Lightweight high-strength concrete and preparation method thereof

A high-strength concrete and concrete technology, applied in the field of building materials, can solve the problems of low strength and poor fluidity of high-strength lightweight aggregate concrete, and achieve the effects of improving toughness, reducing shear stress and plastic viscosity, and reducing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

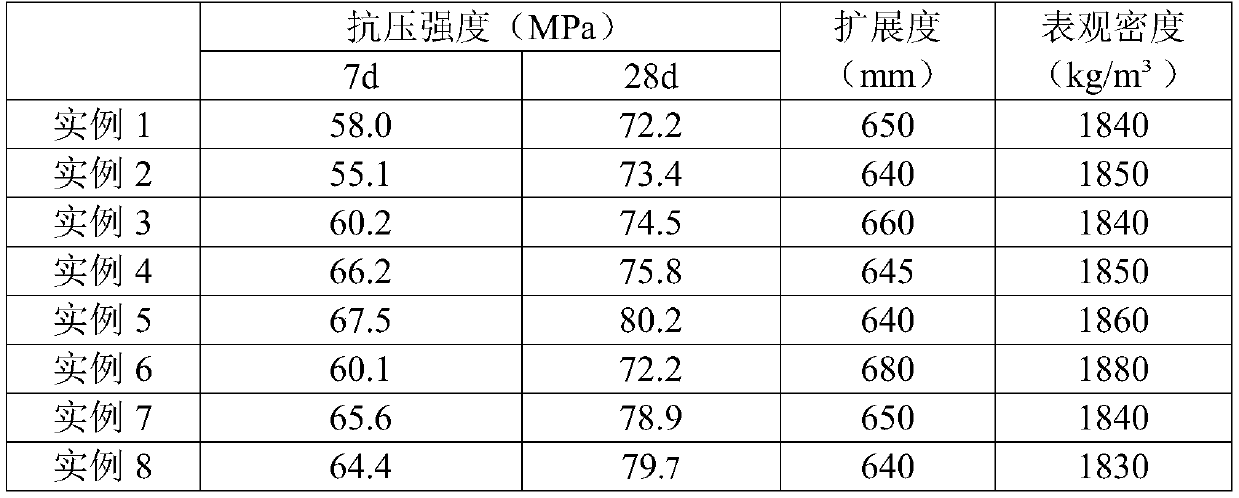

Examples

Embodiment Construction

[0022] A preparation method for lightweight high-strength concrete, comprising the following steps:

[0023] Step 1: put the lightweight spherical coarse aggregate into water for pre-wet treatment for 24 hours, and then dry it naturally so that the moisture content is 0.2%-0.5%;

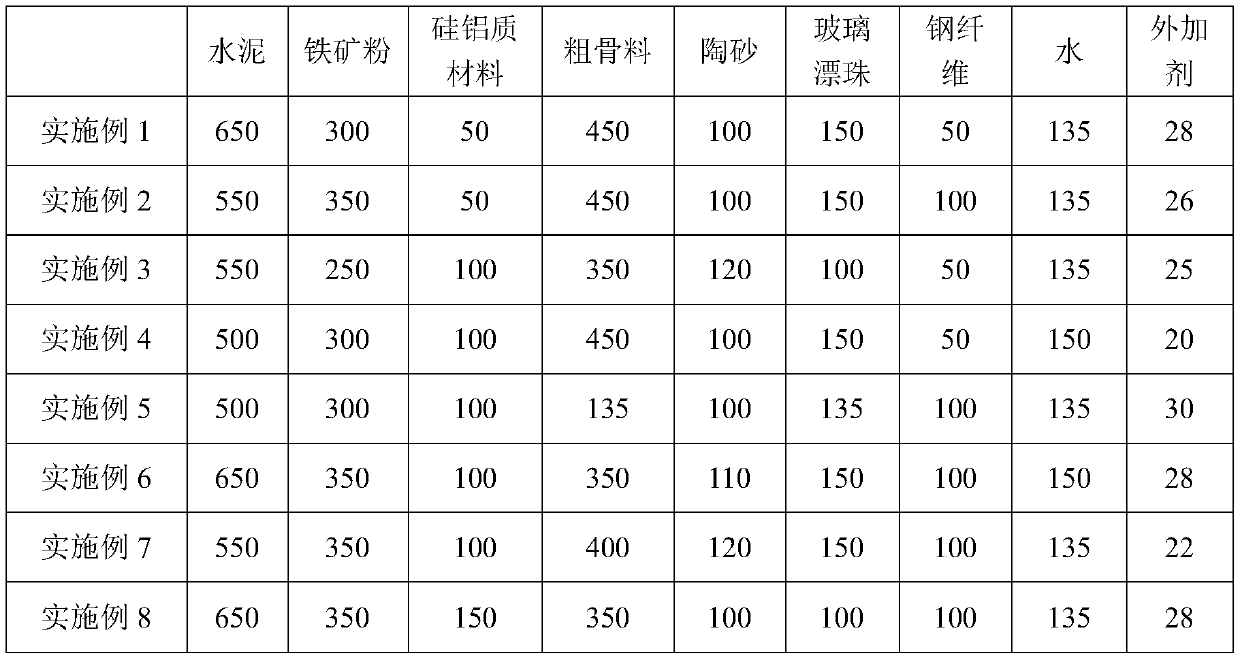

[0024] Step 2: the unilateral consumption of each component of the concrete is weighed according to Embodiment 1-8;

[0025]

[0026] Step 3: First add the weighed cement, high-activity spherical silicon-aluminum material, low-activity alkaline calcareous material iron ore powder, light spherical fine material glass beads into the mixing pot, and stir for 30 seconds to make the powder Fully and evenly disperse, then add water and 2 / 3 of the admixture to stir to obtain a slurry, then add the steel fiber into the stirring pot within 2 minutes to obtain a uniform steel fiber slurry, and then add the light Fine aggregate shale clay sand and lightweight spherical coarse aggregate are added to the mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com