A kind of cellulose compound system drilling fluid fluid loss reducer and preparation method thereof

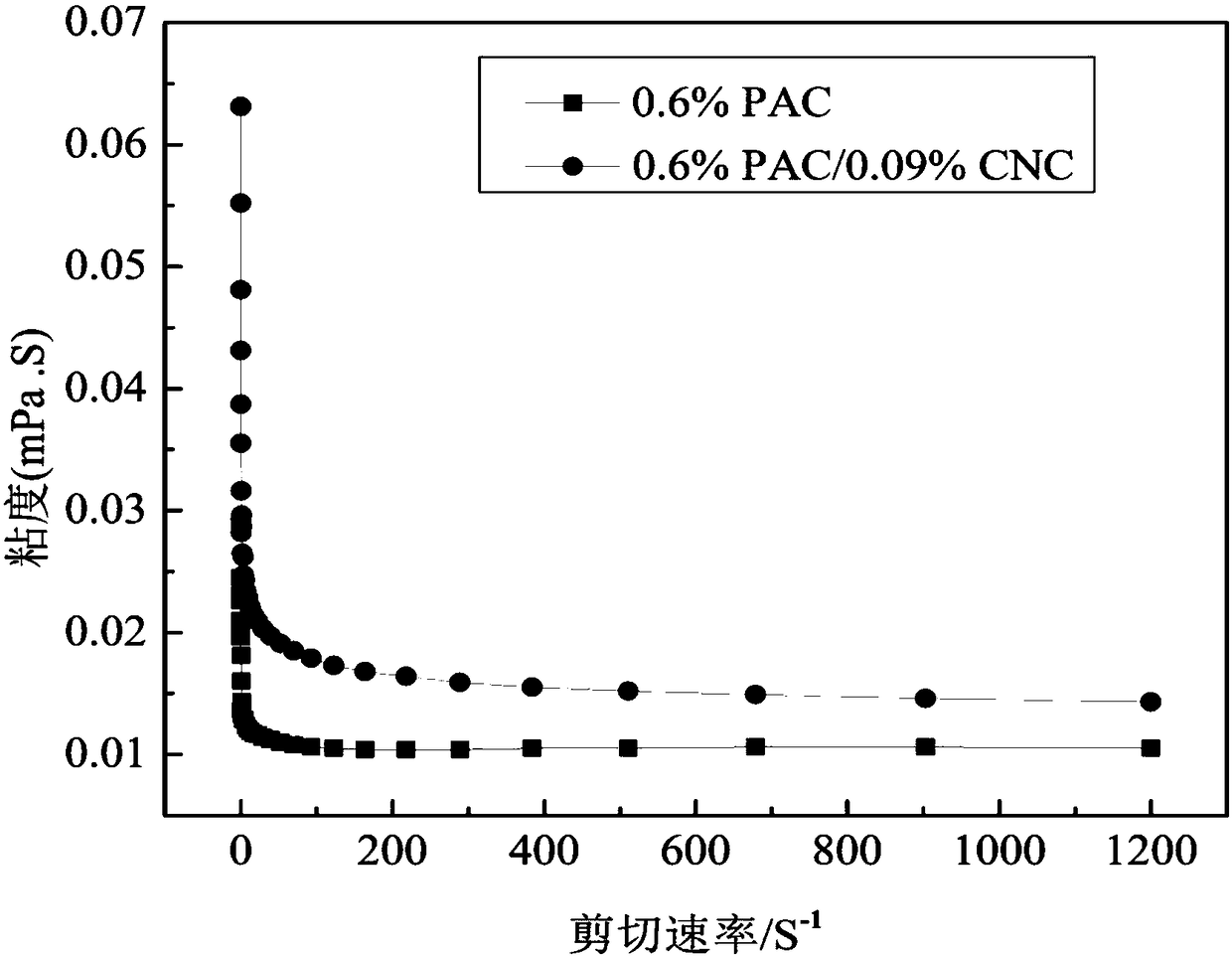

A fluid loss reducer, cellulose technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of no research on the influence of the addition method, no exploration of the effect, and no research on the application effect, etc. Achieve the effect of obvious shear thinning, obvious shear thinning, and reducing the amount of API filtration at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific embodiments. The described embodiments are only preferred embodiments of the present invention, and are not intended to limit the present invention. For those skilled in the art, the present invention may have various modifications and changes. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included within the protection scope of the present invention.

