Patents

Literature

52results about How to "Processing saves time and effort" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

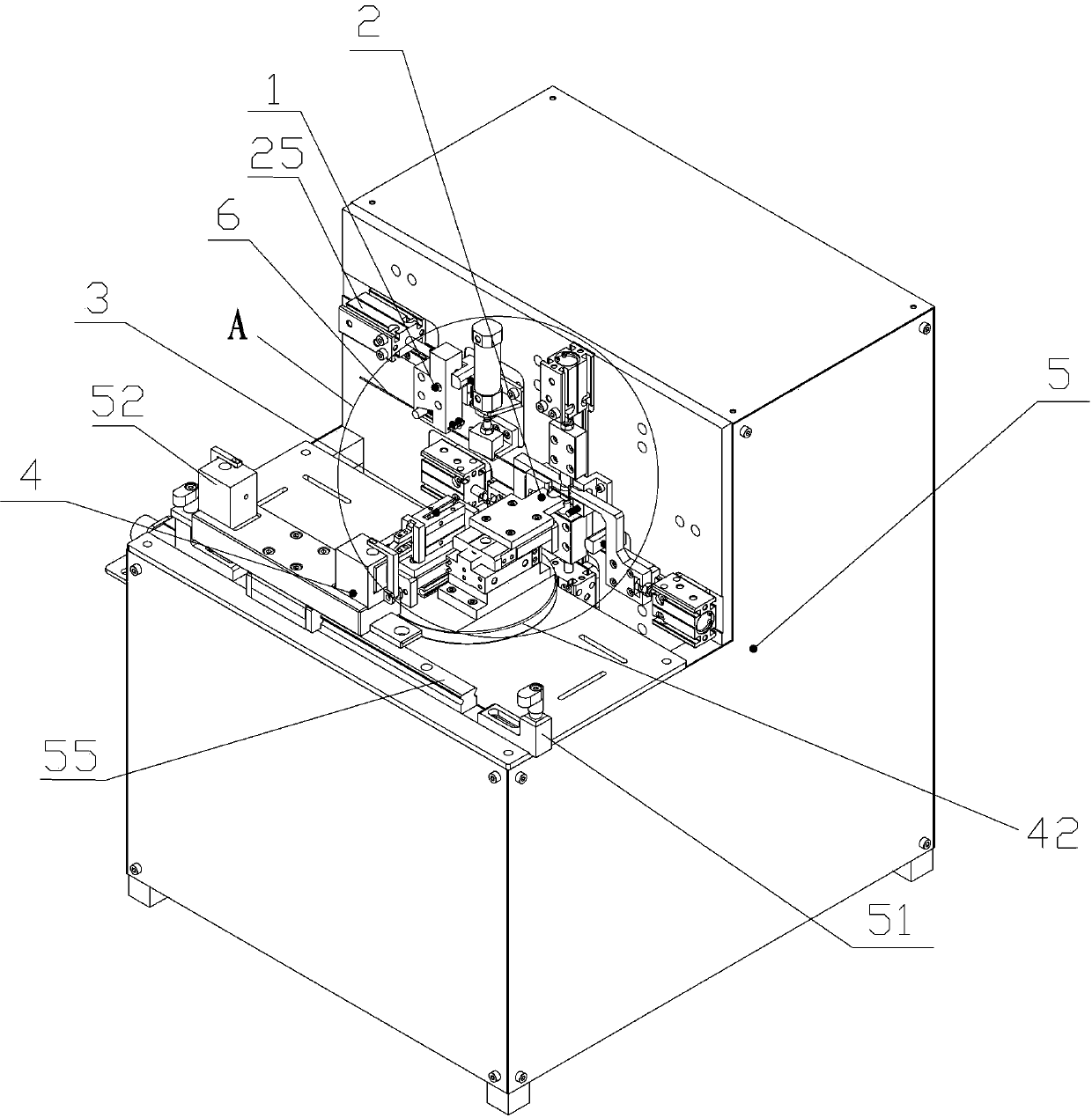

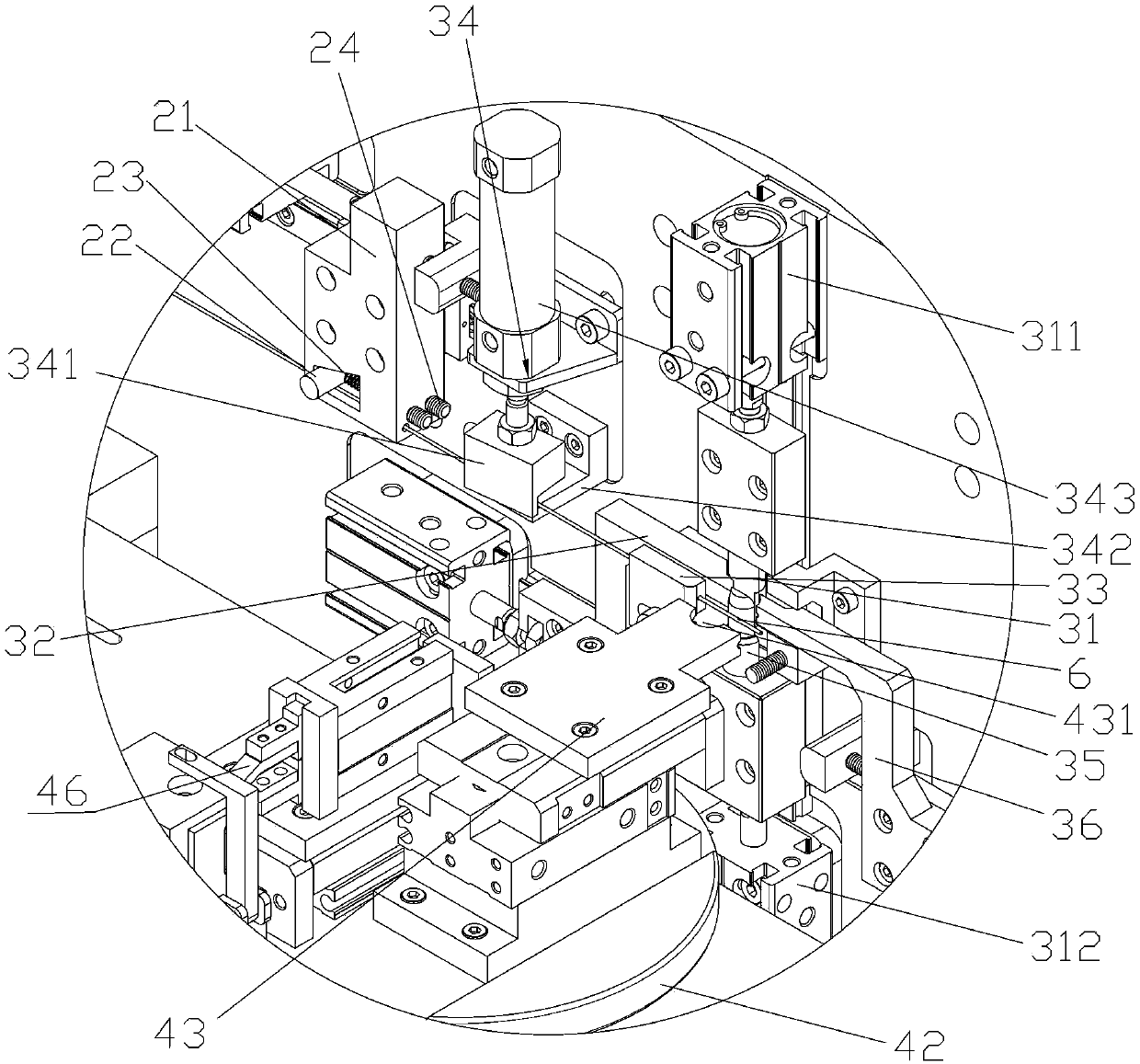

