Preparation method of inert dilution agent for oil-based drilling fluid

An inert diluent, oil-based drilling fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of inhibition decrease, drilling fluid thickening, performance change, etc. Plastic viscosity, the effect of enhancing lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The inert diluent for oil-based drilling fluid mentioned in the present invention includes 5% calcium chloride aqueous solution, 90% synthetic base oil, 2% emulsifier, 1% wetting agent, 1% fluid loss reducer, and alkalinity regulator 1%.

[0021] Its preparation method is as follows:

[0022] In a beaker equipped with a stirrer and a thermometer, add 90% of low-viscosity synthetic base oil, react at 50°C to 90°C for 6 hours, stop heating; add 2% emulsifier into the reactor, and stir for 4 hours; Losing agent, wetting agent, alkalinity regulator, calcium chloride aqueous solution and other components were mixed in proportion, added to the reactor, stirred for 6 hours, and the mixture in the reactor was stirred at a high speed, and reacted for 6 hours at 50°C to 90°C. to room temperature; forming an emulsion is an inert diluent for oil-based drilling fluid.

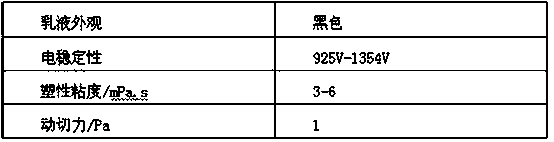

[0023] Prepare the oil-based drilling fluid inert diluent according to the method described above, and investiga...

Embodiment 2

[0029] The inert diluent for oil-based drilling fluid mentioned in the present invention includes 10% calcium chloride aqueous solution, 80% synthetic base oil, 5% emulsifier, 2% wetting agent, 2% fluid loss reducer, and alkalinity regulator 1%.

[0030] Its preparation method is as follows:

[0031] In a beaker equipped with a stirrer and a thermometer, add 80% of low-viscosity synthetic base oil, react at 50°C to 90°C for 6 hours, stop heating; add 5% of emulsifier into the reactor, and stir for 4 hours; Losing agent, wetting agent, alkalinity regulator, calcium chloride aqueous solution and other components were mixed in proportion, added to the reactor, stirred for 6 hours, and the mixture in the reactor was stirred at a high speed, and reacted for 6 hours at 50°C to 90°C. to room temperature; forming an emulsion is an inert diluent for oil-based drilling fluid.

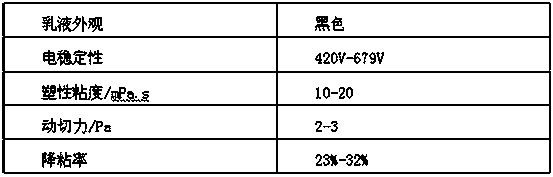

[0032] Prepare the oil-based drilling fluid inert diluent according to the method mentioned above, and inves...

Embodiment 3

[0038] The inert diluent for oil-based drilling fluid mentioned in the present invention includes 20% of calcium chloride aqueous solution, 70% of synthetic base oil, 5% of emulsifier, 2 parts of wetting agent, 2% of fluid loss reducer, and alkalinity regulator 1%.

[0039] Its preparation method is as follows:

[0040] In a beaker equipped with a stirrer and a thermometer, add 70% of low-viscosity synthetic base oil, react at 50°C to 90°C for 6 hours, stop heating; add 5% of emulsifier into the reactor, and stir for 4 hours; Losing agent, wetting agent, alkalinity regulator, calcium chloride aqueous solution and other components were mixed in proportion, added to the reactor, stirred for 6 hours, and the mixture in the reactor was stirred at a high speed, and reacted for 6 hours at 50°C to 90°C. to room temperature; forming an emulsion is an inert diluent for oil-based drilling fluid.

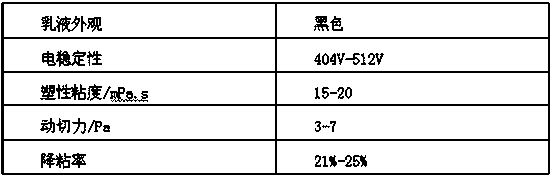

[0041] The inert diluent for oil-based drilling fluid was prepared according to the meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com