Method for detecting internal friction in a steering system

一种电动转向系统、内摩擦的技术,应用在转向机构、动力转向机构、车辆转向/颠簸性能等方向,能够解决计算和储存能力有限等问题,达到易于应用和适应、避免错误警告的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

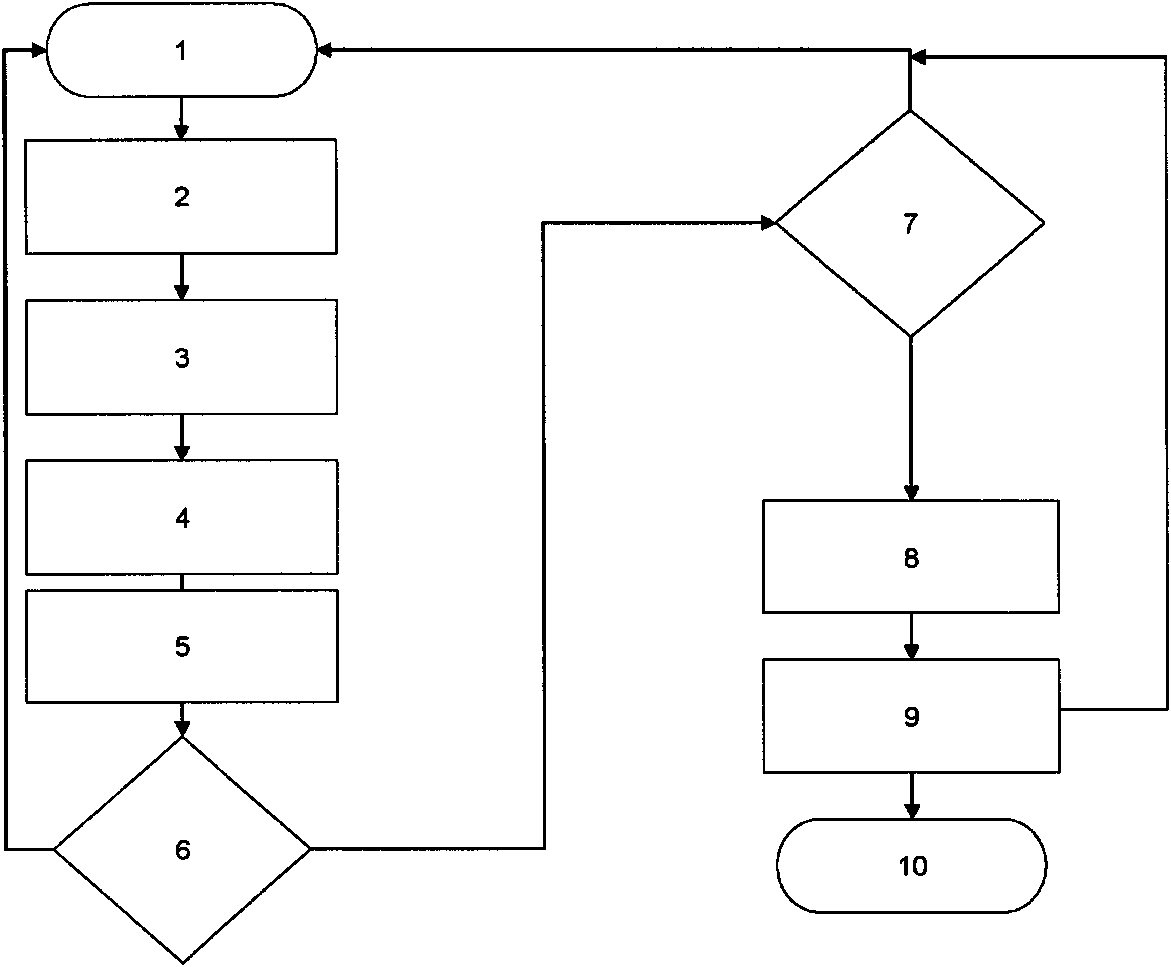

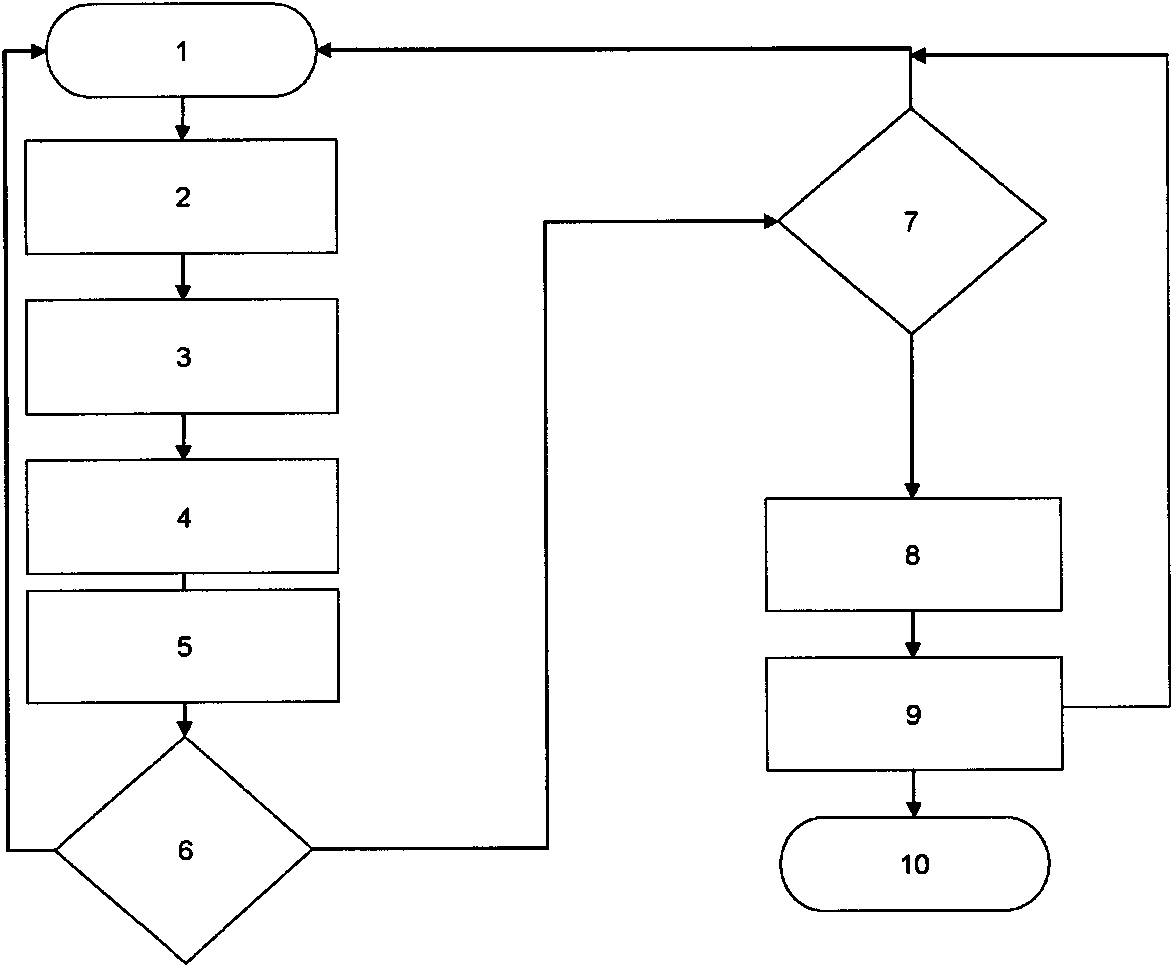

[0023] The method of the present invention starts at starting block 1 . In box 2, the limit value for the variation of the steering column torque (relative to the variation for steady straight driving at 0 Nm manual torque) is defined. The limit value depends on the configuration of the vehicle. The absolute limit value is higher for a vehicle with a sporty tune than for a vehicle with a comfort tune. Of course this is just an example. In block 2 it is also possible to define limit values for the change in position of the steering rack. On the steering wheel, this limit value can have, for example, a rotation angle with an absolute value of 1°. This means that the limit value is exceeded if the steering rack moves more than 1° from its previous position due to the steering column torque. Limit values are defined and maintained once. Of course, the above-mentioned absolute limit values are only exemplary and should not limit the present invention.

[0024] In box 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com