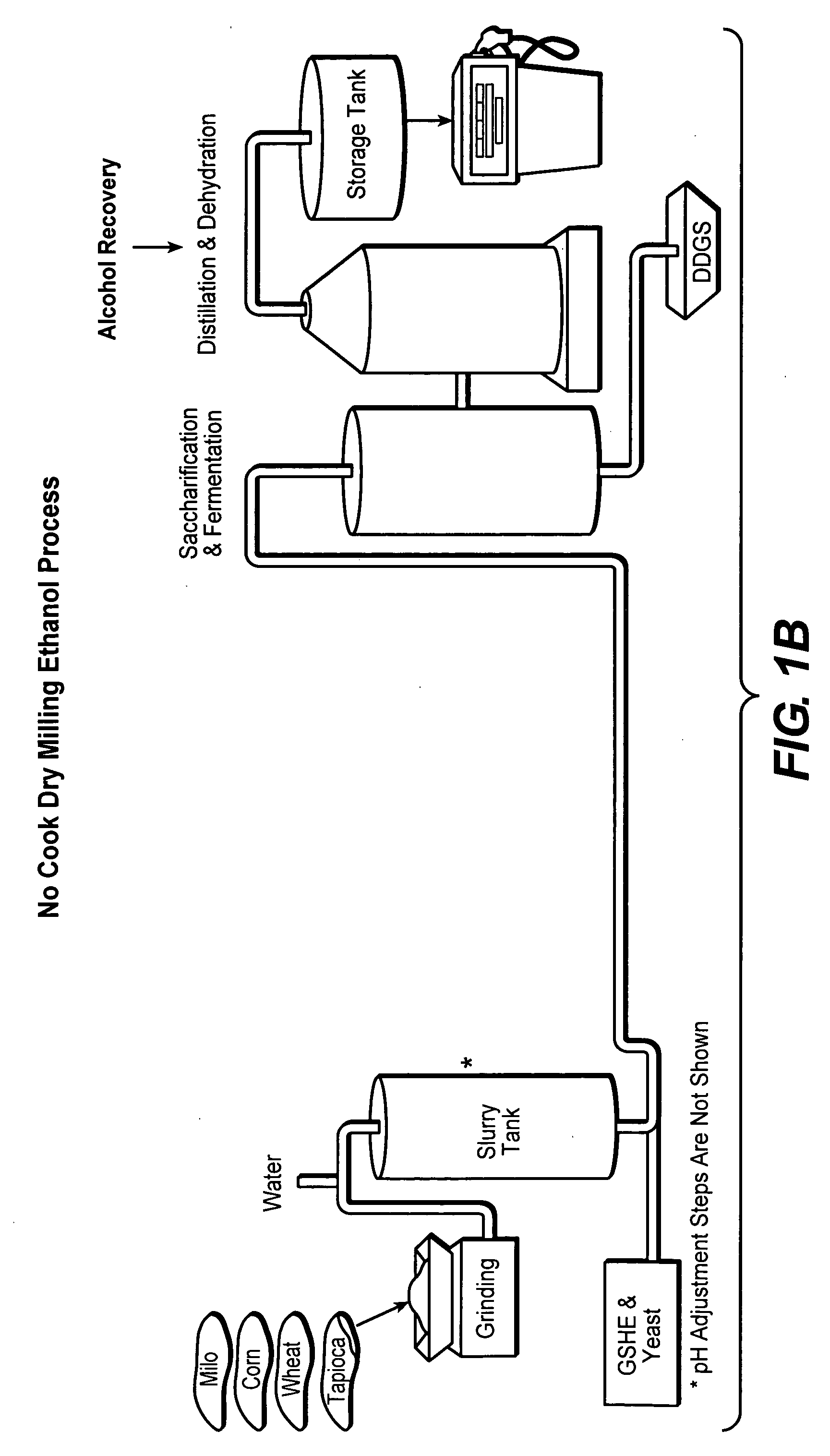

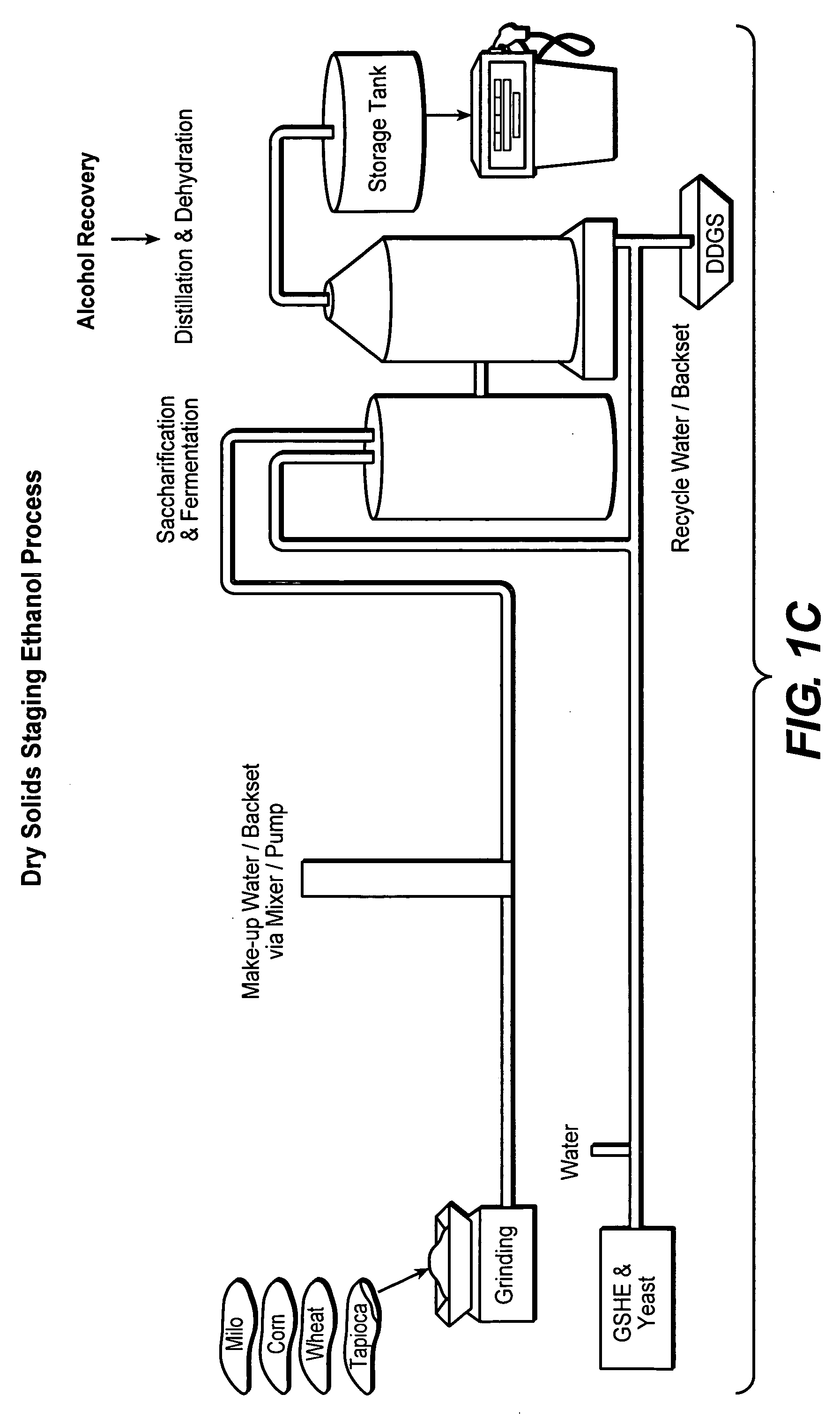

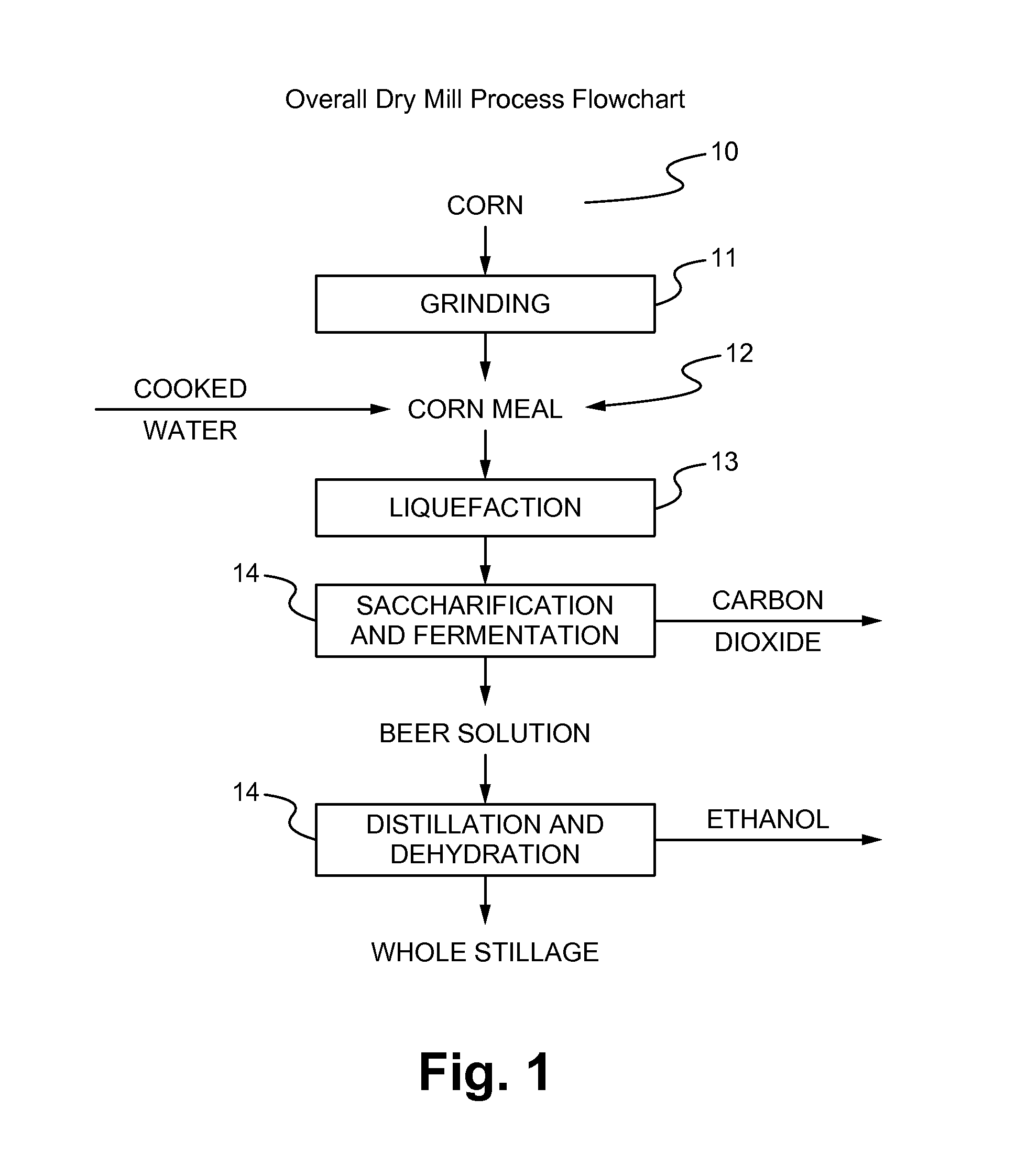

Dry solids staging fermentation process

InactiveUS20060281157A1Reduce bacterial contaminationBiofuelsFermentationBiological bodyFermentation broth

A dry solids staging fermentation process for producing an end-product, such as ethanol is disclosed said process including an initial fermentation step including combining a first fermentable substrate with one or more starch hydrolyzing enzymes and fermenting organisms in a fermentation vessel and a loading step which includes adding a second fermentable substrate to the fermentation vessel wherein the percent dry solids (% DS) of the fermentation broth increases over time.

