Diluent for oil-based drilling fluid, preparation method and application thereof

A technology of oil-based drilling fluid and water-in-oil drilling fluid, which is applied in the field of drilling, can solve problems such as downhole salt invasion, poor quality solid phase, difficulty in drilling construction, and instability of treatment agents, so as to reduce the occurrence of downhole complex situations and achieve good performance. , the effect of reducing the apparent viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

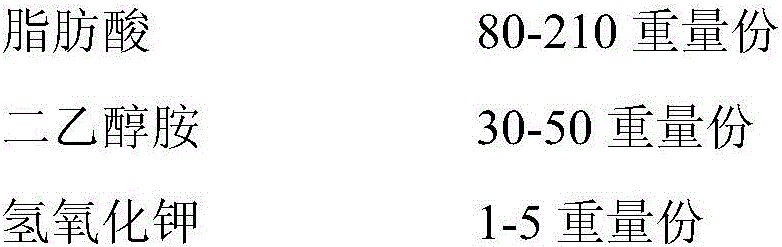

[0032] This embodiment provides a diluent for oil-based drilling fluid, and the raw material components for preparing the diluent include:

[0033]

[0034] This embodiment also provides the preparation method of above-mentioned diluent, and this preparation method comprises the following steps:

[0035] (1) The oleic acid of weighing 90g, the diethanolamine of 42g, the potassium hydroxide of 1g join in the there-necked flask, stir while vacuumizing under the condition that vacuum degree is 0.02-0.06, rotating speed is 3000r / min, gradually warming up to 150°C, after 2-4 hours of reaction, stop vacuuming and stirring, and keep warm for 1.5-2 hours to obtain amides;

[0036] (2) Add 16.9 g of dodecylbenzenesulfonic acid into the three-necked flask of the above-mentioned amide compound, continue to vacuumize and stir the reaction for 2 hours at 150 ° C, and the rotation speed is 3000 r / min, and the reaction is terminated to obtain oil-based drilling fluid diluent.

[0037] T...

Embodiment 2

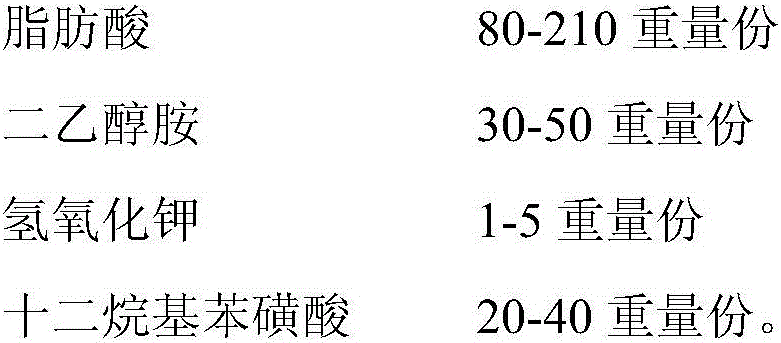

[0039] This embodiment provides a diluent for oil-based drilling fluid, and the raw material components for preparing the diluent include:

[0040]

[0041] This embodiment also provides the preparation method of above-mentioned diluent, and this preparation method comprises the following steps:

[0042] (1) The oleic acid of weighing 202g, the diethanolamine of 42g, the potassium hydroxide of 1g join in the there-necked flask, stir while vacuumizing under the condition that vacuum degree is 0.02-0.06, the rotating speed is 4000r / min, gradually warming up to 150°C, after 2-4 hours of reaction, stop vacuuming and stirring, and keep warm for 1.5-2 hours to obtain amides;

[0043] (2) Add 16.9 g of dodecylbenzenesulfonic acid into the three-necked flask of the above-mentioned amide compound, continue to vacuumize and stir the reaction for 4 hours at 150 ° C, and the rotation speed is 4000 r / min, and the reaction is terminated to obtain oil-based drilling fluid diluent.

[00...

Embodiment 3

[0046] This embodiment provides a diluent for oil-based drilling fluid, and the raw material components for preparing the diluent include:

[0047]

[0048] This embodiment also provides the preparation method of above-mentioned diluent, and this preparation method comprises the following steps:

[0049] (1) The oleic acid of weighing 202g, the diethanolamine of 42g, the potassium hydroxide of 1g join in the there-necked flask, stir while vacuumizing under the condition that vacuum is 0.02-0.06, the rotating speed is 3000r / min, gradually warming up to 150°C, after 2-4 hours of reaction, stop vacuuming and stirring, and keep warm for 1.5-2 hours to obtain amides;

[0050] (2) Add 23.35 g of dodecylbenzenesulfonic acid into the three-necked flask of the above-mentioned amide compound, continue to vacuumize and stir the reaction for 5 hours at 160 ° C, and the rotation speed is 3000 r / min, and the reaction is terminated to obtain oil-based drilling fluid diluent.

[0051]Thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com