Drilling fluid completion fluid for increasing drilling speed and preparation method of drilling fluid completion fluid

A drilling fluid and completion fluid technology, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of foaming, lack of speed-up effect, technical formula of drilling fluid and completion fluid, and high cost of vegetable oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Accurately measure 500mL of fresh water and pour it into a 1000mL mud cup, place it under the S7401 low-speed stirrer, adjust the stirrer, add 0.06% anhydrous sodium carbonate while stirring, continue stirring for 5 minutes, and then add 2 % sodium bentonite, continue to stir for 2 hours, take out the mud cup and seal it for more than 16 hours; take the static mud sample and stir for 10 minutes in advance; then add 3% sulfomethyl phenolic resin while stirring, and continue stirring for 10 minutes; slowly add 0.5 % sulfonate copolymer fluid loss reducer, continue stirring for 2 hours; add 2% lignite resin while stirring, continue stirring for 10 minutes; add 0.1% viscoelastic polymer while stirring, continue stirring for 2 hours; add 0.5% Span-80 , continue to stir for 5 minutes; add 0.5% amine inhibitor, continue to stir for 5 minutes; add 3% superfine calcium carbonate, continue to stir for 10 minutes;

Embodiment 2

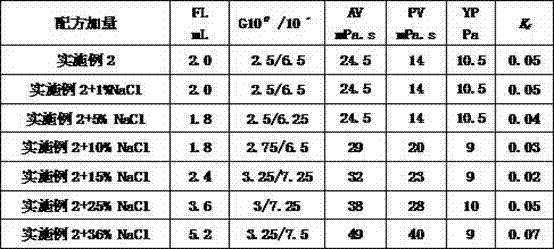

[0046] Embodiment 2: as embodiment 1, the difference is to add 0.5% clean and lubricating quick-drilling agent while stirring in the sample prepared by the embodiment, such as the quick-drilling agent KSZJ commonly used in the oil field mentioned in the background technology, continue to stir 10min.

Embodiment 3

[0047] Example 3: As in Example 1 and Example 2, the difference is that the samples prepared in Example 1 and Example 2 are tested for their extreme pressure lubrication coefficient by the American EP extreme pressure lubrication instrument, and Qingdao Haitongda GNF- Type 1 high temperature and high pressure adhesion tester tested the mud cake adhesion torque value, and the obtained data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com