Owner:GENENCOR INT INC

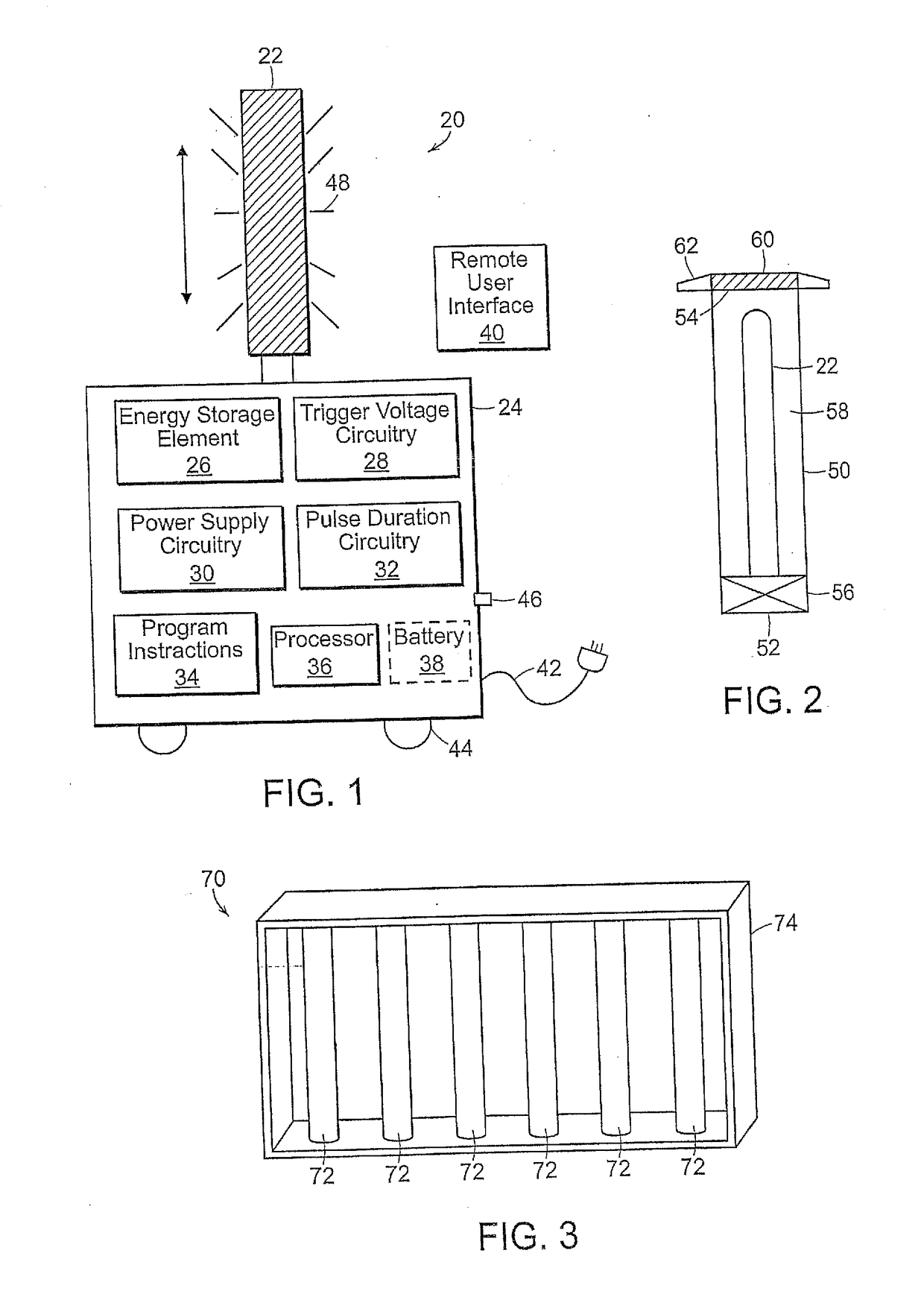

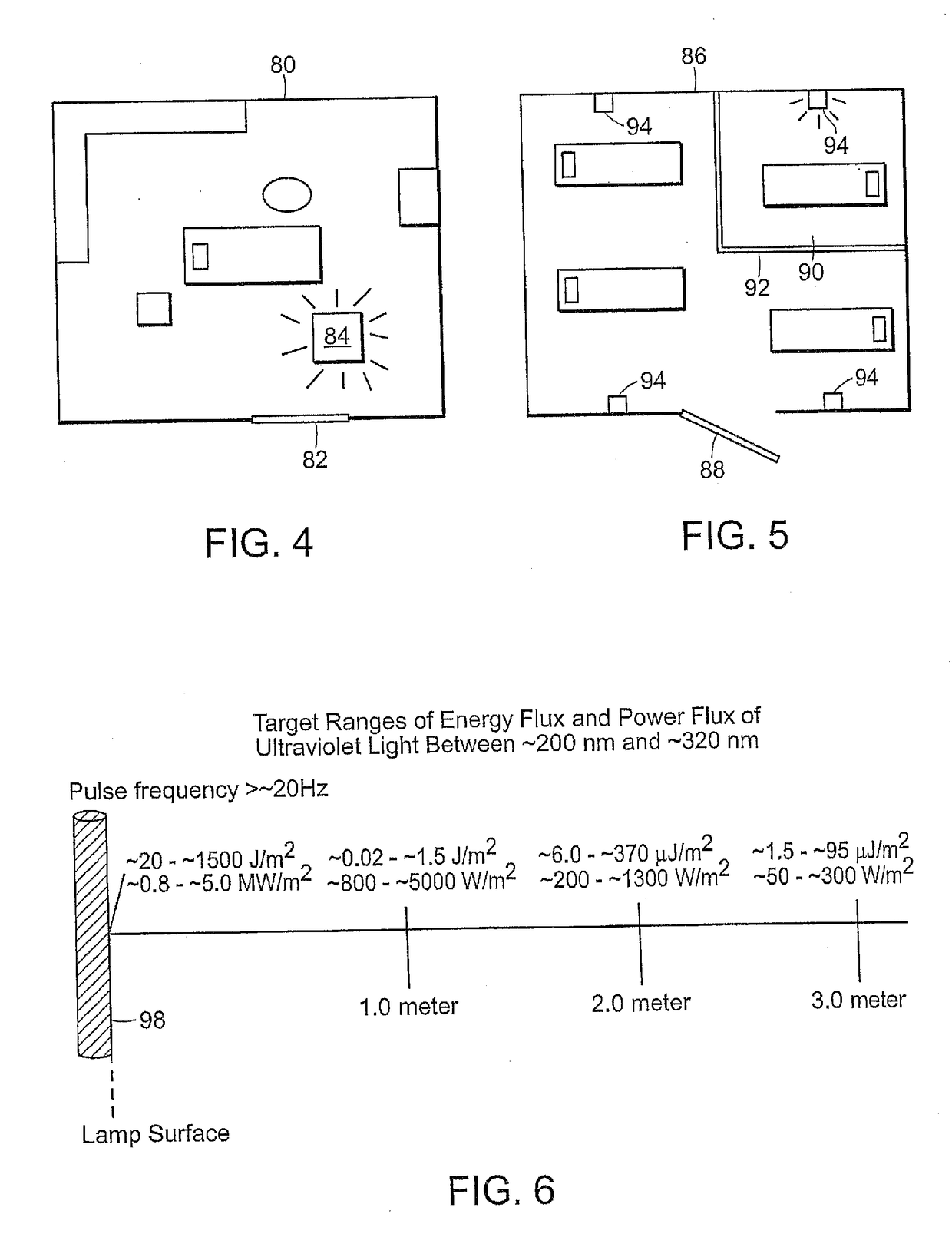

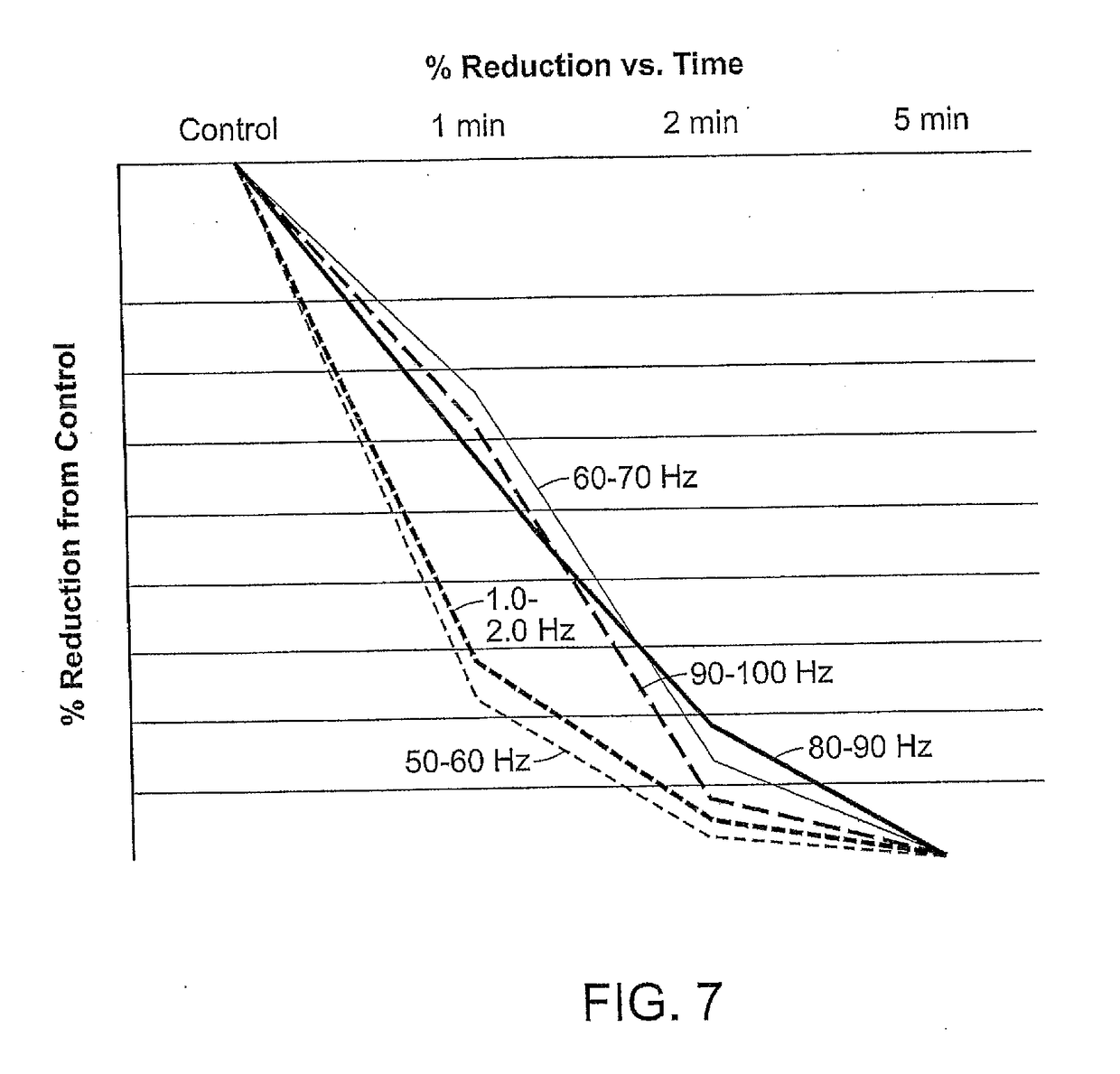

Room And Area Disinfection Utilizing Pulsed Light With Modulated Power Flux And Light Systems With Visible Light Compensation Between Pulses

ActiveUS20170173195A1Reduce bacterial contaminationFood preservationLavatory sanitoryUltraviolet lightsEnergy flux

Disinfection methods and apparatuses are provided which generate pulses of germicidal light at a frequency greater than 20 Hz and project the pulses of light to surfaces at least 1.0 meter from the disinfection apparatus. The pulses of light comprise a pulse duration and an energy flux sufficient to generate a power flux between approximately 200 W / m2 and approximately 5000 W / m2 of ultraviolet light in the wavelength range between 200 nm and 320 nm at the surfaces. Other disinfection methods and apparatuses are provided which generate pulses of light comprising germicidal light and visible light from a germicidal light source and generate pulses of light from a visible light source that is distinct from the germicidal light source. The projections of visible light from the light sources produce a continuous stream of visible light or a collective stream of visible light pulsed at a frequency greater than 60 Hz.

Owner:XENEX DISINFECTION SERVICES

Plant extract and microbe composite deodorant

ActiveCN105536509AReduce generationGrowth inhibitionGas treatmentDispersed particle separationMicroorganismDeodorant

The invention relates to the field of deodorization, and especially relates to a plant extract and microbe composite deodorant. According to the invention, a plant extract and a microbial fermentation broth are mixed according to a ratio of 1:3; the mixture is placed in plastic buckets; and sealed anaerobic fermentation is carried out for 5-9 days, such that the composite deodorant is obtained. The microbial fermentation broth is obtained through the following steps: saccharomycetes, lactobacillus, bacillus subtilis, acetobacter pasteurianus and photosynthetic bacteria are inoculated according to the ratio of 1-4:2-6:5-25:1-4:1-2, and mixed fermentation is carried out; and after 60-84h of aerobic fermentation, the microbial fermentation broth is obtained. The invention aims at providing the plant extract and microbe composite deodorant. Deodorizing is realized with the combination of the plant extract and microbes. With the deodorant, fast and continuous deodorization can be realized; production cost is reduced; and a deodorization effect is good. With the deodorant, deodorization can be achieved fundamentally.

Owner:HUNAN PUTAIER ENVIRONMENTAL CO LTD

Microbiological control in animal processing

InactiveUS6919364B2Reduce Microbial ContaminationProduced economicallyOrganic active ingredientsBiocideWater chlorinationZoology

Fecal bacterial contamination in an animal is reduced by providing it with drinking water containing a microbiocidally-effective amount of halogen-based microbiocide resulting from mixing with water (A) a product formed in water from (i) bromine, chlorine, or bromine chloride, or any two or more thereof, (ii) a water-soluble source of sulfamate anion, and (iii) a water-soluble base; (B) at least one 1,3-dihalo-5,5-dialkylhydantoin in which one of the halogen atoms is a chlorine atom and the other is a chlorine or bromine atom, and in which each alkyl group, independently, contains in the range of 1 to about 4 carbon atoms; (C) at least one 1,3-dibromo-5,5-dialkylhydantoin in which one of the alkyl groups is a methyl group and the other alkyl group contains in the range of 1 to about 4 carbon atoms; or (D) any two or more of (A), (B), and (C).

