Axial ultrasonic vibration drilling device fixed by lathe carriage

A technology of lathe tool holder and ultrasonic vibration, which is applied in the direction of boring/drilling device, fluid using vibration, boring machine/drilling machine parts, etc., which can solve the problems of inconvenient disassembly and assembly of the device, high cost and complicated structure, and achieve convenient installation, The effect of reducing drilling force and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

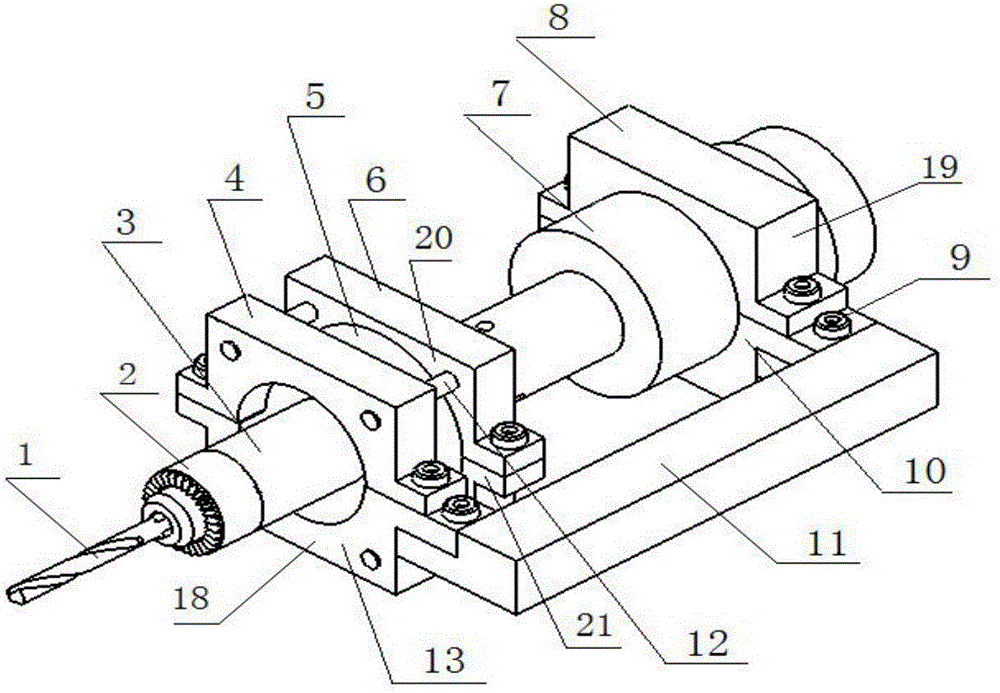

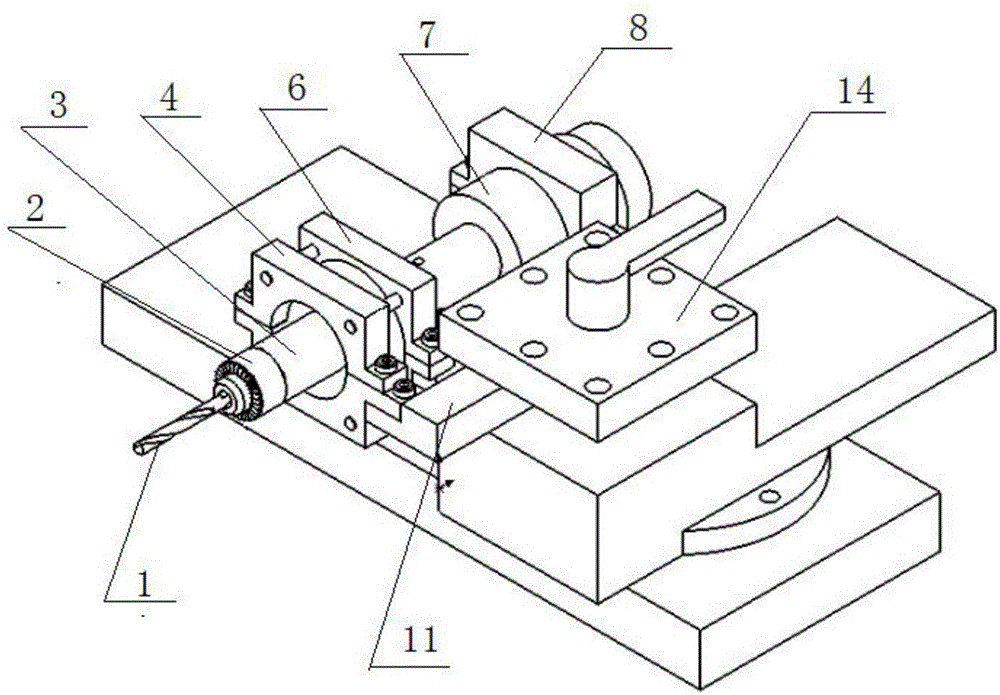

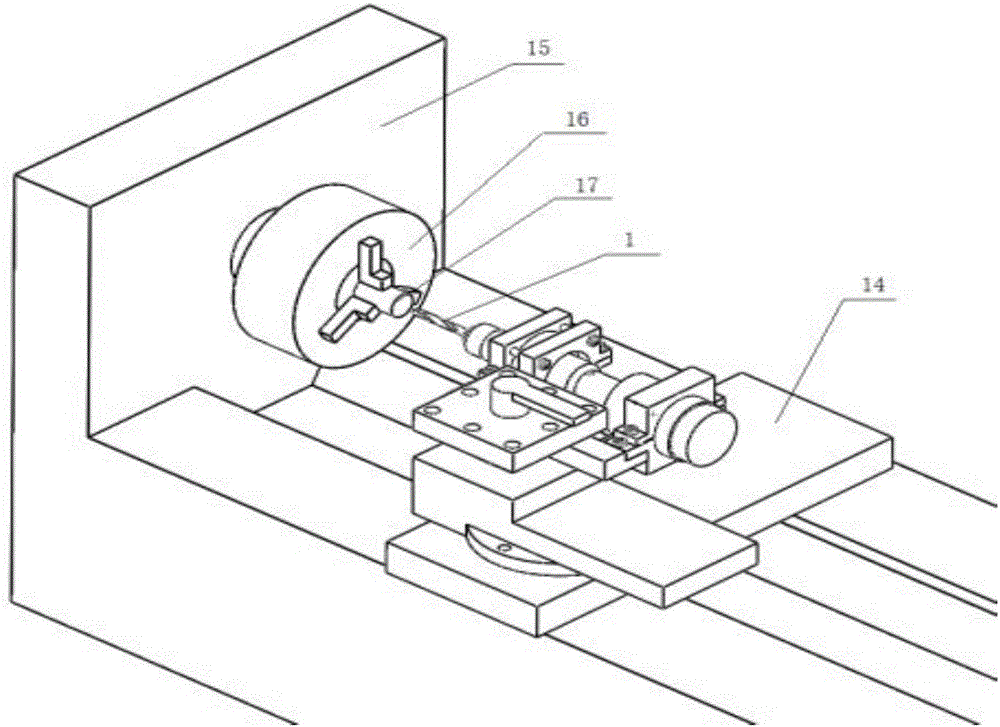

[0024] Such as Figure 1 to Figure 3 The shown a kind of axial ultrasonic vibration drilling device that is fixed by lathe turret comprises ultrasonic vibration device and cantilever type fixing device, and described ultrasonic vibration device comprises a drill bit 1, horn 3, transducer 7 and The transducer 7 is connected to an ultrasonic generator (not shown) by wires.

[0025] Such as figure 1 and Figure 4 As shown, the drill bit 1 is fixed on the drill chuck 2, the drill chuck 2 is connected to the front end of the horn 3 through a first stud, and the drill bit 1 and the horn 3 Keeping the coaxial arrangement, the transducer 7 is connected to the rear end of the horn 3 through a second stud. Such as figure 1 , figure 2 and image 3 As shown, the cantilever beam type fixing device is fixed on the lathe tool rest 14, includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com