Patents

Literature

75results about How to "Reduce Microbial Contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and composition for washing poultry during processing

InactiveUS6514556B2Reduce Microbial ContaminationHigh degreeBiocideDough treatmentBiologyMicrobial contamination

The present invention relates to compositions including peroxyacetic acid and peroxyoctanoic acid and methods for reducing microbial contamination on poultry. The methods include the step of applying a mixed peroxycarboxylic acid composition to poultry.

Owner:ECOLAB USA INC

Antimicrobial compositions and methods

InactiveUS20050053593A1Easy to handleReduce Microbial ContaminationAntibacterial agentsBiocideLipid formationAlcohol sugars

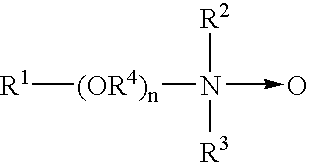

The present invention is generally related to a product and process to reduce the microbial contamination on organic matter, such as processed meat, fruits and vegetables, plant parts, inanimate surfaces such as textiles and stainless steel, and in the mouth or on dental products. In particular, the invention is related to a product and process to disinfect surfaces using an antimicrobial composition containing an antimicrobial lipid, an enhancer selected from the group consisting of bacteriocins, antimicrobial enzymes, sugars, sugar alcohols, iron-binding proteins and derivatives thereof, siderophores, and combinations thereof, and optionally a surfactant.