Owner:ALBEMARLE CORP

Compositions and methods for the treatment, mitigation and remediation of biocorrosion

InactiveUS20090180992A1Reducing biocorrosionReducing biofilm blockageBiocideMicrobiological testing/measurementBiofilmOrganism

A method of reducing biocorrosion or biofilm blockage in by identifying a target suspected of comprising one or more biocorrosive organisms and delivering to the target suspected of comprising the biocorrosive organisms an effective amount of a composition comprising an infective virulent viral panel sufficient to reduce the amount of biocorrosive organisms at the target.

Owner:TEXAS A&M UNIVERSITY

Method for producing glutamic acid through double-feeding fermentation optimization of corn steep liquor and glucose

ActiveCN103243132AFast growthImprove adaptabilityMicroorganism based processesFermentationBiotechnologyDouble-time

The invention discloses a method for producing glutamic acid through double-feeding fermentation optimization of corn steep liquor and glucose, which comprises the following steps of: in fermentation culture of glutamic acid, initially adding 1-10g / L of glucose to a fermentation culture medium, and initially adding 1-10g / L of corn steep liquor; after the fermentation culture starts, starting feeding the corn steep liquor and glucose at the same time, wherein 5-19g / L of corn steep liquor is fed and completely added within 5-10 hours since the fermentation starts, and the total amount of the corn steep liquor is 15-20g / L; feeding the concentrated solution of glucose until the fermentation is over; maintaining the amount of residual sugar in the fermentation culture medium at 0.05-10g / L; and controlling the pH value of the liquid ammonia in the whole process of fermentation to 6.8-7.3. The method disclosed by the invention effectively increases the growth speed of thalli and shortens the adaptation period in the initial stage of thallus fermentation and the thallus doubling time, thus shortening the overall fermentation time and reducing the overall production cost of glutamic acid.

Owner:山东祥维斯生物科技股份有限公司

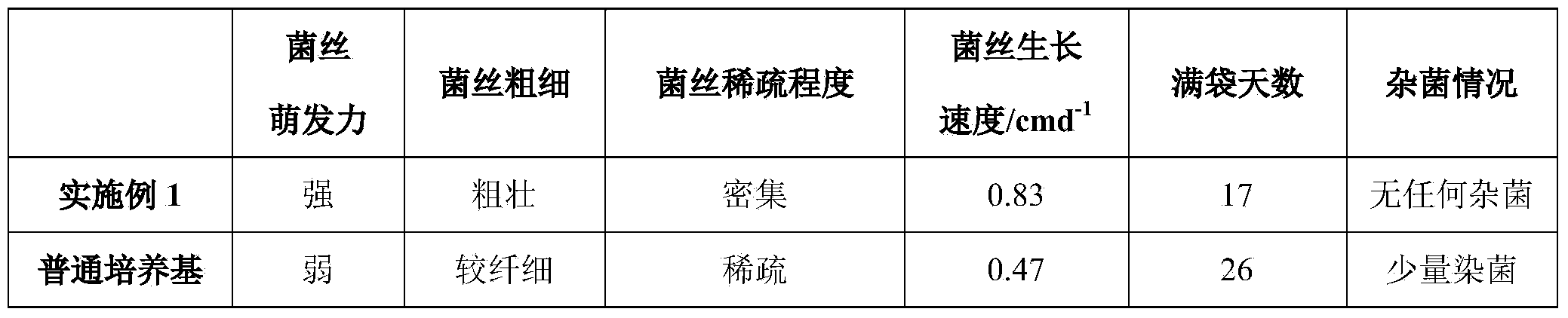

Method for manufacturing edible mushroom solid liquefied strains

The invention relates to the field of mushroom cultivation technologies, in particular to a method for manufacturing edible mushroom solid liquefied strains. The method comprises the steps that first-level liquid strains are inoculated into a culture flask, and liquid spawn is obtained; a solid cultivation material is prepared, the liquid spawn is cultured in strain bottles, the cultivation temperature ranges from 22 DEG C to 25 DEG C, cultivation is conducted in a dark place, the cultivation humidity ranges from 50% to 60%, and the strains can grow full of the strain bottles after being cultured by 20-30 days; the strain bottles filled with the strains and having no infectious microbe are selected, and the strains are crushed in a pulverizer and inoculated into sterile water for direct production and inoculation. The method for manufacturing the edible mushroom solid liquefied strains has the advantages that the strain running speed is high and is 1 / 3 higher than that of solid strain running, 3-4 times of expansion inoculation are not needed, the strain contamination problem caused in the expansion inoculation process is solved, and time needed by expanding propagation is saved; growing points are more than the growing points of common liquid strains, strain running is uniform, the strain ages are consistent, produced mushrooms are orderly and good in quality, and fruit body yield can be improved by 20%-30%; sterile water is adopted for liquefying mycelia, molds and other infectious microbes can not grow, and contamination can be reduced by 5%-10%.

Owner:青岛联合菌业科技发展有限公司

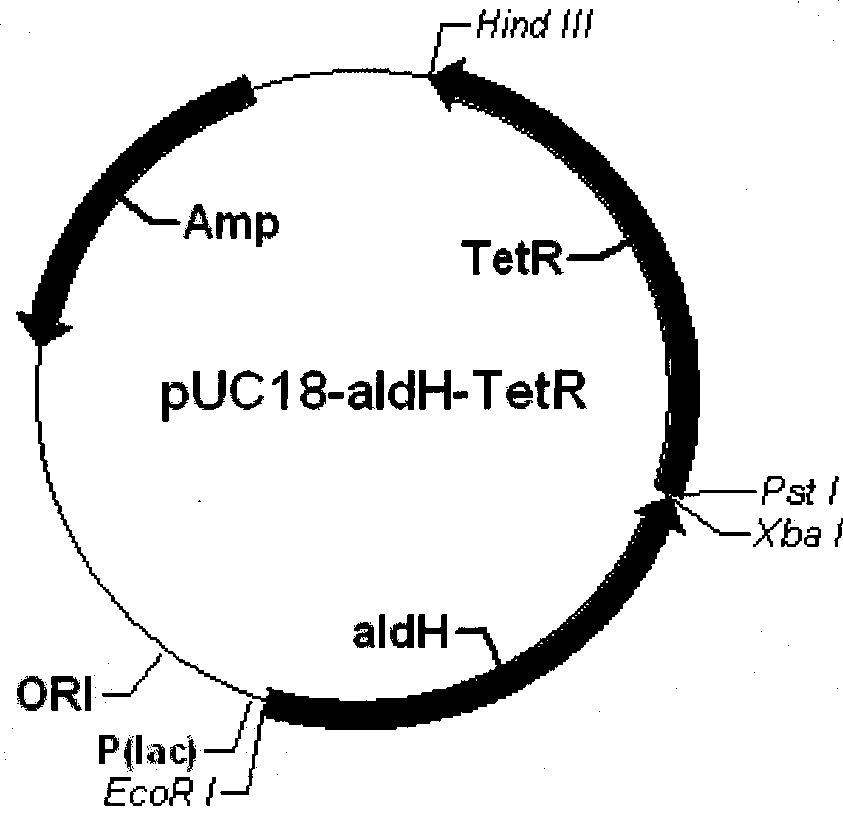

Gene engineering bacterium for producing 1,3-propanediol and its preparation method and application

InactiveCN101260379AImprove stabilityHigh final concentrationBacteriaMicroorganism based processesIsozymeGlycerol

The invention belongs to the biochemical field and discloses a 1, 3-propylene glycol genetic engineering bacterium and a preparation method and application thereof. The strain is classified and named as Klebsiella pneumoniae ATCC 25955-pUC18-yqhD-Tet<R>, and is obtained by connection of a 3-propylene redoxase isozyme gene yqhD from Escherichia coli and a tetracycline resistant gene Tet<R> from a plasmid pHY300PLK, insertion of a carrier pUC18 and conversion of Klebsiella pneumoniae ATCC 25955. The bacterium can obviously improve the capacity for conversion of glycerol into 1, 3-propylene glycol, improve the utilization ability and the conversion rate of the substrate glycerol and the final concentration of the final offspring 1, 3-propylene glycol, simultaneously shorten the fermentation time, and is convenient for industrial production of the 1, 3-propylene glycol through the microbial fermentation method.

Owner:NANJING UNIV OF TECH

Method for preparing fuel of ethanol from immobilized mixed strain fermented cellulosic hydrolysate

InactiveCN101555494AIncrease profitImprove fermentation effectBiofuelsMicroorganism based processesXyloseSide product

The invention relates to a method for preparing fuel of ethanol from immobilized mixed strain fermented cellulosic hydrolysate, which is characterized by utilizing mixed strains of P. tannophilus and S. cerevisilae to graft into diluted acid hydrolysate and fermenting the mixed solution by a supplemented material batch fermentation mode. The method is realized by the following steps: (1) domestication of the P. tannophilus and the S. cerevisilae; (2) immobilization of the mixed strains by calcium alginate; (3) multiplication culture of the immobilized mixed strains; and (4) supplemented material batch fermentation of the immobilized mixed strains. The immobilized mixed strains can be fermented while using xylems and glucose in the hydrolysate for fermentation, thereby the fermentation period is shortened, the utilization ratio of the xylose and the glucose is improved and the ethanol concentration is increased; the immobilized mixed strains can be repeatedly used and have strong anti-hybrid bacteria capability; the supplemented material batch fermentation mode is applied to hydrolysate with cellulose raw material for producing the fuel of ethanol, thereby reducing inhibiting factors in the hydrolysate; and the method is beneficial to thoroughly eliminating the inhibition on substrates, diluting poisonous metabolite, reducing contaminated bacterial, controlling the fermentation time and preventing the generation of side products.

