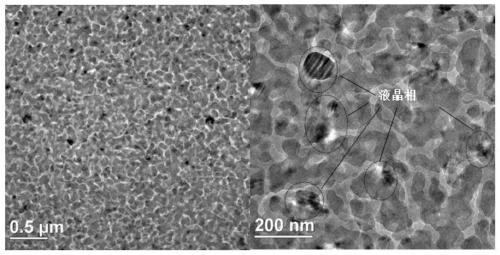

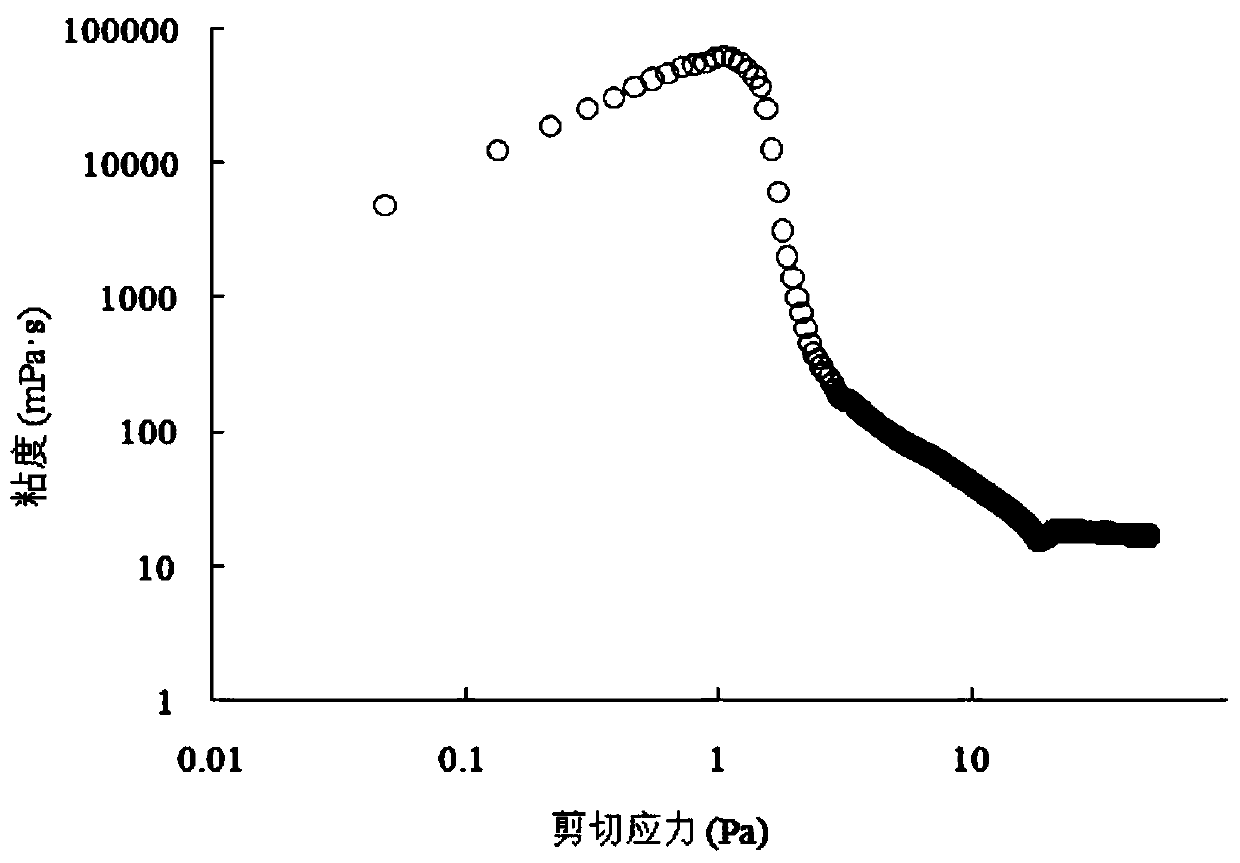

Bicontinuous phase micro-emulsion, preparation method thereof, drilling fluid containing micro-emulsion and preparation method thereof

A dual-continuous phase and microemulsion technology is applied to drilling fluid and its preparation, and its preparation, in the field of dual-continuous phase microemulsion, can solve the problems of complicated procedures, increased cost, increased environmental pollution, etc., and achieves good inhibition and easy removal. , Easy to remove oil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: a kind of double continuous phase microemulsion provided by the present invention, raw material comprises emulsifier, water-soluble acid, oil phase, and water phase, and emulsifier is amine nonionic emulsifier, and water-soluble acid is hydrochloric acid, acetic acid , propionic acid mixture, the oil phase is a mixture of mineral oil and diesel oil, and the water phase is a mixture of seawater, organic salt brine such as ammonium salt;

[0035] The hydrophilic-lipophilic balance value of the amine nonionic emulsifier is 4 to 6, and has the general molecular structure formula shown in Formula 1;

[0036]

[0037] In formula 1, R is a hydrophobic carbon chain with a chain length of C8-C20, containing at least one unsaturated bond, R' is H, C 1 、C 2 or C 3 , A is O or NH, 1≤m+n≤3.

[0038] For example, the emulsifier is an ethoxylated higher fatty alkylamine, which has a general molecular structure formula shown in Formula 2;

[0039]

[0040] In fo...

Embodiment 2

[0048] Embodiment two: a kind of bicontinuous phase microemulsion provided by the present invention, raw material comprises emulsifier, water-soluble acid, oily phase, and water phase, and emulsifier is amine nonionic emulsifier, and water-soluble acid is lactic acid, halogen Acetic acid and glycolic acid are mixed, the oil phase is a mixture of gas oil and synthetic base liquid, the water phase is a mixture of inorganic salt brine such as sodium chloride, and a water phase containing water-soluble organics such as glycerol;

[0049] The hydrophilic-lipophilic balance value of the amine nonionic emulsifier is 4 to 6, and has the general molecular structure formula shown in Formula 1;

[0050]

[0051] In formula 1, R is a hydrophobic carbon chain with a chain length of C8-C20, containing at least one unsaturated bond, R' is H, C 1 、C 2 or C 3 , A is O or NH, 1≤m+n≤3.

[0052] For example, the emulsifier is aliphatic propylene diamine, which has a molecular structure gene...

Embodiment 3

[0061] Embodiment three: a kind of dual continuous phase microemulsion provided by the present invention, raw material comprises emulsifier, water-soluble acid, oil phase and water phase, emulsifier is amine nonionic emulsifier, water-soluble acid is tartaric acid, oil The phase is mineral oil, and the water phase is a mixture of inorganic salt brine such as calcium chloride and sea water;

[0062] The hydrophilic-lipophilic balance value of the amine nonionic emulsifier is 4 to 6, and has the general molecular structure formula shown in Formula 1;

[0063]

[0064] In formula 1, R is a hydrophobic carbon chain with a chain length of C8-C20, containing at least one unsaturated bond, R' is H, C 1 、C 2 or C 3 , A is O or NH, 1≤m+n≤3.

[0065] For example, the emulsifier is an ethoxylated higher fatty alkylamine, which has a general molecular structure formula shown in Formula 2;

[0066]

[0067] In formula 2, R is a hydrophobic carbon chain, containing at least one un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com