Tackifying and shear strength improving agent as well as preparation method and application of tackifying and shear strength improving agent

A technology of cutting agent and dimer fatty acid, which is applied in the field of viscosity-increasing and cutting agent of soil-free oil-based drilling fluid and its preparation, which can solve the problems of insignificant application effect, low ROP, and poor tripping. , to achieve enhanced performance against solid phase and formation water pollution, increase ROP, and reduce downhole loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

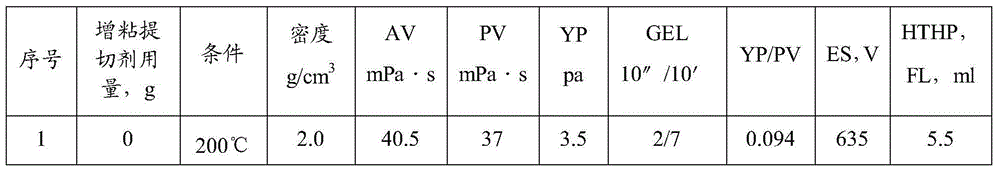

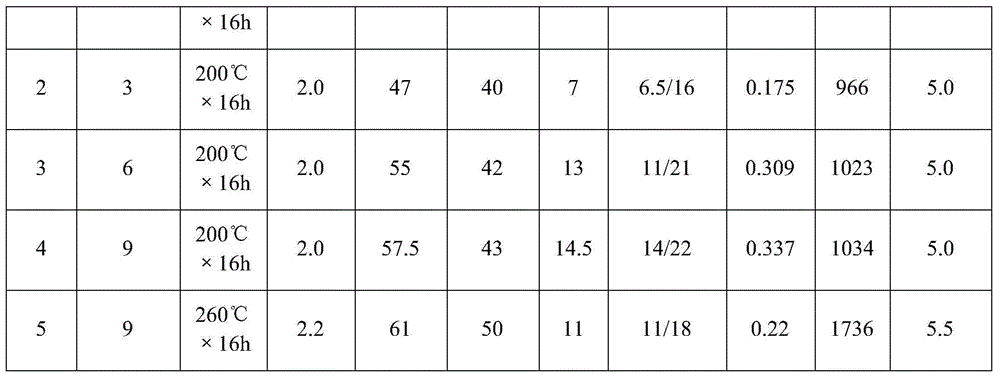

Examples

Embodiment 1

[0028] In a 1000ml four-necked bottle with agitator, heating device, thermometer, dropping funnel and dehydration device, add 336g (0.6mol) of dimer fatty acid and 15% (about 50g) of triethylene glycol of dimer fatty acid quality Monobutyl ether, stir evenly and start heating, put 43.2g (0.42mol) diethylenetriamine into the dropping funnel, under stirring and heating, drop it into the four-necked bottle through the dropping funnel, and heat up after the dropping to 155°C, keep this temperature until no more water comes out, and then continue to react for 15 minutes. After the reaction, cool down to 100°C, add 200ml of xylene, stir evenly and cool down to 60°C to prepare a soil-free oil-based drilling fluid. viscosifying agent.

Embodiment 2

[0030] Add the triethylene glycol monobutyl ether of 336g (0.6mol) dimer fatty acid and 15% (about 50g) of dimer fatty acid quality in the four-neck flask described in embodiment 1, stir and start heating, 49.44 g (0.48mol) diethylenetriamine was put into the dropping funnel, and was added dropwise to the four-necked bottle through the dropping funnel under stirring and heating. Continue to react for 10 minutes after the water is removed. After the reaction, cool down to 100°C, add 200ml of xylene, stir evenly and cool down to 60°C to prepare a viscosity-increasing and shearing agent that can be used for soil-free oil-based drilling fluid.

Embodiment 3

[0032] Add the triethylene glycol monobutyl ether of 17.8% (about 60g) of 336g (0.6mol) dimer fatty acid and fatty acid quality in the four-necked flask described in embodiment 1, stir and start heating, 65.92g ( Put 0.64mol) of diethylenetriamine into the dropping funnel, add it dropwise into the four-necked bottle through the dropping funnel under stirring and heating, and raise the temperature to 155°C after the dropping, keep this temperature until no more water comes out Continue the reaction for another 15 minutes. After the reaction, cool down to 100°C, add 200ml of xylene, stir evenly, and cool down to 60°C to prepare a viscosity-increasing and shearing agent that can be used for soil-free oil-based drilling fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com