Owner:3M INNOVATIVE PROPERTIES CO

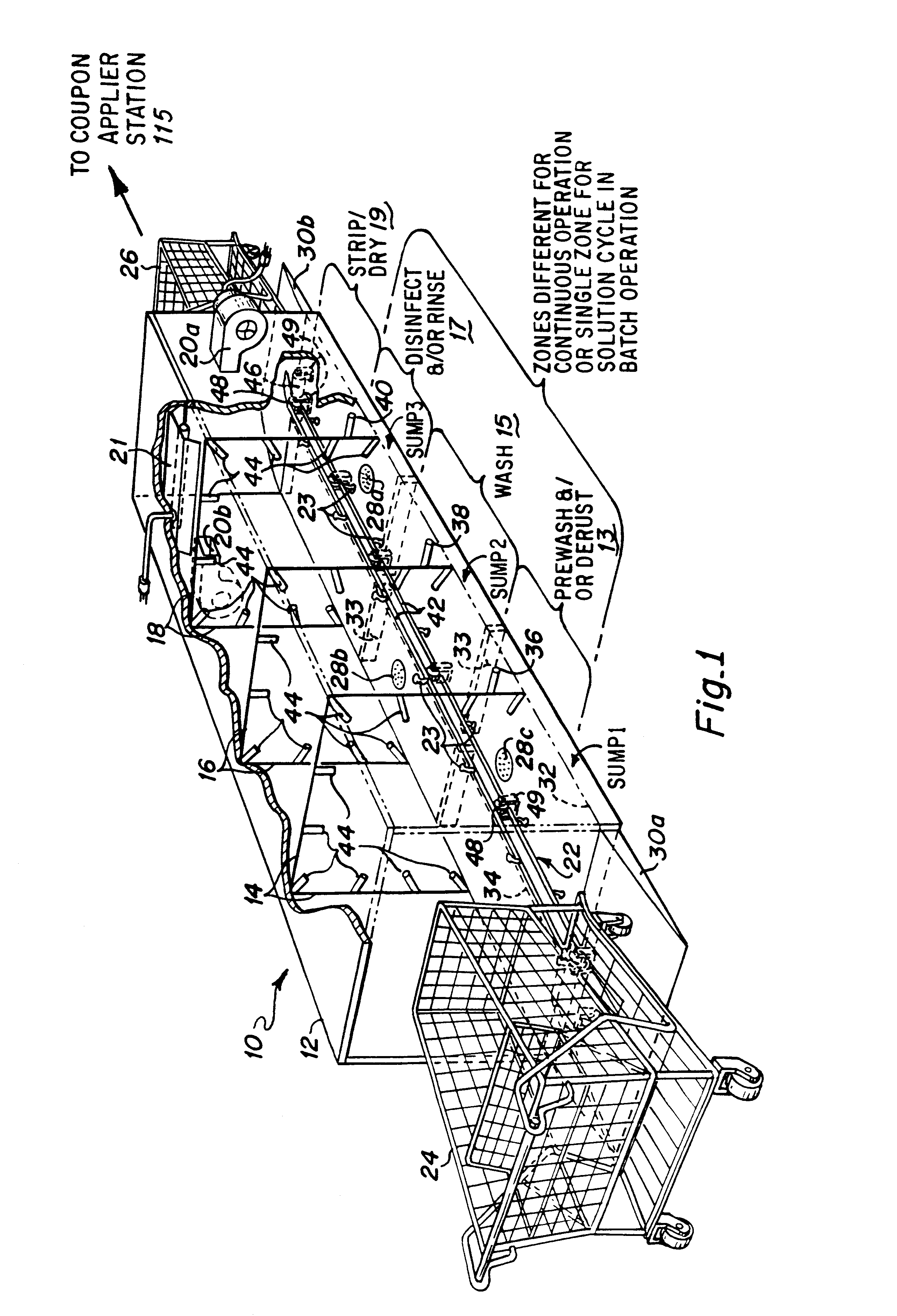

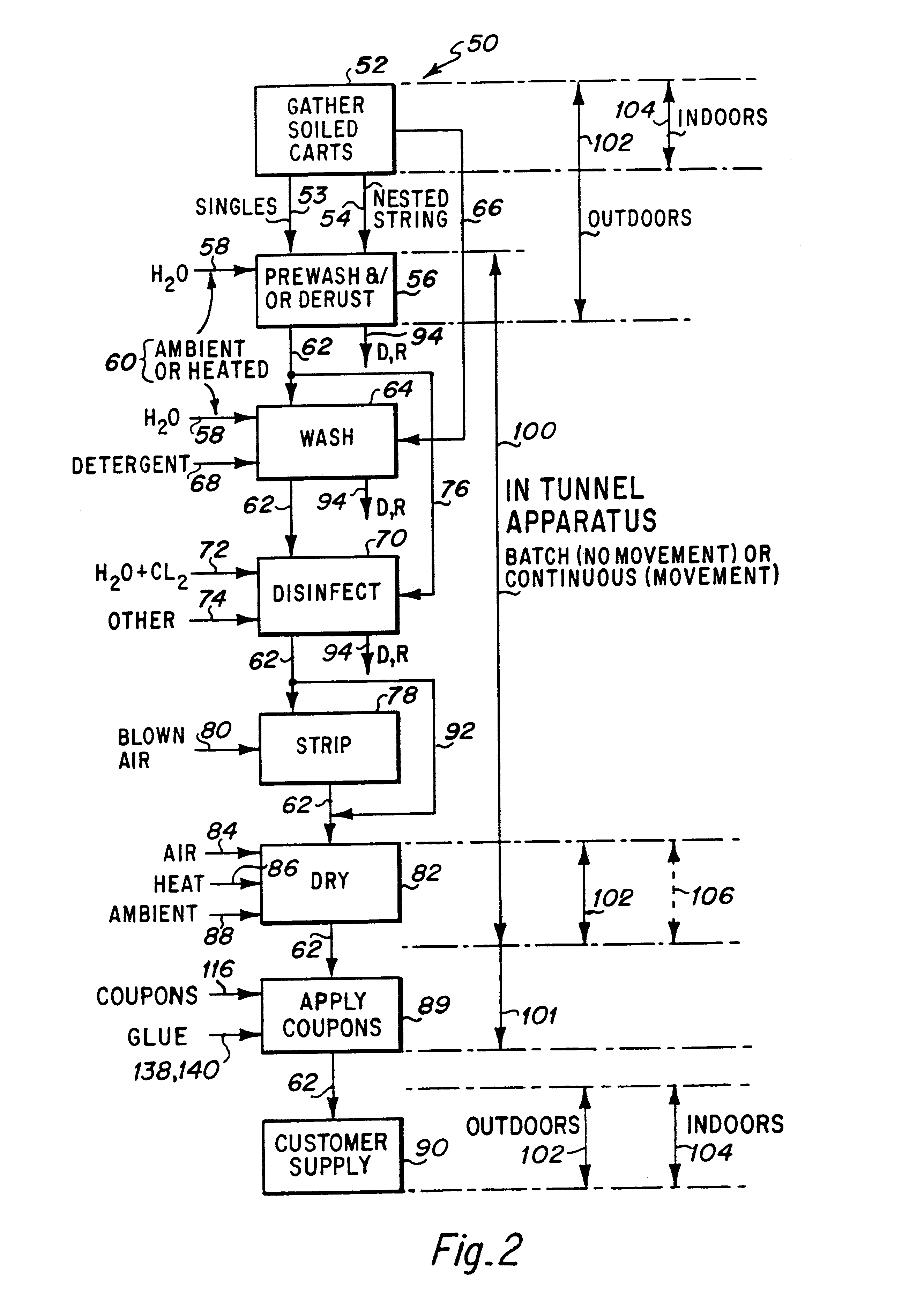

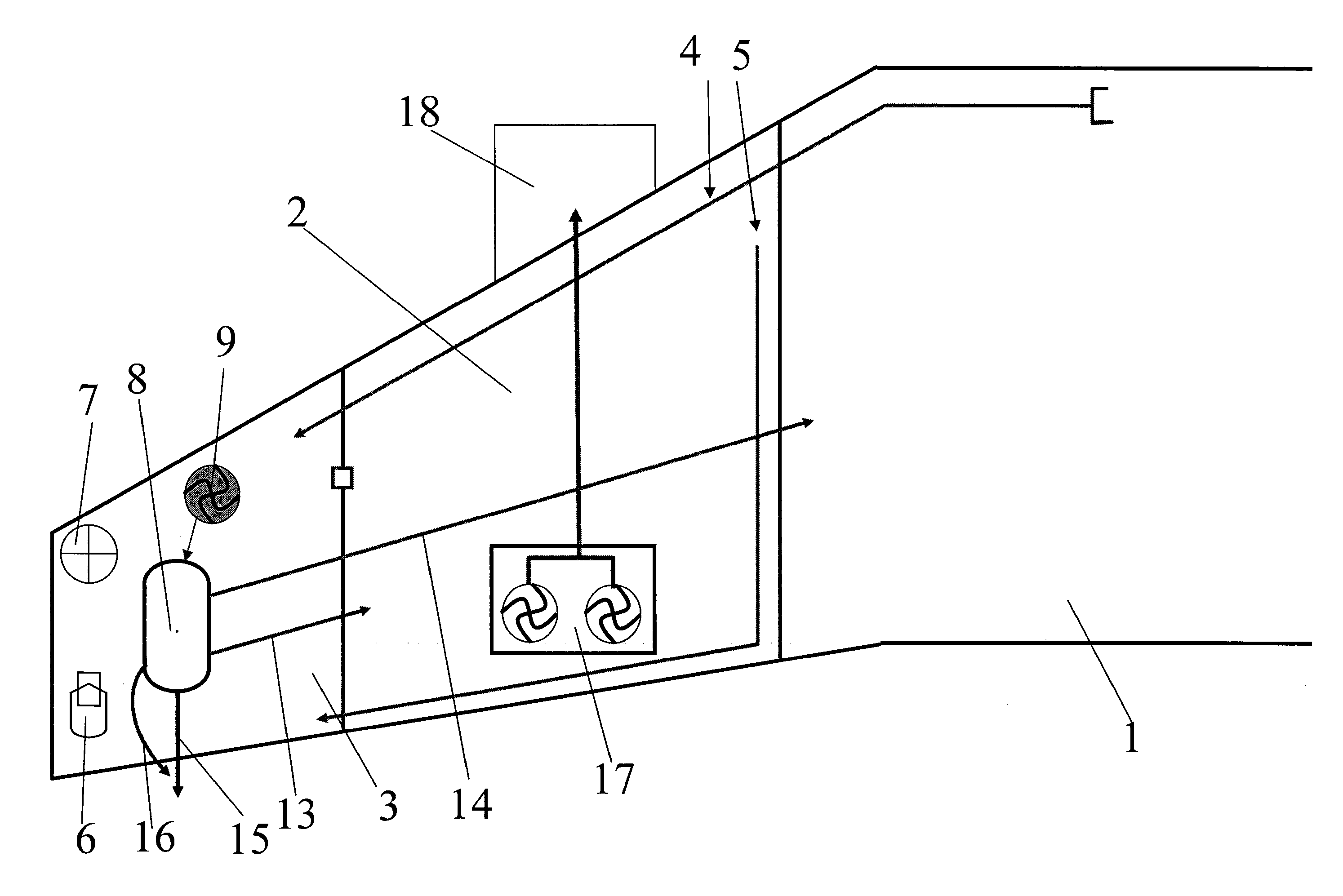

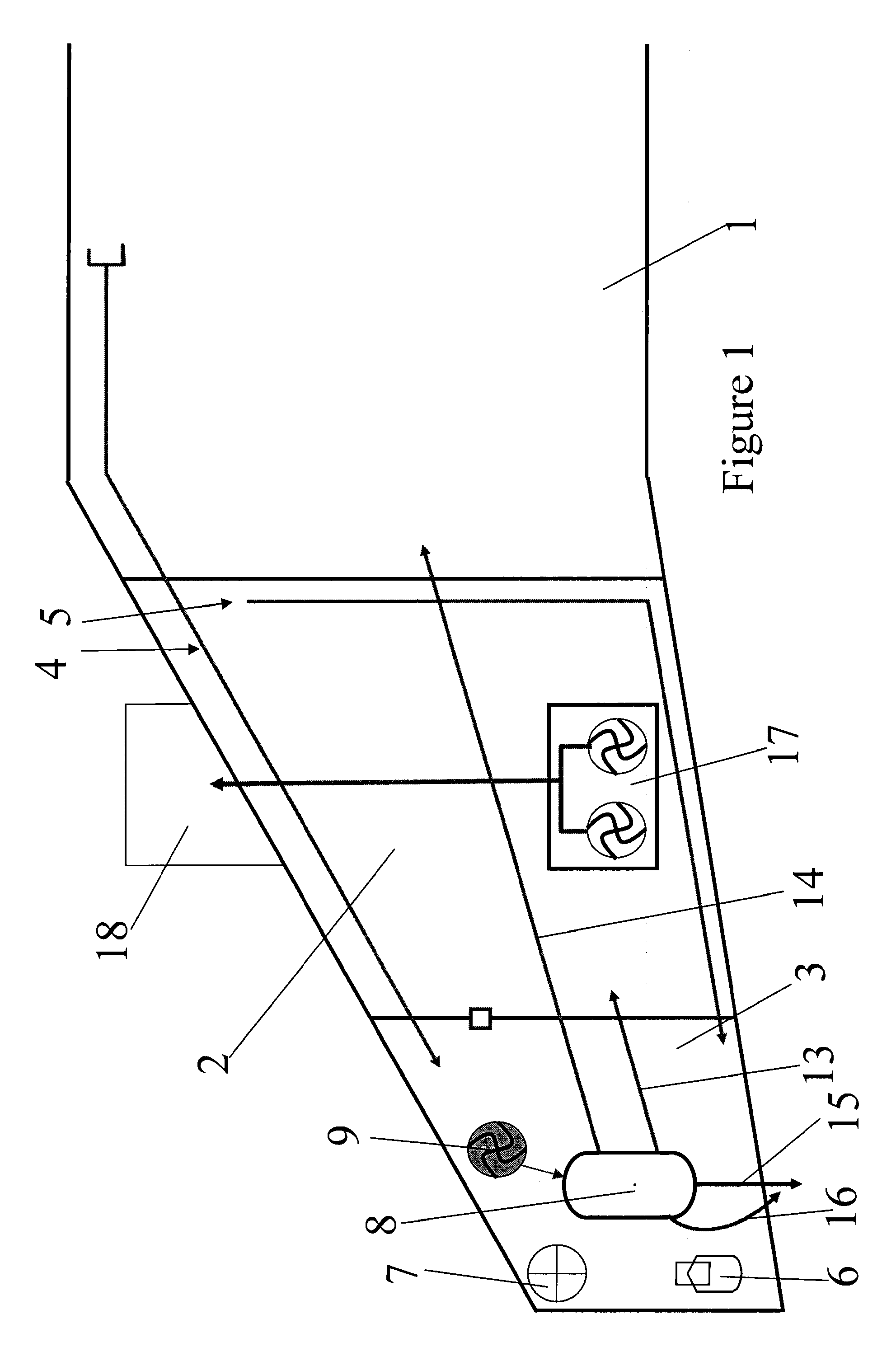

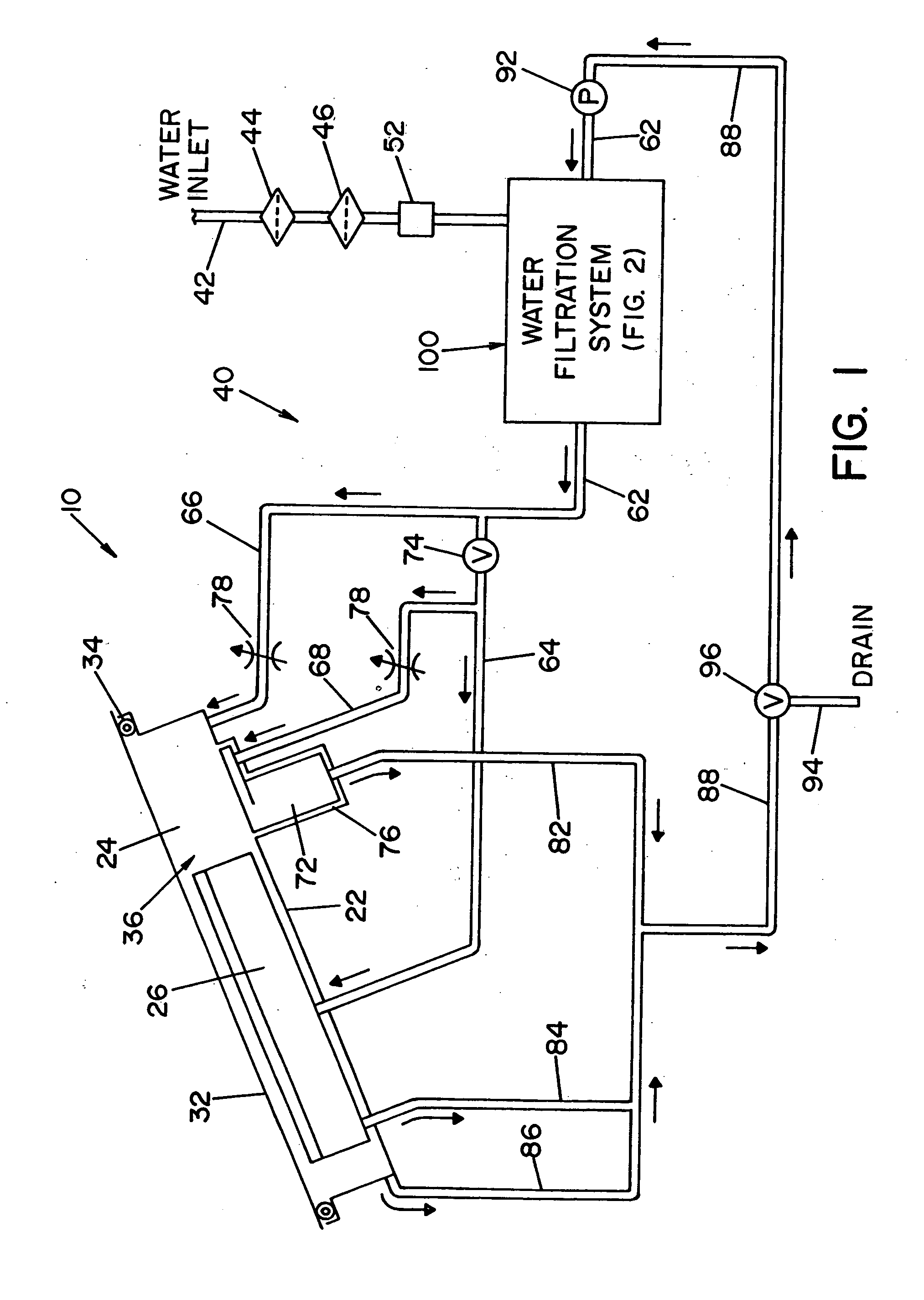

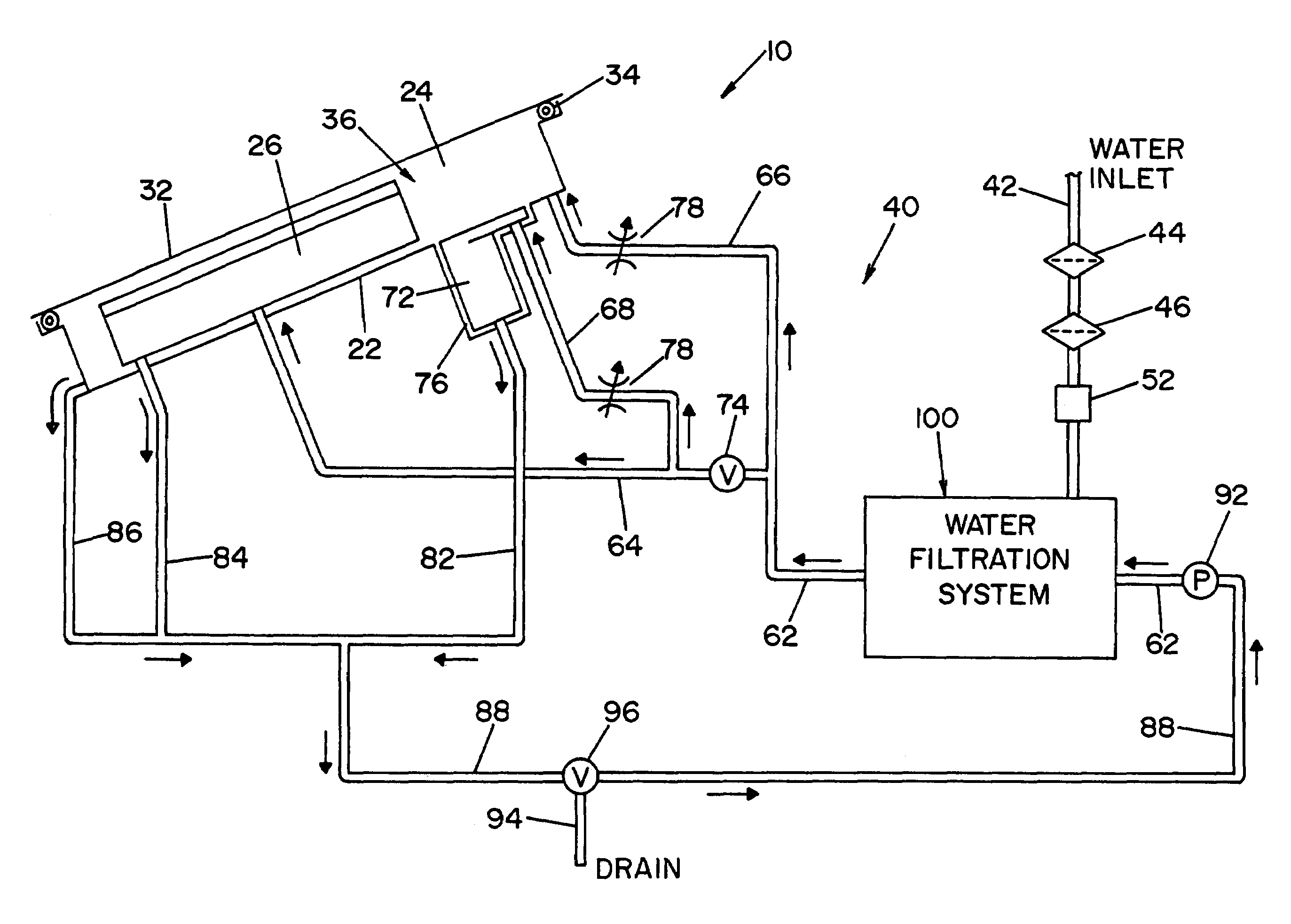

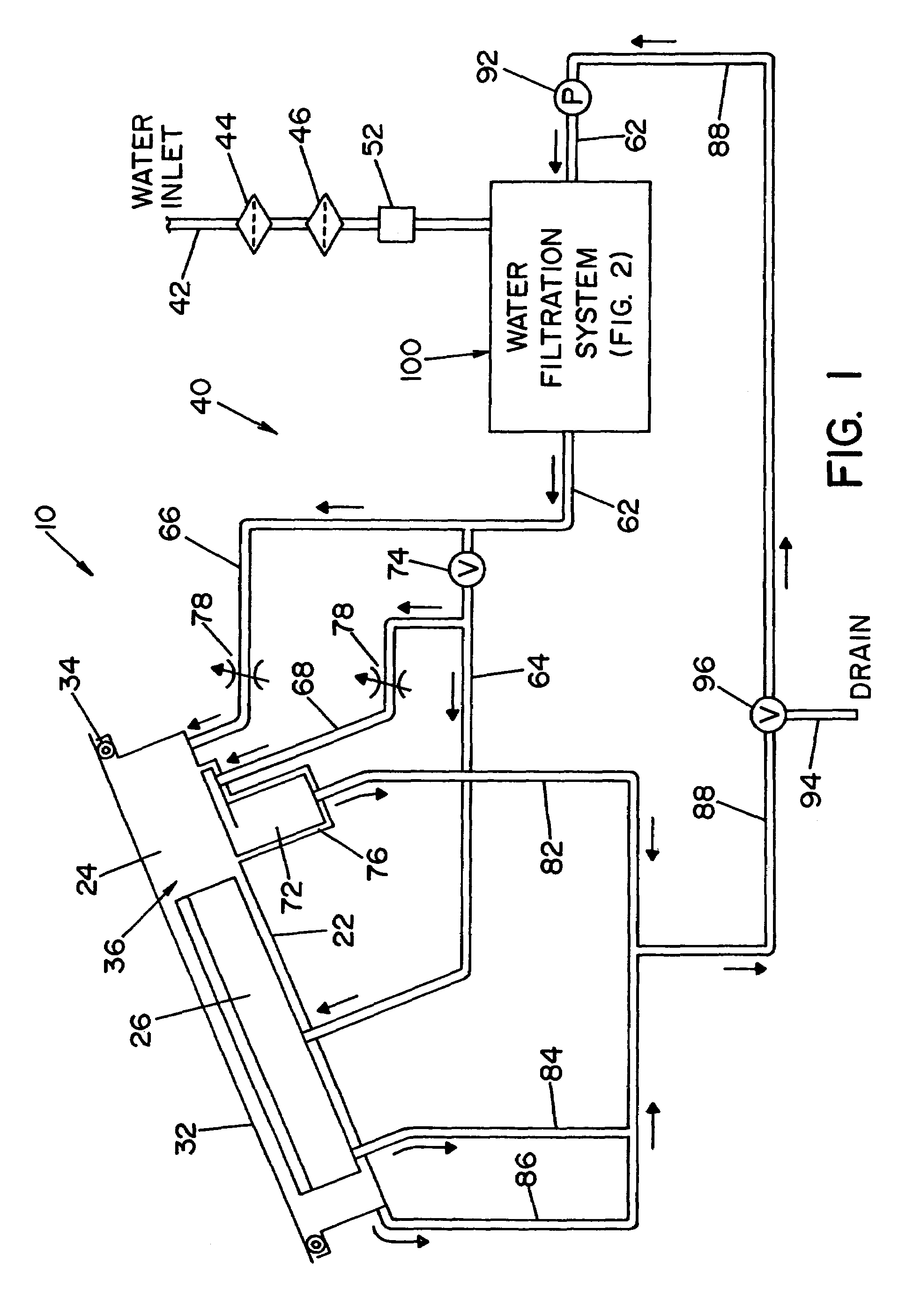

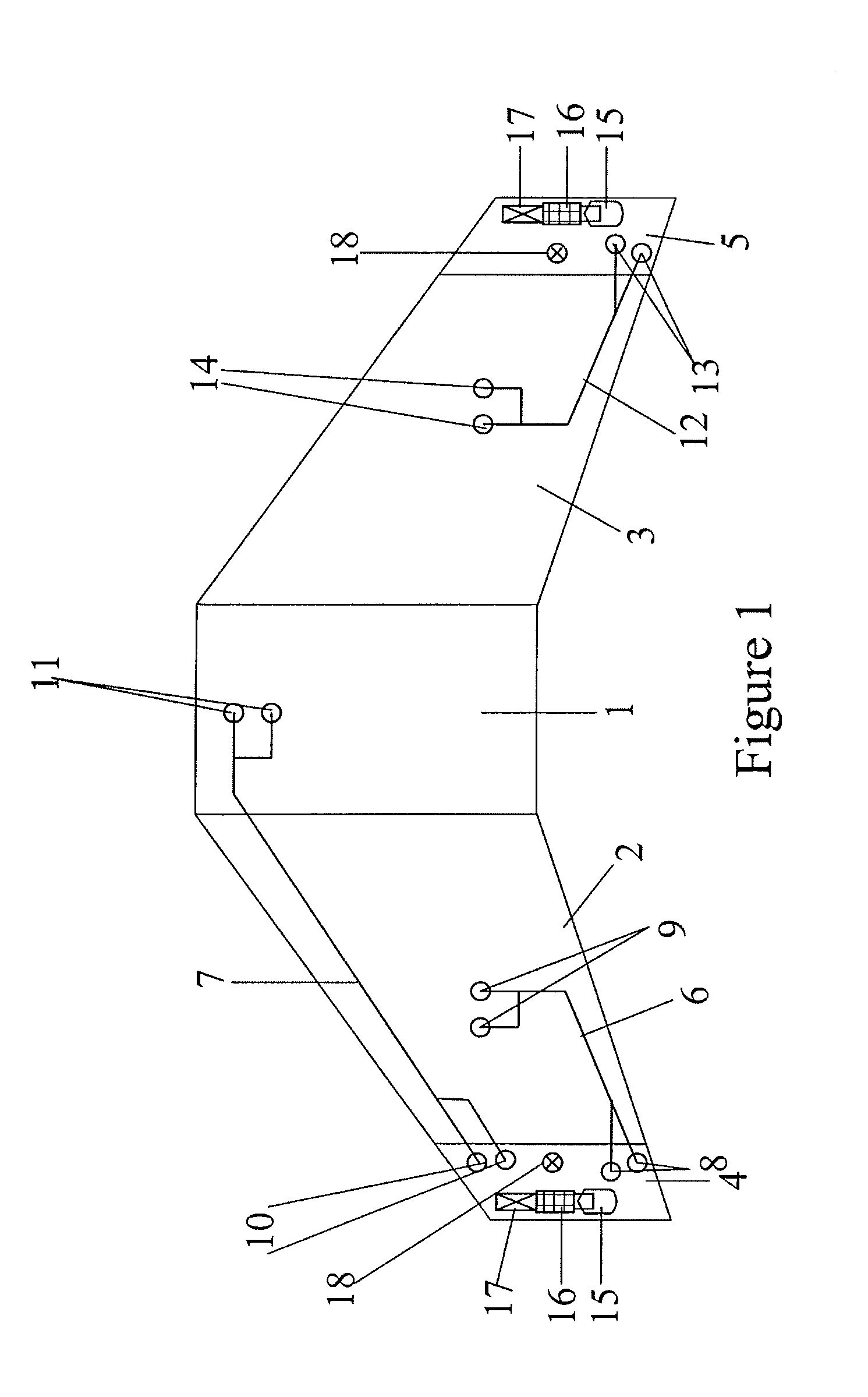

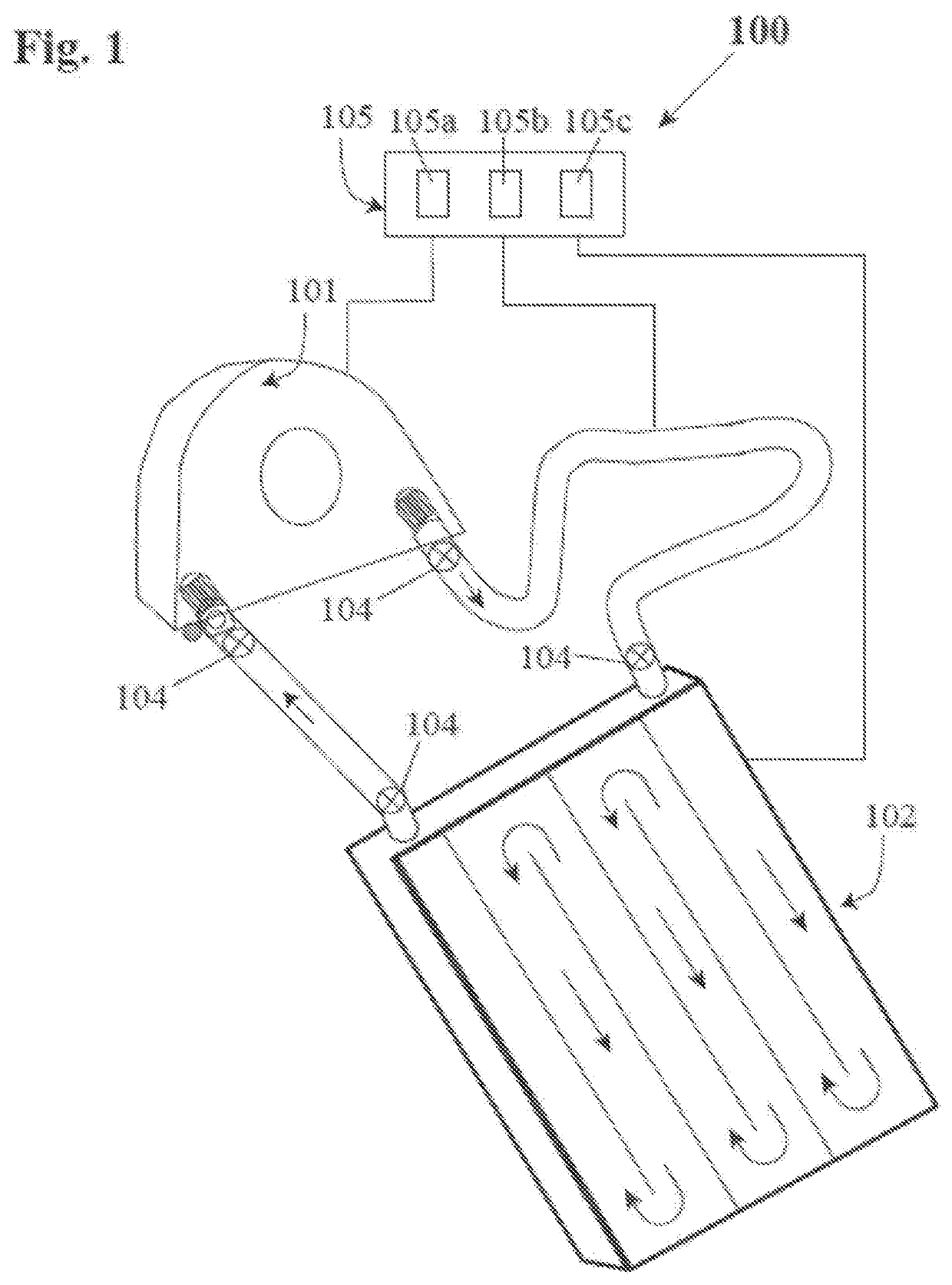

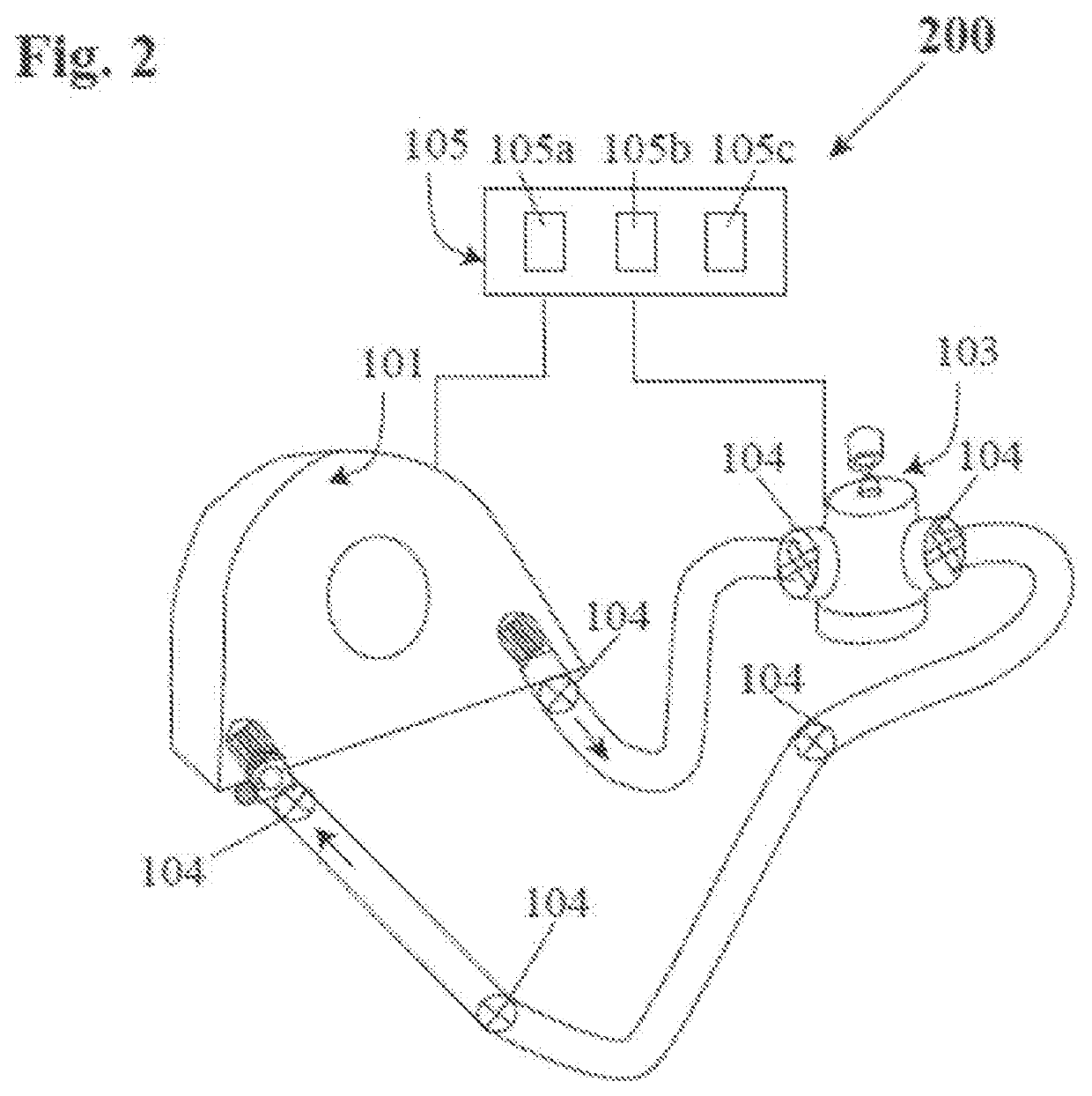

Incentive coupon-based system and apparatus for treating shopping carts

InactiveUS6090218AQuick changeShort timeCash registersService system furnitureHypochloriteSpray nozzle

An incentive-based grocery cart washing and disinfecting system including a consumer special-offer coupon applying apparatus, for use in a batch or continuous process comprising a housing having at least one pipe manifold with nozzles positioned therein to provide at least one treatment zone selected from pre-wash, wash, disinfecting, and rinse zones. In addition, blown air water-stripping / drying zones may be provided, with a heating source to assist drying. Following drying, a strip of specially adapted grocery coupons is optionally applied to the grocery cart handle, so that the coupons can be redeemed by customers during their subsequent shopping. The housing is generally a linear tunnel permitting access of soiled carts at one end and removal of the clean, disinfected carts at the other end. A cart pusher system may be employed to transport the carts through the tunnel either singly or in nested groups. A convenient antimicrobial disinfecting solution is a water solution of hypochlorite. A single zone system is disclosed in which in a selected, optionally preprogrammed, sequence of application of pre-wash, wash, rinse, and disinfecting fluids are delivered to selected surfaces of the cart, followed by blown air, preferably heated, for stripping / drying,. The coupon strip comprises a leader portion and a coupon portion, and the leader can be wrapped and fixed around the grocery cart handle manually or by means of the automated machinery described. The system of the invention may be a fixed or mobile system, with the use preferably being on site at stores.

Owner:DM & BB

Method and composition for washing poultry during processing

InactiveUS7381439B2Reduce Microbial ContaminationHigh degreeBiocideAlcoholic beverage preparationMachining processBiology

The present invention relates to compositions including peroxyacetic acid and peroxyoctanoic acid and methods for reducing microbial contamination on poultry. The methods include the step of applying a mixed peroxycarboxylic acid composition to poultry.

Owner:ECOLAB USA INC

Antimicrobial composition for pre-harvest and post-harvest treatment of plants and animals

ActiveUS7192618B2Minimize growth and spreadReduce Microbial ContaminationHeavy metal active ingredientsFatty acid chemical modificationFood additiveDisinfectant

Owner:CMS TECH INC +1

Method and composition for washing poultry during processing

InactiveUS7316824B2Reduce Microbial ContaminationHigh degreeBiocideAlcoholic beverage preparationMachining processNuclear chemistry

The present invention relates to compositions including peroxyacetic acid and peroxyoctanoic acid and methods for reducing microbial contamination on poultry. The methods include the step of applying a mixed peroxycarboxylic acid composition to poultry.

Owner:ECOLAB USA INC

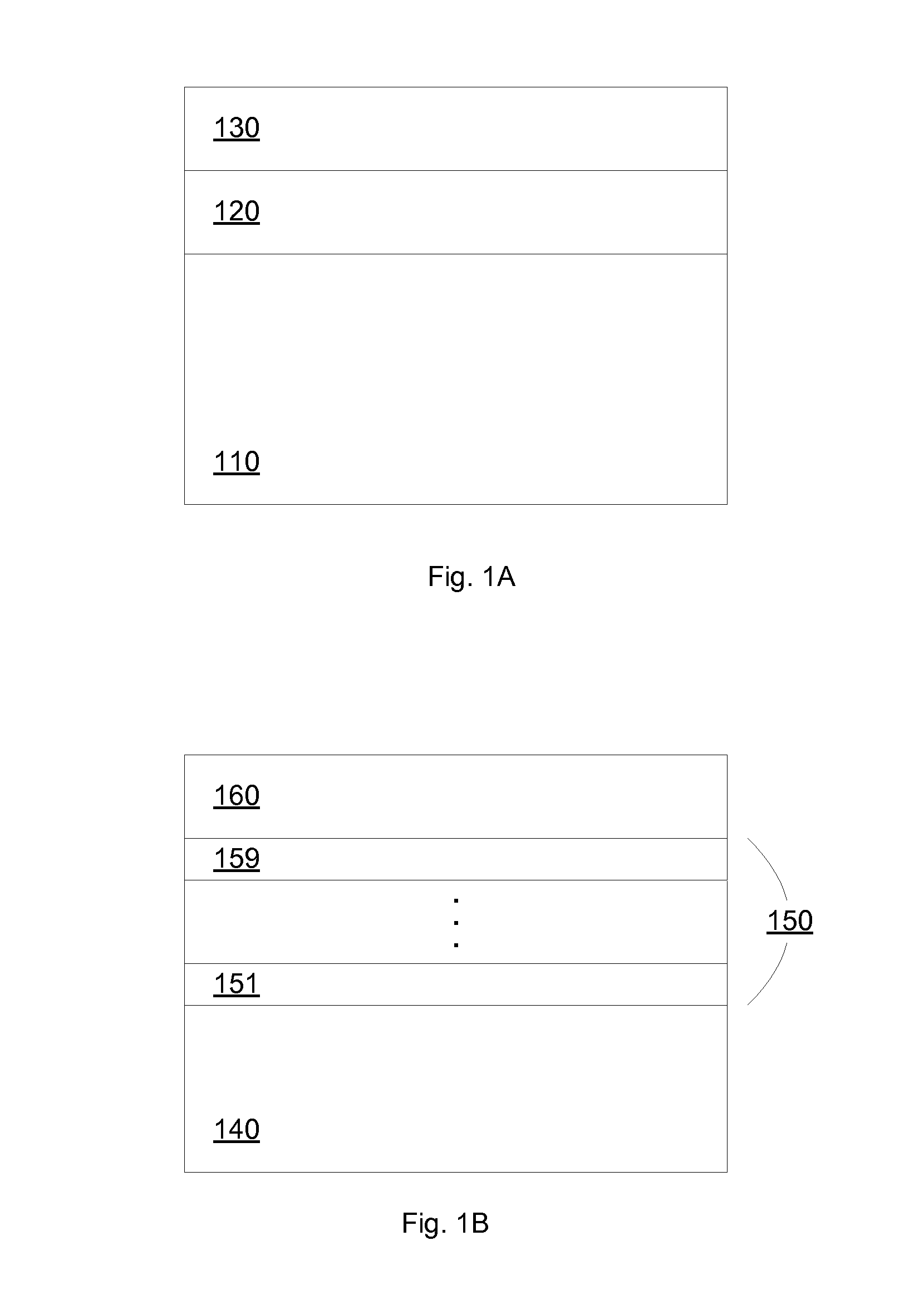

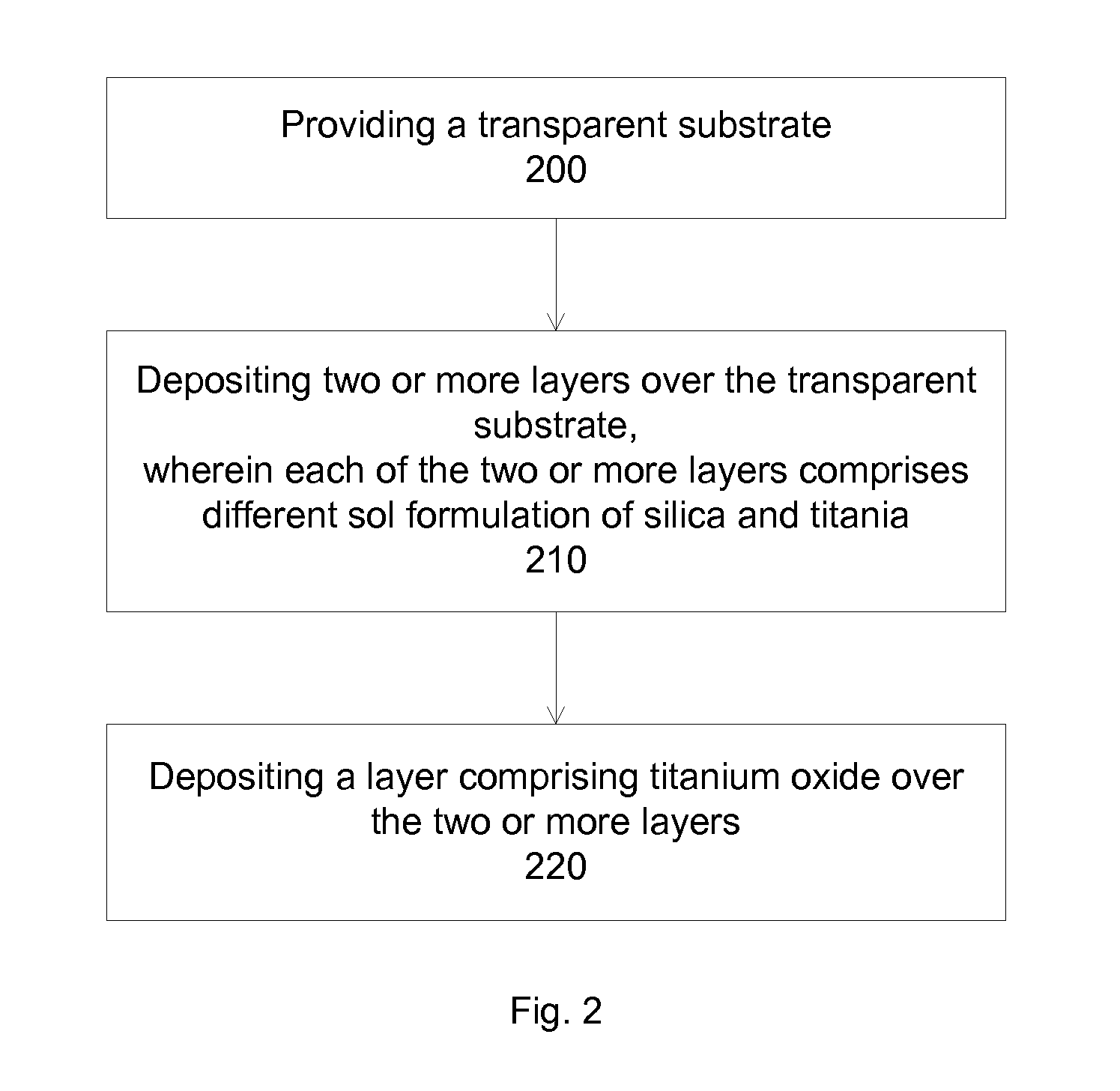

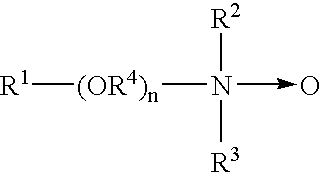

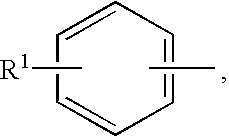

Antireflective coatings with self-cleaning, moisture resistance and antimicrobial properties

InactiveUS20140004334A1Reduce Microbial ContaminationTrend downLayered productsPretreated surfacesPorosityRefractive index

Coated article having antireflective property together with self cleaning, moisture resistance and antimicrobial properties can be prepared with a topmost layer of titanium oxide on an antireflective layer, which can be formed by a sol-gel process. The antireflective layer can comprise a porosity forming agent, or an alkyltrialkoxysilane-based binder. The antireflective coating can comprise silica and titania components, with pores to achieve low index of refraction and titania to achieve self-cleaning and antimicrobial properties.

