Amphiphilic modified nanoparticles, emulsion thereof and high-temperature-resistant high-density reversible oil-based drilling fluid

A nanoparticle and emulsion technology, applied in the field of oil drilling fluid, can solve the problems of low system density and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 Preparation and Characterization of Amphiphilic Modified Nanoparticles

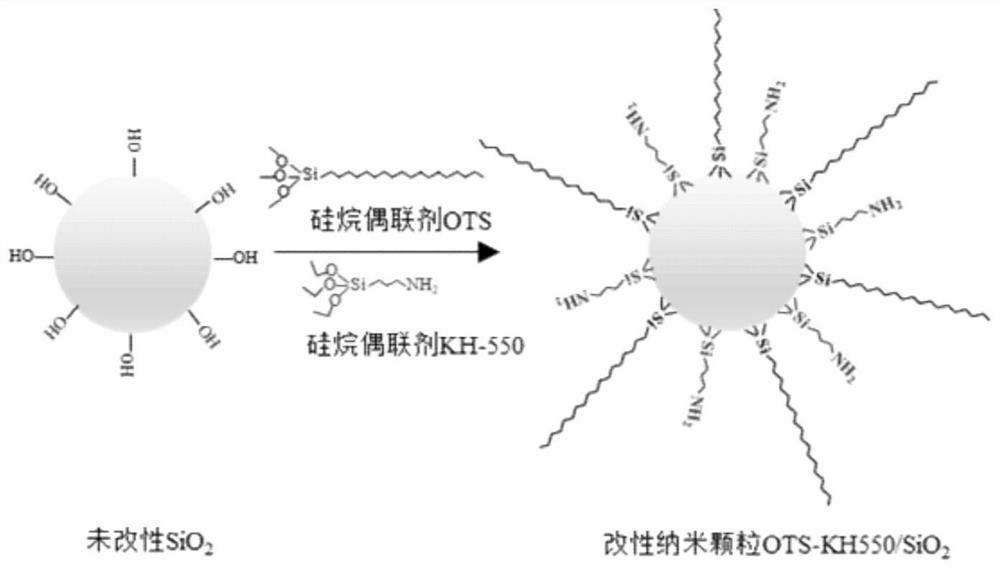

[0048] (1) Preparation of amphiphilic modified nanoparticles

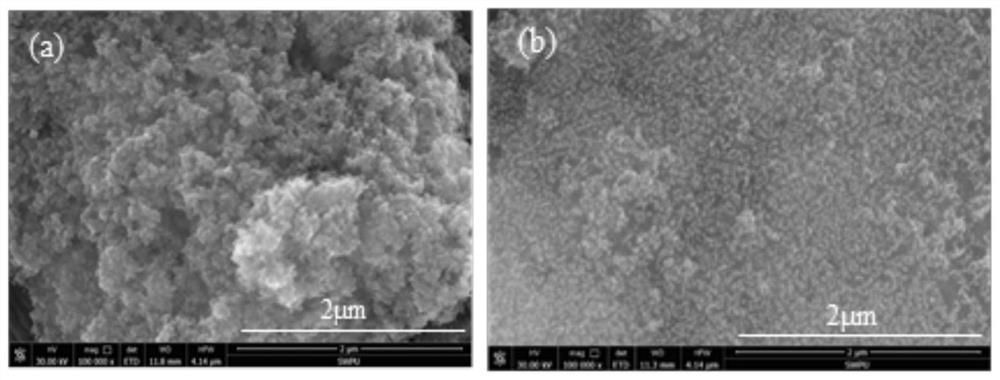

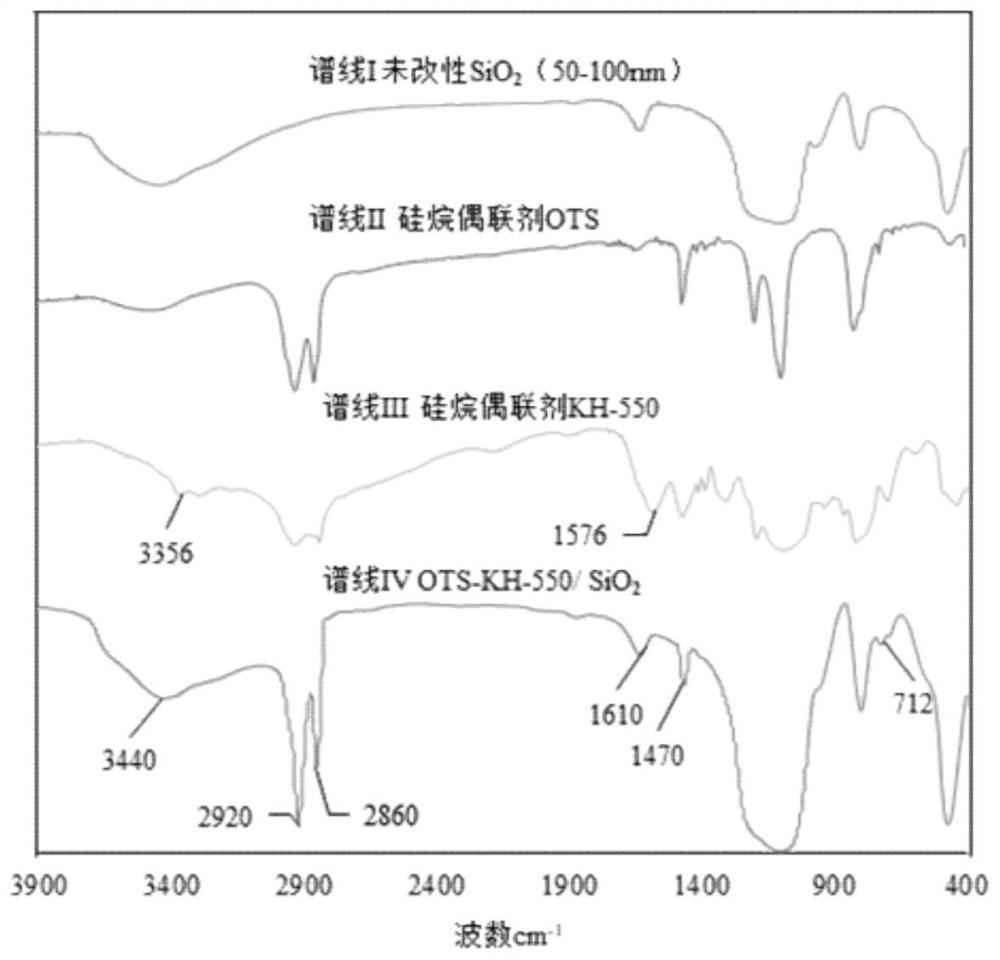

[0049] In the embodiment of the present invention, according to figure 1 Preparation according to the preparation method and structure shown: Add 0.24ml of 98% pure hydrophilic silane coupling agent KH-550 to the mixed solution of 80mL of absolute ethanol and 10mL of deionized water, stir magnetically for 5min to promote hydrolysis, add granules SiO with a diameter of 50-100nm 2 1 g of particles was ultrasonically dispersed for 10 min, then ammonia water and 0.94 ml of lipophilic silane coupling agent OTS with a purity of 98% were added in sequence, and the mixture was stirred under magnetic force at 60°C for 6 h. After the reaction, centrifuge at 8000 rpm for 10 min, and then wash with absolute ethanol. So centrifuged, washed, repeated 2 times. Finally, the centrifuged precipitate was vacuum-dried at 60 °C for 12 h to obt...

Embodiment 2

[0055] Example 2 Preparation of ultra-high temperature resistant emulsion

[0056] In the implementation of the present invention, the preparation method of the ultra-high temperature resistant emulsion is: the emulsifier, amphiphilic modified nanoparticles OTS-KH550 / SiO 2 Dissolve in the oil phase in turn, slowly add CaCl under high-speed stirring at 10000r / min 2 aqueous solution, and continuously stirred for 40 min to obtain the ultra-high temperature resistant emulsion containing the above-mentioned amphiphilic nanoparticles.

