Movable bracket of cantilever beam on platform of drilling for oil

A technology for oil drilling platforms and mobile brackets, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of lower hook load, lower bearing capacity, and lower drilling depth at the top of the drilling rig, and achieve the goal of drilling Increased efficiency and economy, improved bearing conditions, and increased drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

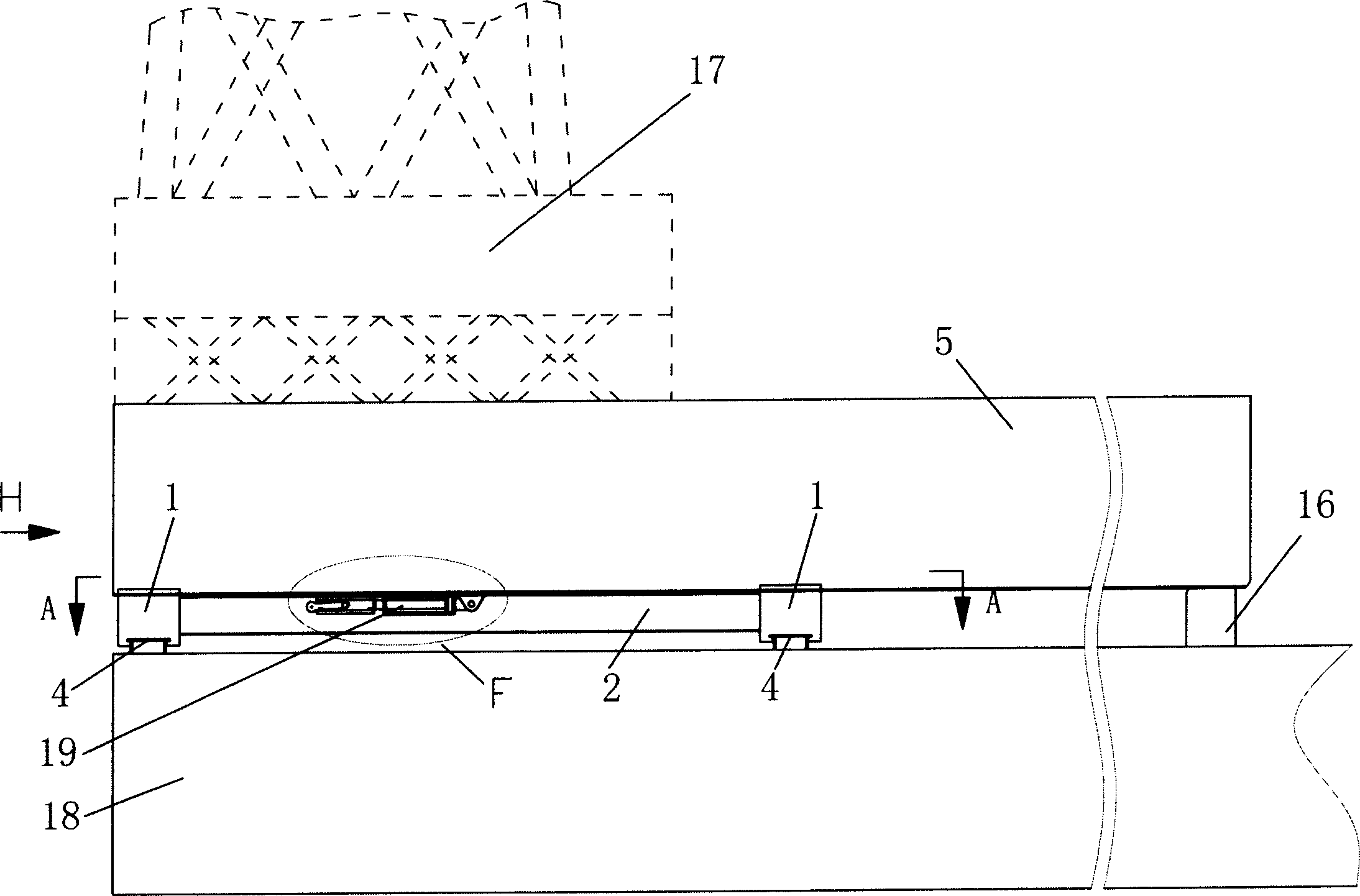

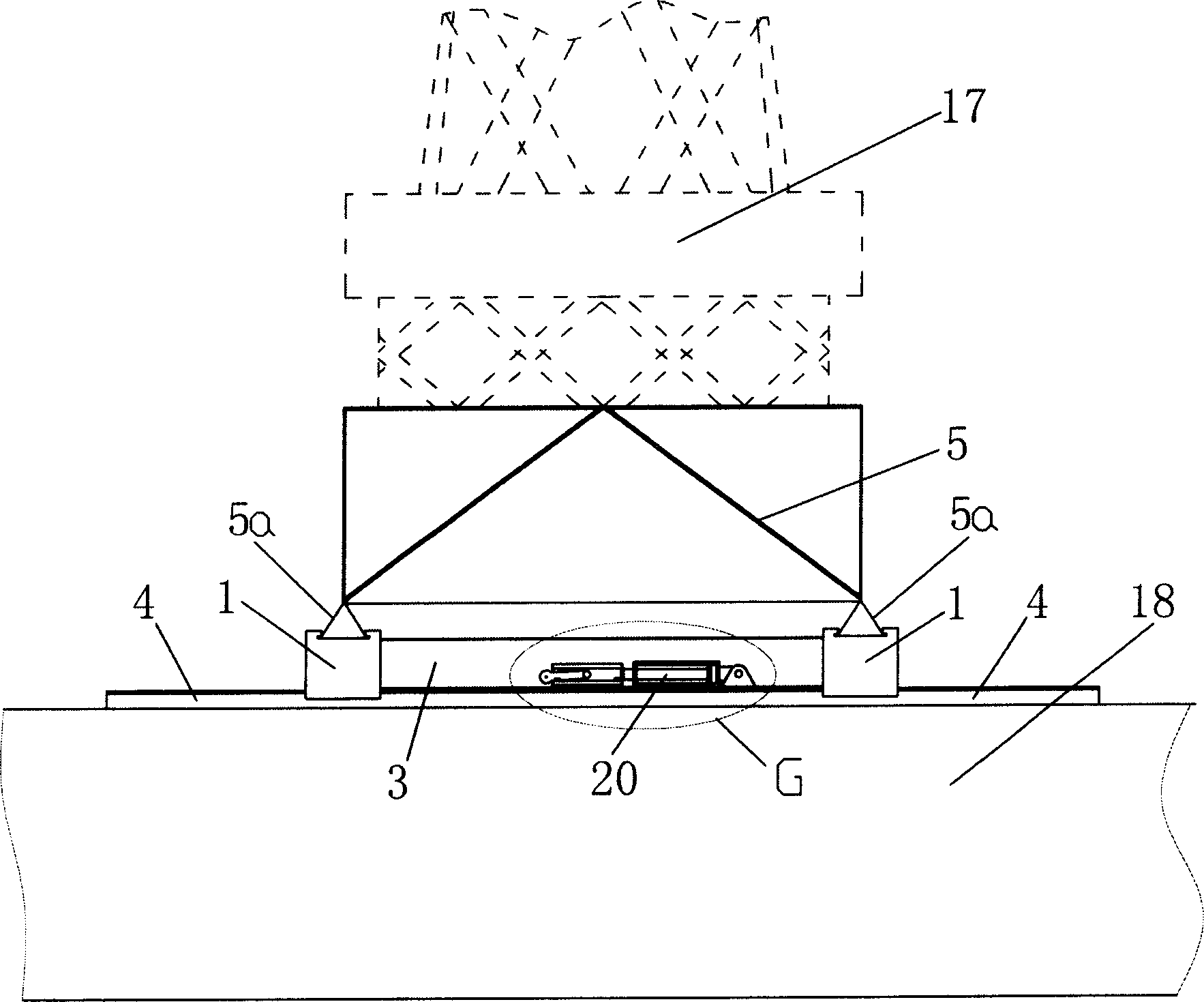