Owner:GUARDIAN GLASS LLC

Microbiological control in animal processing

InactiveUS6919364B2Reduce Microbial ContaminationProduced economicallyOrganic active ingredientsBiocideWater chlorinationZoology

Fecal bacterial contamination in an animal is reduced by providing it with drinking water containing a microbiocidally-effective amount of halogen-based microbiocide resulting from mixing with water (A) a product formed in water from (i) bromine, chlorine, or bromine chloride, or any two or more thereof, (ii) a water-soluble source of sulfamate anion, and (iii) a water-soluble base; (B) at least one 1,3-dihalo-5,5-dialkylhydantoin in which one of the halogen atoms is a chlorine atom and the other is a chlorine or bromine atom, and in which each alkyl group, independently, contains in the range of 1 to about 4 carbon atoms; (C) at least one 1,3-dibromo-5,5-dialkylhydantoin in which one of the alkyl groups is a methyl group and the other alkyl group contains in the range of 1 to about 4 carbon atoms; or (D) any two or more of (A), (B), and (C).

Owner:ALBEMARLE CORP

Methods for washing carcasses, meat, or meat products with medium chain peroxycarboxylic acid compositions

ActiveUS20050153031A1Reduce Microbial ContaminationReduce microbial countMilk preservationAnimal feeding stuffCarboxylic acidChemistry

The present invention relates to methods for reducing microbial contamination on carcass, meat, or meat product; or on surfaces used in processing the carcass, meat, or meat product; employing compositions including medium chain peroxycarboxylic acid, and to the compositions. The methods include applying a medium chain peroxycarboxylic acid composition to carcass, meat, meat product or surface.

Owner:ECOLAB USA INC

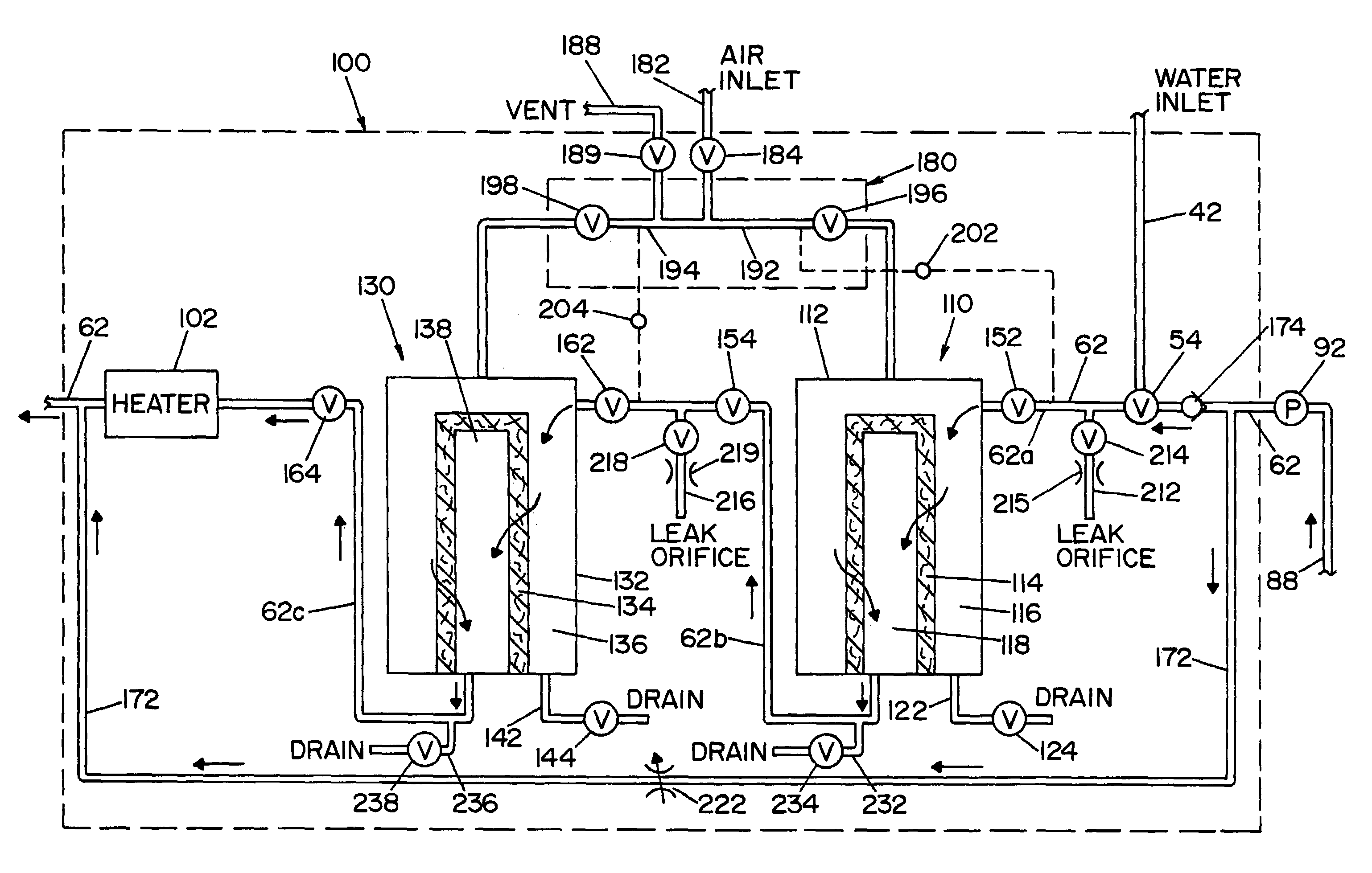

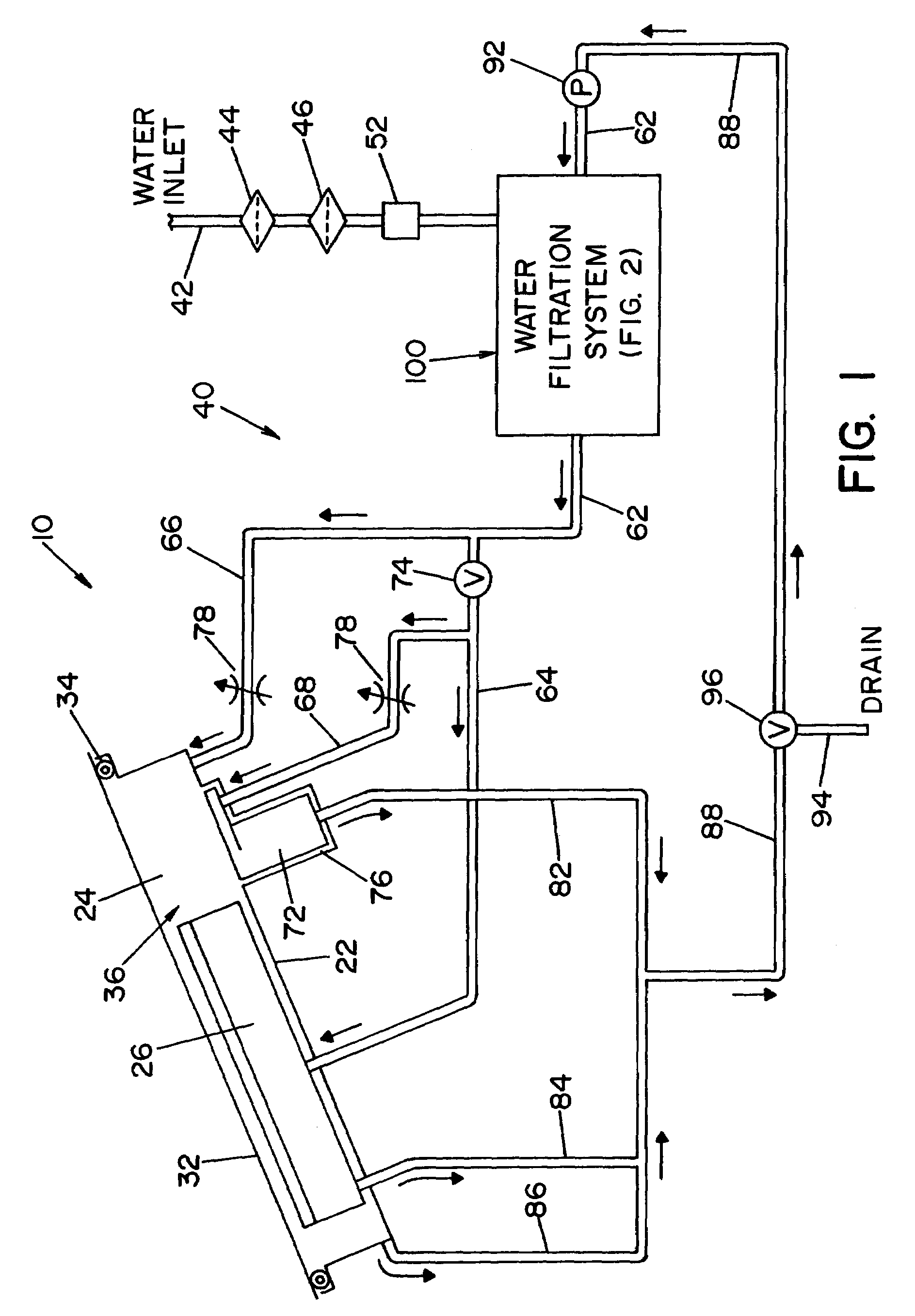

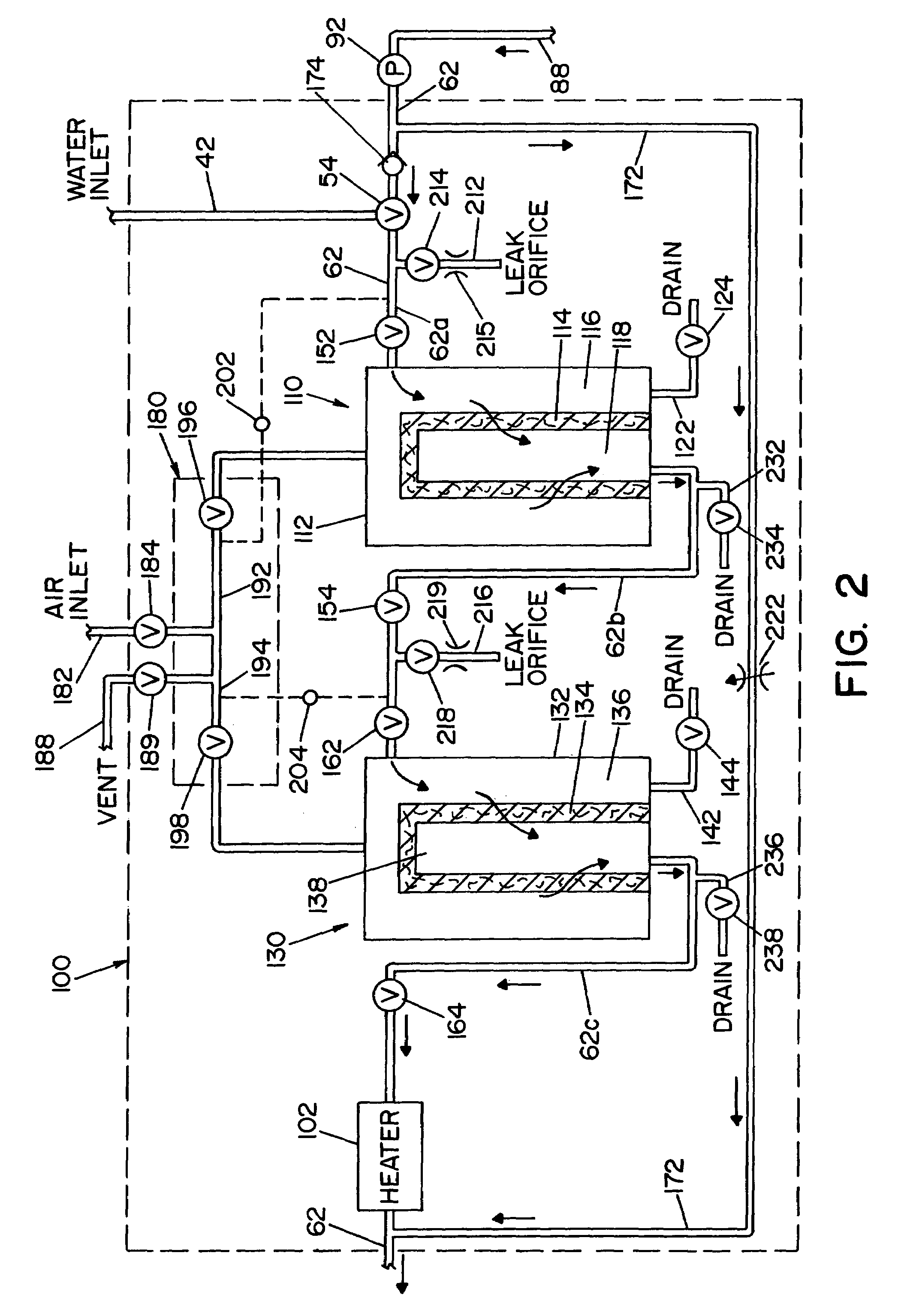

Filter assembly for a reprocessor

InactiveUS7135142B2Reduce Microbial ContaminationReduce the possibilityDetection of fluid at leakage pointTreatment involving filtrationWater useReprocessor

Owner:AMERICAN STERILIZER CO

Method and composition for washing poultry during processing

InactiveUS20050118940A1Reduce Microbial ContaminationHigh degreeBiocideAlcoholic beverage preparationBiologyMicrobial contamination

The present invention relates to compositions including peroxyacetic acid and peroxyoctanoic acid and methods for reducing microbial contamination on poultry. The methods include the step of applying a mixed peroxycarboxylic acid composition to poultry.

Owner:ECOLAB USA INC

Compositions comprising one or more phytosterols and/or phytostanols, or derivatives thereof, and high HLB emulsifiers

ActiveUS20070141224A1Reduce particulate pollutionReduce in quantityMilk preservationSpread compositionsPlant stanolsPhytosterol

A composition for use in foods, beverages and nutraceuticals that includes one or more non-sterol emulsifiers, each having an HLB value of greater than 14 and one or more sterols or stanols or mixtures thereof.

Owner:PHARMACHEM LAB INC

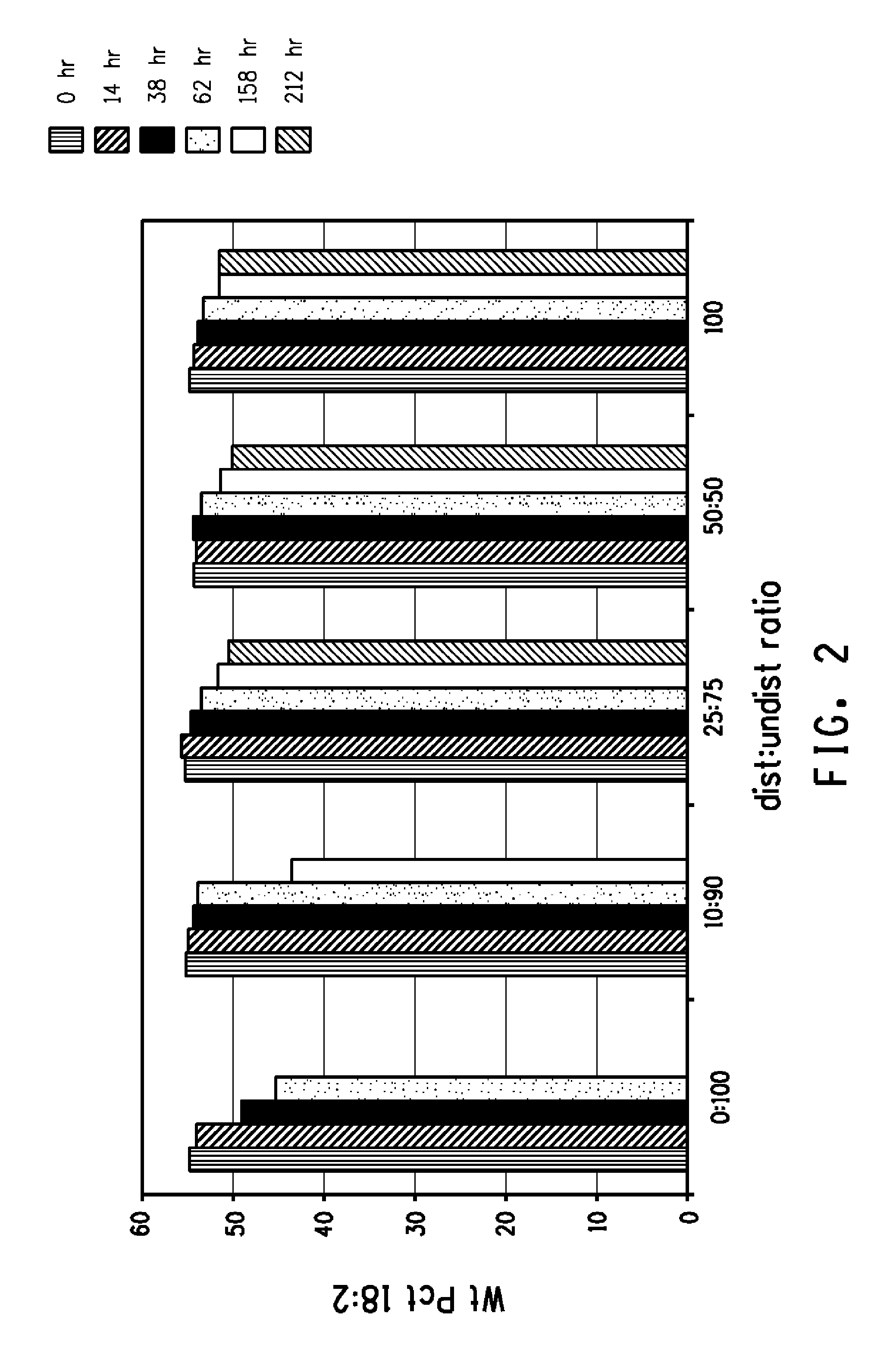

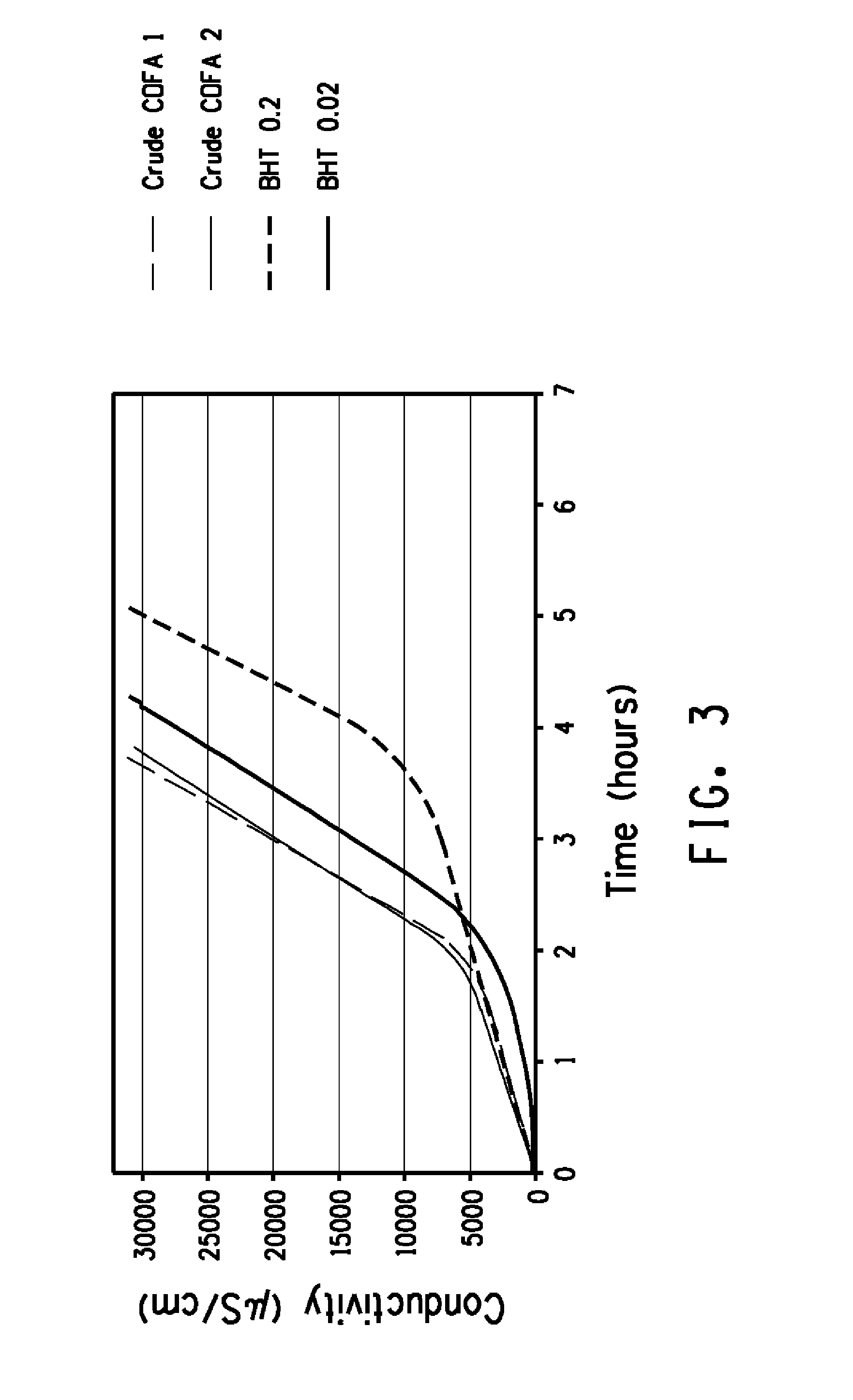

Recyclable extractant compositions

ActiveUS20140094630A1Speed up the extraction processControlling the rate of oxidationOxygen-containing compound preparationOrganic compound preparationMicroorganismChemical compound

Provided herein are processes comprising providing a fermentation medium comprising a fermentable carbon source, a recombinant microorganism comprising an engineered butanol biosynthetic pathway, and butanol; contacting said fermentation medium with an extractant composition comprising an effective amount of antioxidant or antioxidant-like compound, whereby at least a portion of the butanol in the fermentation medium partitions into the extractant; recovering at least a portion of the butanol and extractant composition from the fermentation medium; recycling the extractant composition recovered in (c) one or more times in the fermentation medium; optionally adjusting the effective amount of antioxidant or antioxidant-like compound in the extractant composition, whereby the rate of oxidation or effect of oxidized products in the recycled extractant composition is substantially reduced and / or avoided such that the extractant composition may be recycled.

