Inorganic dispersing agent for improving rheological property of geopolymer slurry as well as preparation method and application of inorganic dispersing agent

A technology of inorganic dispersants and geopolymers, applied in the field of inorganic dispersants for improving the rheological properties of geopolymer slurries and its preparation, can solve the problems affecting the popularization of geopolymer materials, slurry forming and pumping operations and other problems, to achieve the effects of promoting application, low price, and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present embodiment also provides the preparation method of the inorganic dispersant for improving the rheological properties of the geopolymer slurry, which includes:

[0021] Step S1. Chemical etching: the fly ash particles are mixed with lye and stirred at 50-80° C. for 1-6 hours.

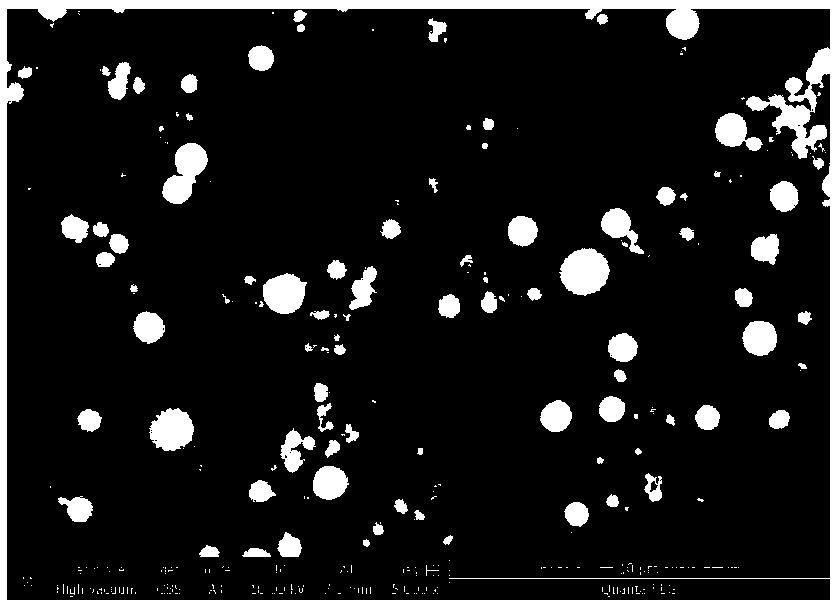

[0022] Mix fly ash particles with lye, and carry out chemical etching under constant stirring at 50-80°C (or 60-70°C; or 63-68°C) to construct rough particle surfaces. The etched fly ash microspheres such as figure 1 As shown, nanoscale particles and pit structures have been formed on the surface of the microspheres, which can reduce the wettability of the fly ash microspheres in the liquid phase.

[0023] Further, the alkali solution has a concentration of 5-10 mol / L, or 6-9 mol / L, or 7-8 mol / L. The solid-to-liquid ratio of the fly ash particles to the lye is 1:25-35, or 1:26-34; or 1:28-32; or 1:29-31. Preferably, the lye is NaOH solution or KOH solution.

[0024] Further, the pa...

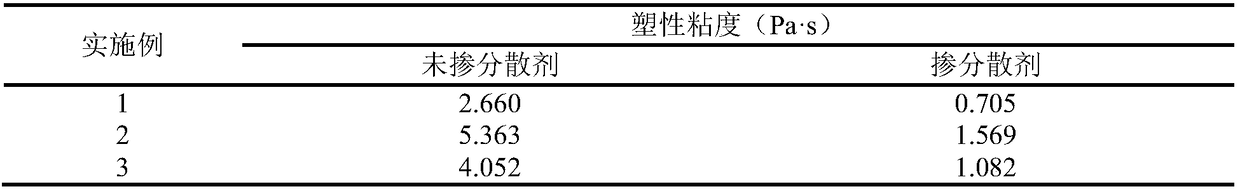

Embodiment 1

[0037] This embodiment provides an inorganic dispersant for improving the rheological properties of geopolymer slurry, and its preparation method comprises:

[0038] Pass the primary fly ash through a 180-mesh square hole sieve, and take the sieved residue to obtain spherical fly ash particles with a particle size of less than 80 μm. Mix fly ash particles with ethanol solution for ultrasonic cleaning, after cleaning, mix with NaOH solution (8mol / L) at a solid-to-liquid ratio of 1:30, stir for 3 hours under hydrothermal conditions at 50°C for chemical etching, and rough particle surfaces .

[0039] Using ethanol as a solvent, heptadecafluorodecyltrimethoxysilane was added to prepare a 1 wt% heptadecafluorodecyltrimethoxysilane / ethanol solution. The roughened fly ash particles were mixed with the prepared solution, and immersed at 60°C for 1 hour to perform low-energy surface modification. After impregnating the microspheres at 105 °C in N 2 Dry under ambient conditions for 2...

Embodiment 2

[0042] This embodiment provides an inorganic dispersant for improving the rheological properties of geopolymer slurry, and its preparation method comprises:

[0043] Pass the primary fly ash through a 180-mesh square hole sieve, and take the sieved residue to obtain spherical particles with a particle size of less than 80 μm. Mix fly ash particles with ethanol solution for ultrasonic cleaning, after cleaning, mix with prepared 10mol / L NaOH solution at a solid-to-liquid ratio of 1:30, stir for 2 hours under hydrothermal conditions at 70°C for chemical etching, the structure is rough particle surface.

[0044] Using ethanol as a solvent, add heptadecafluorodecyltriethoxysilane to configure a 1wt% heptadecafluorodecyltriethoxysilane / ethanol solution, and mix the roughened fly ash particles with the prepared solution , dipped at 60°C for 1h to perform low-energy surface modification. After impregnating the fly ash particles at 105 °C in N 2 Dry under ambient conditions for 2 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com