Owner:BEIJING UNIV OF CHEM TECH

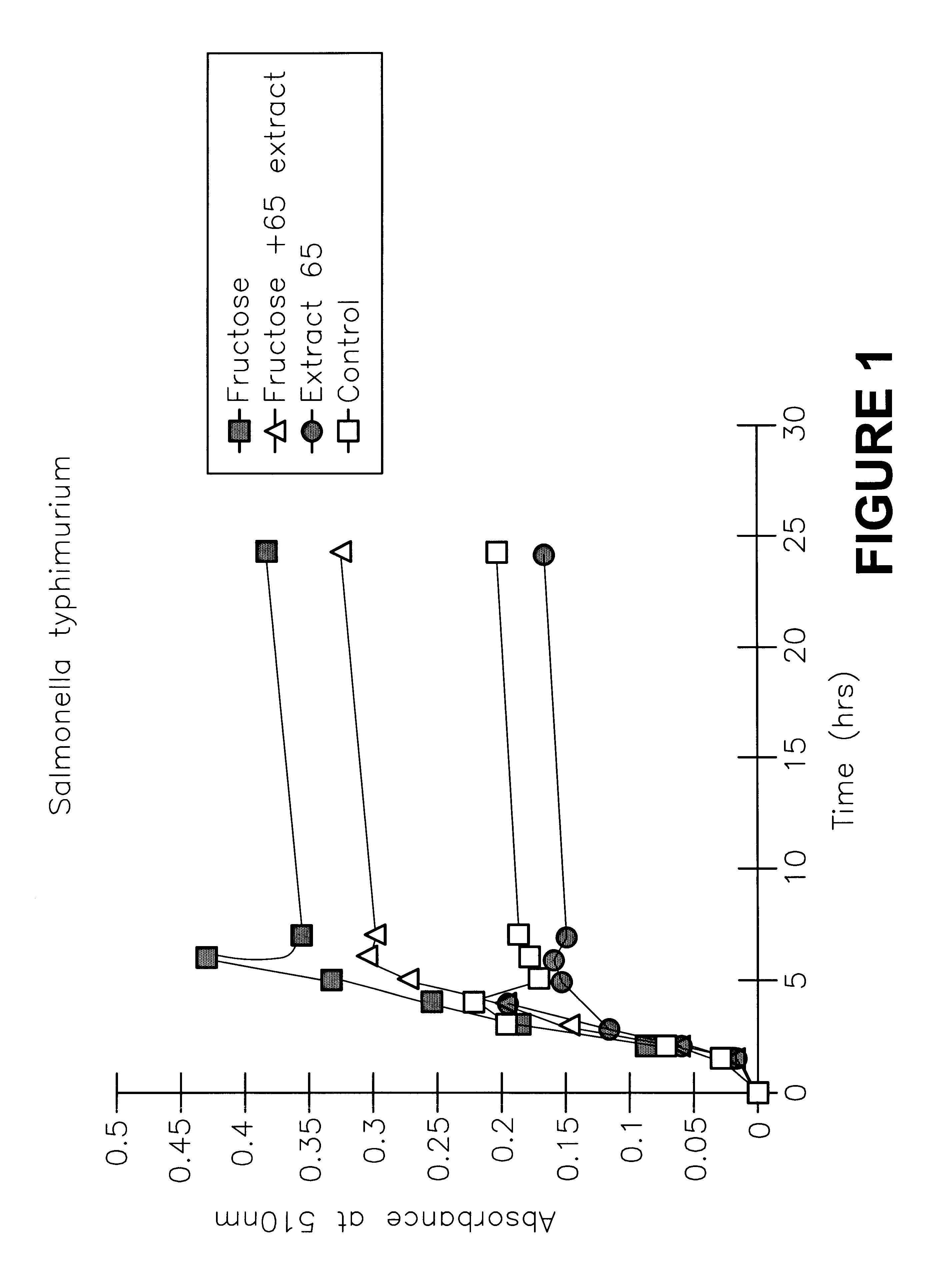

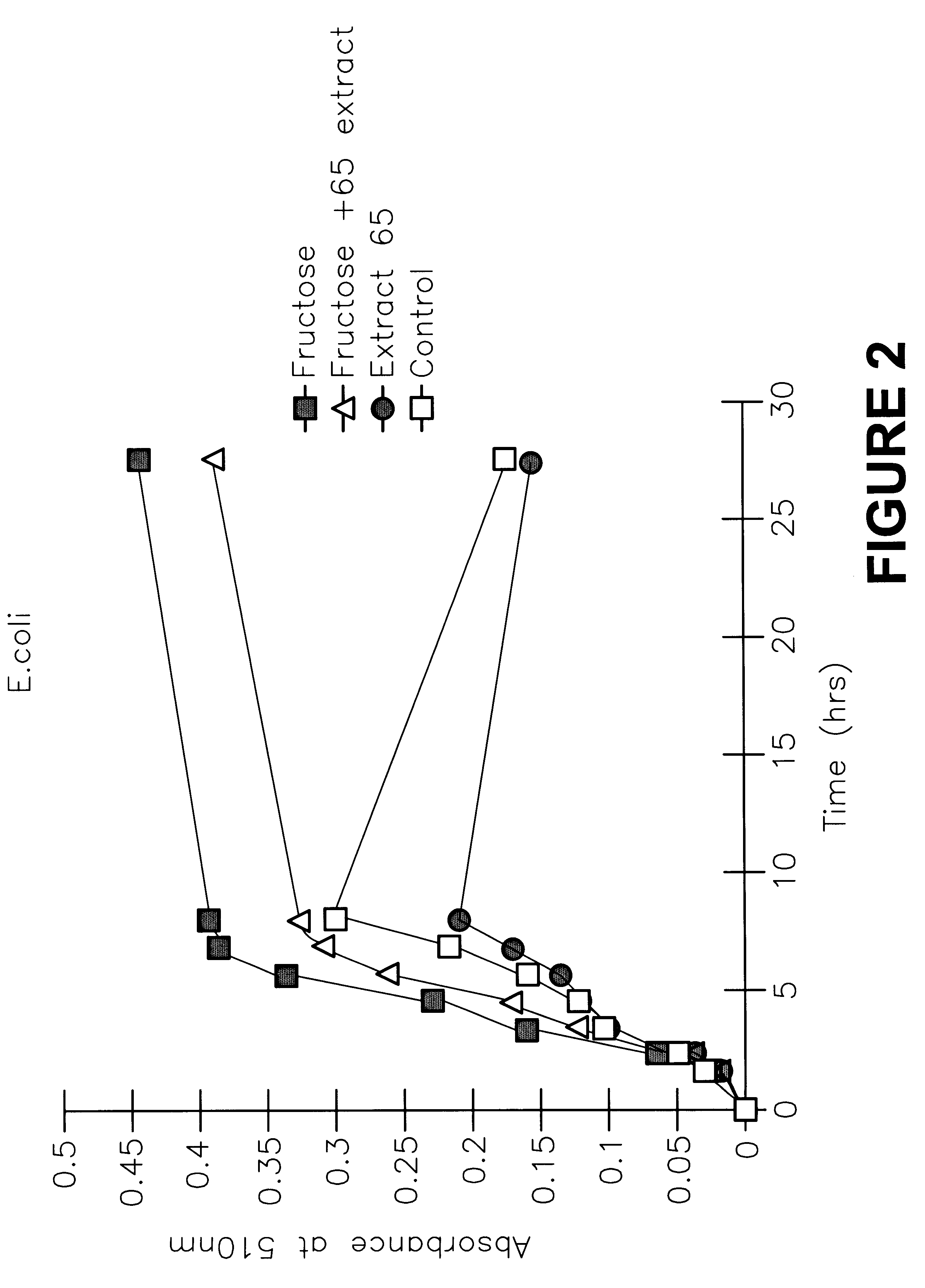

Reduction of pathogenic bacteria in food products

InactiveUS6210678B1Reducing viable bacterial contentReduce bacterial growthBiocideMicroorganismsBiotechnologyBacteroides

A composition is provided for reducing bacterial growth in food products. The composition includes a wood extract containing polyphenols and may contain arabinogalactan. The composition suppresses or prevents the growth of E. coli and of Salmonella sp. The wood extract imparts little or no residual taste to the food product. However, it can readily be removed if desired by washing before use of the food. The composition may be essentially arabinogalactan-free to further reduce bacterial growth.

Owner:MONTANA THE UNIV OF

Simple culture method for effective microorganisms (EM)

ActiveCN102154106AImprove adjustabilityReduce production stepsFungiBacteriaEnvironmental resistanceEffective microorganism

The invention relates to a culture method of mixed bacteria, in particular to a culture method for EM. The simple culture method for EM comprises the following steps: A, preparing culture solution, and filling into a plastic square barrel with a ventilating cover; B, inoculating bacillus; C, culturing under a closed condition for 24 hours; D, inoculating composite lactic acid bacteria, saccharomycetes and photosynthetic bacteria; and E, culturing under a closed condition. In the invention, a cheap plastic square barrel which is common on market is used as an EM culture container; generally, culture can be performed at normal temperature; culture and use on site can be realize; and the method has the advantages of environment protection, flexible production operation, production and use cost conservation and the like.

