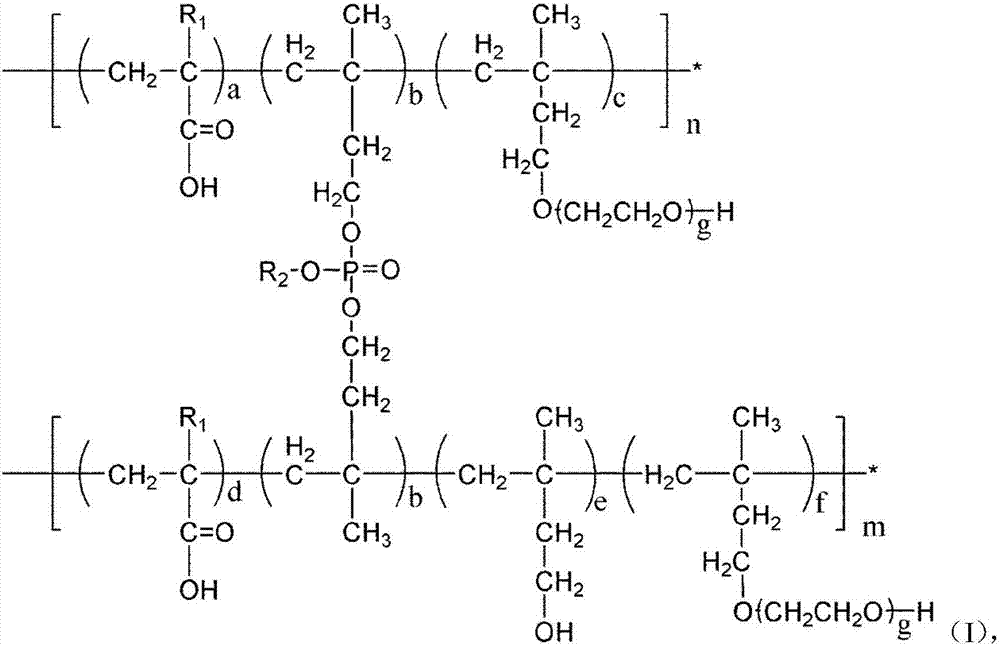

Low air-entraining viscosity reducing polycarboxylic water reducer and preparation method thereof

A technology of viscous polycarboxylic acid and water reducer, which is applied in the field of building material admixtures, can solve problems such as unfavorable production and application, high price of reaction raw materials, and complicated synthesis process, so as to reduce air entrainment, increase thickness, and improve The effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