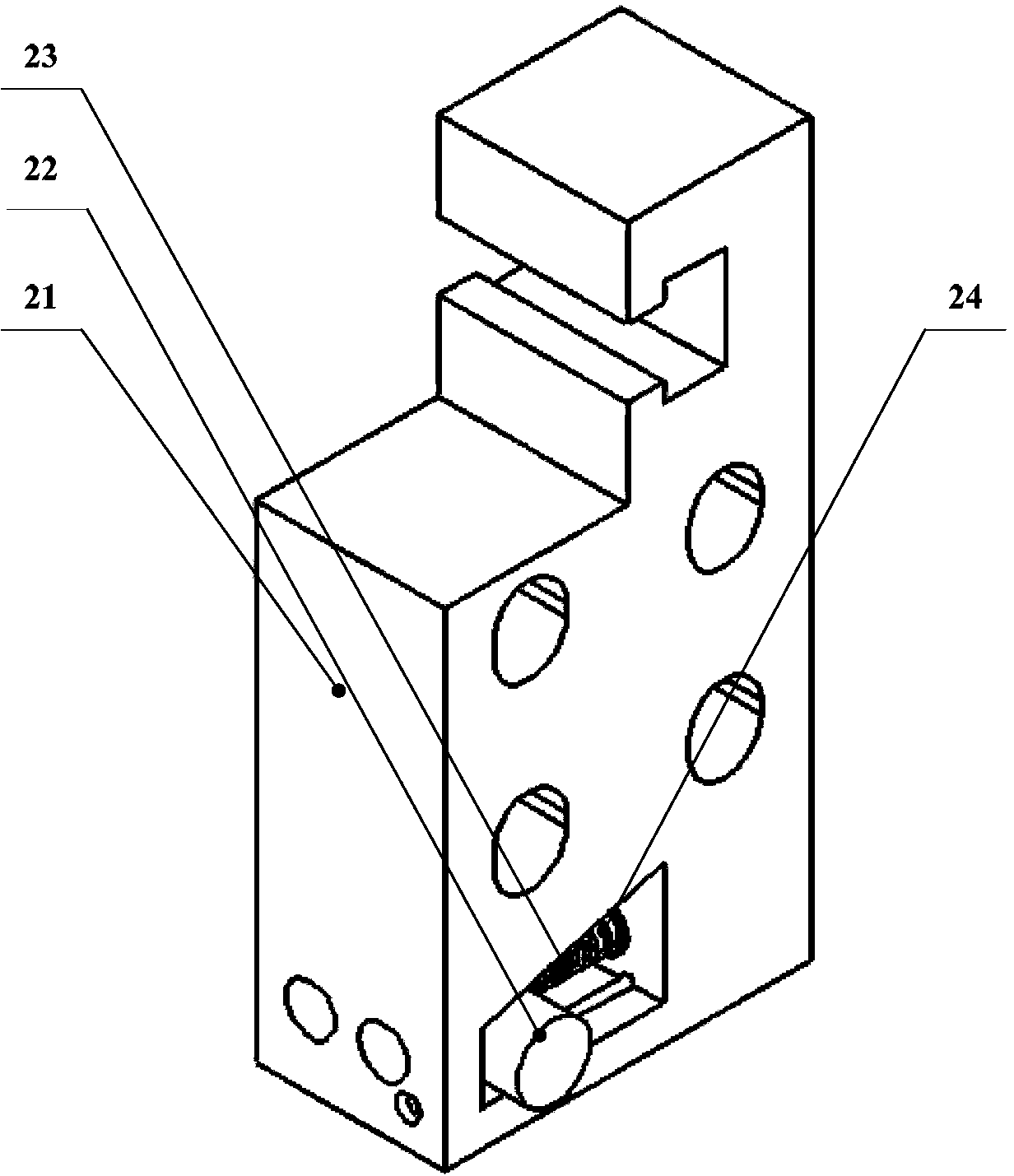

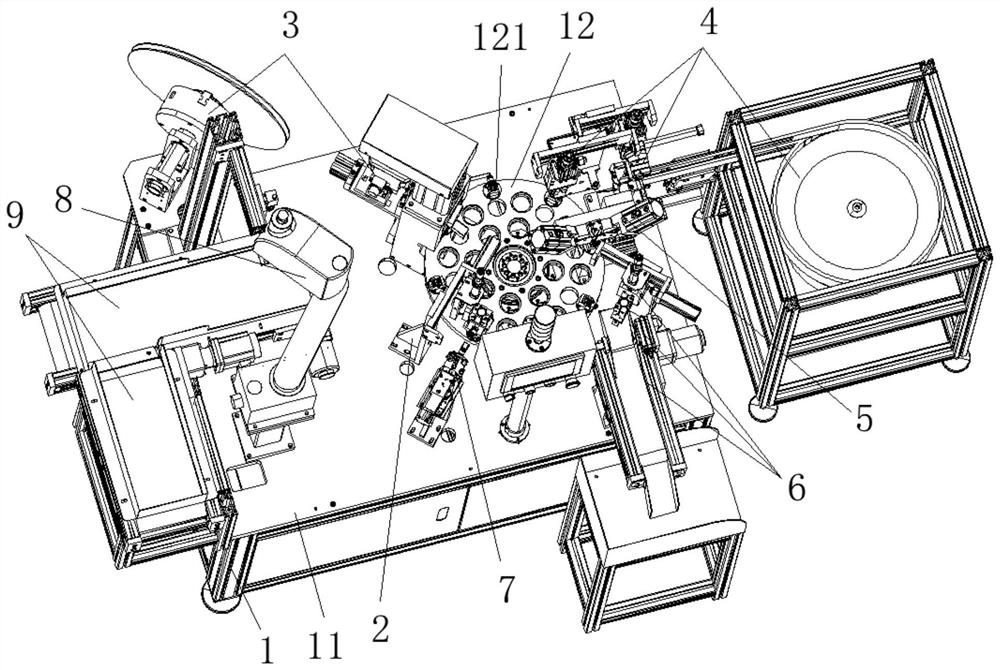