Owner:GEVO INC

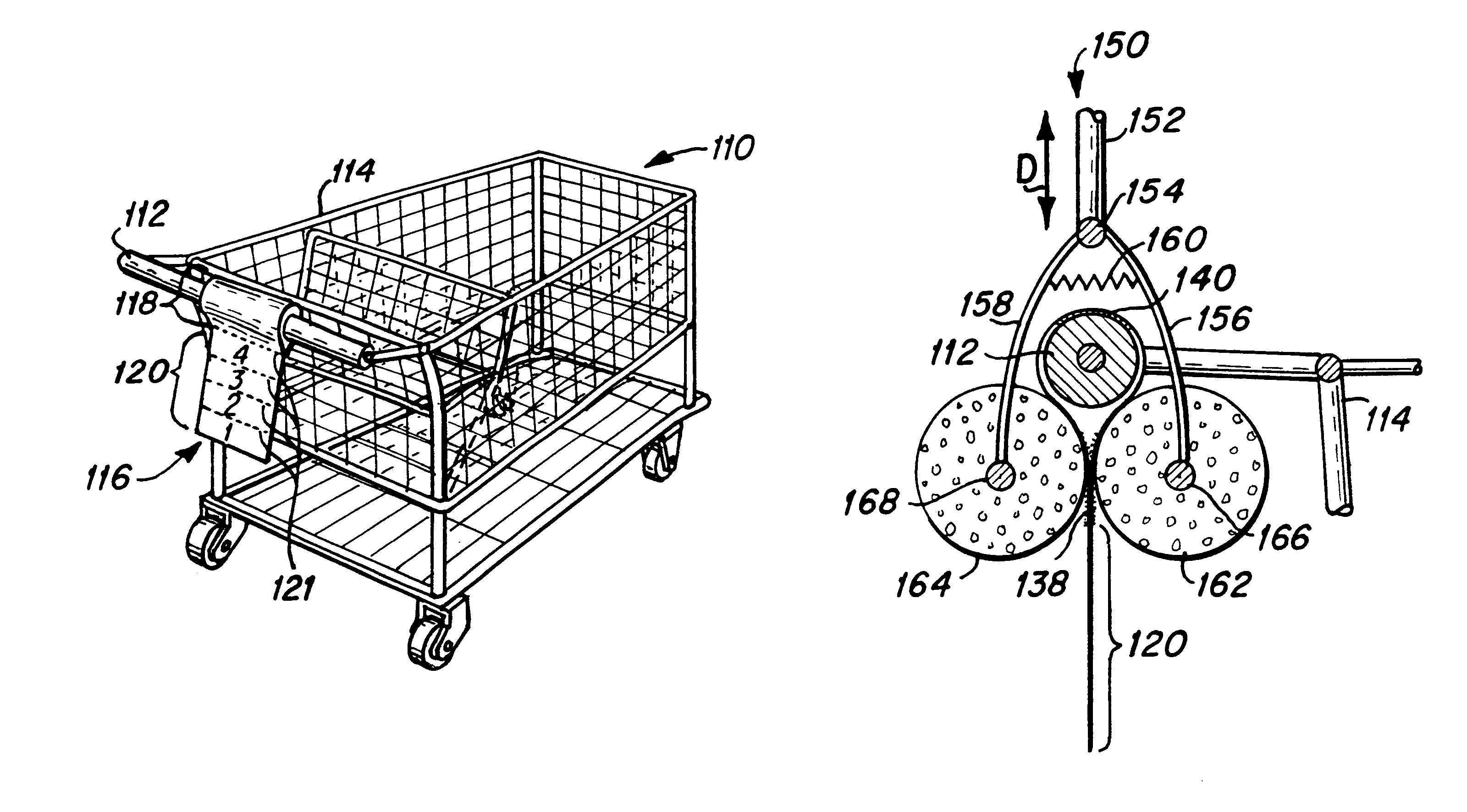

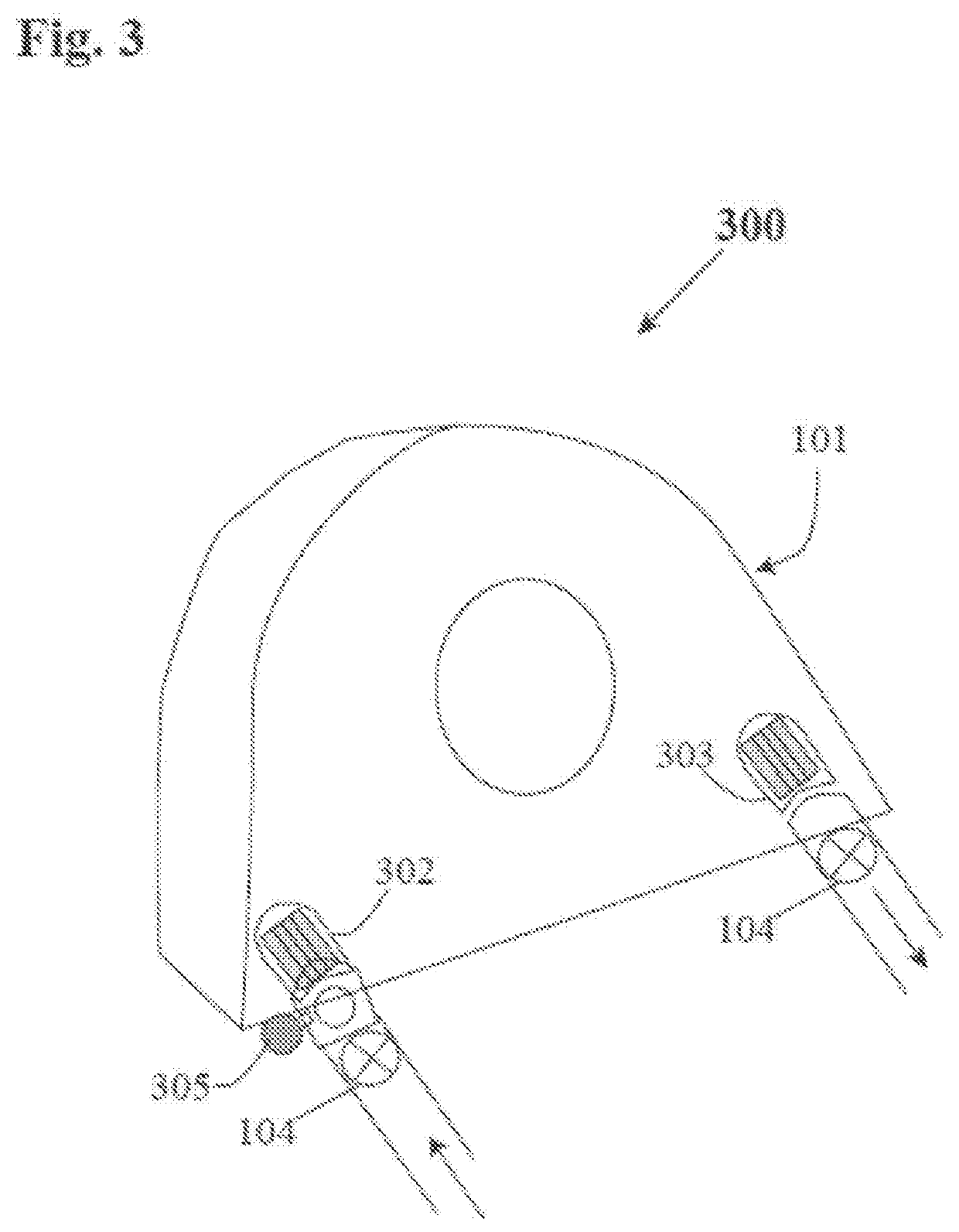

Coupon applicator and methods of applying coupon strips to grocery carts

An incentive-based grocery cart washing and disinfecting system including a consumer special-offer coupon applying apparatus, for use in a batch or continuous process comprising a housing having at least one pipe manifold with nozzles positioned therein to provide at least one treatment zone selected from pre-wash, wash, disinfecting, and rinse zones. In addition, blown air water-stripping / drying zones may be provided, with a heating source to assist drying. Following drying, a strip of specially adapted grocery coupons is optionally applied to the grocery cart handle, so that the coupons can be redeemed by customers during their subsequent shopping. The coupon strip comprises a leader portion and a coupon portion, and the leader can be wrapped and fixed around the grocery cart handle manually or by means of the automated machinery described. The system of the invention may be a fixed or mobile system, with the use preferably being on site at stores.

