Methane dry fermentation compound bacteria

A technology of compound bacteria and dry fermentation, applied in the fields of fermentation, bacteria, biochemical equipment and methods, etc., can solve the problems of microbial compound bacteria that are not involved in dry biogas fermentation, and achieve remarkable effect, high microbial concentration, and enhanced stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

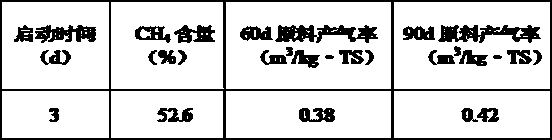

Embodiment 1

[0048] The mixed raw material of pig manure and rice straw powder with a mass ratio of 5:1 was used as the fermentation substrate. The cell number contents of 11 bacterial strains in the composite bacteria are respectively: Bacteroides cellulosilyticus accounted for 15%, Clostridium sufflavum accounted for 11%, Clostridium pasteurianum accounted for 15%, Desulfobulbus rhabdoformis Accounted for 16%, Syntrophomonas sapovorans 9% Syntrophomonas Wolfei accounted for 12%, Desulfovibrio desulfuricans Accounted for 16%, Methanospirillum hungatei Accounting for 0.5%, Methanocorpusculum parvum 1% Methanosarcina barkeri Accounted for 2.5%, Methanosaeta concilii Accounted for 3%. Dry fermentation after mixing the above-mentioned composite bacteria and fermentation substrate. After 60-90 days of fermentation, the indicators are shown in the table below:

[0049]

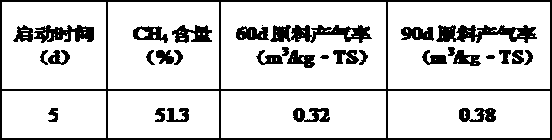

Embodiment 2

[0051] The mixed raw material of pig manure and rice straw powder with a mass ratio of 4:1 was used as the fermentation substrate. The cell number contents of the 11 strains in the composite bacteria are: Bacteroides cellulosilyticus Accounted for 17%, Clostridium sufflavum accounted for 12%, Clostridium pasteurianum accounted for 14%, Desulfobulbus rhabdoformis accounted for 15%, Syntrophomonas sapovorans 9% Syntrophomonas Wolfei accounted for 11%, Desulfovibrio desulfuricans accounted for 15%, Methanospirillum hungatei Accounting for 0.5%, Methanocorpusculum parvum Accounting for 1.5%, Methanosarcina barkeri Accounted for 2.5%, Methanosaeta concilii Accounted for 2.5%. Dry fermentation after mixing the above-mentioned composite bacteria and fermentation substrate. After 60-90 days of fermentation, the indicators are shown in the table below:

[0052]

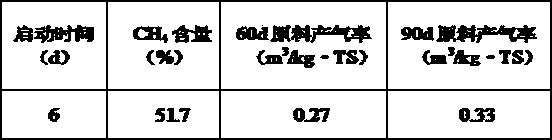

Embodiment 3

[0054] The mixed raw material of pig manure and rice straw powder with a mass ratio of 3:1 was used as the fermentation substrate. The cell number contents of 11 bacterial strains in the composite bacteria are respectively: Bacteroides cellulosilyticus Accounted for 18%, Clostridium sufflavum accounted for 14%, Clostridium pasteurianum accounted for 14%, Desulfobulbus rhabdoformis accounted for 14%, Syntrophomonas sapovorans 9% Syntrophomonas Wolfei accounted for 10.5%, Desulfovibrio desulfuricans accounted for 15%, Methanospirillum hungatei Accounting for 0.5%, Methanocorpusculum parvum 1% Methanosarcina barkeri Accounting for 1.5%, Methanosaeta concilii Accounted for 2.5%. Dry fermentation after mixing the above-mentioned composite bacteria and fermentation substrate. After 60-90 days of fermentation, the indicators are shown in the table below:

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com