Production method for chemicals by continuous fermentation

A technology for chemicals and fermentation raw materials, applied in biochemical equipment and methods, chemical instruments and methods, and methods for sampling biological materials, etc., can solve problems such as complex cleaning steps, reduce costs, reduce processing costs, and improve fermentation production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

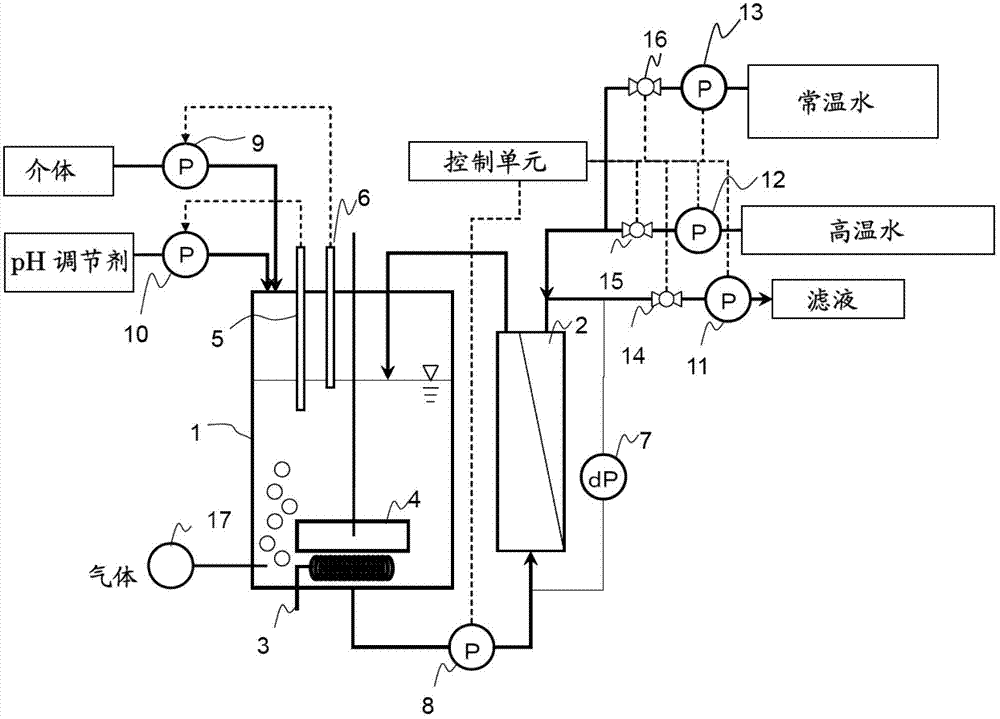

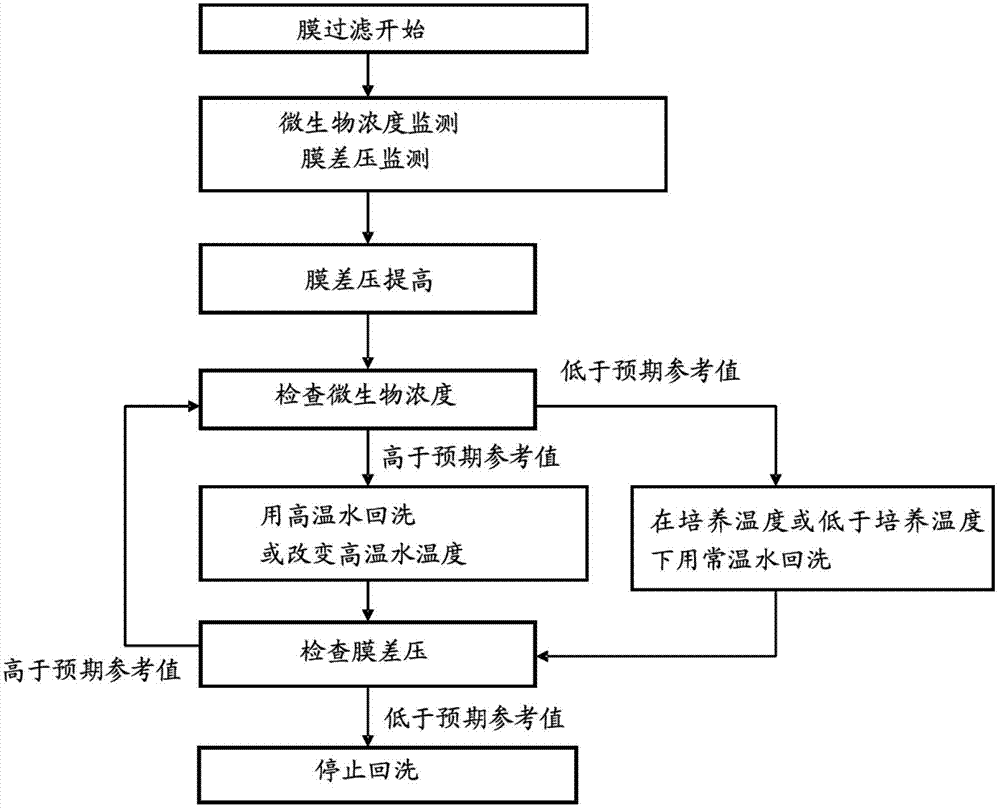

Method used

Image

Examples

Embodiment 1

[0082] First prepare the membrane module. The hollow fiber membranes used to prepare the membrane module were prepared by disassembling the Toray pressure polyvinylidene fluoride hollow fiber membrane module HFS1020 and cutting off only the part of the polyvinylidene fluoride hollow fiber membrane that was not attached and fixed to the module. A molded product of polycarbonate resin was used as the separation membrane module unit. The membrane module has a volume of 0.06L and 200cm 2 effective filter area. The porous hollow fiber membranes and membrane modules thus prepared are used for continuous fermentation. Unless otherwise stated, the operating conditions used in Example 1 are as follows.

[0083] Operating conditions:

[0084] -Volume of fermenter: 2.0L

[0085] - Effective volume of fermenter: 1.5L

[0086] - Separation membrane used: polyvinylidene fluoride hollow fiber membrane (60 fibers)

[0087] - Adjustment temperature: 37°C

