Hydrophobic monomer and hydrogel for drilling plugging based on the monomer

A technology of hydrophobic monomer and hydrogel, which is applied in the field of hydrogel and hydrophobic monomer for drilling plugging, which can solve the problems of plugging failure, repeated leakage, poor deformability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

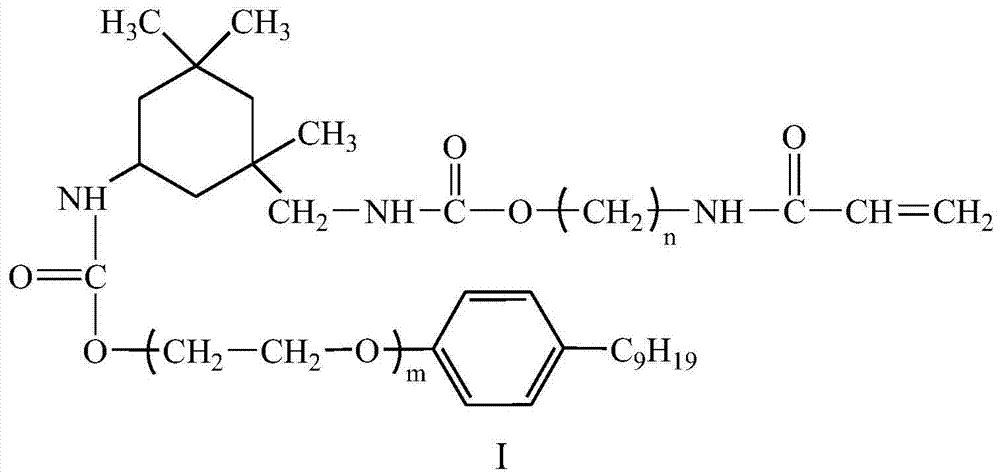

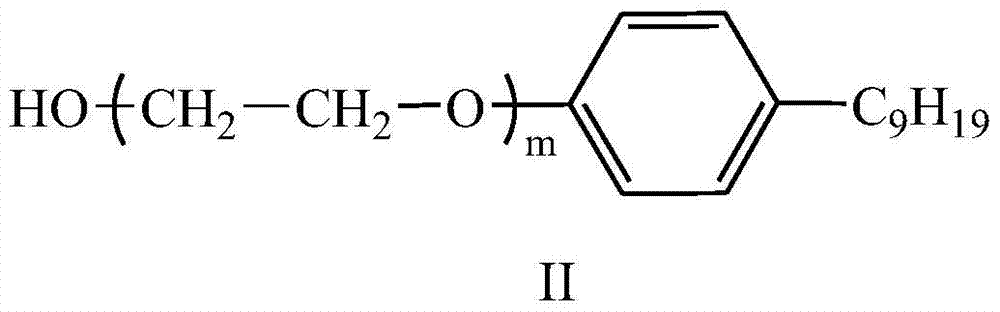

[0061] Preparation of hydrophobic monomers

[0062] Add 2850 mL of xylene and 66.04 g of compound II (m=10) into a dry three-neck flask equipped with a stirrer, condenser and dropping funnel, and add 114.45 g of isophorone diisocyanate into the dropping funnel. Stir until compound II in the flask is fully dissolved. Then the water bath was heated to a temperature of 54° C., and a vacuum was applied for 2.0 hours while heating to remove moisture. Under nitrogen protection, 0.08 g of dibutyltin dilaurate was added. The isophorone diisocyanate in the dropping funnel was dropped into the three-necked flask, and reacted for 3.5 hours under stirring conditions. Then the reaction temperature was raised to 65° C., under nitrogen protection conditions, 0.0572 g of dibutyltin dilaurate and 50.55 g of N-methylolacrylamide were added respectively, and the stirring reaction was continued for 4.5 hours. After the reaction, the acetone was distilled off under reduced pressure to obtain a ...