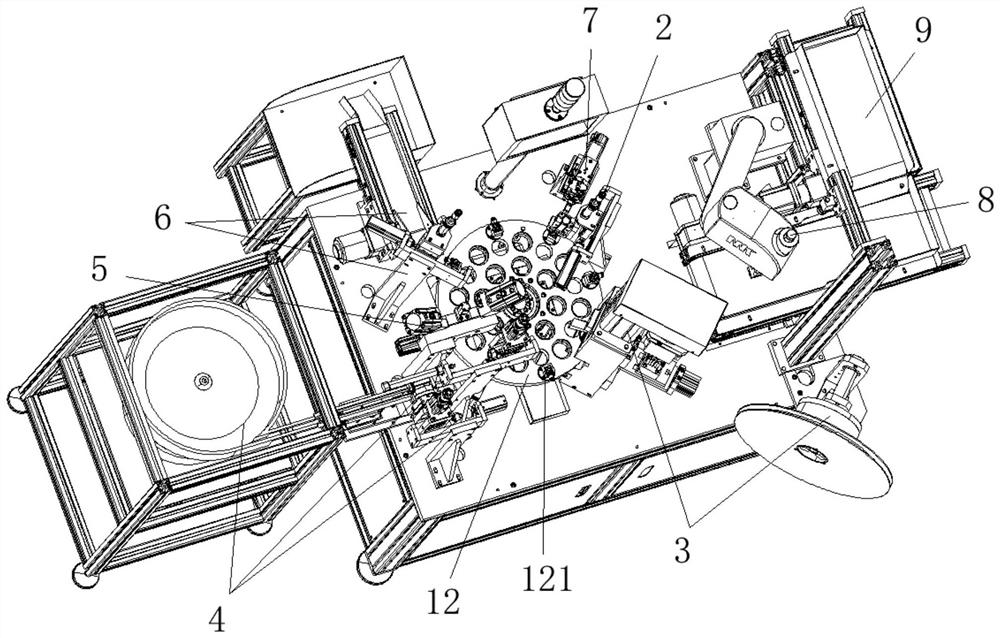

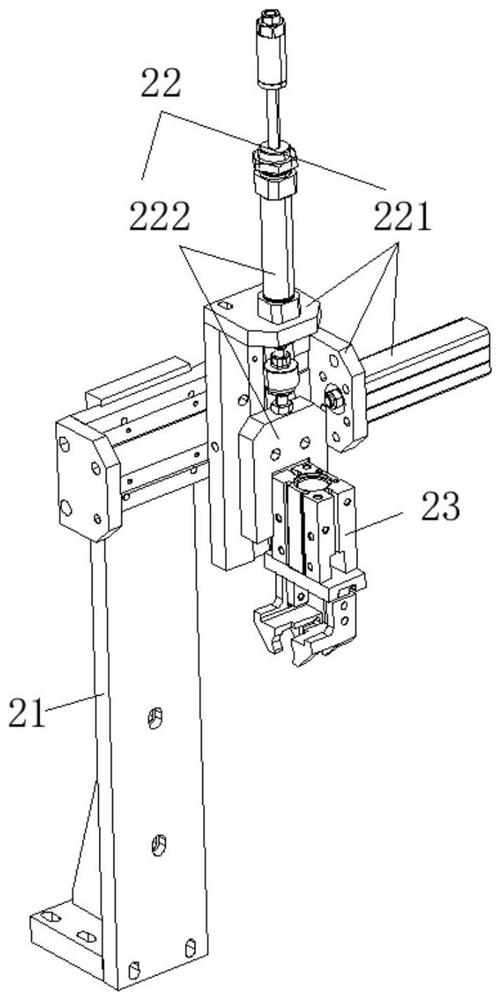