Owner:DONGGUAN SHENGYUAN ENVIRONMENTAL PROTECTION TECH

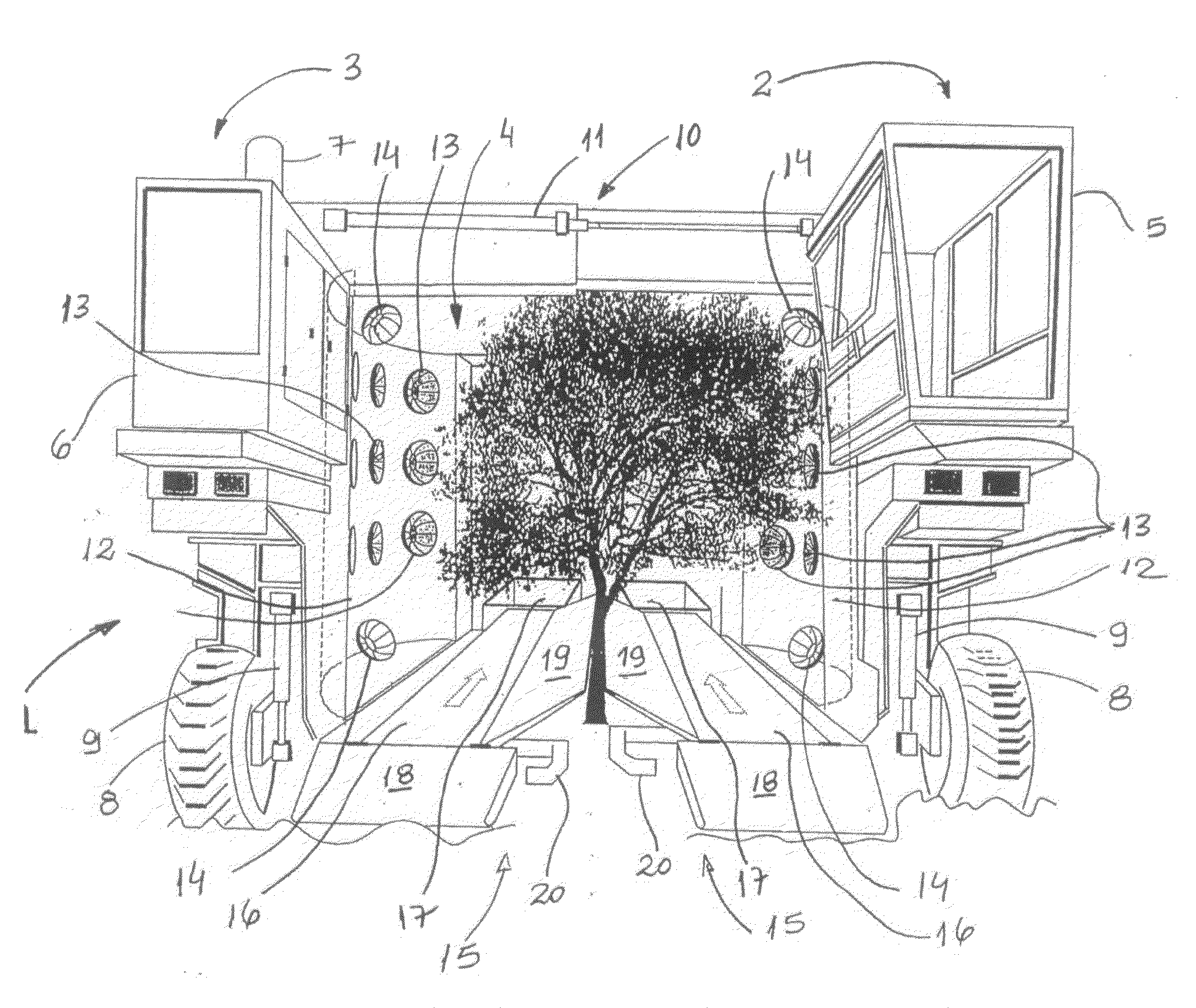

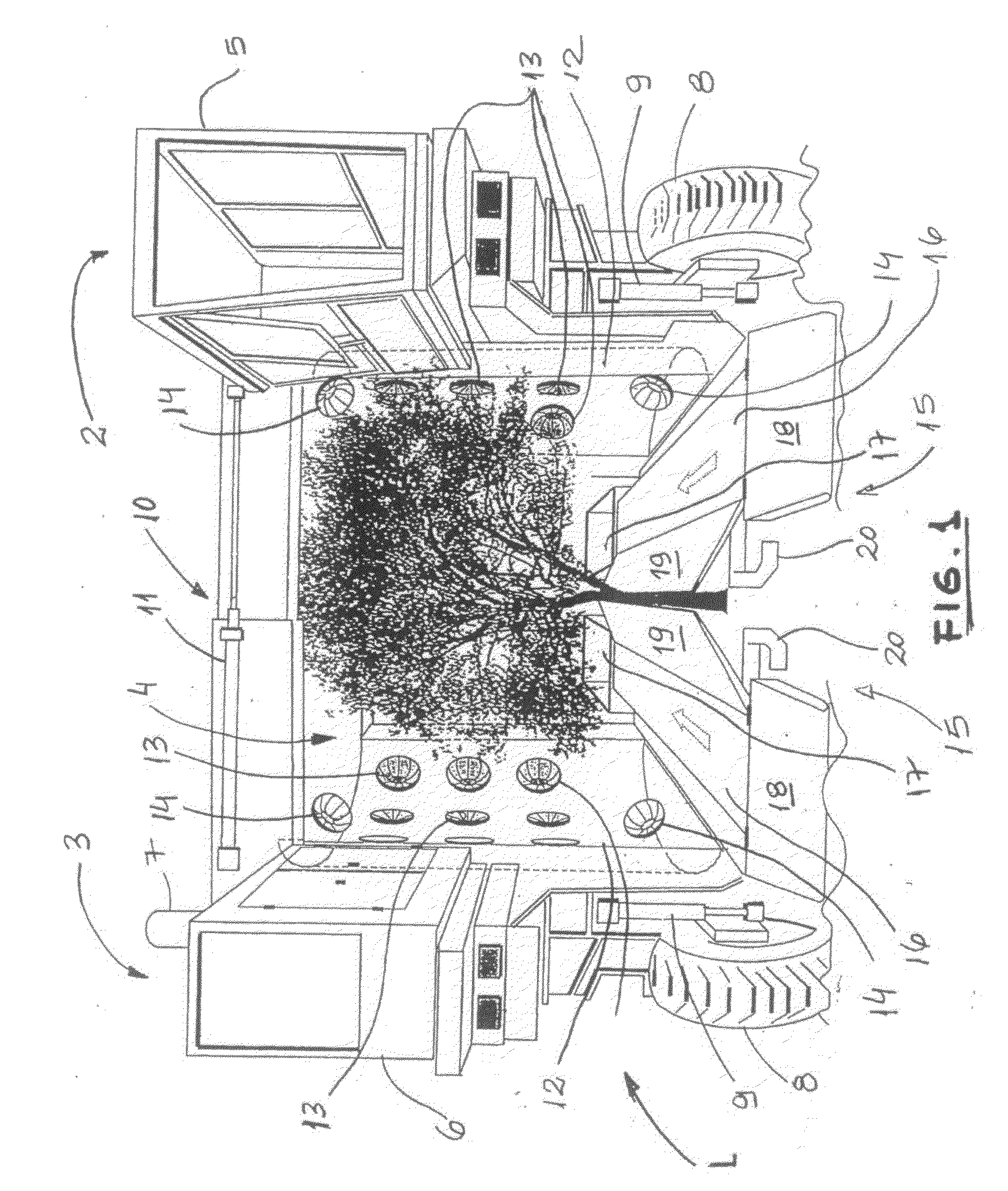

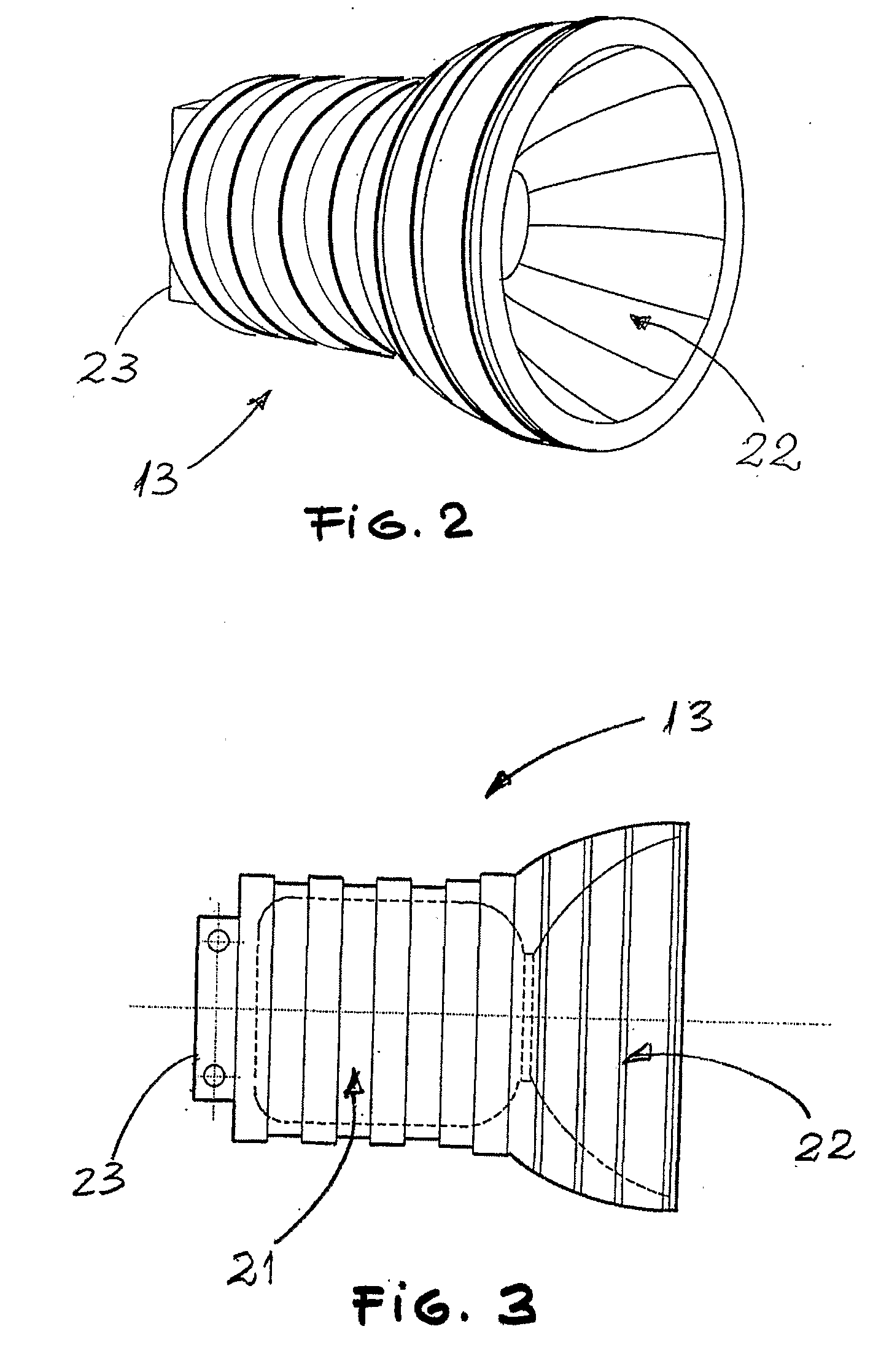

Fruit Harvesting Machine for Trees, Shrubs and the Like

A fruit harvesting machine for trees, shrubs and the like planted in rows, which applies a controlled intensity and direction blast wave to dislodge the fruit from the tree. The fruit-harvesting machine makes use of the advantages of using blast wave generating devices which have a combustion chamber and the combined effect of blast waves with the every released by gases during an explosion to dislodge the fruit from the tree. Additionally, the harvesting machine uses the emission of short, high intensity light pulses directed towards the fruit to be harvested, these pulses act spatially and deactivate microorganisms which are pathogenic for humans and plants.

Owner:CONSTANS CARLOS ENRIQUE

Simple seedling raising method of Arabidopsis thaliana and the device used

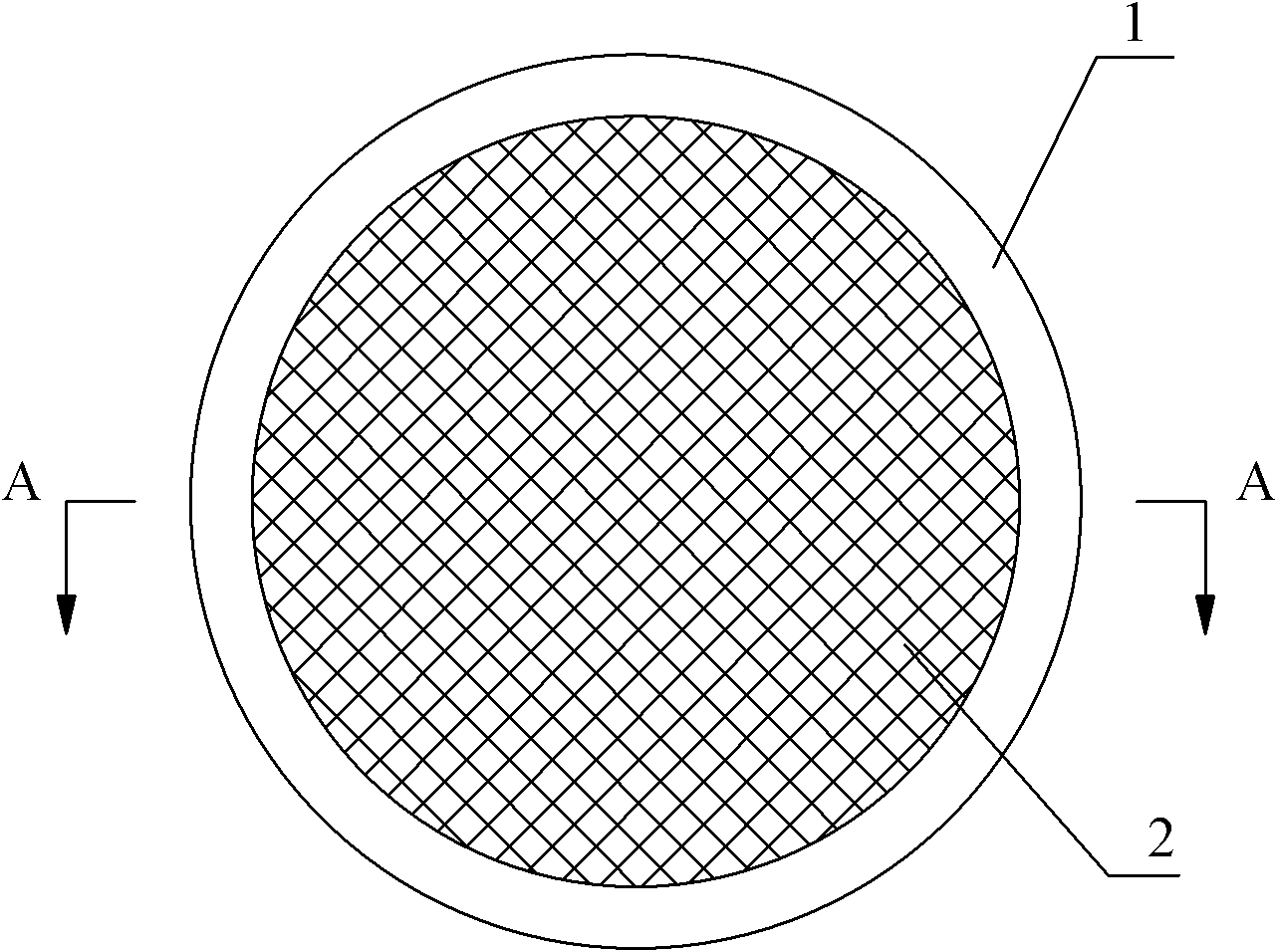

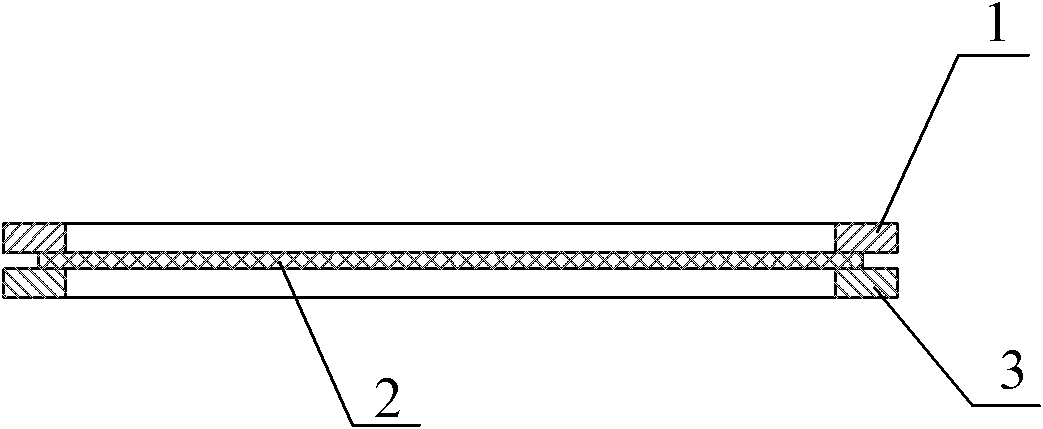

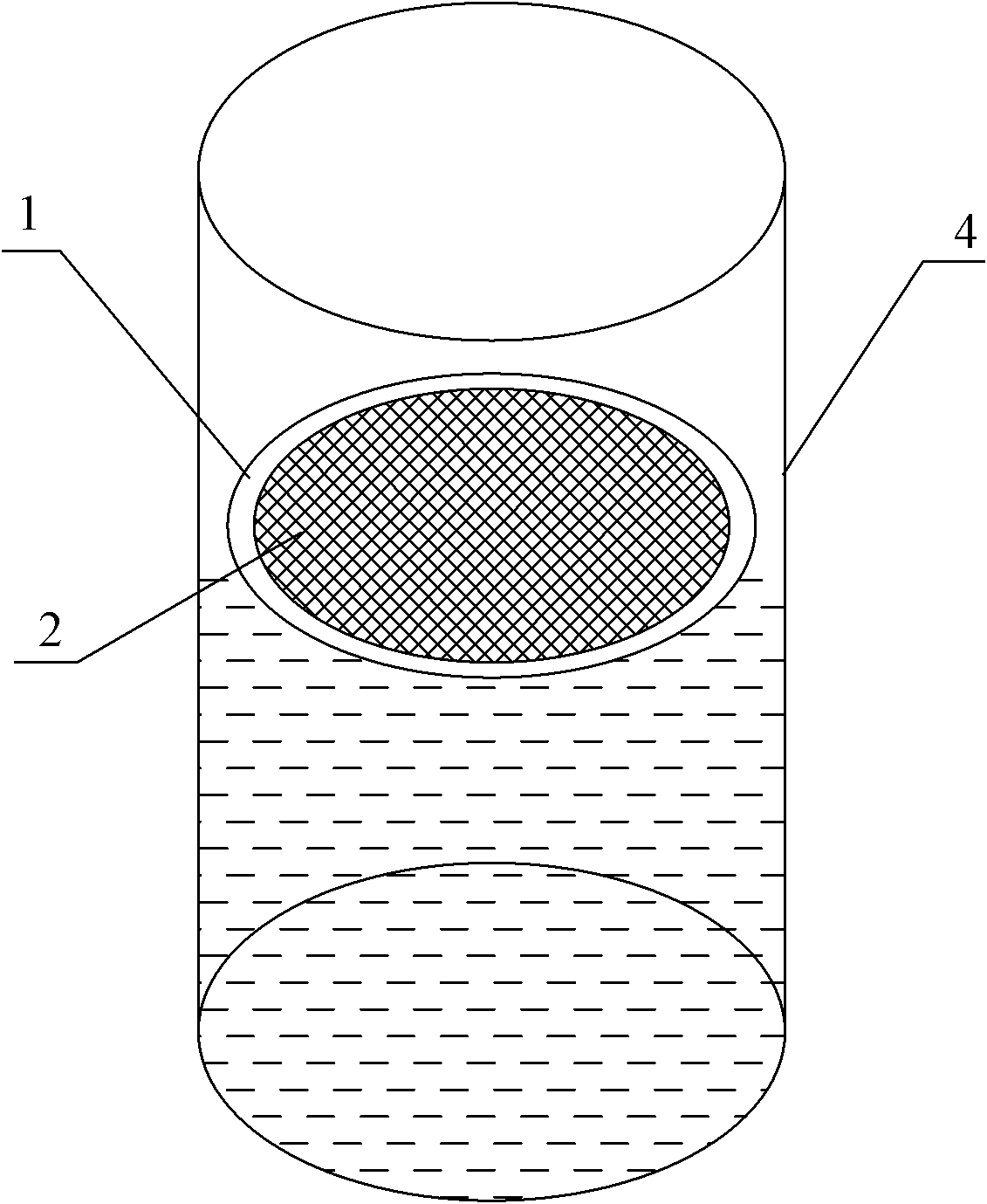

InactiveCN102265780AEasy to processPrevent drynessAgriculture gas emission reductionCultivating equipmentsEngineeringArabidopsis