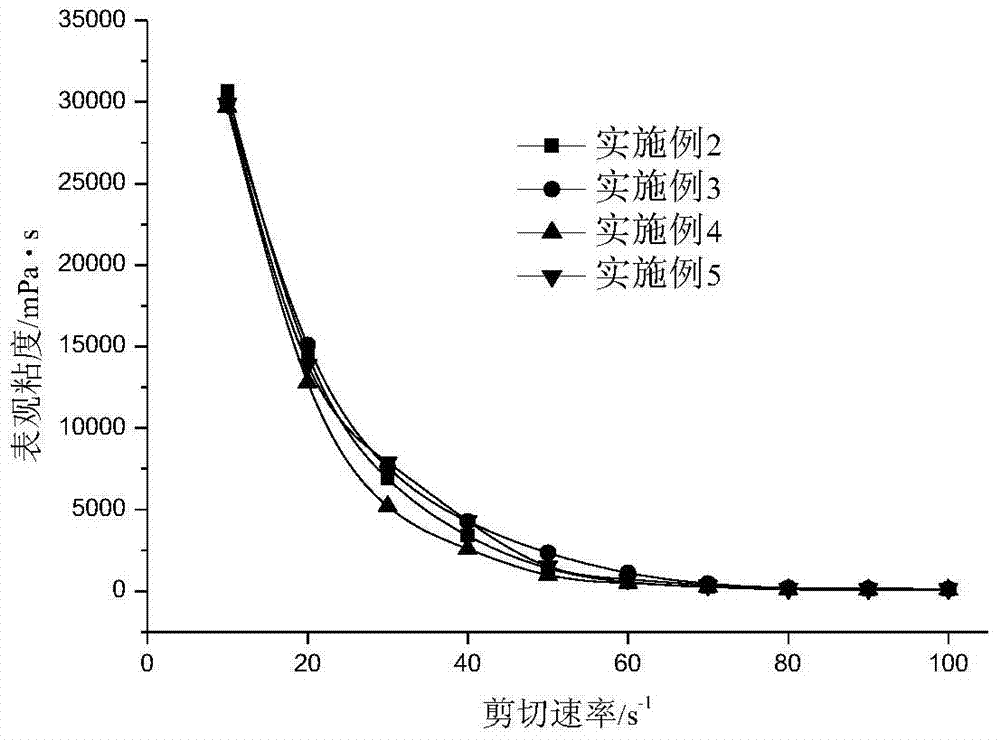

Embodiment 2

[0064] Preparation of hydrogel

[0065] 14.22g of acrylamide, 32.43g of sodium methacrylate, 22.93g of 2-acrylamide-2-methylpropanesulfonate and 800mL of water were successively added into the reactor, and stirred until completely dissolved. Then add the hydrophobic monomer prepared by 2.96g embodiment 1 and 36.35g sodium dodecylbenzenesulfonate, continue to stir so that the hydrophobic monomer is solubilized in the sodium dodecylbenzenesulfonate micelle, logical nitrogen for 30 minutes Evacuate the air. Add 0.7254g (NH 4 ) 2 S 2 o 8 , and the temperature was raised to 40° C. under the condition of continuing nitrogen flow, and the reaction was continued for 12 hours to obtain a gel-like product. Wash with absolute ethanol, pulverize and dry to obtain the target product.

Embodiment 3

[0067] Preparation of hydrogel

[0068] Add 34.70g of N,N-dimethylacrylamide, 47.02g of sodium acrylate, 30.93g of sodium p-styrenesulfonate and 2140mL of water into the reactor in sequence, and stir until completely dissolved. Then add the hydrophobic monomer prepared by 9.84g embodiment 1 and 46.18g sodium octadecylbenzenesulfonate, continue to stir so that the hydrophobic monomer is solubilized in the sodium octadecylbenzenesulfonate micelle, logical nitrogen for 30 minutes Evacuate the air. Add 1.68g (NH 4 ) 2 S 2 o 8 , and the temperature was raised to the predetermined reaction temperature of 55° C. under the condition of continuing nitrogen flow, and the reaction was continued for 8 hours to obtain a gel-like product. Wash with absolute ethanol, pulverize and dry to obtain the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com