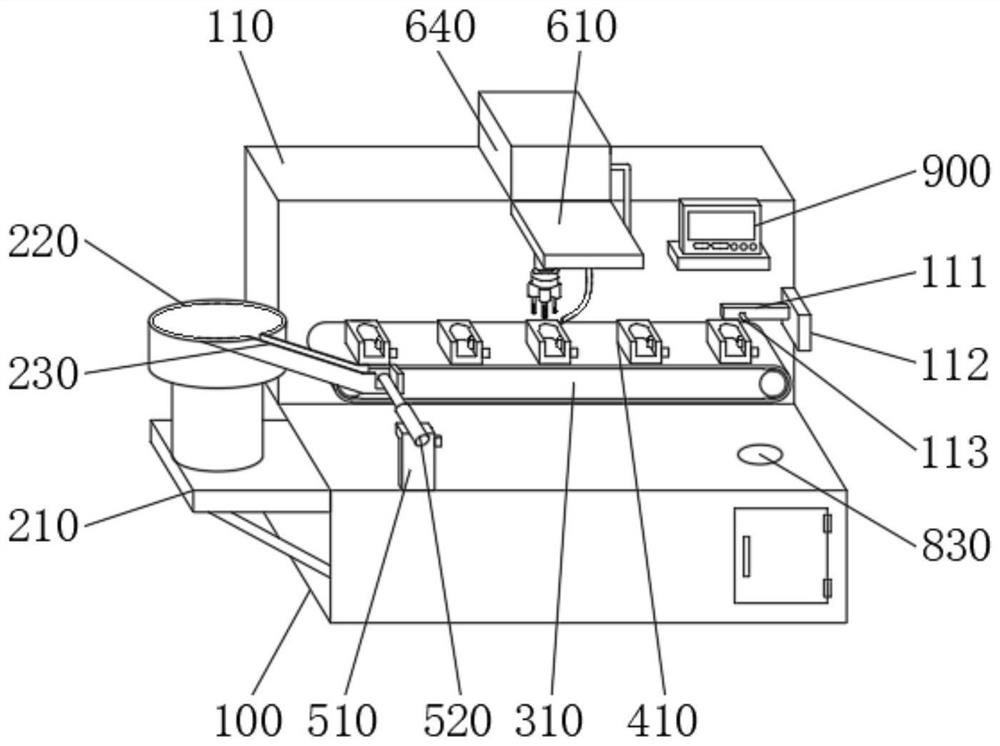