The invention discloses a simple seedling raising device for Arabidopsis thaliana, which comprises an annular upper floating plate (1) and an annular lower floating plate (3). The annular upper floating plate (1) is located above the annular lower floating plate (3), and the annular upper floating plate (1) ) is equal to the inner diameter of the annular lower floating plate (3), a planar mesh (2) is set between the annular upper floating plate (1) and the annular lower floating plate (3), and the outer diameter of the mesh (2) is larger than the annular The inner diameter of the upper floating plate (1). The present invention also discloses a simple method for growing seedlings of Arabidopsis thaliana by using the above-mentioned device, which includes the following steps: 1) pre-disinfection treatment; 2) spreading the above-mentioned disinfected Arabidopsis seeds evenly to the above-mentioned disinfected On the mesh (2) of the simple seedling raising device for Arabidopsis thaliana seeds; 3) make the simple seedling raising device for Arabidopsis thaliana seeds obtained in step 2) float and cultivate in the container (4) with 1 / 2 full Hoagland nutrient solution inside .

Owner:ZHEJIANG UNIV

Transformation microbe generating 3-hydracrylic acid, construction method and application thereof

InactiveCN101519635AImprove stabilityReduce bacterial contaminationBacteriaMicroorganism based processesBiotechnologyMicroorganism

The invention relates to a transformation microbe containing a recombinant vector, wherein the recombinant vector contains protein expressed by a nucleotide sequence shown by a gene code SEQ ID NO.1. A method for preparing the transformation microbe comprises introducing the nucleotide sequence shown by the gene code SEQ ID NO.1 into a host. The transformation microbe containing the recombinant vector is applied to generating 3-hydracrylic acid. A plasmid has high stability in a host strain, and is quite suitable for generating a strain; the final concentration of a product has competitiveness; in addition, trace tetracycline can be added during fermentation so as to achieve the aim of inhibiting part hybrid bacteria, greatly reduce the phenomenon of easily dyeing the hybrid bacteria during industrialization, shorten the fermentation time and lay a good foundation for industrialization production of the 3-hydracrylic acid by a microbe fermentation method.

Owner:NANJING UNIV OF TECH

Automatic trash bagger

InactiveUS20080135558A1Avoid problemsEliminates decision making processFilament handlingLarge containersLitterEngineering

Owner:UDODOR JESSICA RENEE +1

Method of quickly biodegrading lignocellulose source inhibiting substance

InactiveCN105734087AShort cycleReduce bacterial contaminationBiofuelsFermentationPre treatmentChemistry

The invention relates to a method of quickly biodegrading a lignocellulose source inhibiting substance. The method particularly includes the steps of: 1) pre-treating a lignocellulose raw material; 2) quickly biodegrading the lignocellulose raw material in a reactor to remove the compounds which are generated during the pretreatment and have inhibition effects on subsequent enzymolysis and fermentation; and 3) performing the enzymolysis and subsequent processes to the material treated in the step 2). The method reduces treatment period to 6-36 h on the basis of ensuring biodegrading efficiency on the inhibiting substances, so that efficiency and practicability of the process are greatly improved. The biodegrading process is amplified into reactor level and is integrated with a subsequent conversion process in the same reactor, so that the integration degree of a bio-refining process is increased. The method lays the foundation of application of biodegradation of the inhibiting substances in the lignocellulose bio-refining process.

Owner:EAST CHINA UNIV OF SCI & TECH

Cigarette tipping paper coated with composite natural plant extract

InactiveCN104611993AIncrease cigarette flavorReduce bacterial contaminationNon-fibrous pulp additionPaper coatingIrritationSweetness

The invention discloses cigarette tipping paper coated with a composite natural plant extract having antiviral and antibacterial effects as well as a preparation method of the cigarette tipping paper. The composite natural plant extract comprises extracts of south isatis roots, lophatherum herbs, chrysanthemums, liquorice roots, honeysuckle flowers and pearl corn in the ratio of (0.5-5):(0.7-6):(0.6-4):(0.5-4):(0.5-5):1, and the coating weight of the composite natural plant extract on the cigarette tipping paper is in a range of 0.2-3 g / m<2>. After the cigarette tipping paper is applied to cigarettes, the probability that a smoker is infected with bacteria or viruses due to the fact that the smoker is contacted with the tipping paper through lips can be decreased, the smoke aroma quantity of the cigarettes can be increased, the aroma quality and the harmony can be improved, impure gases and the irritation can be reduced, the sweetness can be increased, and the interior quality of the cigarettes can be improved integrally.

Owner:CHINA TOBACCO GUANGXI IND

Edible mushroom culture medium and preparation method thereof

The invention provides an edible mushroom culture medium which comprises, by weight, 30-50 parts of biogas residues and biogas slurry, 30-50 parts of crop straws, 10-20 parts of grape pips and peels and a sterilizing agent with 0.5-2% of the volume-weight ratio. Hydrogen peroxide is adopted for the sterilizing agent, and the invention further provides a preparation method of the culture medium. The edible mushroom culture medium has the advantages that the grape pipes and peels comprise a large quantity of polyphenol substances and a large amount of linoleic acid and further have a certain bacteriostatic effect, so that more rich nutrition is provided for the culture medium, and the bacteriostatic effect enables the prepared culture medium not to be prone to being infected with infectious microbes; due to the fact that 35% of the hydrogen peroxide is selected and used for the sterilizing agent, the sterilizing effect is remarkable, in addition, due to the selection and use of the grape pips and peels, the culture medium is little infected with bacteria, in the process of high temperature sterilization, the culture medium is volatilized to generate water and oxygen, and no residue and contamination exist; a large amount of agricultural and stock farming waste such as the straws and the biogas residues and biogas slurry are further selected and used for the culture medium, so that reusing of the waste is achieved, and the culture medium meets the requirements of environmental protection and circular economy.

Owner:TIANJIN HONGSHENGYUAN EDIBLE FUNGUS TECH DEV

Microbiological control in animal processing

InactiveUS20060004072A1Reduce Microbial ContaminationProduced economicallyBiocideOrganic active ingredientsWater chlorinationZoology

Fecal bacterial contamination in an animal is reduced by providing it with drinking water containing a microbiocidally-effective amount of halogen-based microbiocide resulting from mixing with water (A) a product formed in water from (i) bromine, chlorine, or bromine chloride, or any two or more thereof, (ii) a water-soluble source of sulfamate anion, and (iii) a water-soluble base; (B) at least one 1,3-dihalo-5,5-dialkylhydantoin in which one of the halogen atoms is a chlorine atom and the other is a chlorine or bromine atom, and in which each alkyl group, independently, contains in the range of 1 to about 4 carbon atoms; (C) at least one 1,3-dibromo-5,5-dialkylhydantoin in which one of the alkyl groups is a methyl group and the other alkyl group contains in the range of 1 to about 4 carbon atoms; or (D) any two or more of (A), (B), and (C).

Owner:HOWARTH JONATHAN N +1

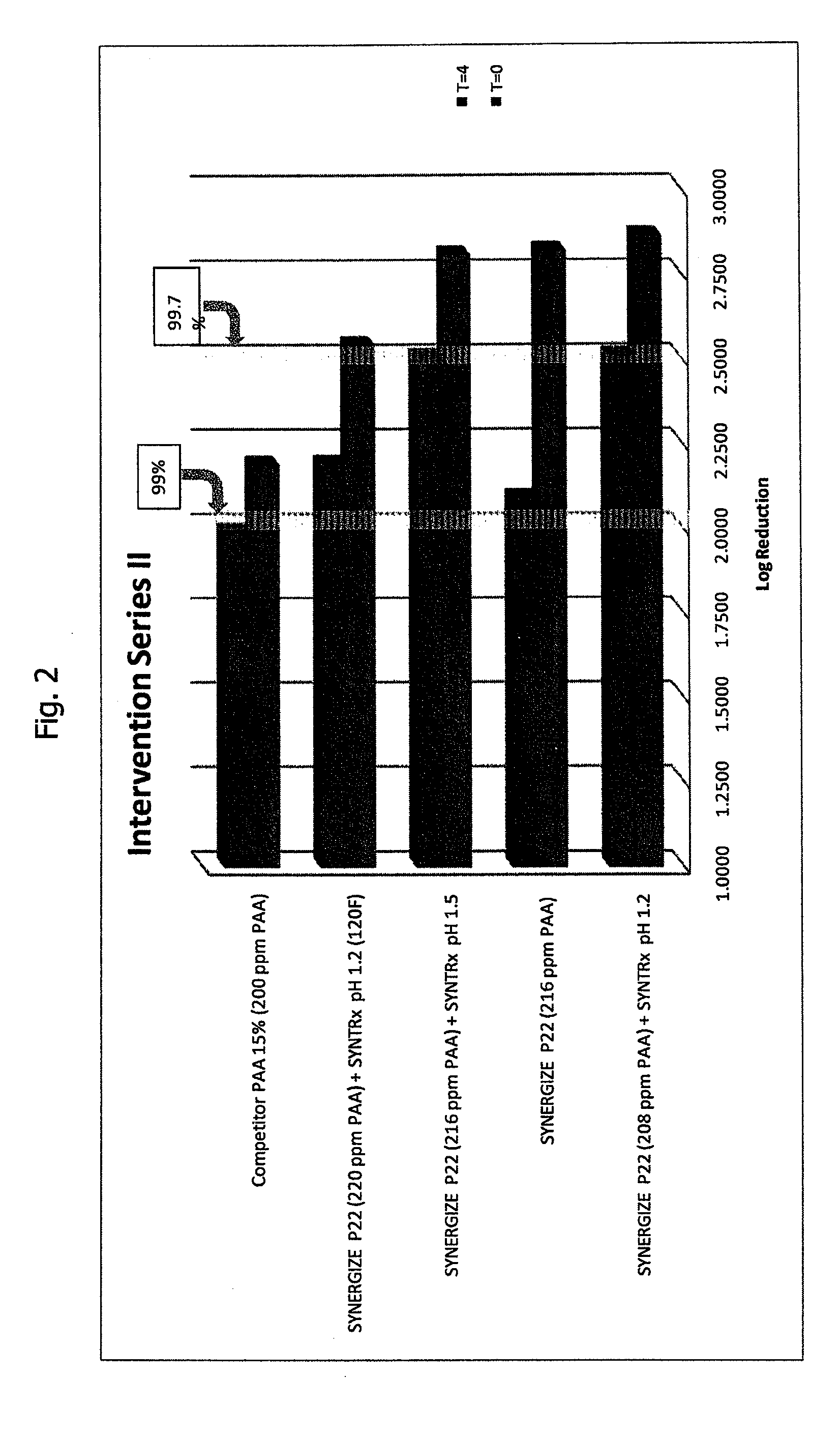

Synergy of strong acids and peroxy compounds

ActiveUS9005669B2Reduce bacterial contaminationEfficient reductionBiocideFruit and vegetables preservationWater flowStrong acids

Disclosed is a method for improving decontamination in meat, poultry, fish, fruit and vegetable processing using a combination of acid(s) and peroxy compound(s). The method comprises a “stacked” approach, sequentially adding the acid(s) and peroxy compound(s) to an aqueous stream to provide a point-of-use low-pH antimicrobial composition that is highly effective for decontamination of food products, as well as safer for use in a processing facility.