Owner:DM & BB

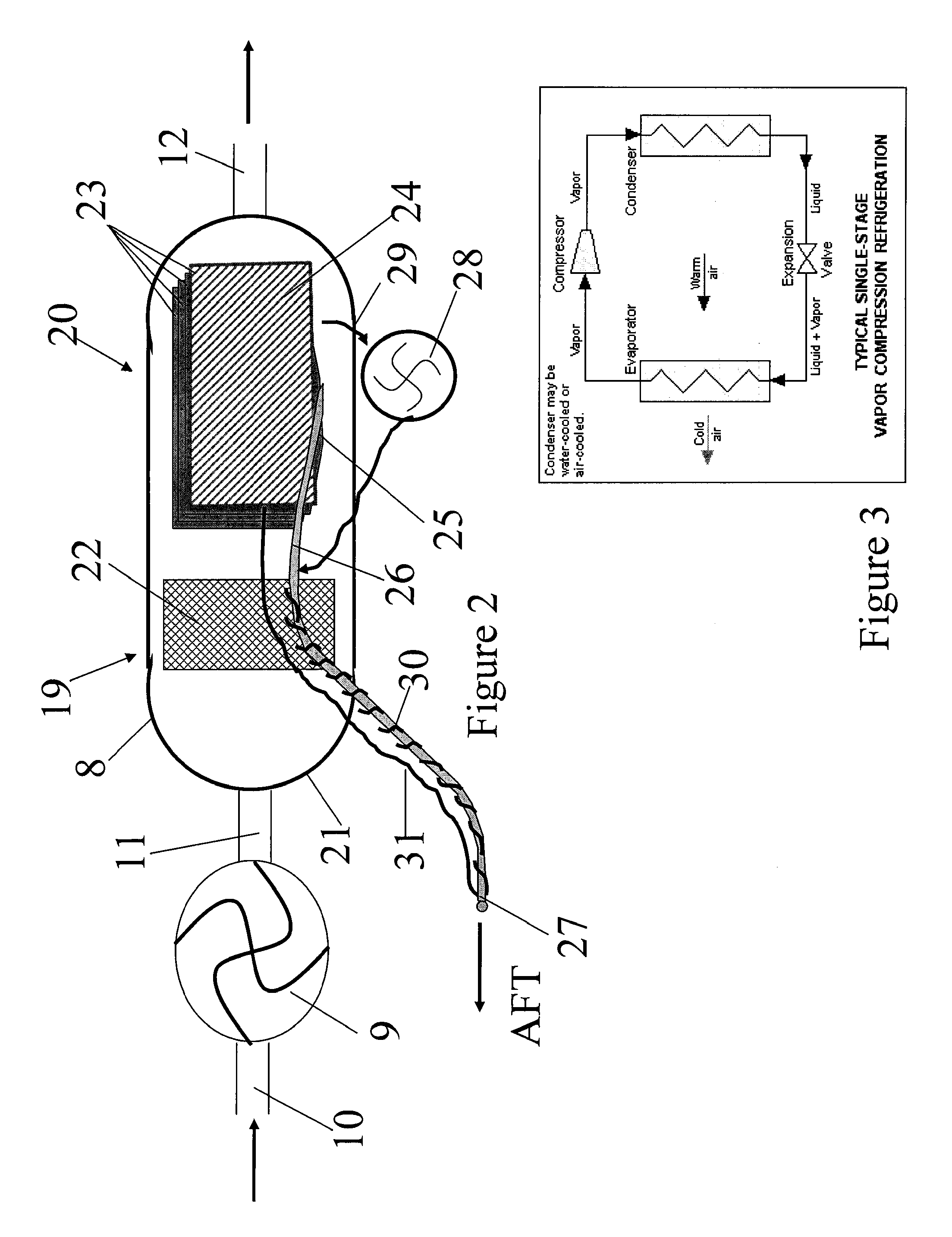

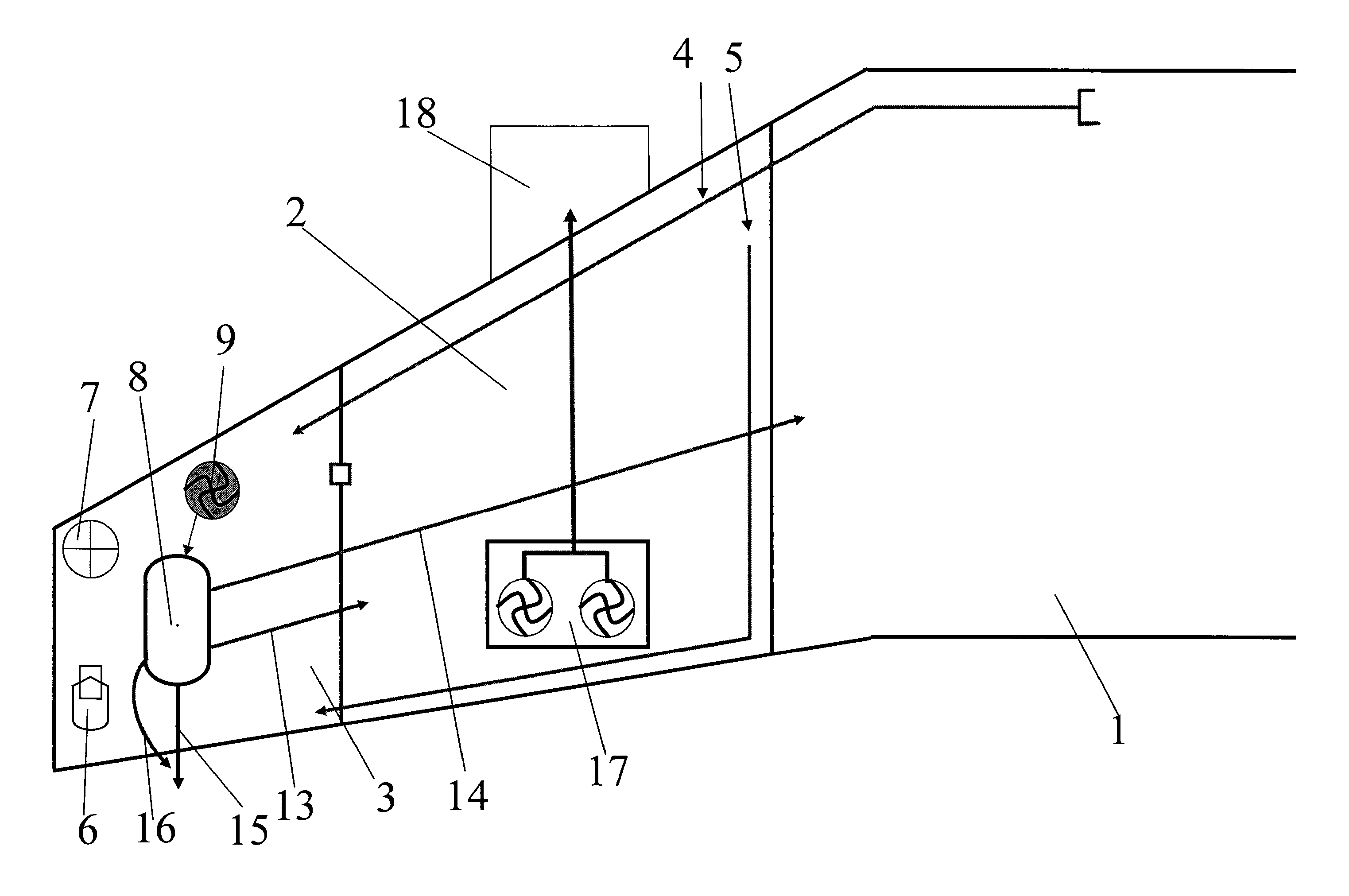

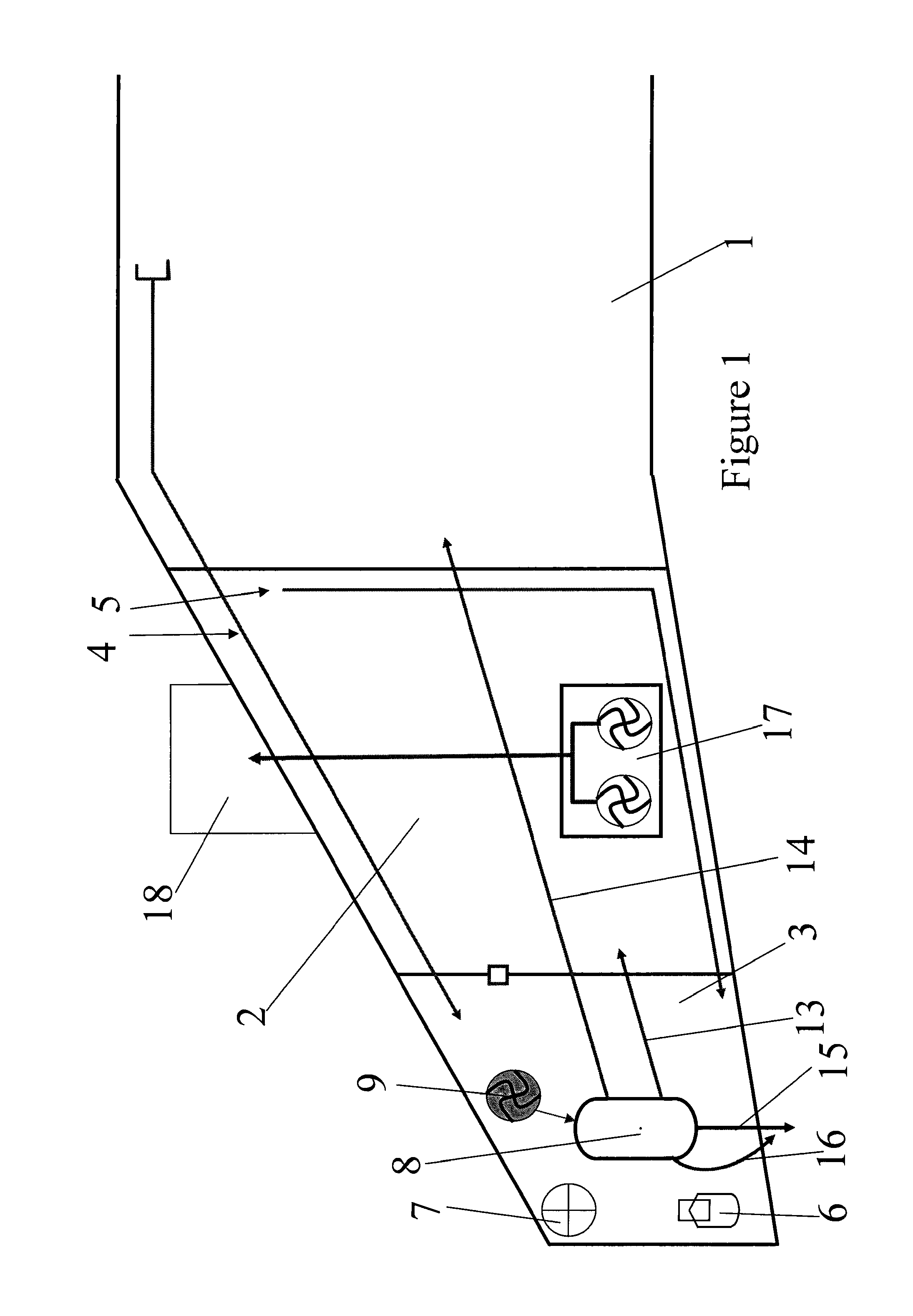

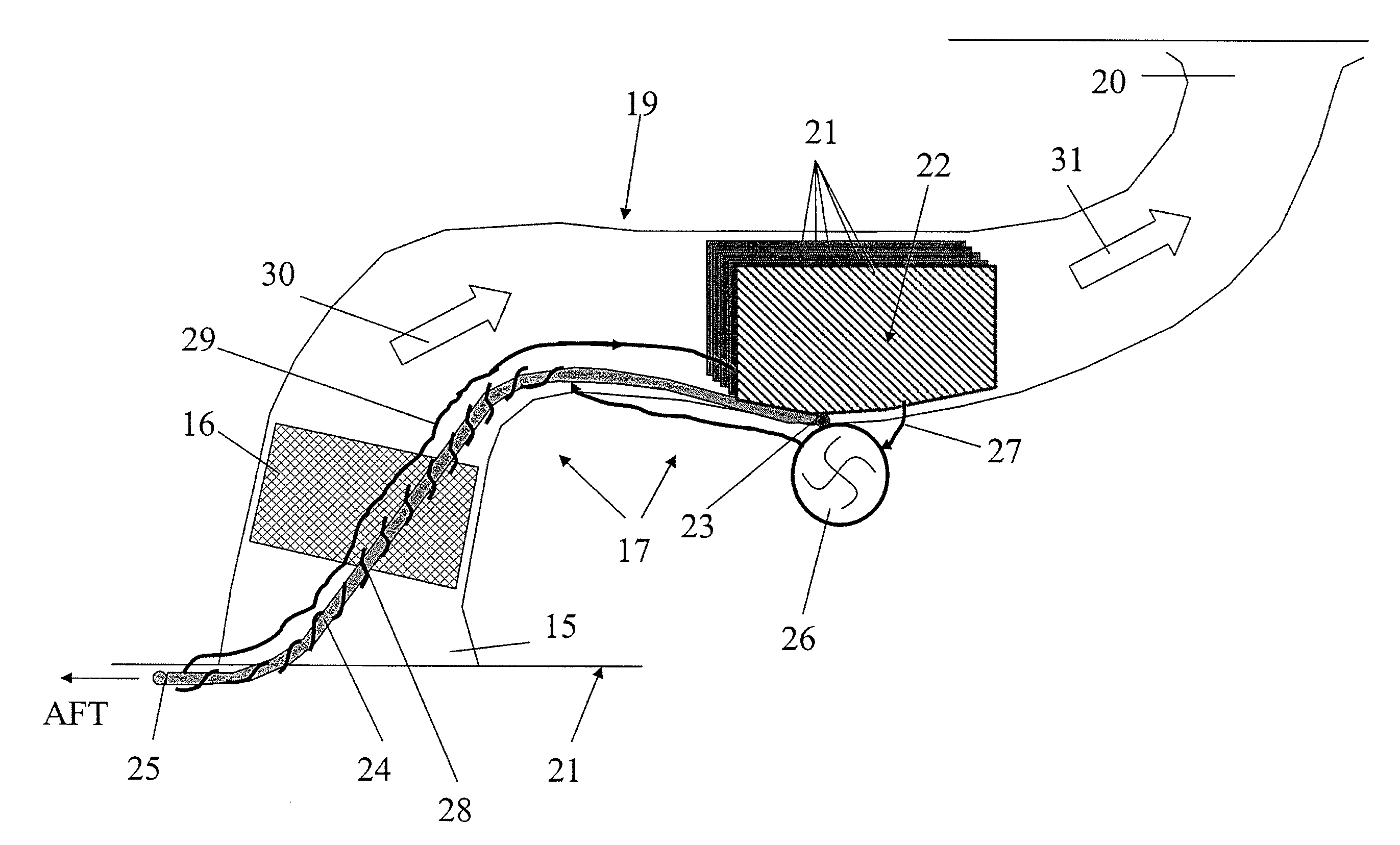

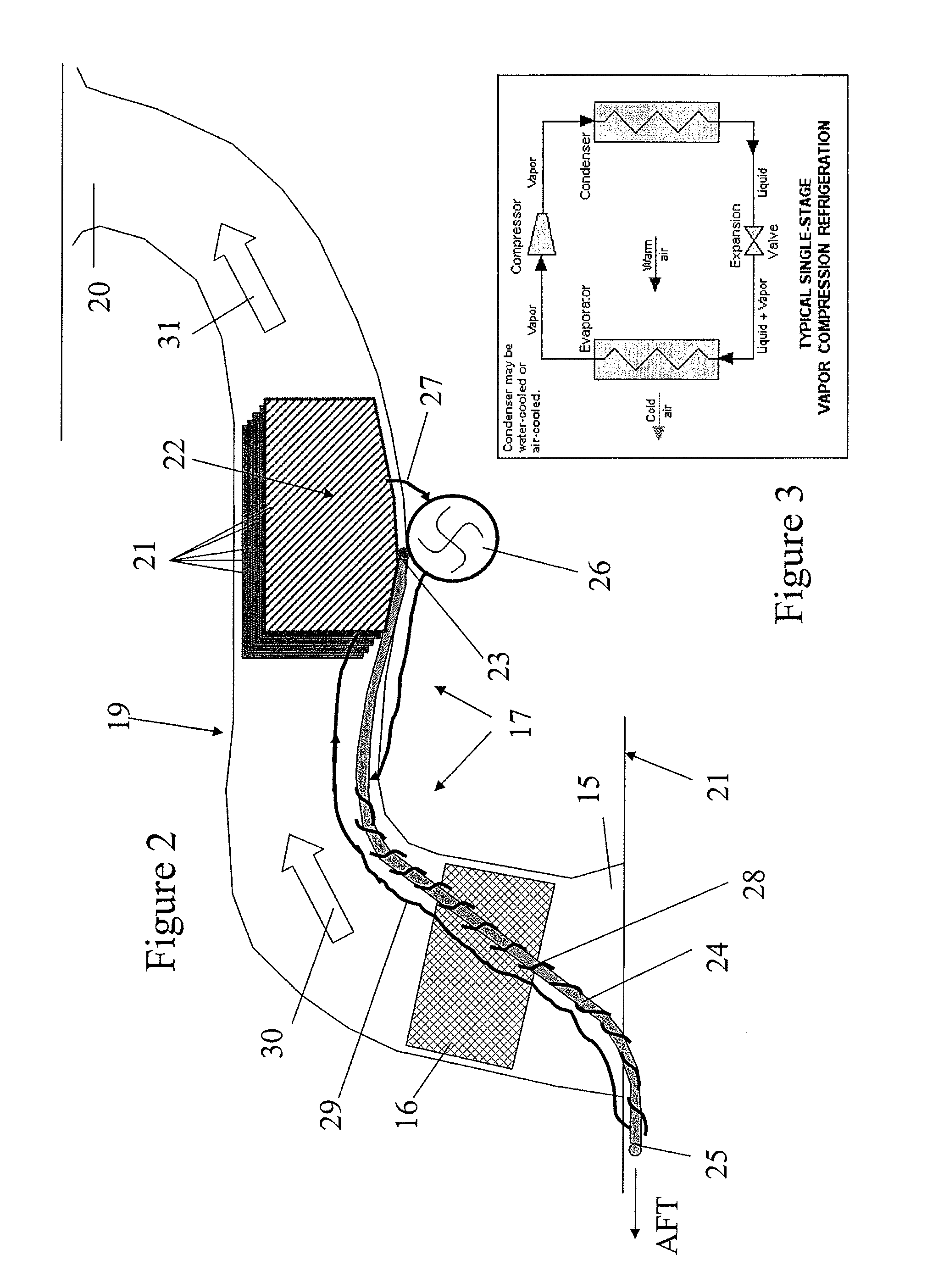

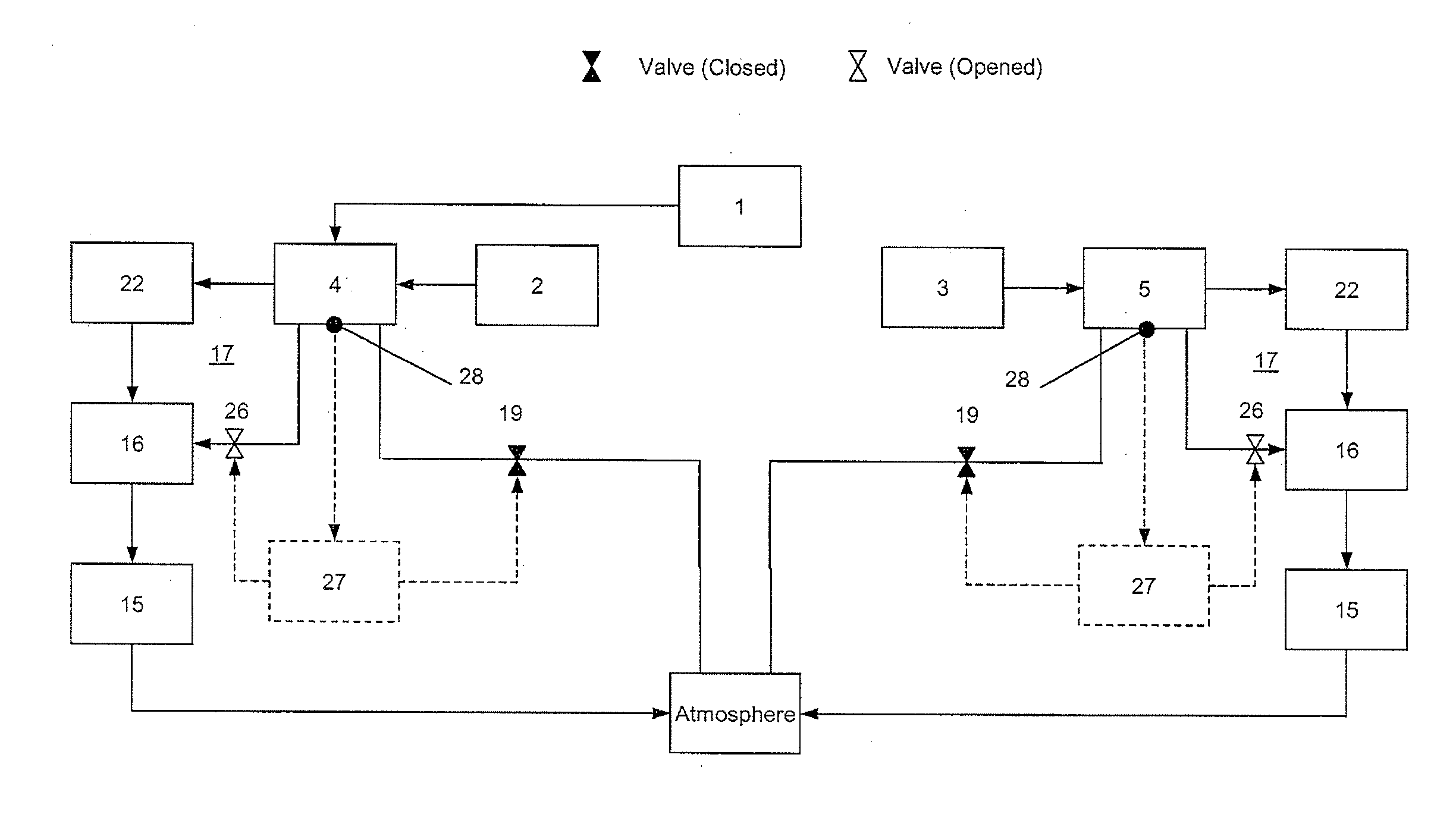

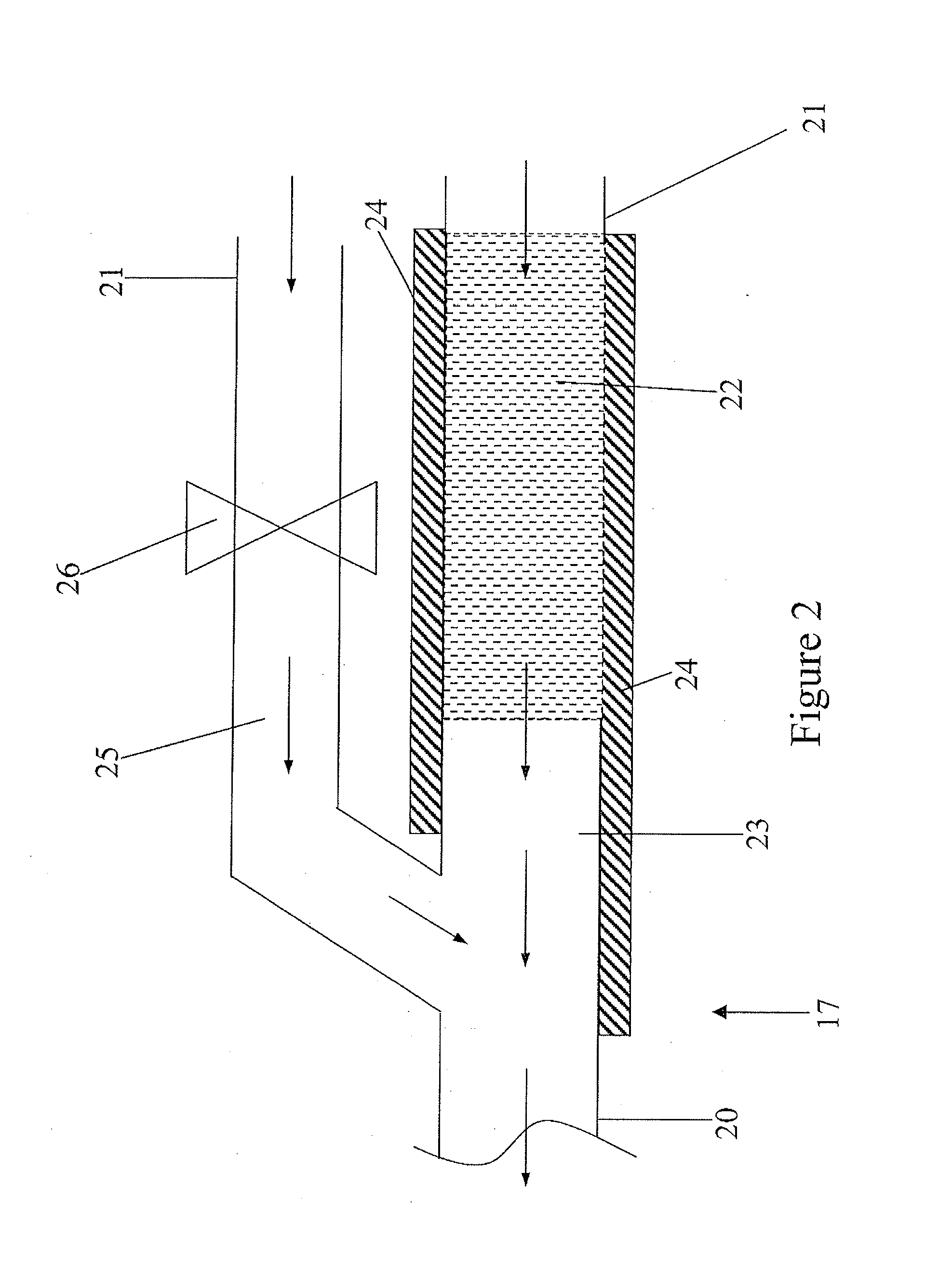

Fuel system and method

ActiveUS20130000142A1Reduce installation costsSaving weightDrying using combination processesGas treatmentInerting systemProcess engineering

A fuel system comprising a fuel tank, a vent tank having a duct open to the ambient atmosphere, a first vent line fluidically connecting the fuel tank ullage to the vent tank, a gas drying system including a pump and a dehumidifying device disposed within the vent tank, and a second vent line fluidically connecting a dry gas outlet of the dehumidifying device to the ullage, wherein the pump is operable to maintain a higher pressure within the ullage than in the vent tank so as to drive vapour rich gas from the ullage into the vent tank via the first vent line. Also, a method of operating the fuel system and a method of retro-fitting the gas drying system in an existing fuel system. The gas drying system may optionally be a gas drying / inerting system.

Owner:AIRBUS OPERATIONS LTD

Fuel system and method

ActiveUS8904669B2Lower levelAccelerate evaporationLiquid degasificationDrying solid materials with heatInerting systemEngineering

A fuel system comprising a fuel tank, a vent tank having a duct open to the ambient atmosphere, a first vent line fluidically connecting the fuel tank ullage to the vent tank, a gas drying system including a pump and a dehumidifying device disposed within the vent tank, and a second vent line fluidically connecting a dry gas outlet of the dehumidifying device to the ullage, wherein the pump is operable to maintain a higher pressure within the ullage than in the vent tank so as to drive vapor rich gas from the ullage into the vent tank via the first vent line. Also, a method of operating the fuel system and a method of retro-fitting the gas drying system in an existing fuel system. The gas drying system may optionally be a gas drying / inerting system.

Owner:AIRBUS OPERATIONS LTD

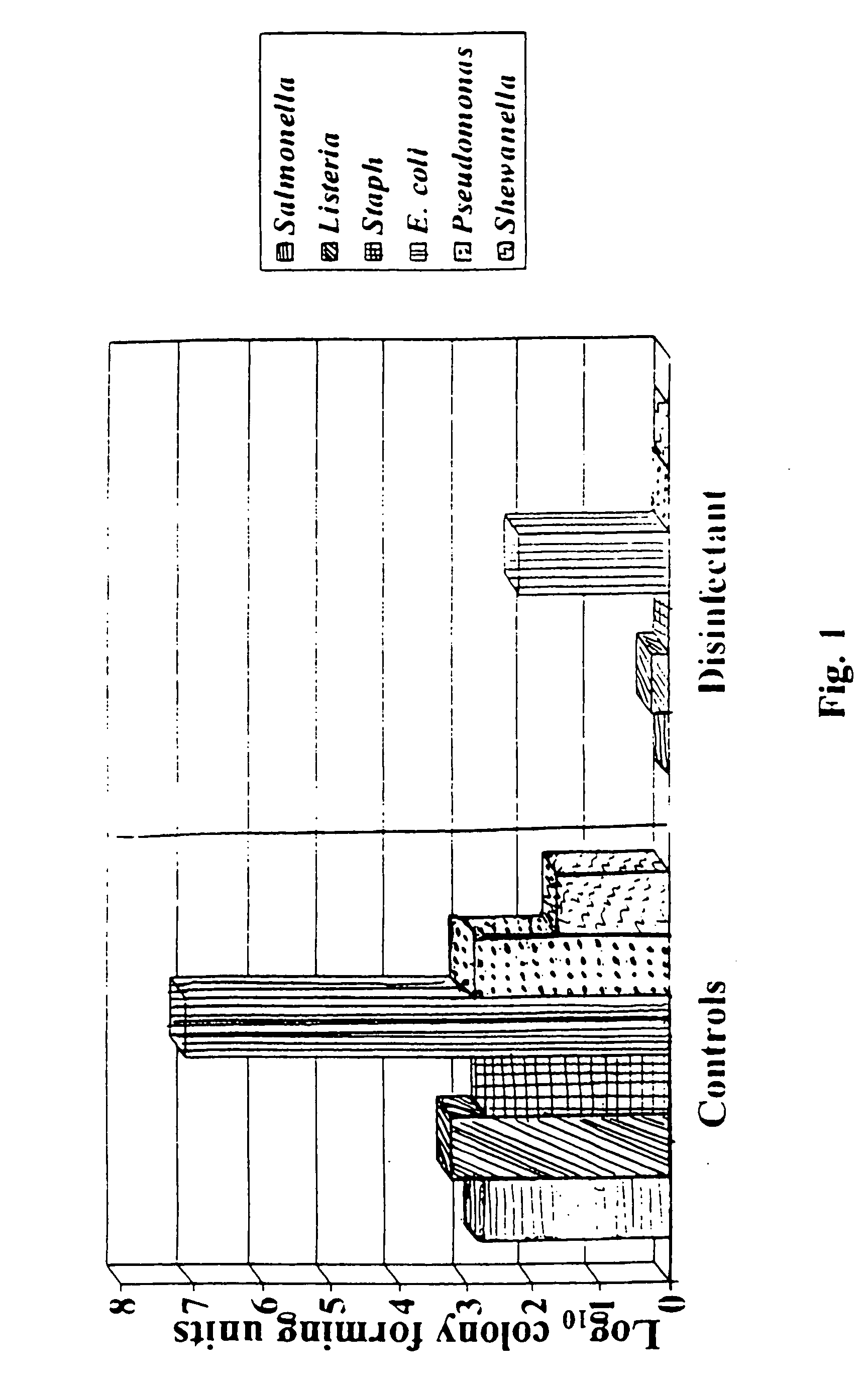

Antimicrobial composition for pre-harvest and post-harvest treatment of plants and animals

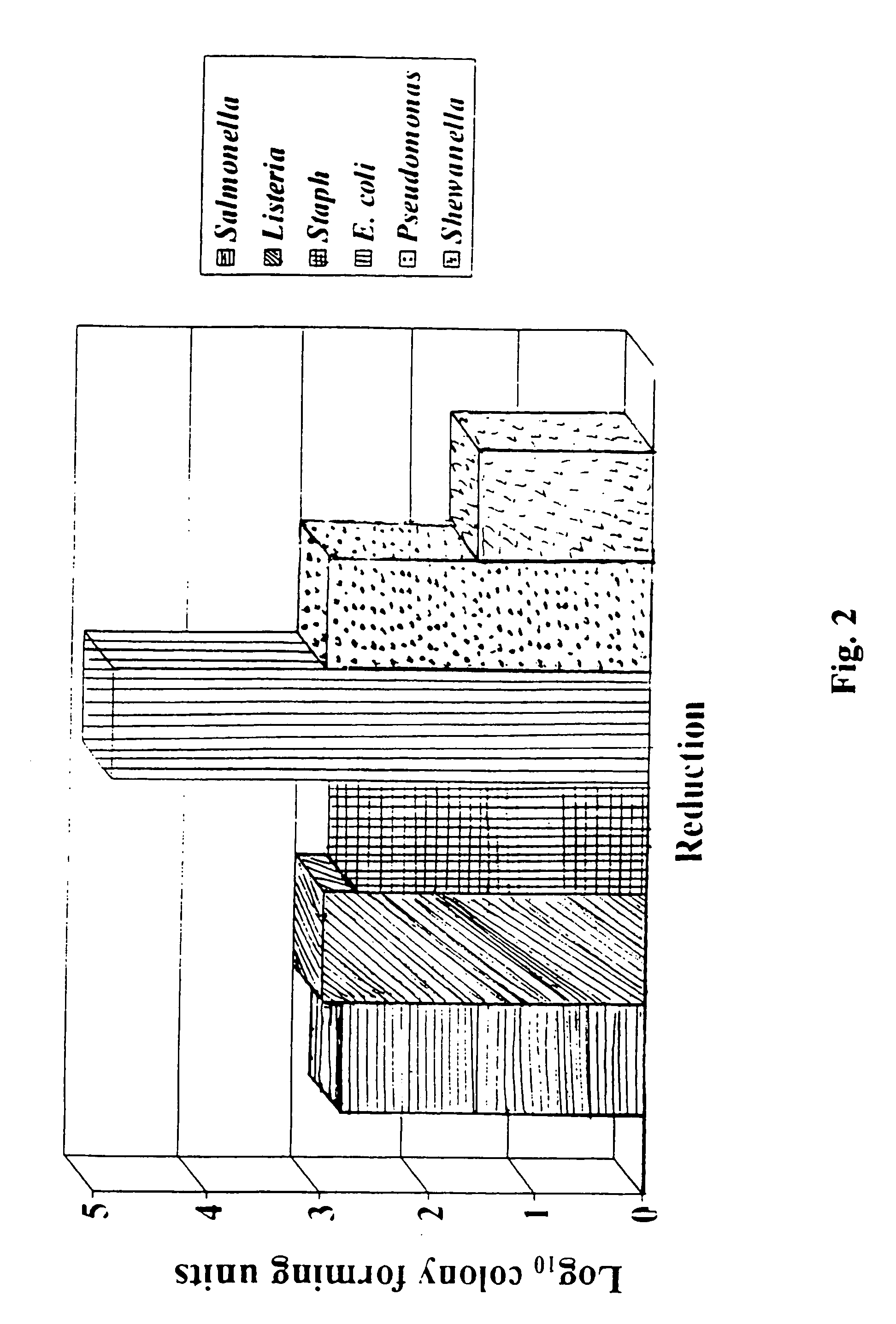

ActiveUS20050191394A1Reduce Microbial ContaminationMinimize growth and spreadHeavy metal active ingredientsFood preservationEscherichia coliFood additive

An antimicrobial, anti-bacterial processing aid, food additive and food ingredient is provided to inhibit cellular growth of known pathogenic, indicator and spoilage organisms, such as salmonella, stahphylococcus, listeria, e coli, and the like. The antimicrobial agent of the present invention is useful as a treatment for animal feed, a treatment for pre-harvest and post-harvest processing of foodstuffs, a treatment for cooked food subject to airborne contaminants and many other conditions in need of disinfectants and sanitizers. One of the primary benefits of the antimicrobial agent is that it inhibits the growth of bacteria that have become antibiotic resistant.

Owner:CMS TECH +1

Methods for washing poultry during processing with medium chain peroxycarboxylic acid compositions

InactiveUS20050163896A1Reduce Microbial ContaminationReduce microbial countBiocideOrganic/inorganic per-compounds compounding agentsMicroorganismCarboxylic acid

Owner:ECOLAB USA INC

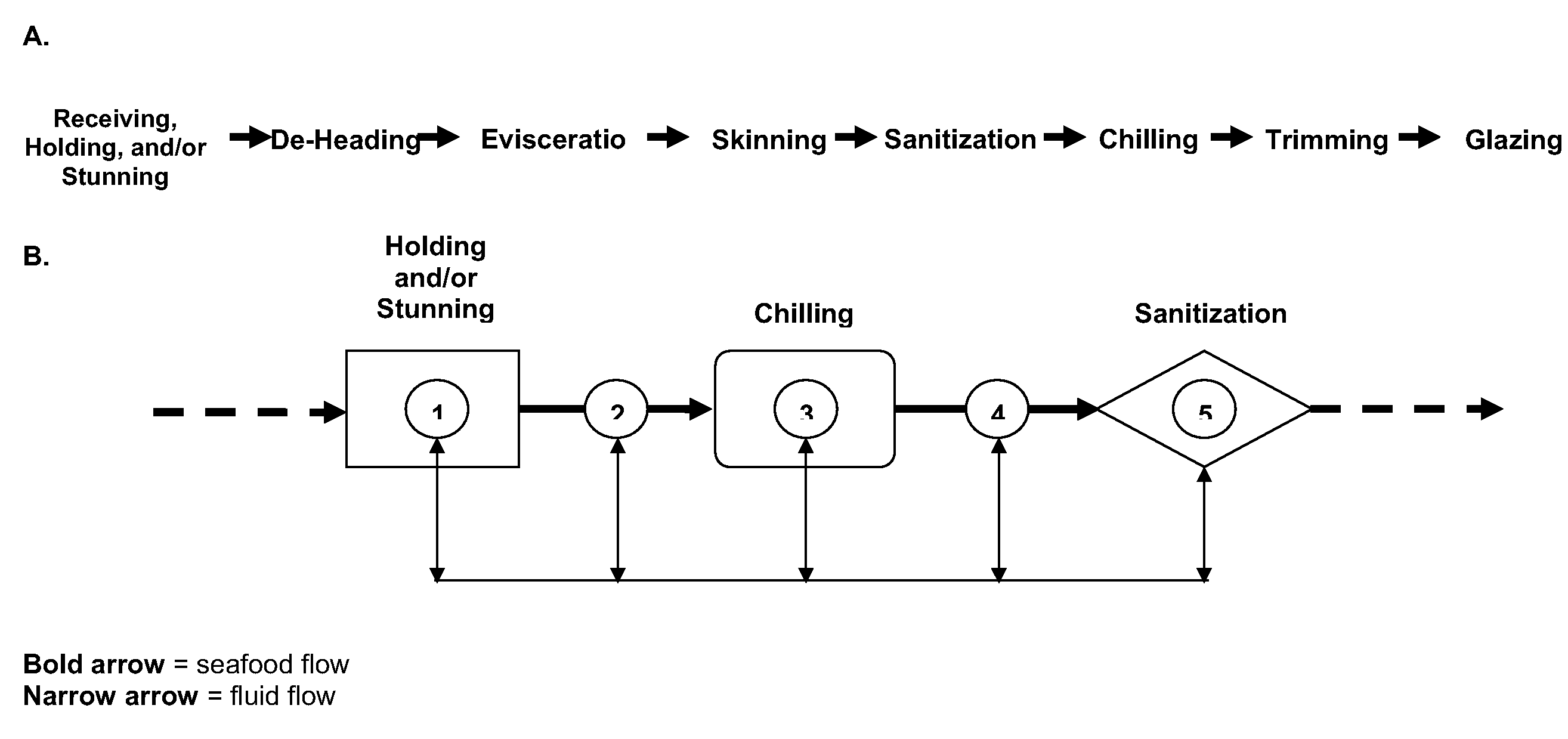

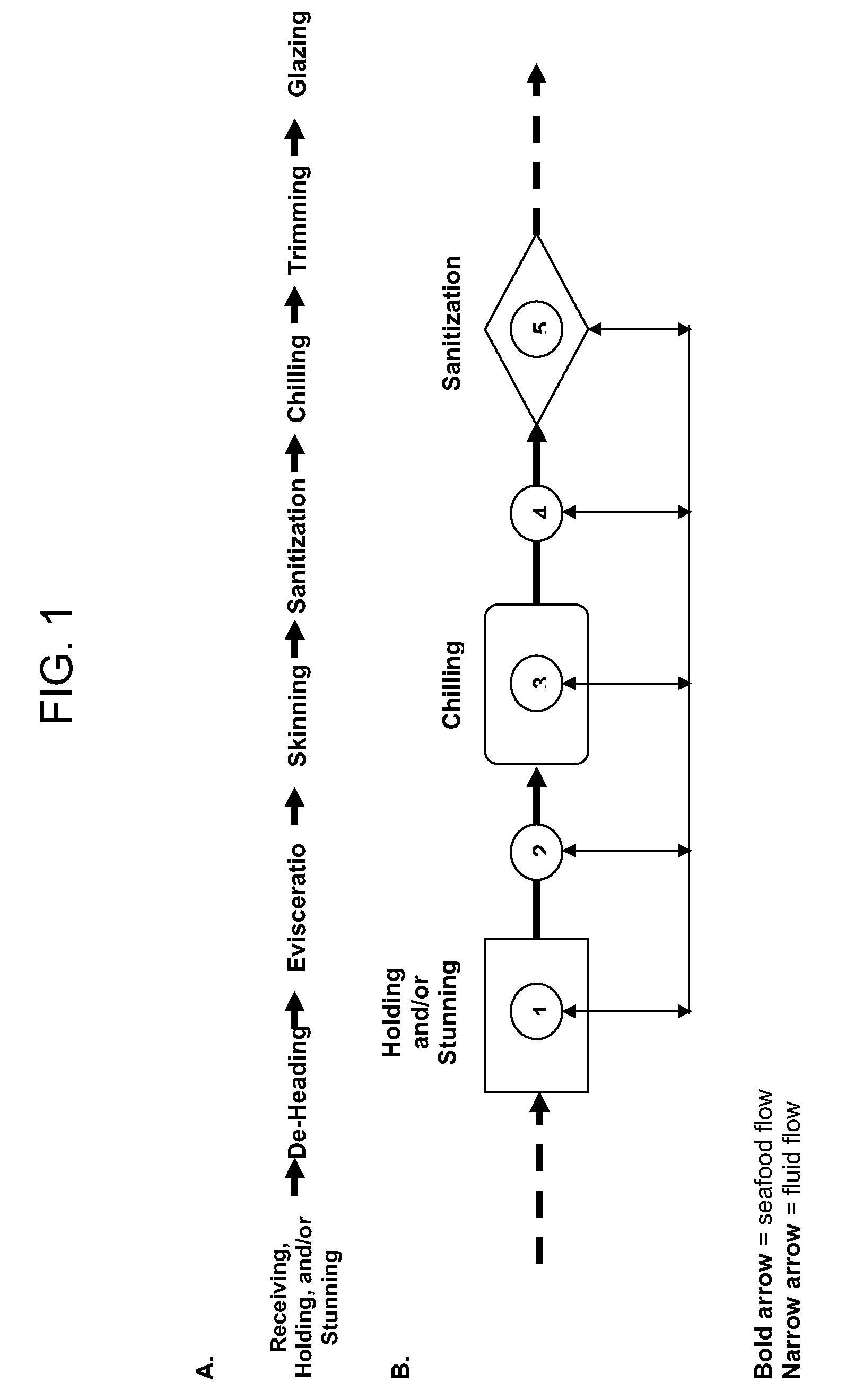

Methods for reducing microbial contamination in seafood processing

InactiveUS20080171117A1Decrease pathogen loadExtended shelf lifeMilk preservationAcidic food ingredientsBiotechnologyMicroorganism