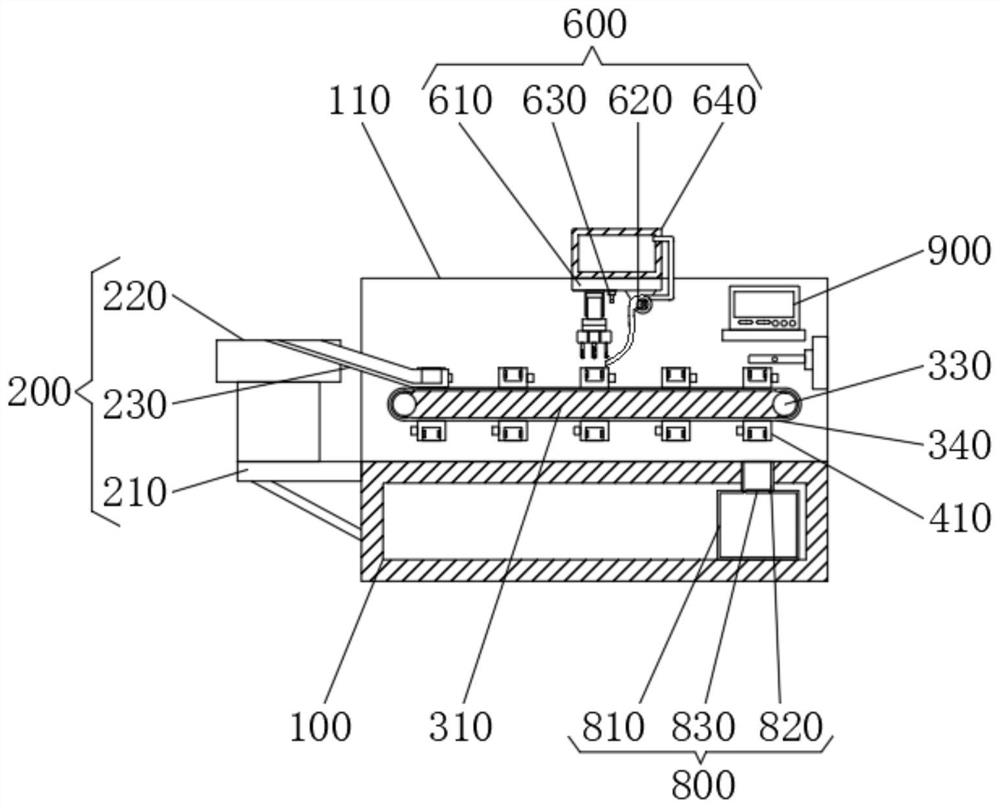

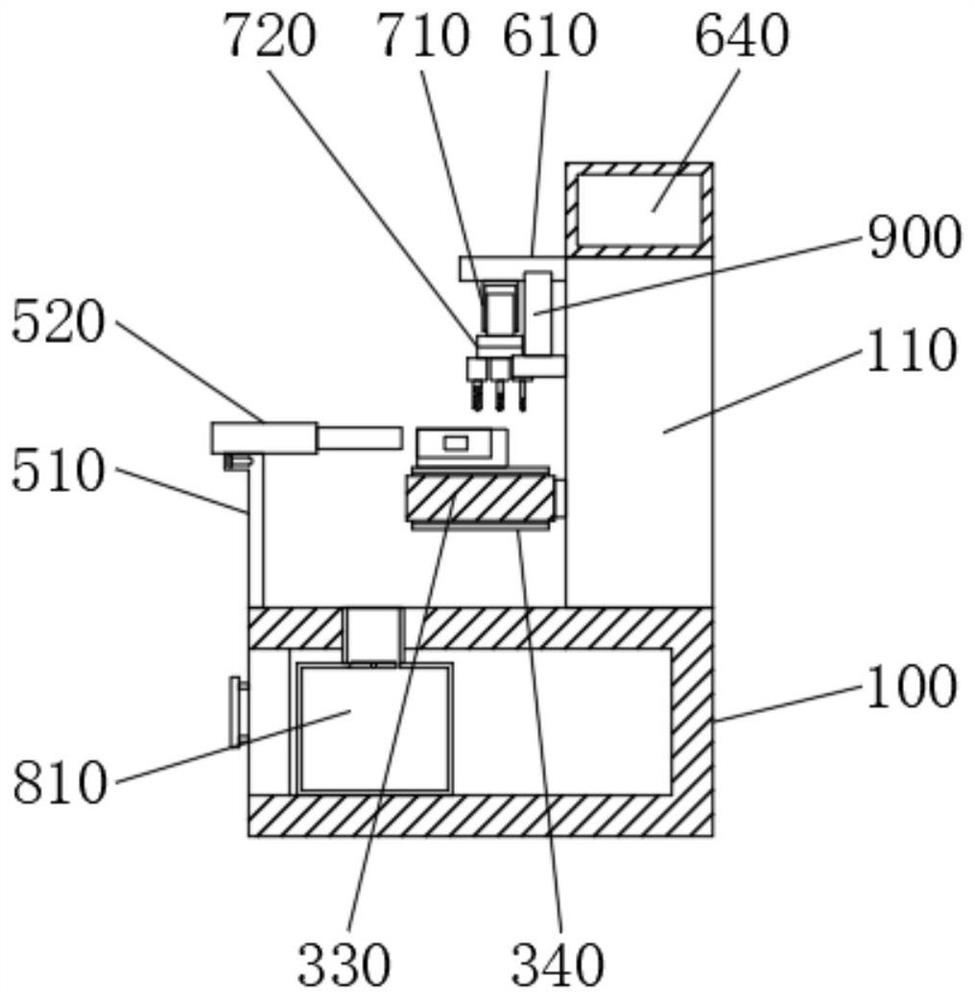