Owner:PEROXYCHEM LLC

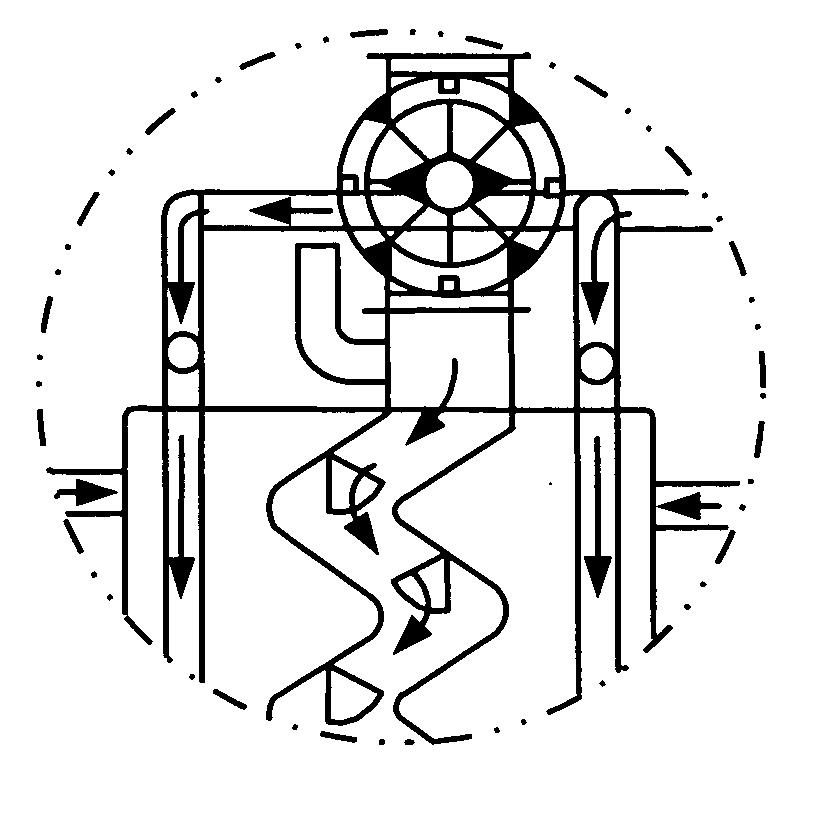

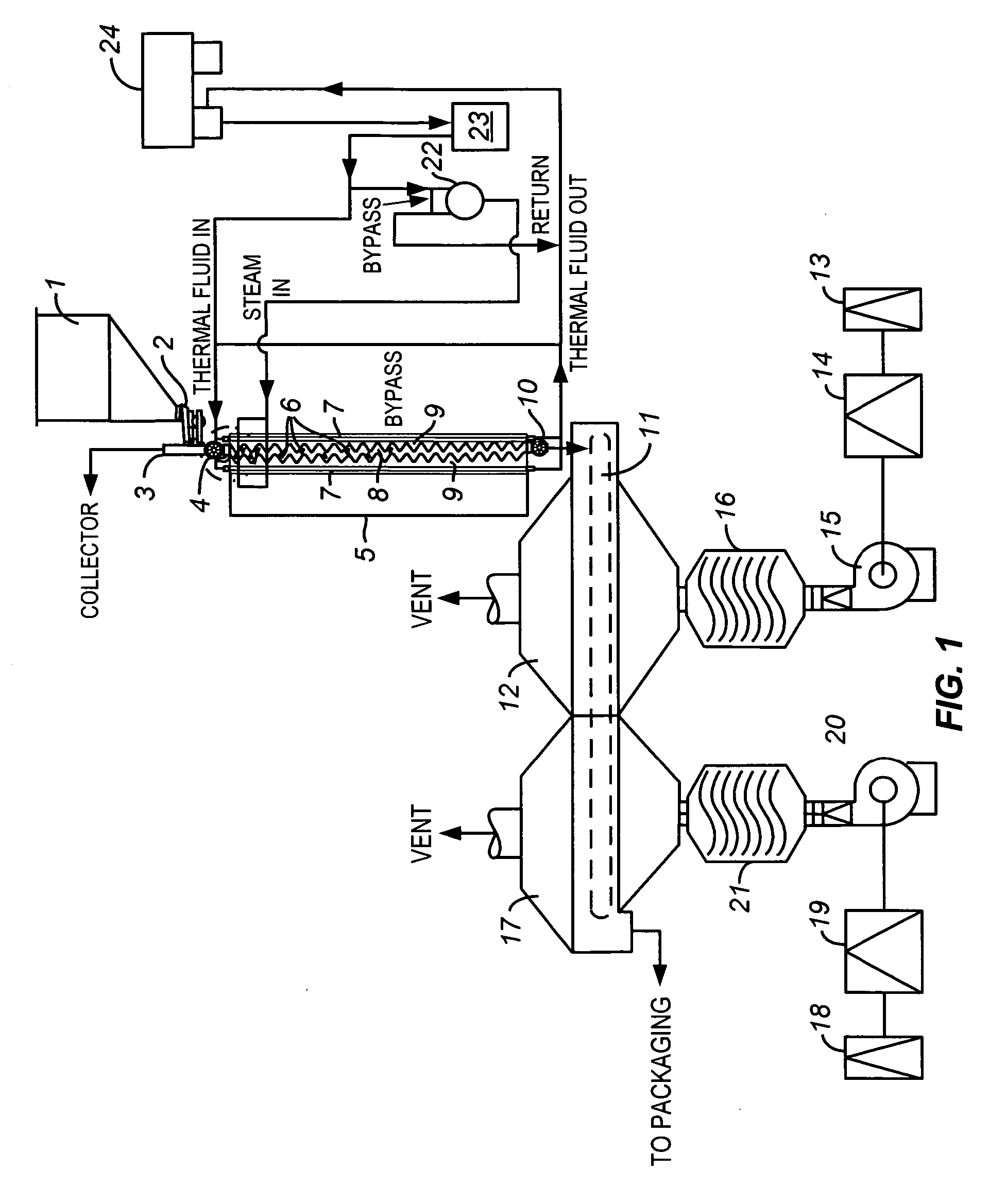

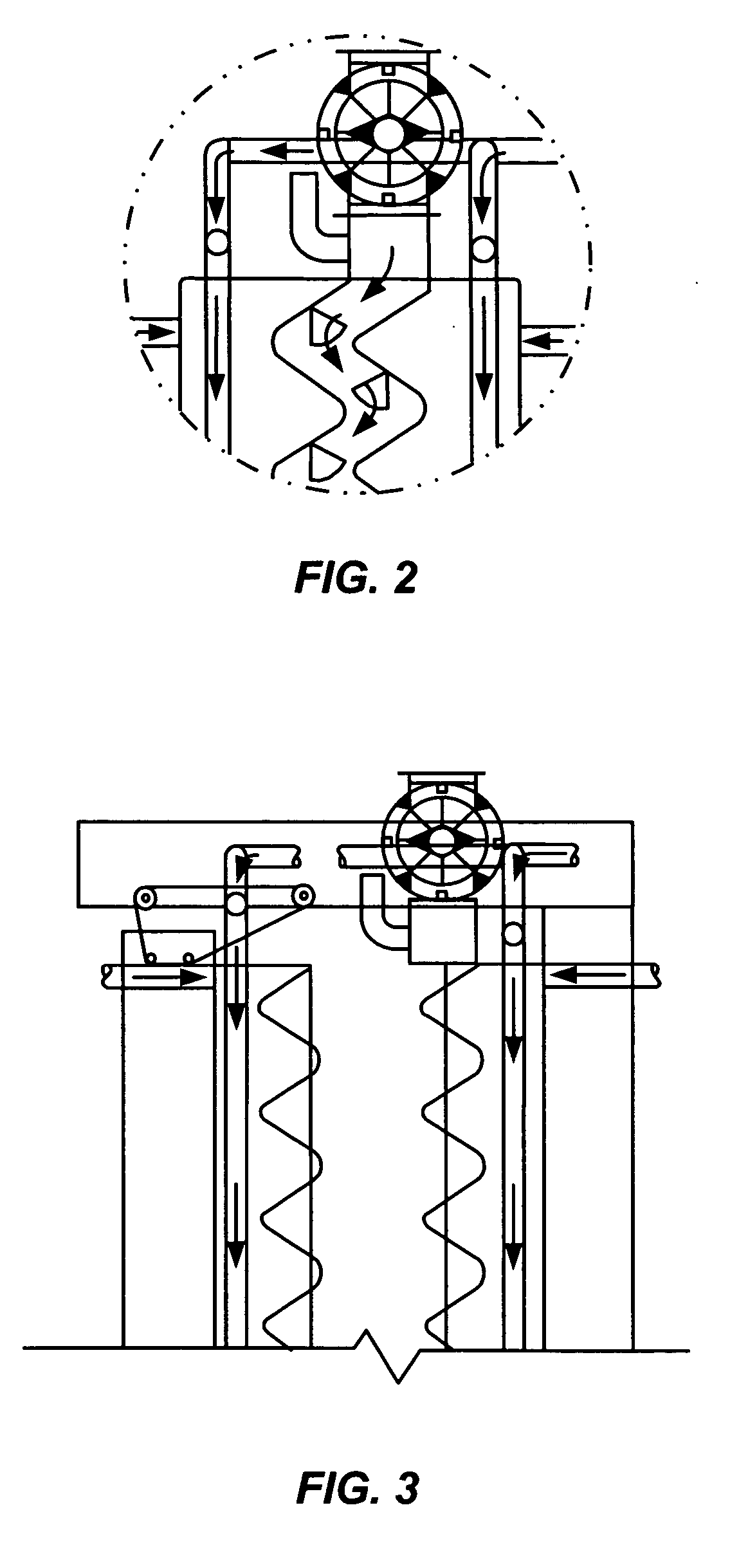

Apparatus and process for reducing microbial contamination of nuts

InactiveUS20060147594A1Reduce bacterial contaminationPoint becomes highFruit and vegetables preservationFood preparationMicrobial contaminationVertical path

The invention provides methods and devices for reducing microbial contamination of nuts. An enclosed vertical path permits nuts to descend from an upper elevation to a lower elevation. Steam introduced into the enclosed vertical path from two or more orifices contacts the nuts to accomplish pasteurization.

Owner:HILLTOP RANCH

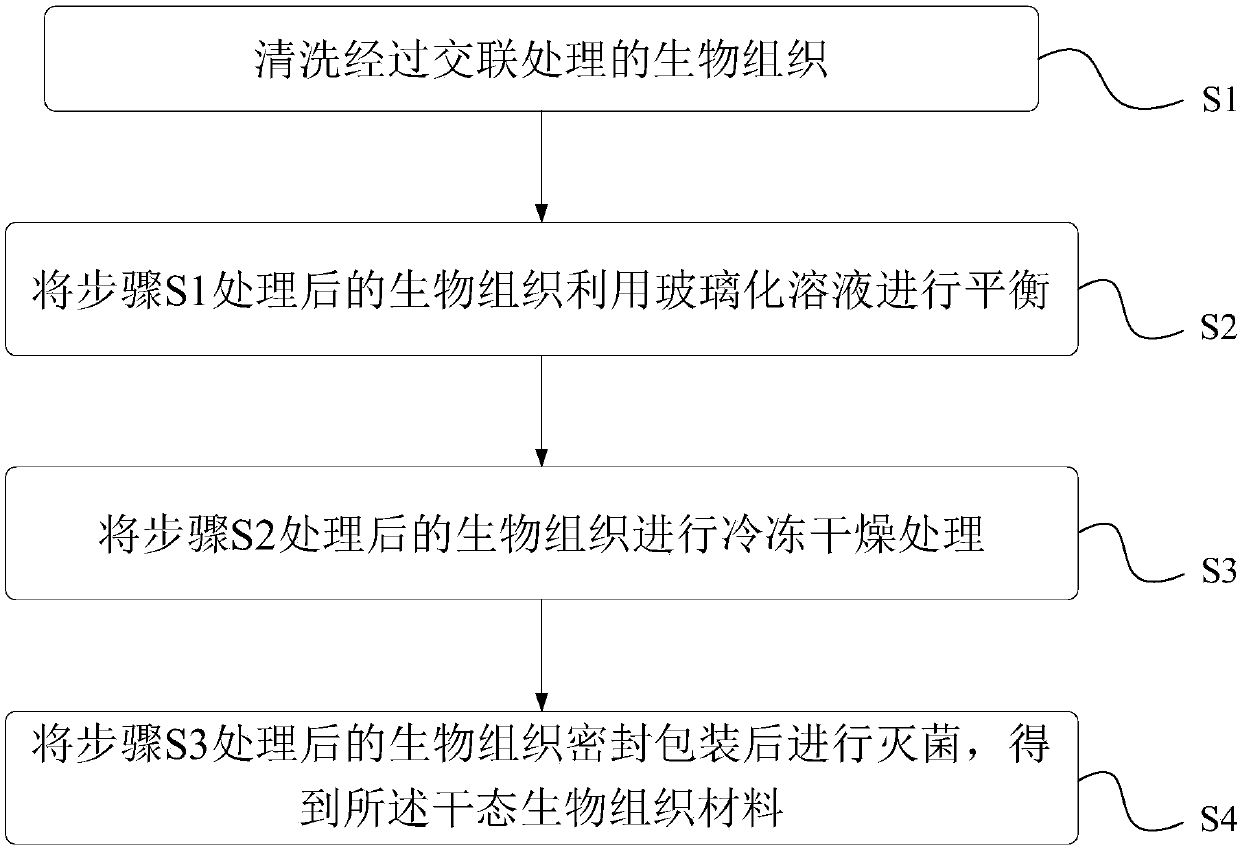

Dry biological tissue material and preparation method thereof

ActiveCN110193095AAvoid destructionImprove protectionDead animal preservationTissue regenerationCross-linkFiber

The invention provides a dry biological tissue material and a preparation method thereof. The preparation method comprises the following steps: S1, cleaning a biological tissue subjected to cross-linking treatment; S2, balancing the biological tissue treated in the S1 with a vitrification solution; S3, carrying out freeze-drying treatment of the biological tissue treated in the S2; and S4, sealingand packaging the biological tissue treated in the S3 and sterilizing to obtain the dry biological tissue material. The invention provides the dry biological tissue material and the preparation method thereof. By the treatment method of vitrification solution balance and freeze-drying, the water solution in the biological tissue material keeps a glassy state during cooling treatment, ice crystalscannot be formed, damage to a structure of collagen fibers is avoided, and the dry biological tissue material has good protective effect on a three-dimensional structure of the tissue; the morphologyand tensile strength of the biological tissue obtained by the method cannot be changed significantly.