[0088] - Aeration volume afte...

Embodiment 2

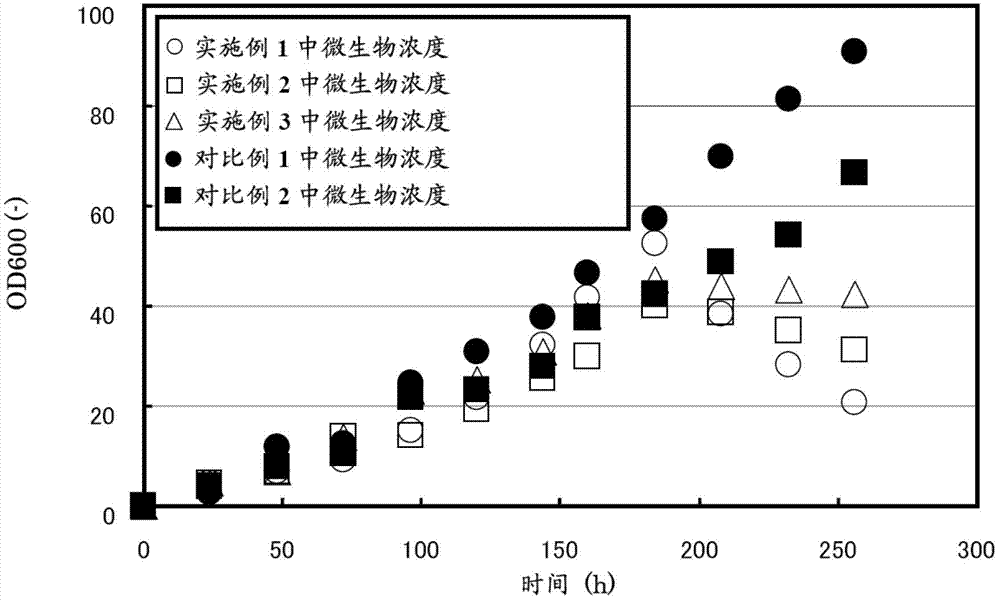

[0119] The continuous fermentation test for D-lactic acid was carried out in the same manner as in Example 1, except that after maintaining the temperature at 60° C. according to the temperature adjustment of the constant temperature unit, the high-temperature water used for backwashing was used from the first 200 hours of continuous fermentation to the 250th hour. The results are shown in image 3 and 4 middle. Therefore, the concentration of microorganisms can be reduced to an OD600 of about 30 and the permeable membrane pressure can be stably maintained. In other words, effective membrane cleaning is possible at controlled microbial concentrations.

Embodiment 3

[0121]The continuous fermentation test for D-lactic acid was carried out in the same manner as in Example 1, except that after maintaining the temperature at 45° C. according to the temperature adjustment of the constant temperature unit, the high-temperature water used for backwashing was used from the first 200 hours of continuous fermentation to the 250th hour. The results are shown in image 3 and 4 middle. Therefore, the concentration of microorganisms can be reduced to an OD600 of about 40 and the permeable membrane pressure can be stably maintained. In other words, effective membrane cleaning is possible at controlled microbial concentrations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com