[0057] In the embodiment of the present invention, the ultra-high temperature resistant emulsion is prepared according to the following formula: 3# white oil and CaCl with a concentration of 25%-35% 2 The volume ratio of the aqueous solution is 50:50-70:30, the emulsifier content is 3w / v%-4w / v%, the amphiphilic nanoparticles OTS-KH550 / SiO prepared in Example 1 2 The mass percentage is 0.5%-1%.

[0058] In the embodiment of the present invention, t...

Embodiment 3

[0062] Embodiment 3 Anti-ultrahigh temperature emulsion breaking voltage

[0063] In the embodiment of the present invention, the emulsion was placed at 180°C, 200°C, 225°C, and 250°C for continuous hot rolling aging, aging at each temperature for 16 hours, standing for 2 hours after each aging, and testing the demulsification voltage.

[0064] (1) When CN-2 is selected as the emulsifier in Example 2 alone, and the concentration rises from 2% to 4%, the prepared emulsion (without modified nanoparticles) will be clearly delaminated and demulsified after aging at 180°C The voltage dropped from above 300V to close to 0V; the concentration of emulsifier CN-2 increased from 2% to 4%, which failed to significantly improve the temperature resistance of the emulsion. The results were as follows Figure 5 shown.

[0065] (2) When the emulsifier in Example 2 selects CN-2 alone, the concentration rises from 3w / v% to 4w / v%, and adds 1w / v% modified nanoparticles CTAB / SiO 2 The prepared u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com