The present invention is generally directed to methods for reducing microbial population on food, especially seafood, during processing. Provided are methods of seafood processing that involve contacting seafood with a disinfection composition comprising an acid, a buffer, and an antimicrobial metal. Such methods can result in reduced pathogen load, reduced spoilage odor, and prolonged shelf-life of seafood. Also provided are systems for seafood processing employing said disinfectant compositions.

Owner:TASKER PRODS CORP

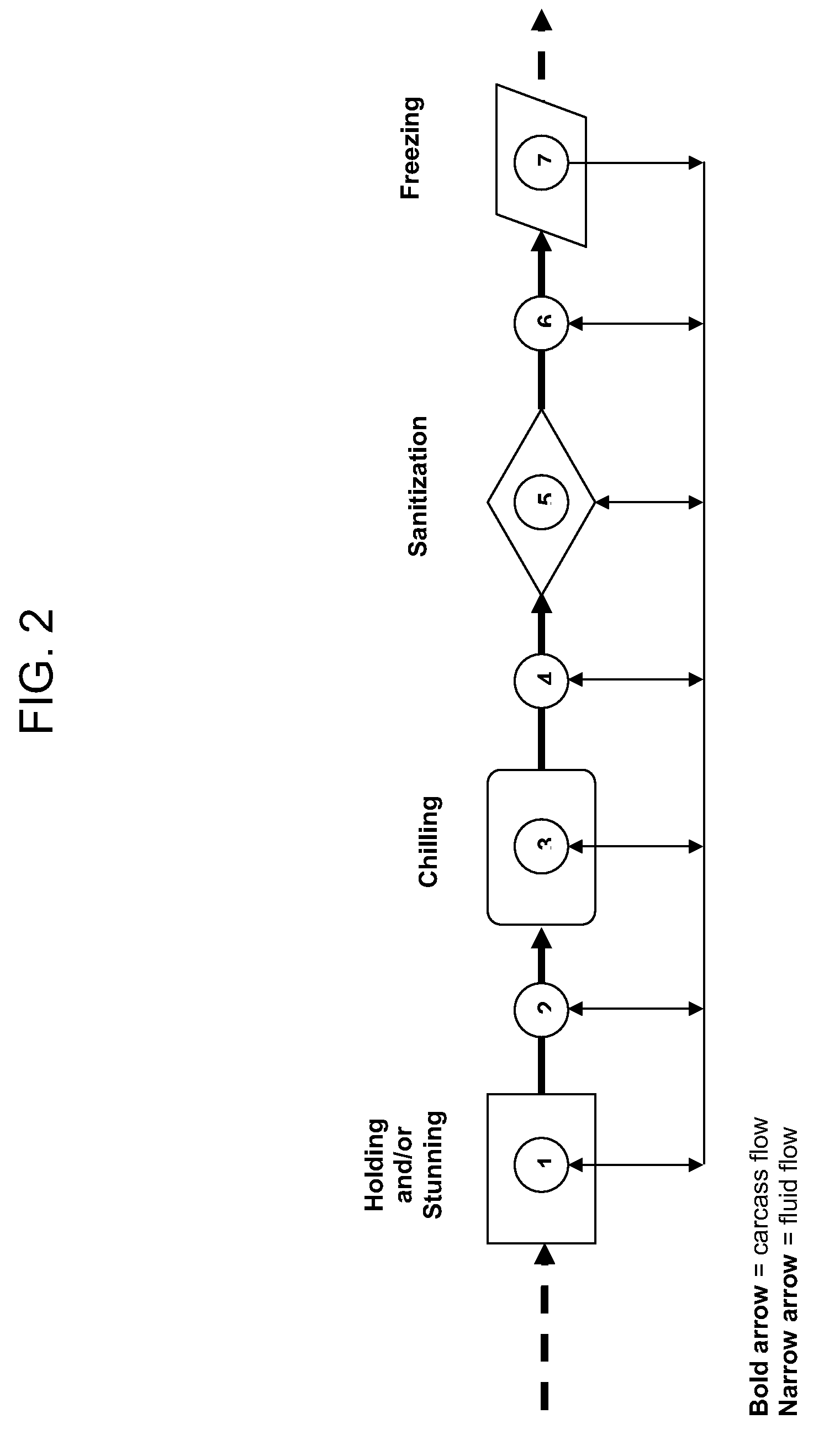

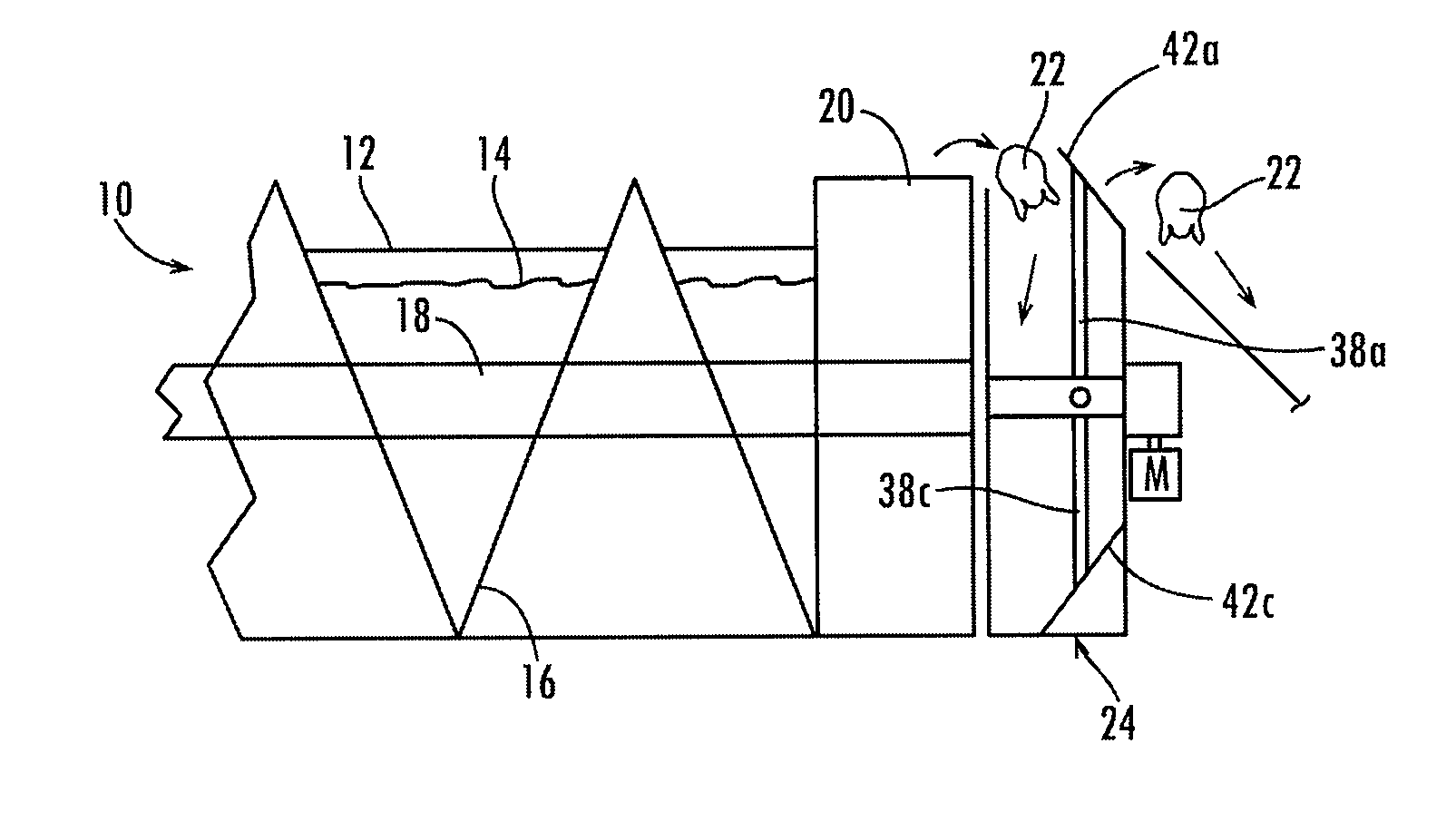

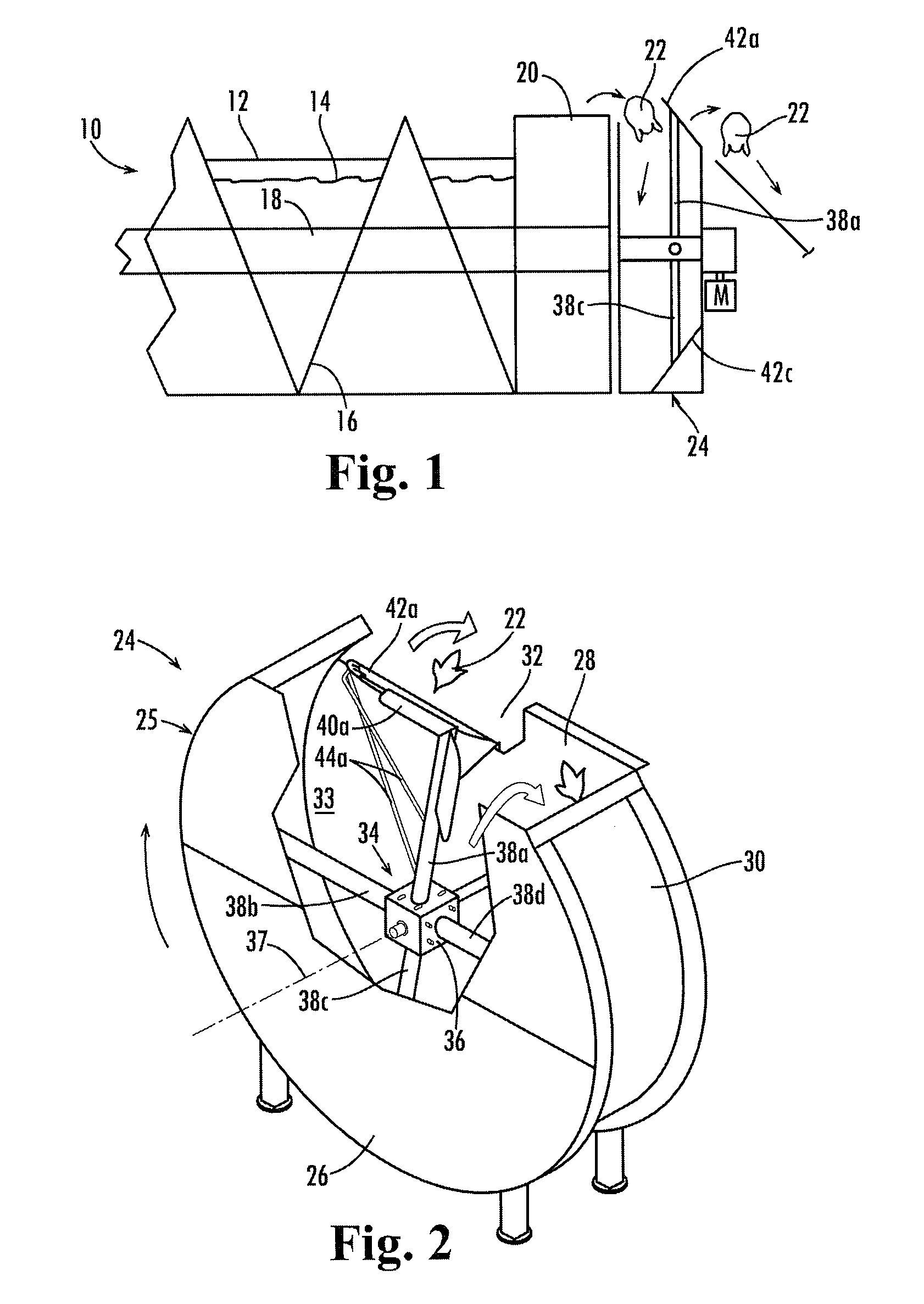

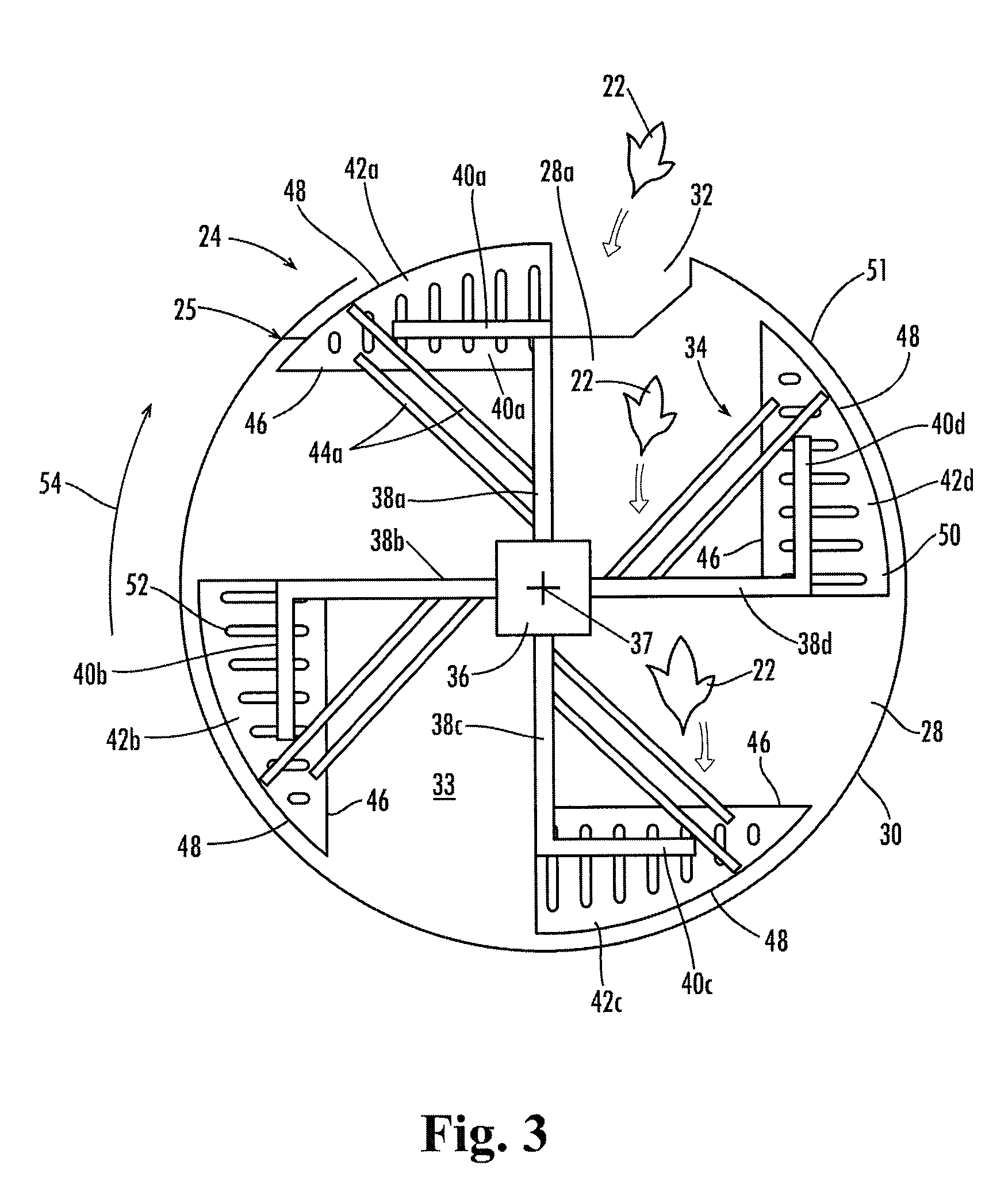

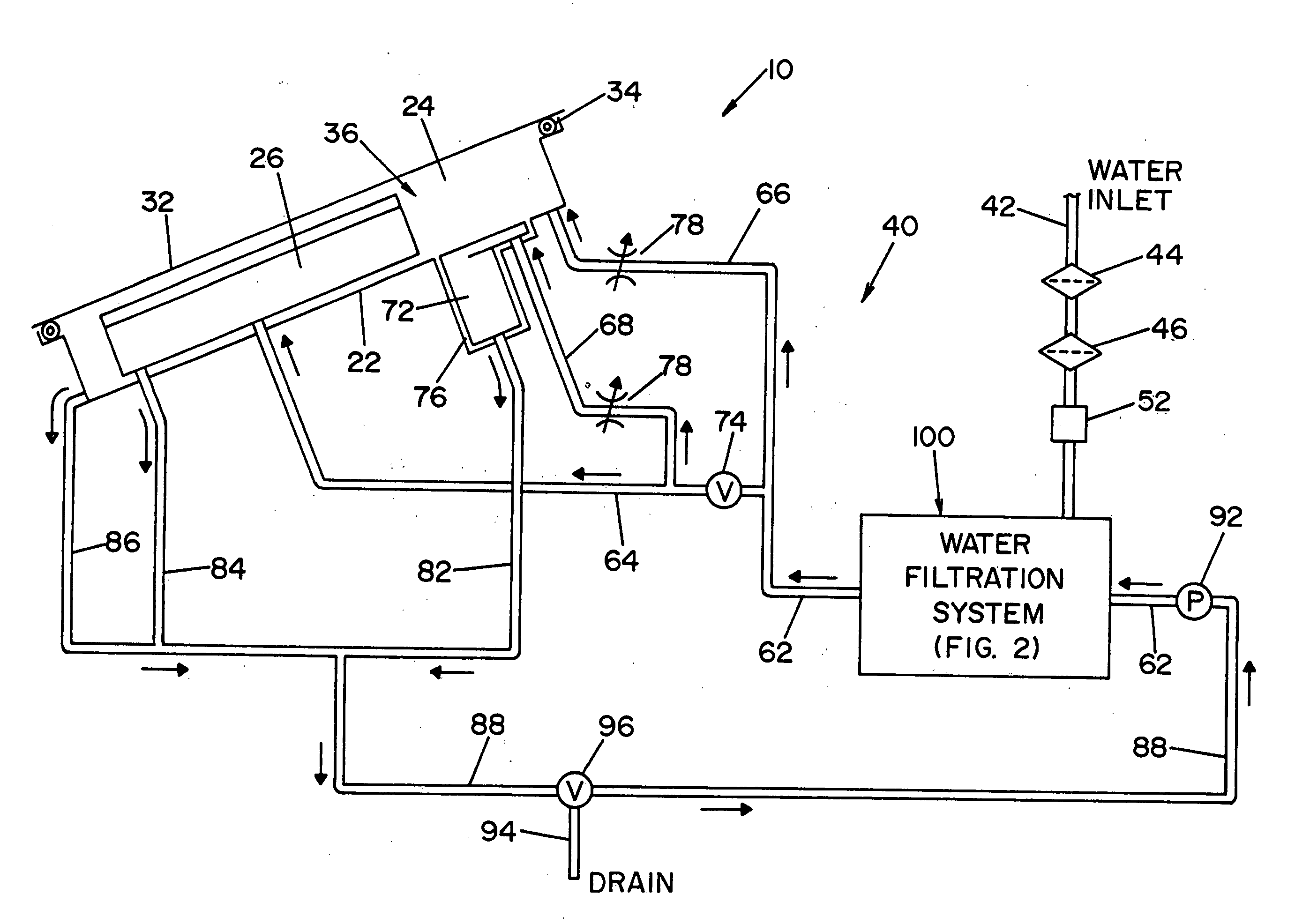

Post chill decontamination tank

ActiveUS7470173B2Enhance liquid and mechanical agitationReduce Microbial ContaminationFish washing/descalingPoultry cleaning/disinfectionEngineeringChiller

The post chill decontamination tank assembly 24 usually is positioned at the exit end of a chiller 10 of a poultry processing line. Eviscerated birds fall into the decontamination tank 25 and the paddles 42A-42D of the paddle assembly 34 revolve in the tank about the axis 37 and collect and lift the birds through the liquid and discharge the birds from the tank. An antimicrobial is added to the liquid for treating the exposed surfaces of the birds.

