Method for adjusting fluidity and setting time of chemically activated cementing material system

A cementitious material and chemically stimulated technology, applied in cement production, etc., can solve the problems of loss of mechanical strength, large dosage, poor fluidity retention of slurry or mixture, etc., and achieve low cost and small dosage of inorganic salts , easy-to-obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

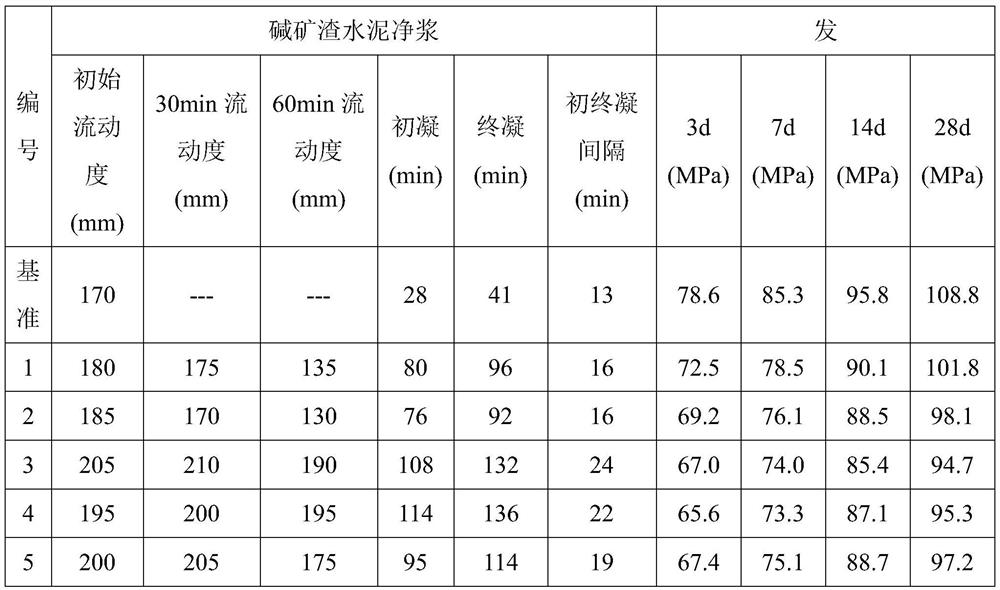

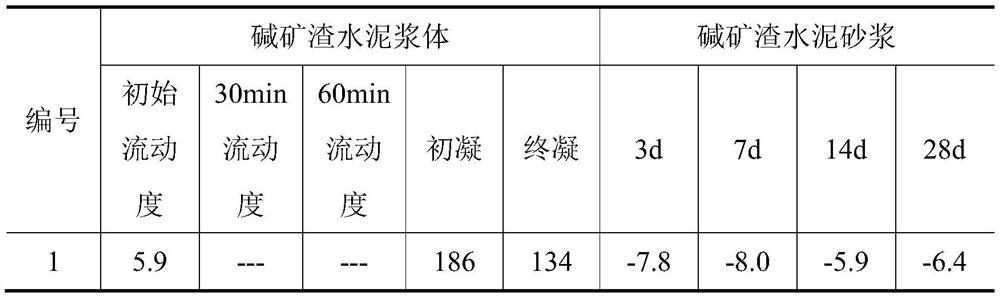

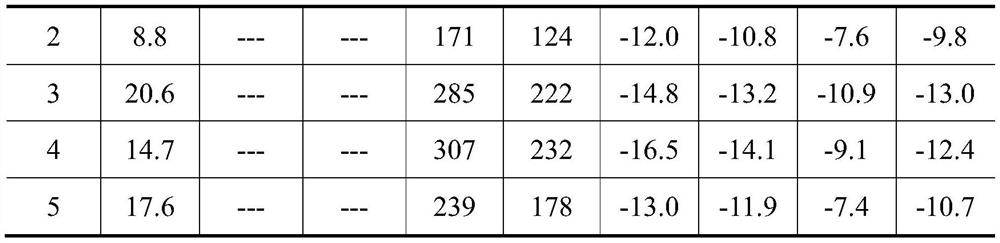

Embodiment 1

[0028] Each raw material is weighed according to the following quality: granulated blast furnace slag powder 65%, water glass solution 35%, respectively 600g and 318g. KNO 3 and Ba(NO 3 ) 2 They are respectively 3% and 0.15% of the granulated blast furnace slag powder, that is, 18g and 0.9g respectively. The above-mentioned powder materials are sequentially added to a slurry mixer and mixed evenly, and then water glass solution is added. The mixer stirred at a speed of 140r / min for 120s, stopped for 15s, and then stirred at a speed of 285r / min for 120s to obtain an alkali slag cement slurry.

[0029] On the basis of the above-mentioned alkali slag cement slurry material ratio, add river sand with a maximum particle size of 4.75mm according to the mortar-sand ratio of 1:3, that is, the raw materials are 600g of granulated blast furnace slag powder, 318g of water glass solution, and KNO 3 18g, Ba(NO 3 ) 2 0.9g, sand 1800g, stir evenly to prepare alkali slag cement mortar. ...

Embodiment 2

[0031] Each raw material is weighed according to the following quality: granulated blast furnace slag powder 70%, water glass solution 30%, respectively 600g and 262g. KNO 3 and Ba(NO 3 ) 2 They are respectively 4% and 0.1% of the granulated blast furnace slag powder, that is, 24g and 0.6g respectively, and are stirred uniformly according to the stirring system in Example 1 to obtain the alkali slag cement slurry.

[0032] On the basis of the above-mentioned alkali slag cement slurry material ratio, 1800 g of river sand with a maximum particle size of 4.75 mm was added according to the mortar-sand ratio of 1:3, and stirred evenly to prepare alkali slag cement mortar.

Embodiment 3

[0034] Each raw material is weighed according to the following quality: granulated blast furnace slag powder 67.5%, water glass solution 32.5%, are respectively 600g and 289g. KCl and Ba(NO 3 ) 2 They are respectively 5% and 0.2% of granulated blast furnace slag powder, that is, 30g and 1.2g respectively. Stir according to the stirring system of Example 1 to obtain alkali slag cement slurry.

[0035] On the basis of the above-mentioned alkali slag cement slurry material ratio, 1800 g of river sand with a maximum particle size of 4.75 mm was added according to the mortar-sand ratio of 1:3, and stirred evenly to prepare alkali slag cement mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com