Owner:SHANGHAI MICROPORT CARDIOFLOW MEDTECH CO LTD

Process for making ethanol by fermentation

ActiveUS20170002383A1Reduce bacterial contaminationBiofuelsFermentationFermentable sugarYEAST CONCENTRATE

A process for making ethanol by fermentation comprises the steps fermenting a mash comprising a fermentable sugar with a yeast to form a fermented mash comprising ethanol, separating a yeast concentrate from the fermentation mash, adding a mineral acid to the yeast concentrate to provide an acidified yeast concentrate having a pH between 1.8 and 3.0, adding a peroxycarboxylic acid to the acidified yeast concentrate in an amount of from 5 to 80 ppm by weight to provide a treated yeast concentrate, and fermenting a mash comprising a fermentable sugar with addition of treated yeast concentrate to form a fermented mash comprising ethanol.

Owner:EVONIK OPERATIONS GMBH

Method for producing solid liquefied strains of oyster mushrooms

InactiveCN104718995AKeep activeBacteria consistentCultivating equipmentsMushroom cultivationOysterSterile water

The invention relates to the field of mushroom cultivation processes, in particular to a method for producing solid liquefied strains of oyster mushrooms. First-grade liquid strains are inoculated in culture bottles to obtain liquid strains through cultivation; a solid culture compost is prepared, the liquid strains are cultivated in strain bottles, the cultivation temperature ranges from 22 DEG C to 25 DEG C, light-shielding cultivation is performed, cultivation humidity ranges from 50% to 60%, and the strain bottles can be full of strains after cultivation for 20 to 30 days; the strain bottles full of strains and free of contaminating microbes are selected out, and the strains are smashed in a smashing machine and are inoculated in sterile water to directly produce strains. By means of the method, strain growing speed is high and can be 1 / 3 higher than the solid strain growing speed, inoculation expanding of three to four times is not needed, the contamination problems in the inoculation expanding process are decreased, and the time required by propagation expanding is saved; growing points are more than growing points of common liquid strains, strains are consistent in growing speed and are relatively consistent in age, fruiting mushrooms are relatively order and good in quality, and fruiting body yield can be improved by 20%-30%; the sterile water is adopted to liquefy hyphae, mould and other contaminating microbes do not grow, and pollution rate can be reduced by 5%-10%.

Owner:青岛联合菌业科技发展有限公司

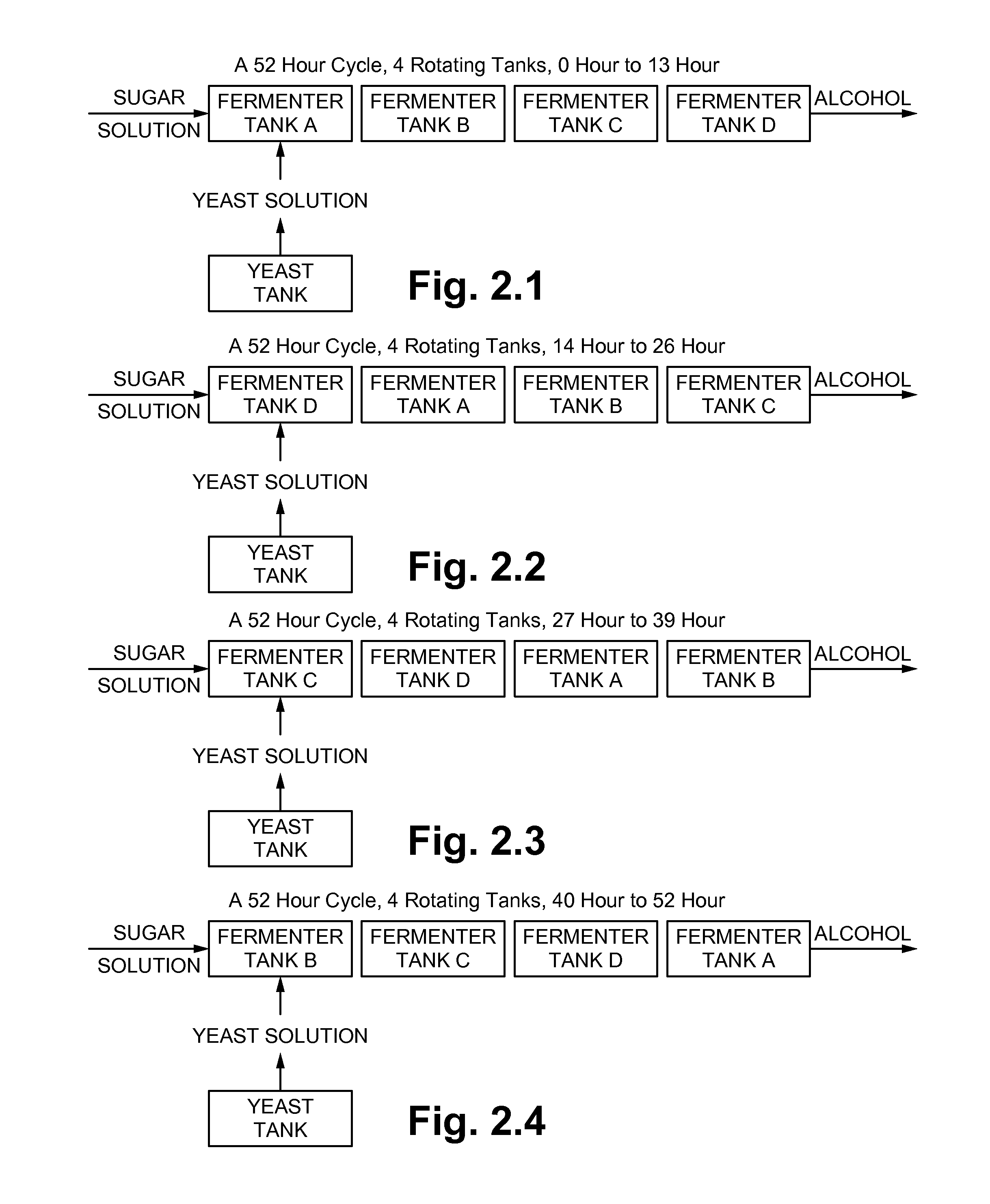

Fermentation system for dry mill processes

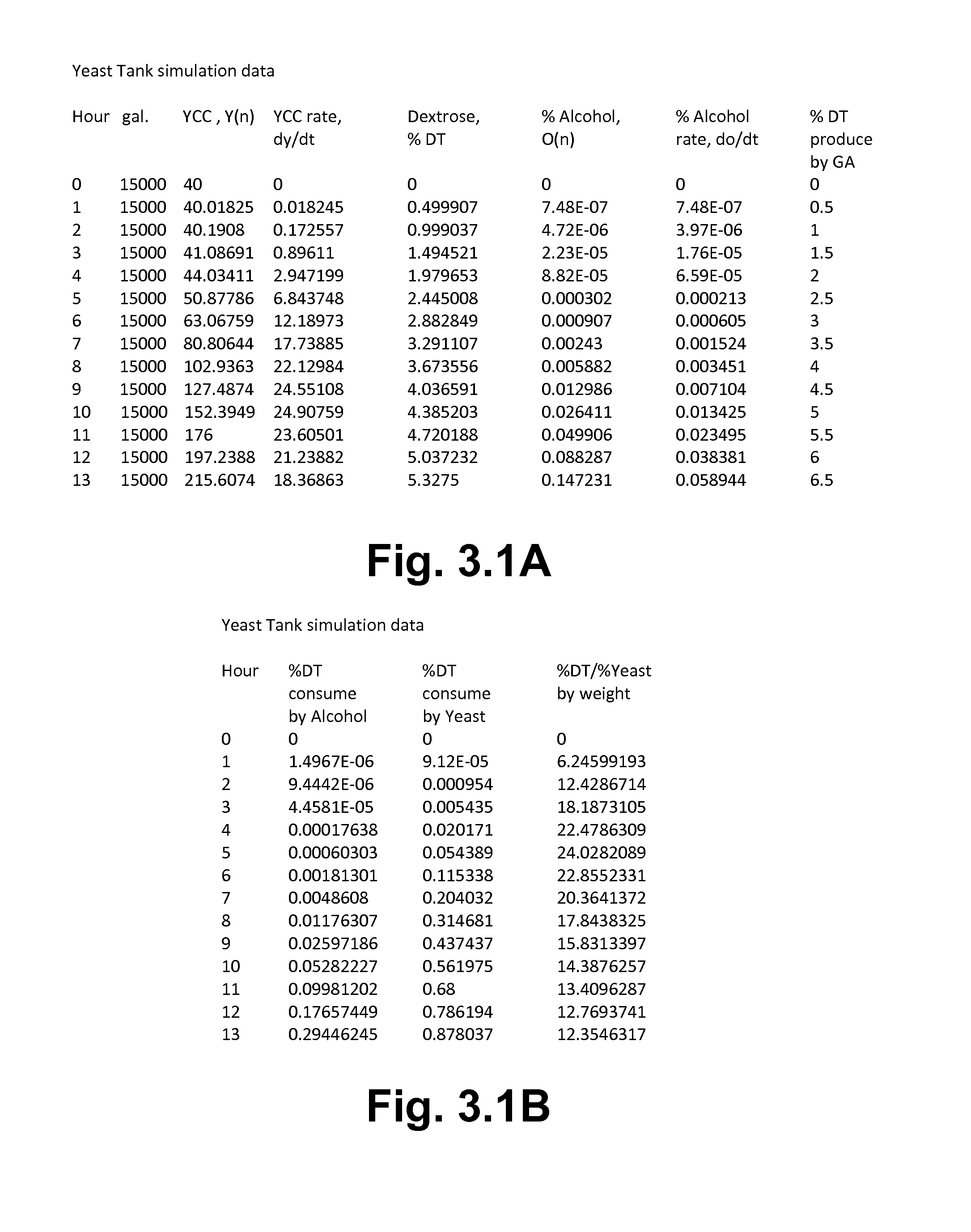

Methods of and system for growing higher and stronger levels of yeast in the Yeast Tank and Fermenter Tank during the fermentation filling cycle are provided. The yeast growth is reconfigured by continuing pumping yeast under the most active conditions while at a lower YCC (yeast cell count) into the Fermenter Tank during a filling period. A measurable and useful parameter, % DT / % Yeast by weight ratio (or “food” to yeast ratio), is introduced (e.g., % DT=glucose), which offers information on the health status of the yeast.

Owner:LEE TECH LLC

Cigarette tipping paper coated with natural plant extract composite water-based polishing oil and preparation method and application thereof

InactiveCN104805735AIncrease cigarette flavorReduce bacterial contaminationSpecial paperPaper coatingChemistryHoneysuckle

The invention discloses cigarette tipping paper coated with natural plant extract composite water-based polishing oil and a preparation method and an application thereof. The natural plant extract composite water-based polishing oil comprises a composite natural plant extract, water-based polishing oil and edible alcohol. The ratio of the composite natural plant extract to the water-based polishing oil to the edible alcohol is 1:1-3:2-7. The composite natural plant extract comprises extracts of rhizoma et radix baphicacanthis cusae, lophatherum gracile, chrysanthemum, licorice and honeysuckle flower according to the weight ratio of 0.5-5:0.7-6:0.6-4:0.5-4:1. Coating weight of the natural plant extract composite water-based polishing oil on cigarette tipping paper is 0.3-3 g / m<2>. According to the invention, the possibility that a smoker is contacted and infected with bacteria or virus through lip is reduced, and cigarette smoke aroma amount is increased, aroma quality and coordination are improved, miscellaneous gas and irritation are minimized, sweet and moistening feel is increased, and interior quality of cigarette can be improved integrally.

Owner:CHINA TOBACCO GUANGXI IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com