Owner:MORRIS & ASSOCS

Filter assembly for a reprocessor

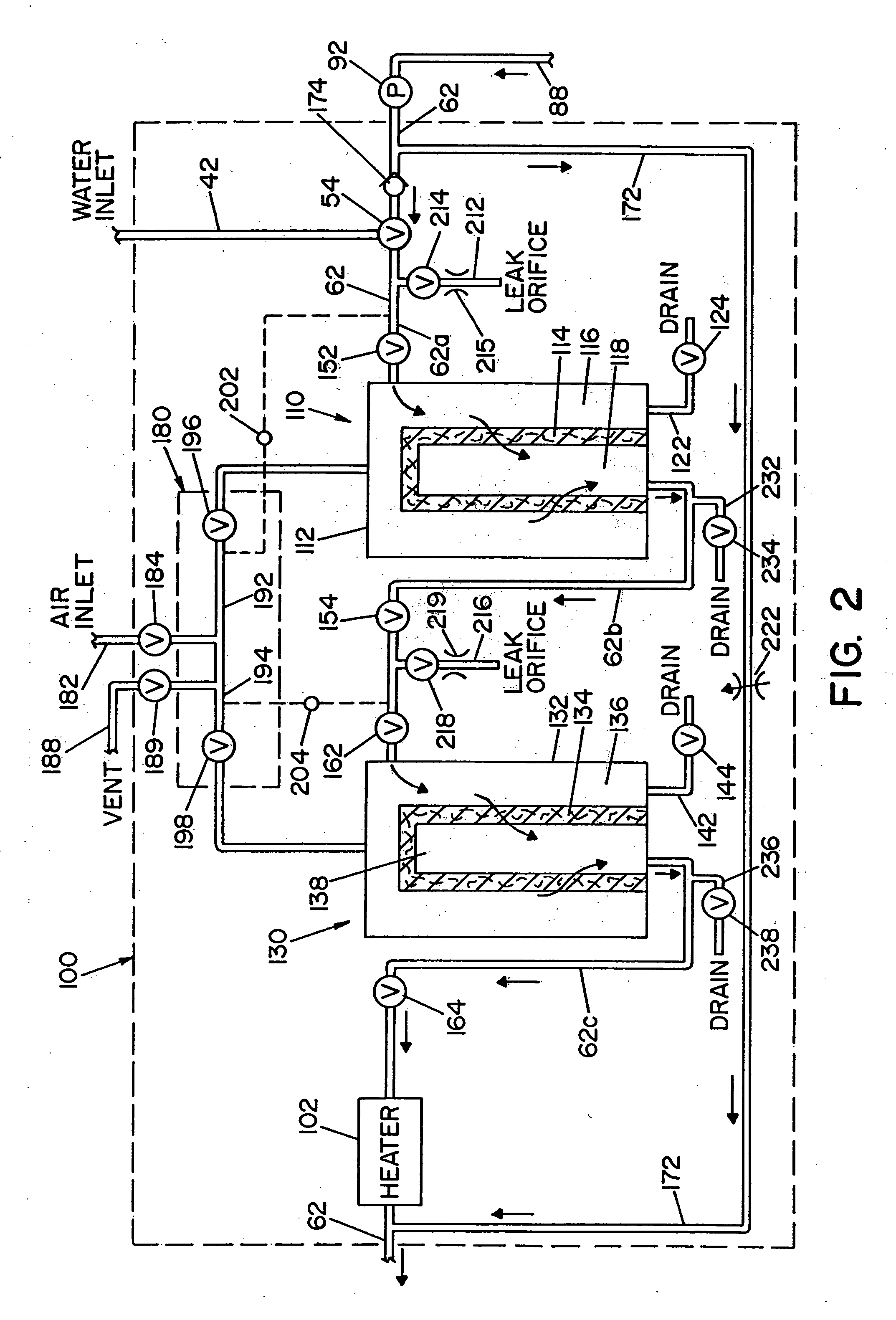

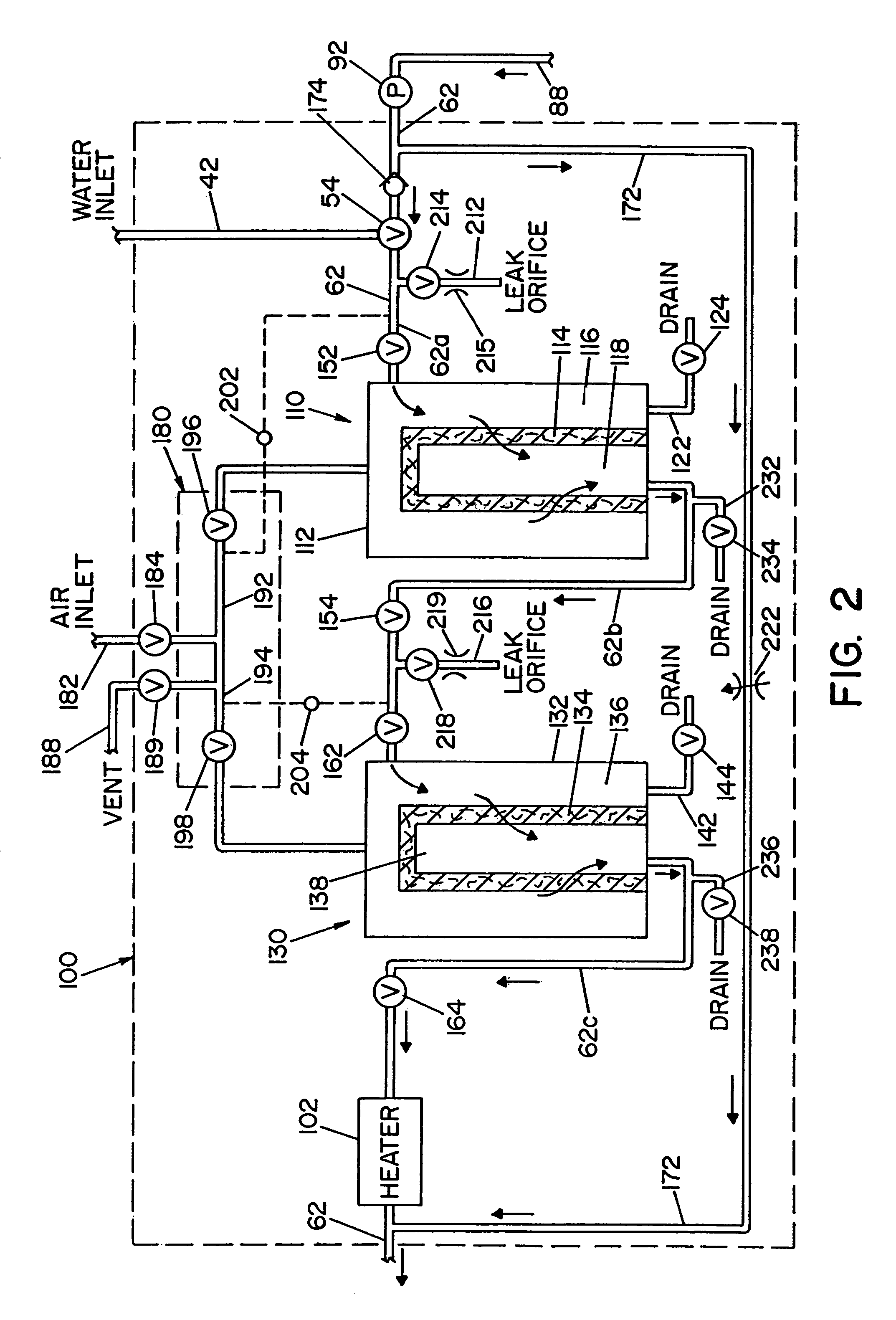

InactiveUS20060280647A1Reduce Microbial ContaminationHigh level of assuranceDetection of fluid at leakage pointTreatment involving filtrationReprocessorFiltration

The present invention provides a method of operating a reprocessor that has a chamber for receiving items to be sterilized. The reprocessor is filled with water that has passed through a first and a second filter element that both comprise a filtration system. A liquid sterilant is generated by mixing the water with dry chemical reagents. The liquid sterilant is circulated through a fluid circulation system and the filtration system wherein a portion of the liquid sterilant is directed through a bypass conduit and another portion is directed through the first and second filter elements. After a predetermined exposure time, the reprocessor is drained. Then the reprocessor is filled with water for rinsing that has passed through the first and the second filter elements. The water for rinsing is heated prior to being introduced into the reprocessor.

Owner:AMERICAN STERILIZER CO

Filter assembly for a reprocessor

InactiveUS7569182B2Reduce Microbial ContaminationReduce the possibilityDetection of fluid at leakage pointTreatment involving filtrationReprocessorFiltration

The present invention provides a method of operating a reprocessor that has a chamber for receiving items to be sterilized. The reprocessor is filled with water that has passed through a first and a second filter element that both comprise a filtration system. A liquid sterilant is generated by mixing the water with dry chemical reagents. The liquid sterilant is circulated through a fluid circulation system and the filtration system wherein a portion of the liquid sterilant is directed through a bypass conduit and another portion is directed through the first and second filter elements. After a predetermined exposure time, the reprocessor is drained. Then the reprocessor is filled with water for rinsing that has passed through the first and the second filter elements. The water for rinsing is heated prior to being introduced into the reprocessor.

Owner:AMERICAN STERILIZER CO

Method and composition for washing poultry during processing

InactiveUS20080199562A1Reduce Microbial ContaminationHigh degreeBiocideDough treatmentMachining processBiology

The present invention relates to compositions including peroxyacetic acid and peroxyoctanoic acid and methods for reducing microbial contamination on poultry. The methods include the step of applying a mixed peroxycarboxylic acid composition to poultry.

Owner:ECOLAB USA INC

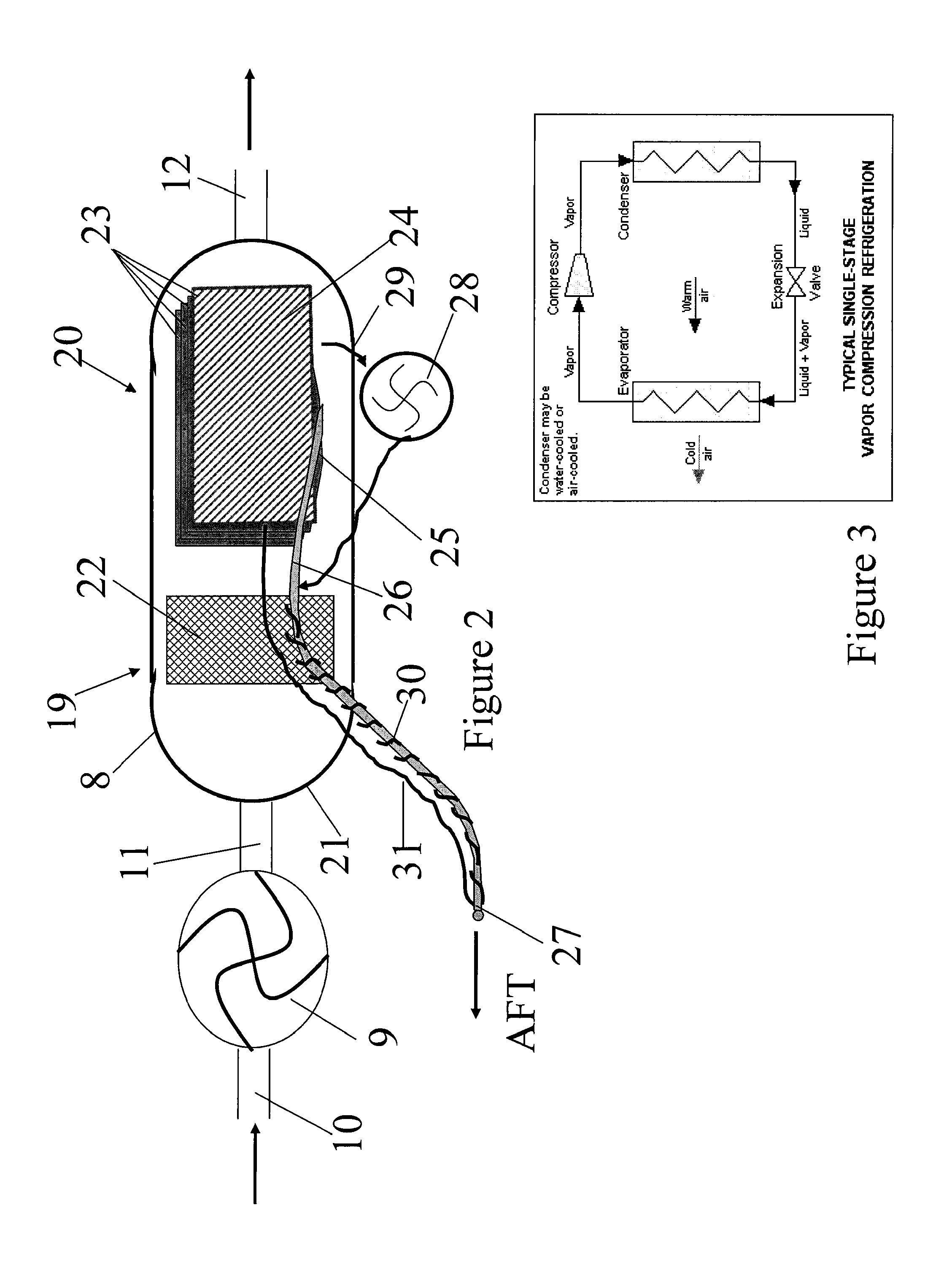

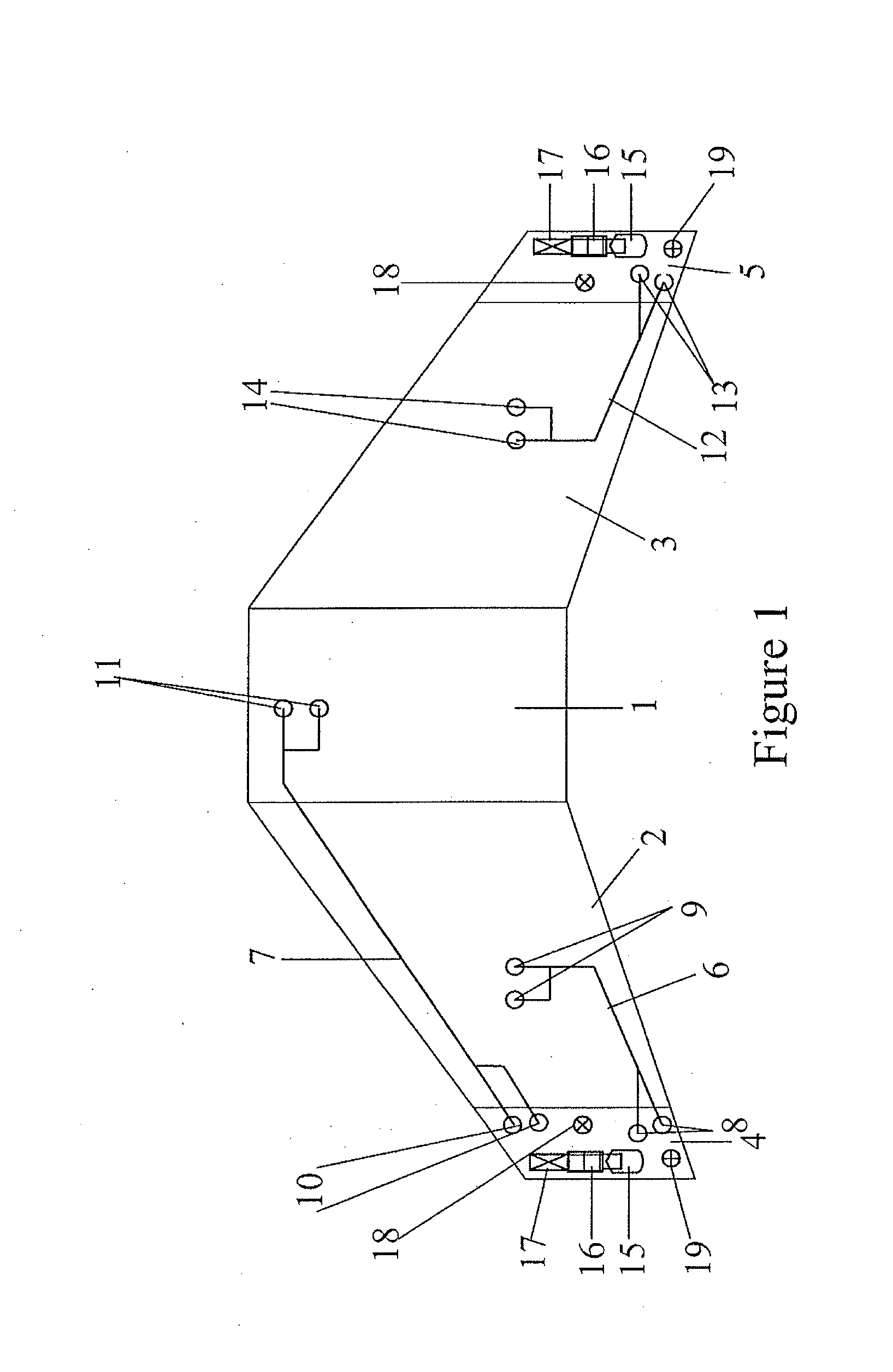

Aircraft fuel tank ventilation

ActiveUS20120096879A1Improve component reliabilityReduced activityPower plant fuel tanksFuel tank safety measuresWater vaporAtmospheric air

An aircraft fuel tank ventilation system, comprising a refrigerative dehumidifying device having a refrigerating element in contact with air flowing between a vent open to the atmosphere and a fuel tank. Also, a method of dehumidifying air introduced into an aircraft fuel tank via the ventilation system, the method comprising directing atmospheric air from the vent into contact with the refrigerating element, and cooling the refrigerating element so as to remove water vapour from the air flowing from the vent towards the fuel tank by condensation. An aircraft fuel tank ventilation system, comprising a refrigerative dehumidifying device having a refrigerating element in contact with air flowing between a vent open to the atmosphere and a fuel tank. Also, a method of dehumidifying air introduced into an aircraft fuel tank via the ventilation system, the method comprising directing atmospheric air from the vent into contact with the refrigerating element, and cooling the refrigerating element so as to remove water vapour from the air flowing from the vent towards the fuel tank by condensation.