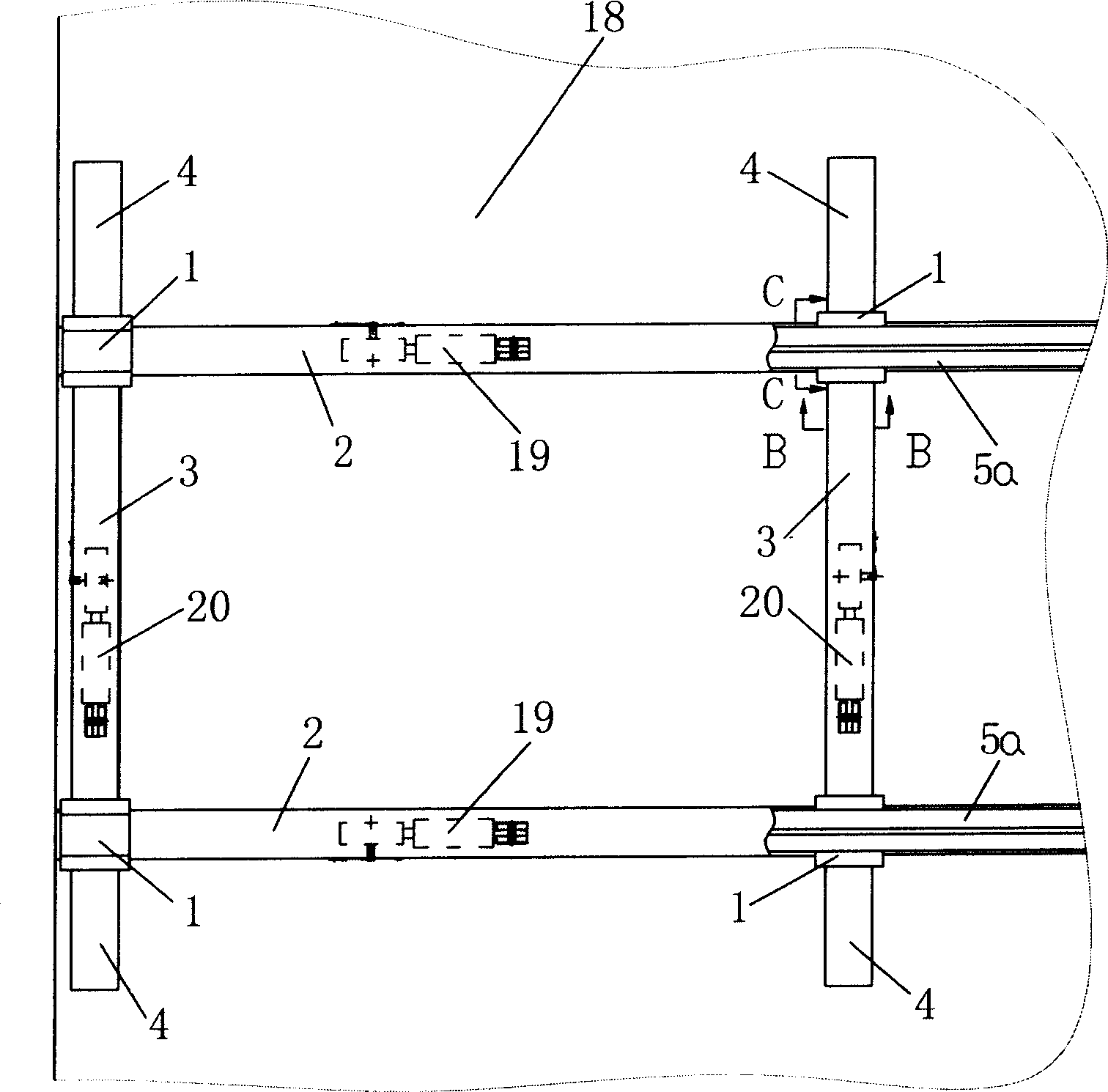

[0020] exist figure 1 , 2 In the embodiment shown in , 3: the afterbody of drilling platform 18 is fixed with two bracket glideslopes 4, and the mobile bracket that is made up of four bracket bases 1, two bracket longitudinal beams 2 and two bracket beams 3 The frame is a square frame structure, and the bracket base 1 is located at the four corners of the square frame. The lower part of the bracket base 1 is provided with a transverse chute matched with the bracket glide path 4, and a transverse moving device 20 is respectively arranged in the bracket beam 3, and the transverse moving device 20 can drive and move the bracket by means of hydraulic action. Move laterally on the carriage glideway 4. The upper part of the bracket base 1 is provided with a longitudinal chute matched with the two bracket upper slides 5a at the lower part of the cantilever beam 5, and a longitudinal moving device 19 is respectively provided in the bracket longitudinal beam 2. The longitudinal movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com