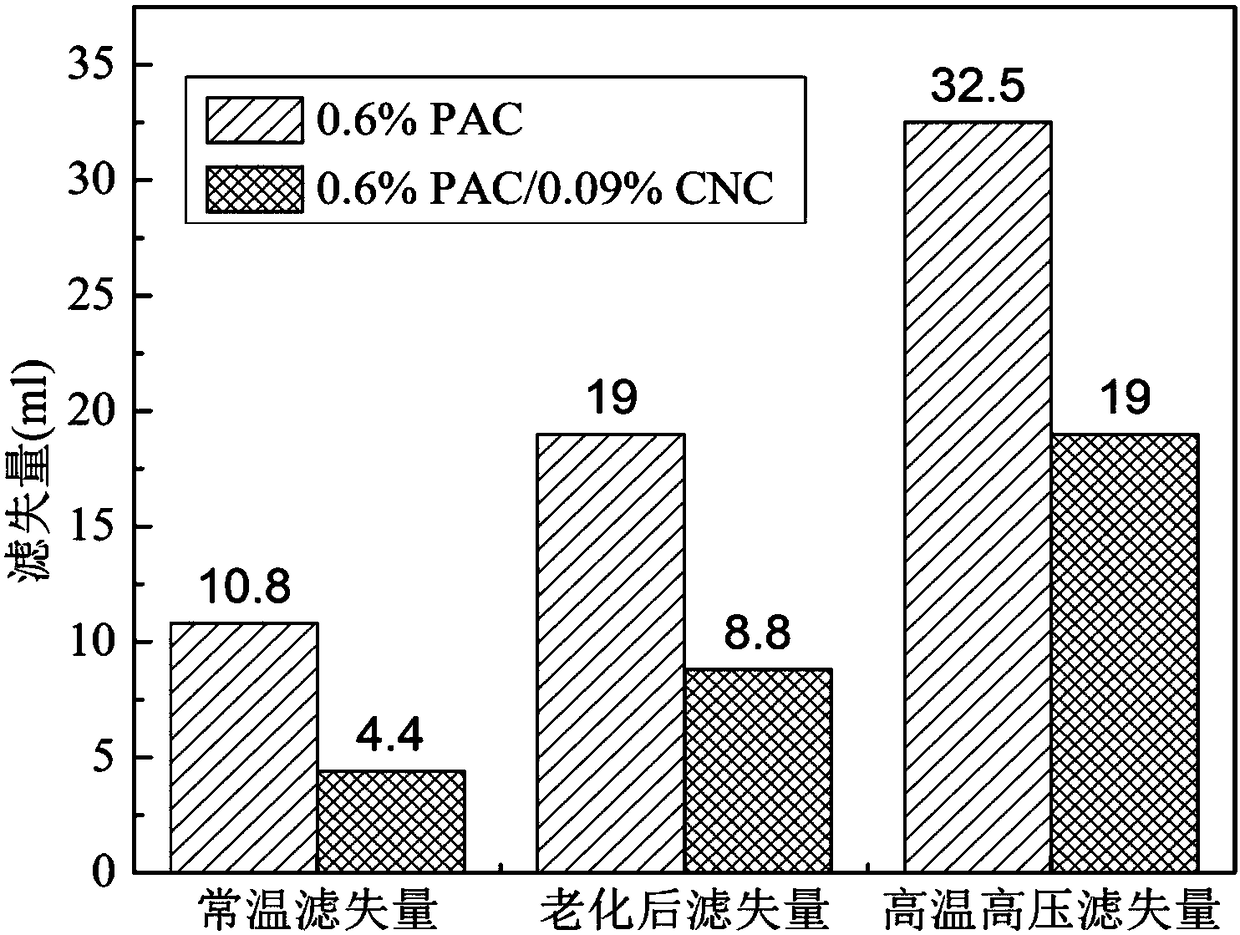

[0033] According to the "Technical Specifications for Drilling Fluid" issued by China National Petroleum Corporation in August 2010, the requirements for fluid loss in different formations are shown in Table 2. For general formations, the API water loss should be within 10-15mL. For water-sensitive formations or For oil and gas reservoirs, the API water loss should be less than 5mL.

[0034] Table 2 API water loss and high-temperature and high-pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com