Owner:AIRBUS OPERATIONS LTD

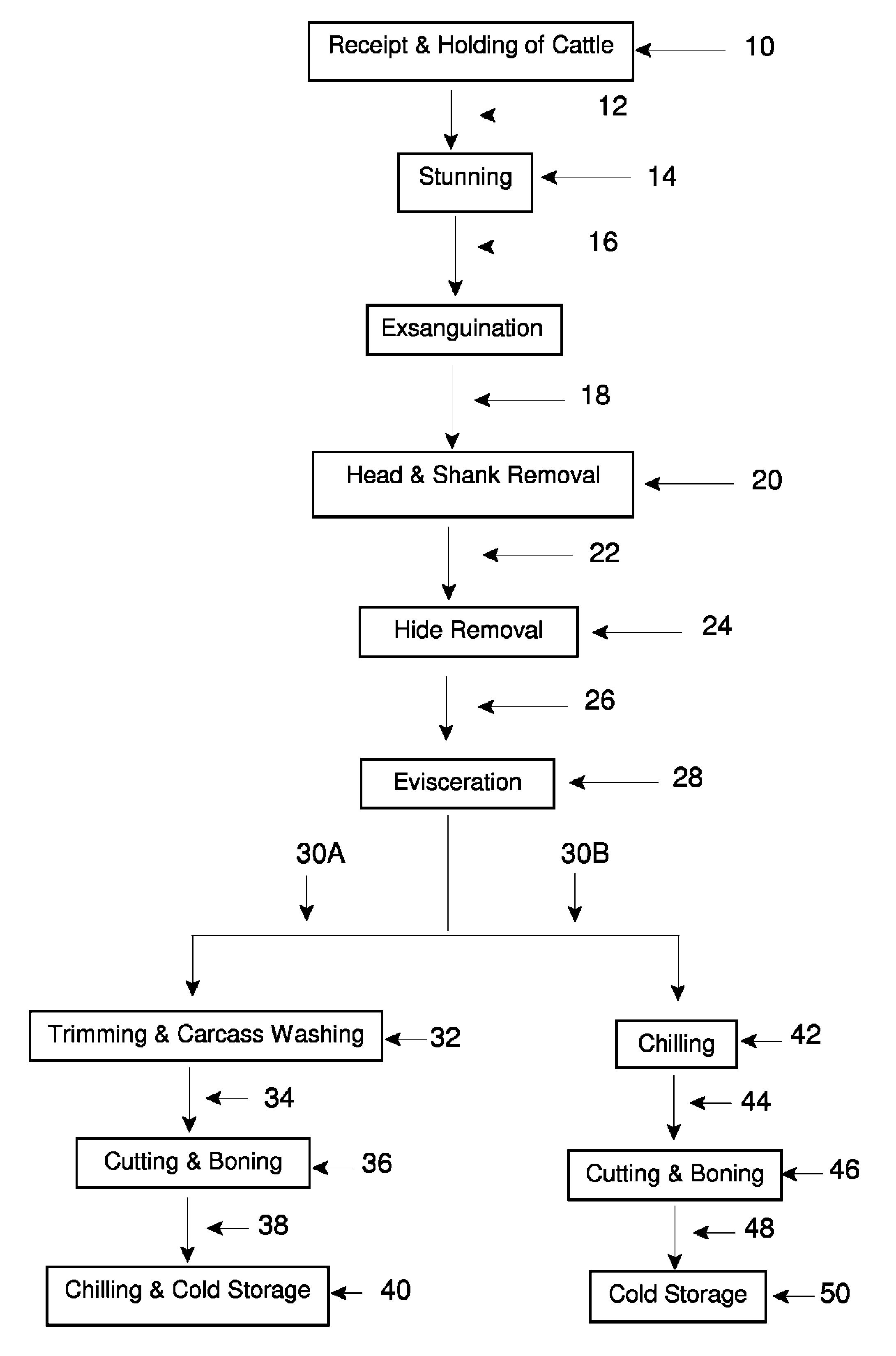

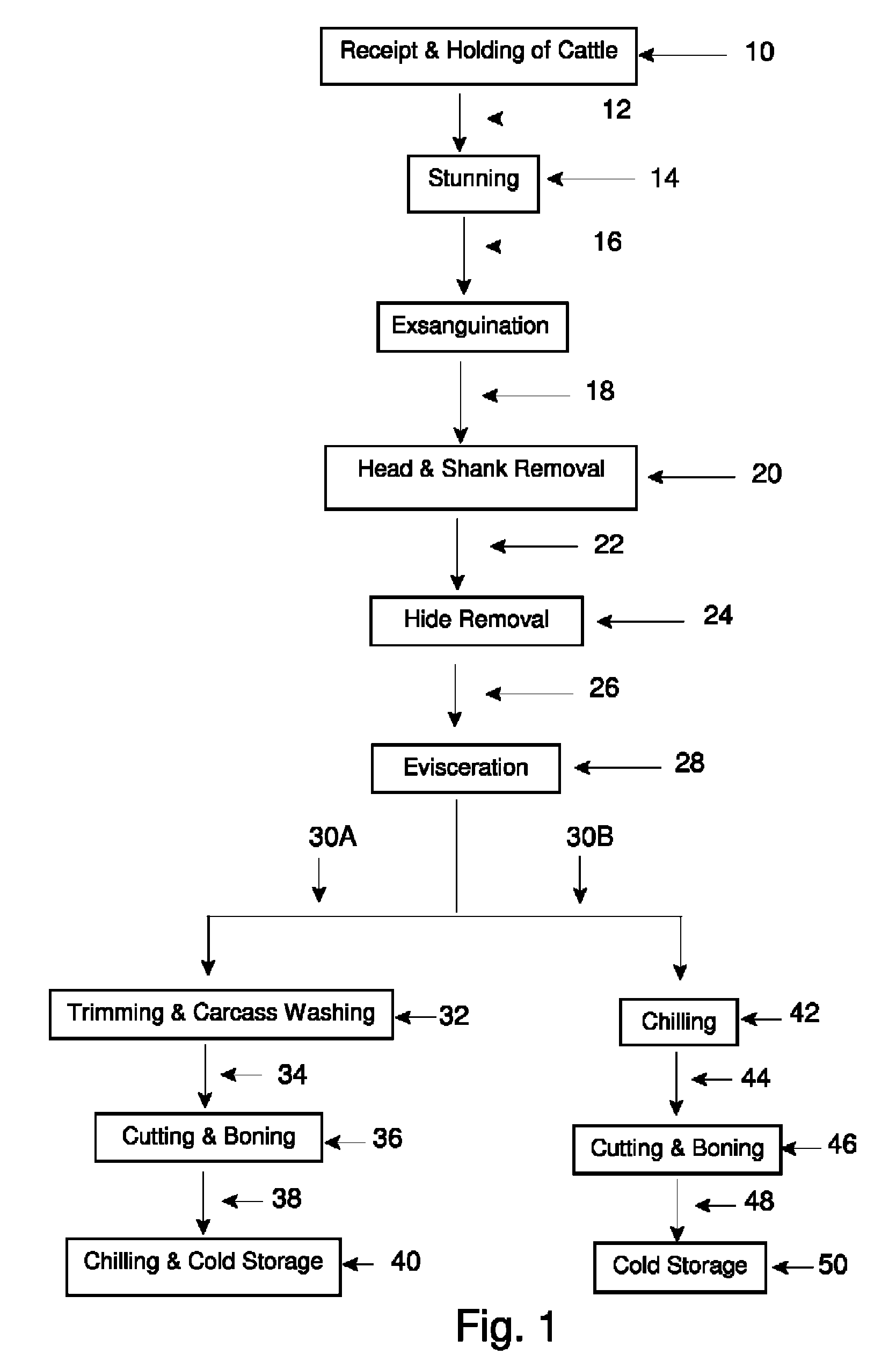

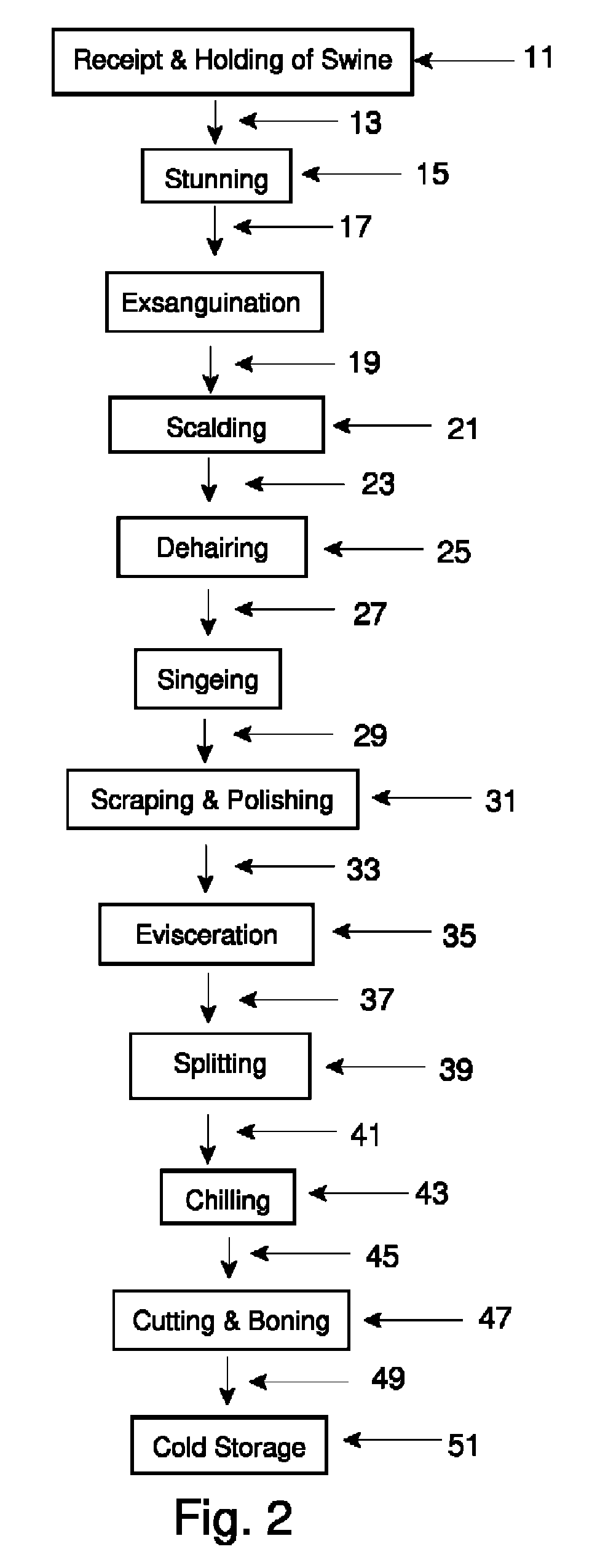

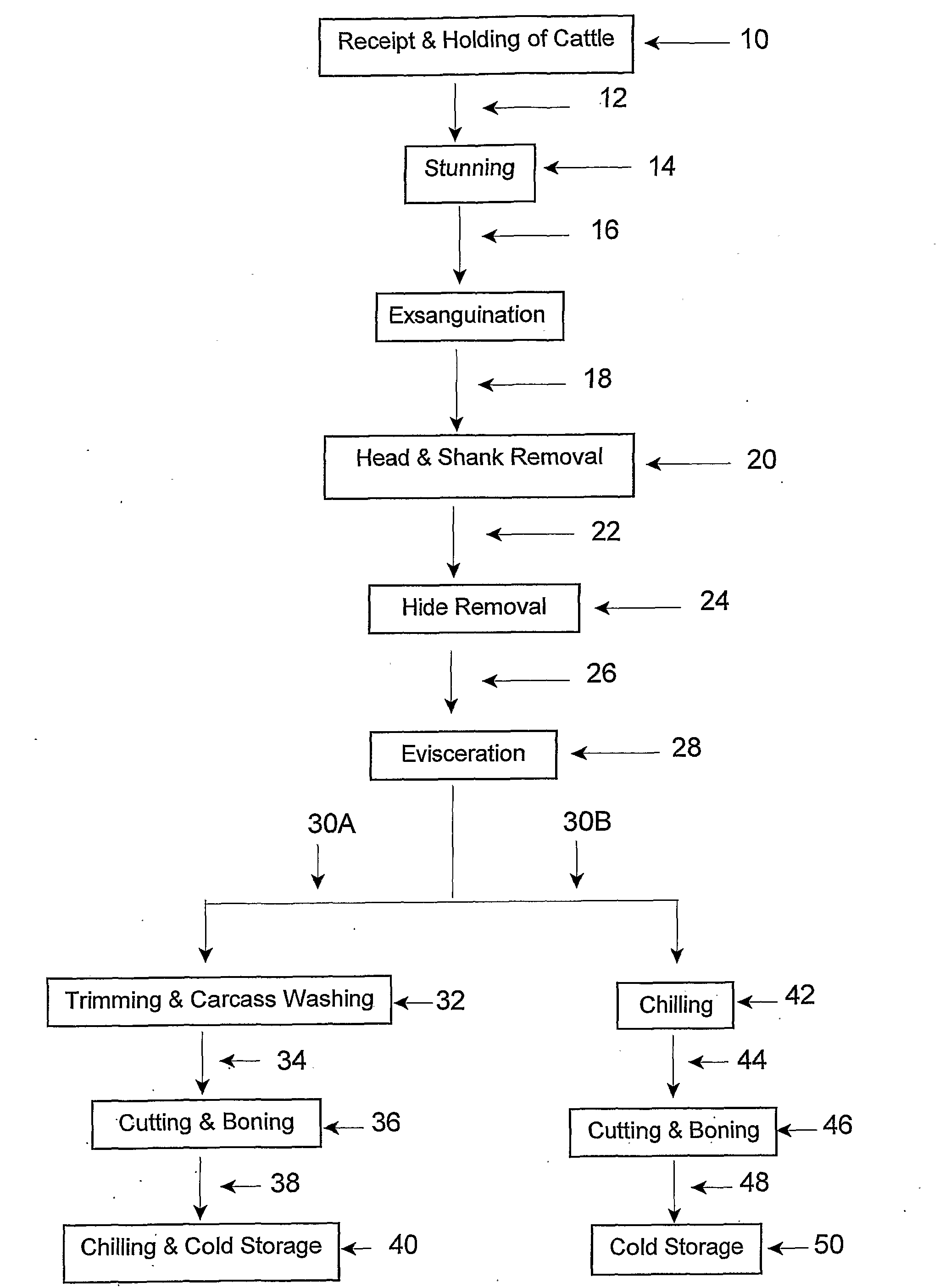

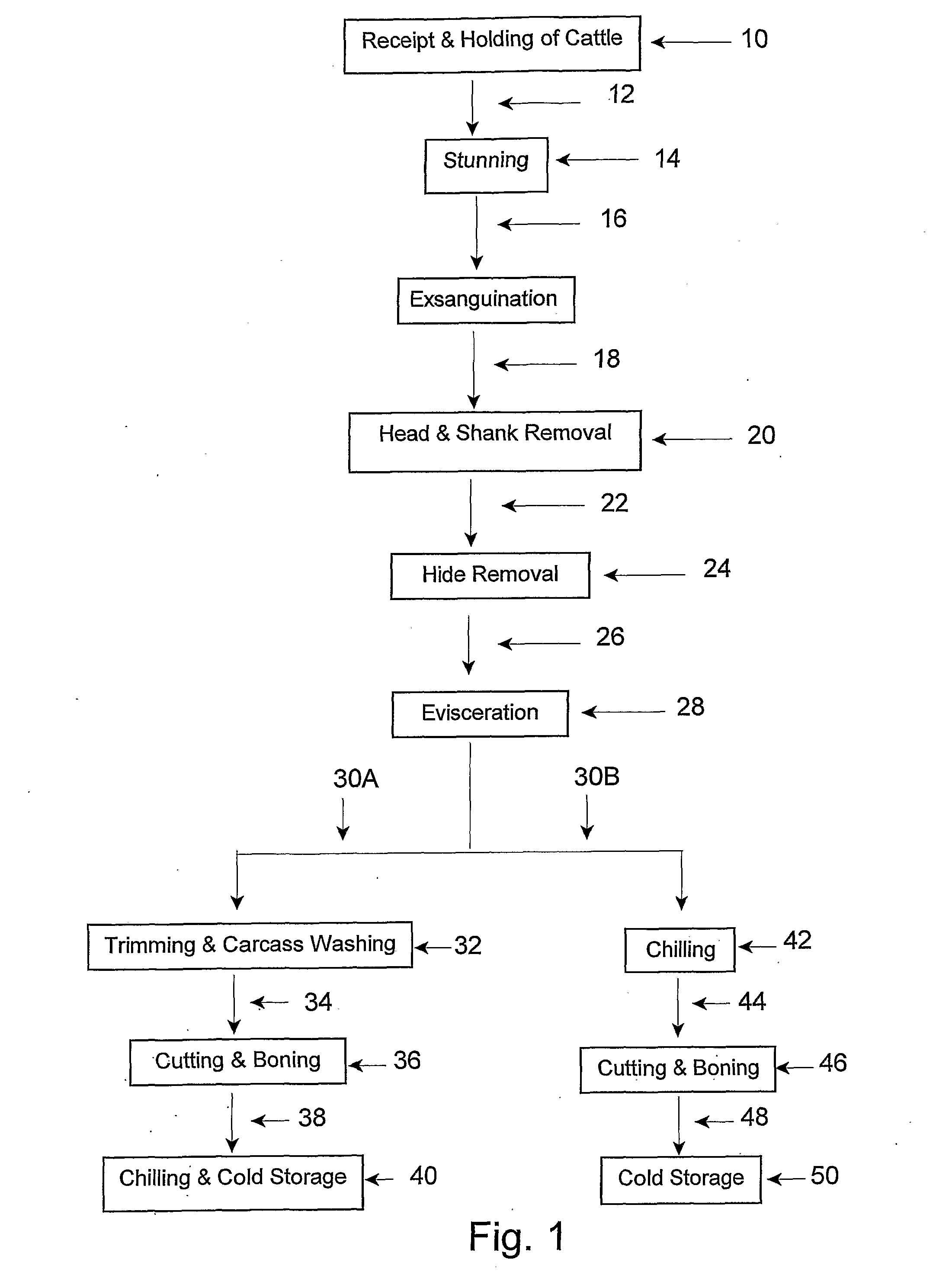

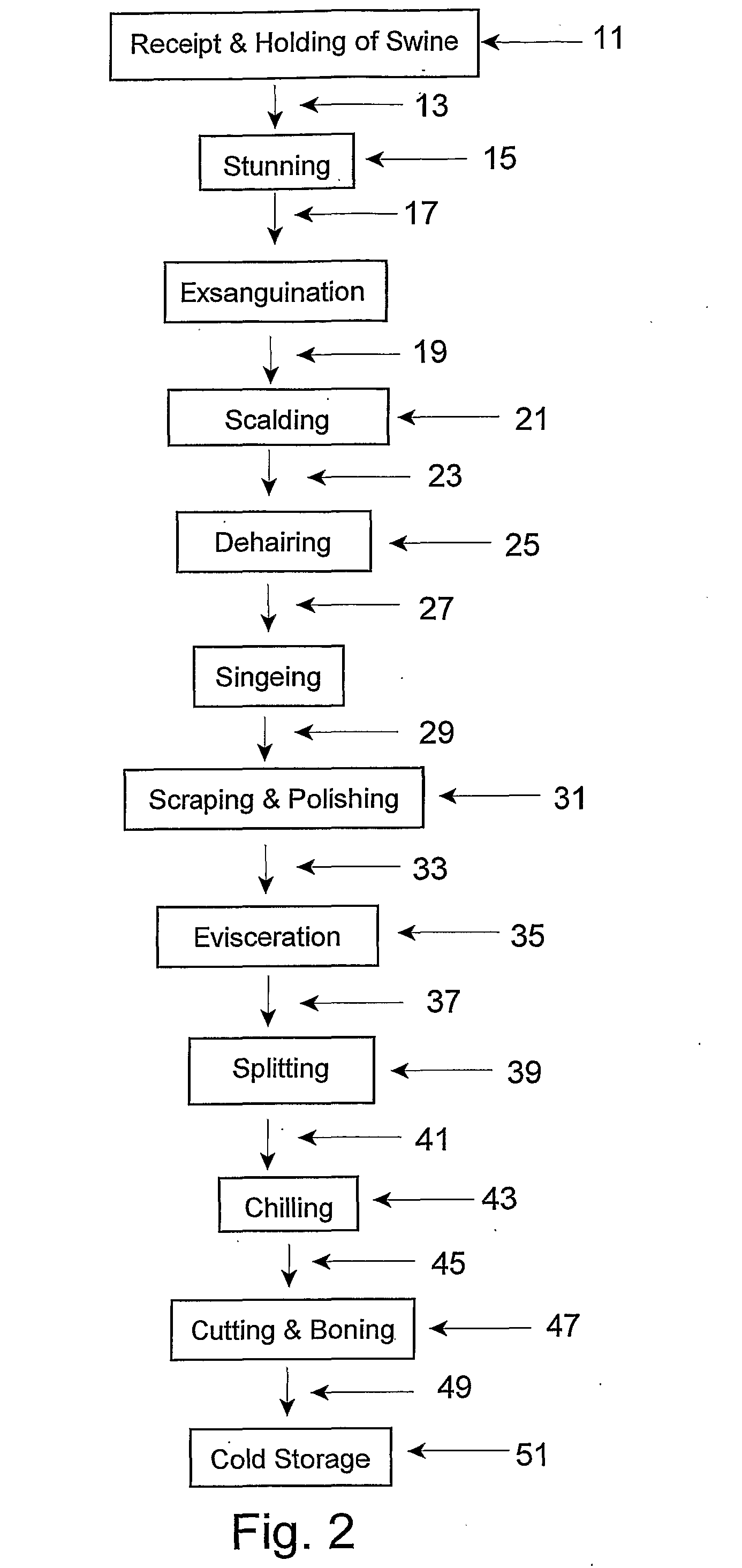

Microbiocidal control in the processing of meat-producing four-legged animals

InactiveUS8033898B2Reduce Microbial ContaminationSignificant comprehensive benefitsBiocidePoultry cleaning/disinfectionBiotechnologyMicroorganism

Owner:ALBEMARLE CORP

Microbiocidal Control in the Processing of Meat-Producing Four-Legged Animals

InactiveUS20090081317A1Reduce Microbial ContaminationSignificant comprehensive benefitsBiocideMilk preservationMicroorganismAlkaline earth metal

Methods of processing four-legged slaughter animals for consumption as meat and / or meat product(s) are described. The methods comprise (I) contacting exterior surfaces of the live animal at least once when the animal is en route to being slaughtered but before it is killed by exsanguination, with a microbiocidal solution, or (II) contacting a carcass of the animal, after exsanguination, with a microbiocidal solution, or (III) contacting at least one raw meat product and / or at least one processed meat product derived from the carcass at least once with a microbiocidal solution, or (IV) conducting any two or all three of (I), (II), and (III). In each case the microbiocidal solution is, independently, comprised of: (a) water having a bromine residual derived from (i) at least one bromine source, (ii) at least one alkali metal base, and / or at least one alkaline earth metal base, and (iii) at least one halogen stabilizer; or (b) water having a bromine residual derived from (i) ammonium bromide, and / or at least one alkali metal bromide, and / or at least one alkaline earth metal bromide, and (ii) at least one alkali metal hypohalite and / or at least one alkaline earth metal hypohalite; or (c) water having a bromine residual derived from a mixture or combination of any one or more of (a) and any one or more of (b); the bromine residual in each of (a), (b), and (c) being sufficient to provide microbiocidal activity.

Owner:ALBEMARLE CORP

Aircraft fuel tank ventilation

ActiveUS20120103192A1Avoid icingKeep dryPower plant fuel tanksDomestic cooling apparatusAtmospheric airWater vapor

An aircraft fuel tank ventilation system includes a dehumidifying device disposed in flow communication between a vent open to the atmosphere and a fuel tank. A method of dehumidifying air introduced into an aircraft fuel tank via a ventilation system includes directing atmospheric air through a dehumidifying device disposed in flow communication between a vent of the ventilation system and the fuel tank, which removes water vapour from the air flowing from the vent towards the fuel tank. A method of regenerating a desiccant medium used to dehumidify air introduced into an aircraft fuel tank via a ventilation system includes directing air through the desiccant medium so as to dry the desiccant medium.

Owner:AIRBUS OPERATIONS LTD

Mist generator for sterilizing forced air systems

PendingUS20200345885A1Improve sterilityReduce Microbial ContaminationRespiratorsMedical devicesAir cycleUltraviolet lights

A mist generator is a standalone device that improves the internal sterility of controlled forced air systems. Sterilizing mist is generated when forced air circulates above or through a liquid disinfectant. The disinfectant is taken up into the circulating air and distributed throughout the internal structure of the system, sterilizing its internal surfaces. The mist generator contains no ionizers, atomizers, ultraviolet lamps, or other electric or mechanical devices.In one embodiment, the mist generator has a chamber with an inlet adapted for attachment to a blower or duct delivering forced air into the chamber. The chamber also includes an output duct or aperture adapted for attachment to a second hose which, in turn, is adapted for attachment to the inlet of the blower for delivery of disinfectant-misted air through internal components of the blower. Alternatively, there is used a disinfectant filter formed as a sterilizing grid having a screen coated with a soft porous surface material impregnated with a liquid disinfectant. The soft porous surface material releases said liquid disinfectant when forced air moves through the filter and through the system. In both embodiments, sterile water can be introduced to take up residual disinfectant and the vapor is captured in a dry filter or desiccant material and removed from the system.In the alternative embodiment, the sterilizing mist produced by the uptake of liquid disinfectant into circulating air and distributed throughout the forced air system can be formed when air from a blower or air handler is circulated across a sterilizing screen with a porous surface material impregnated with a liquid disinfectant. The antimicrobial mist is distributed throughout the system and acts to disinfect the internal surfaces and components. Additional water may be added to the sterilizing screen and distributed similarly by the forced air. A dry, desiccating filter, remote from the blower, traps the water and any residual disinfectant as it exits from the system. A dehumidifier, if installed, may also be used to remove water and can be readily emptied.The mist generator improves the sterility of the blower and mitigates microbial contamination of forced-air delivery systems.

Owner:LEWIS RANDALL J

Microbiological control in animal processing

InactiveUS20060004072A1Reduce Microbial ContaminationProduced economicallyBiocideOrganic active ingredientsWater chlorinationZoology

Fecal bacterial contamination in an animal is reduced by providing it with drinking water containing a microbiocidally-effective amount of halogen-based microbiocide resulting from mixing with water (A) a product formed in water from (i) bromine, chlorine, or bromine chloride, or any two or more thereof, (ii) a water-soluble source of sulfamate anion, and (iii) a water-soluble base; (B) at least one 1,3-dihalo-5,5-dialkylhydantoin in which one of the halogen atoms is a chlorine atom and the other is a chlorine or bromine atom, and in which each alkyl group, independently, contains in the range of 1 to about 4 carbon atoms; (C) at least one 1,3-dibromo-5,5-dialkylhydantoin in which one of the alkyl groups is a methyl group and the other alkyl group contains in the range of 1 to about 4 carbon atoms; or (D) any two or more of (A), (B), and (C).

Owner:HOWARTH JONATHAN N +1

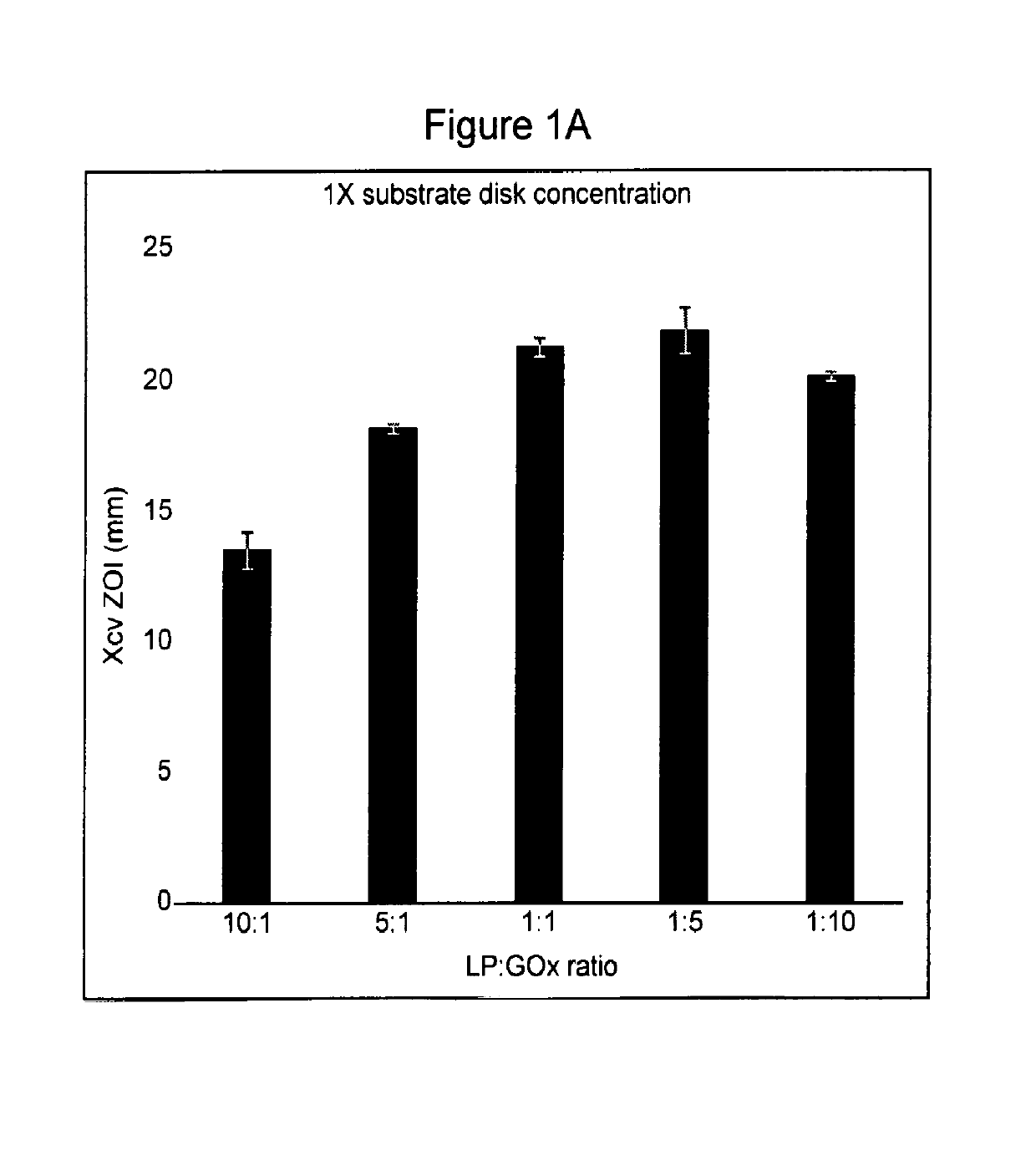

Magnetically immobilized biocidal enzymes and biocidal chemicals

PendingUS20190174746A1Reduce infectionReduce Microbial ContaminationBiocideAbsorbent padsMicroorganismAntibiotic resistance

The present invention provides compositions and methods for reducing microbial and nematodal contamination or infection in plants, animals, fabrics, and products therefrom. The present invention also provides compositions and methods for reducing human infections and the emergence of antimicrobial resistance. In particular, the invention provides magnetic nanoparticles comprising biocidal or biostatic enzymes in one component, substrates for the enzymes in a second component, and a biocidal chemical agent that works in combination or synergistically with the enzymes. The compositions are dormant and become active upon exposure to hydration, oxygen, or mixing.

Owner:ZYMTRONIX CATALYTIC SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com