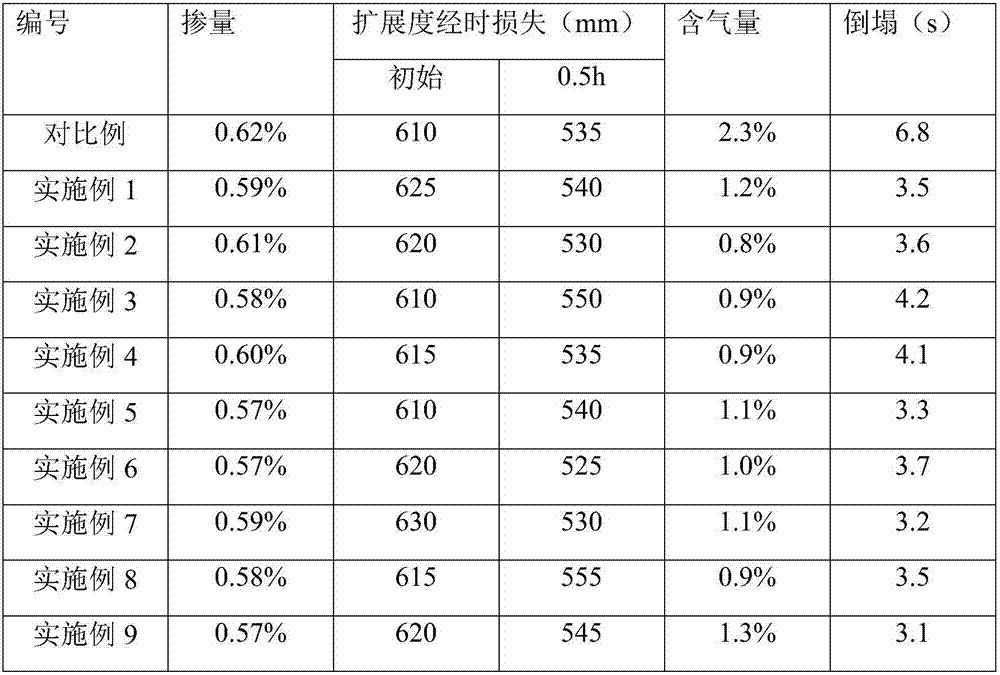

Examples

Embodiment 1

[0045] A low-air-entraining and viscosity-reducing polycarboxylate superplasticizer, which uses alkyl phosphate triester mixture, isopentenol polyoxyethylene ether, and unsaturated carboxylic acid as the main raw materials, plays the role of initiator and chain transfer agent Next, it is formed by free radical polymerization, and the specific steps are as follows:

[0046] 1) Preparation of alkyl phosphate triester mixture: put 1 mol of phosphorus pentoxide in the reactor, slowly add 1 mol of n-butanol dropwise, react at 20-30°C for 2 hours; continue to add 2.0 g polymerization inhibitor hydroquinone, then slowly add 2.1mol prenyl alcohol dropwise, and after the addition of prenyl alcohol is completed, the temperature is raised to 60°C, and the mixture is kept for three hours to obtain the mixture of alkyl phosphate triesters;

[0047] 2) Preparation of low-air-entraining and viscosity-reducing polycarboxylate superplasticizer:

[0048] Weigh 200g (85.11%) of isopentenol poly...

Embodiment 2

[0054] A low-air-entraining and viscosity-reducing polycarboxylate superplasticizer, which uses alkyl phosphate triester mixture, isopentenol polyoxyethylene ether, and unsaturated carboxylic acid as the main raw materials, plays the role of initiator and chain transfer agent Next, it is formed by free radical polymerization, and the specific steps are as follows:

[0055] 1) the preparation of alkyl phosphate triester mixture is with embodiment 1;

[0056] 2) Preparation of low-air-entraining and viscosity-reducing polycarboxylate superplasticizer:

[0057] Weigh 200g (83.3%) of isopentenol polyoxyethylene ether monomer (molecular weight 2400) and dissolve it in 100g of deionized water, pass through nitrogen to exhaust the air, heat up to 40°C and keep it warm to obtain solution A;

[0058] Weigh 24g (10%) of alkyl phosphate triester mixture, 16g (6.7%) of acrylic acid, 0.048g of chain transfer agent, and 0.72g of sodium hydrosulfide and dissolve them in 30g of deionized wat...

Embodiment 3

[0063] A low-air-entraining and viscosity-reducing polycarboxylate superplasticizer, which uses alkyl phosphate triester mixture, isopentenol polyoxyethylene ether, and unsaturated carboxylic acid as the main raw materials, plays the role of initiator and chain transfer agent Next, it is formed by free radical polymerization, and the specific steps are as follows:

[0064] 1) Preparation of alkyl phosphate triester mixture: put 1 mol of phosphorus pentoxide in the reactor, slowly add 1 mol of n-amyl alcohol dropwise, react at 20-30°C for 2 hours; continue to add 2.0 g polymerization inhibitor, then slowly add 2.3mol prenyl alcohol dropwise, after the prenyl alcohol dropwise is completed, the temperature is raised to 60°C, and the mixture is incubated for three hours to obtain the alkyl phosphate triester mixture;

[0065] 2) Preparation of low-air-entraining and viscosity-reducing polycarboxylate superplasticizer:

[0066] Weigh 200g (84%) of isopentenol polyoxyethylene ether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com