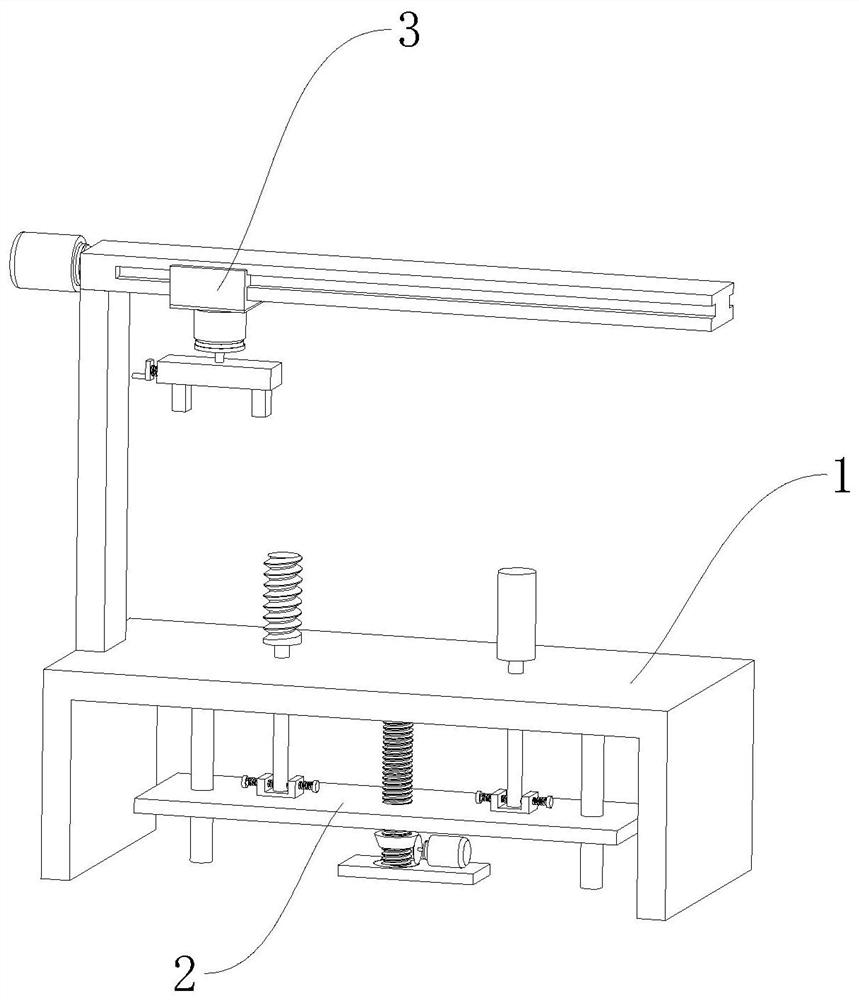

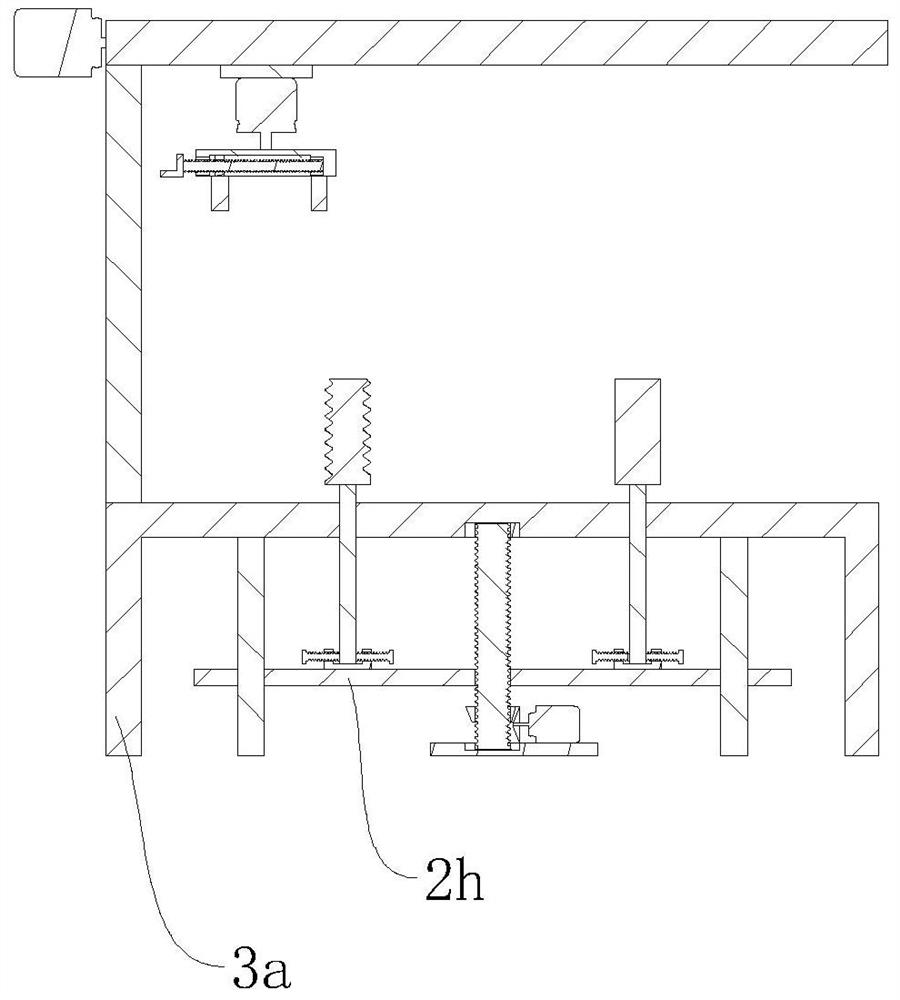

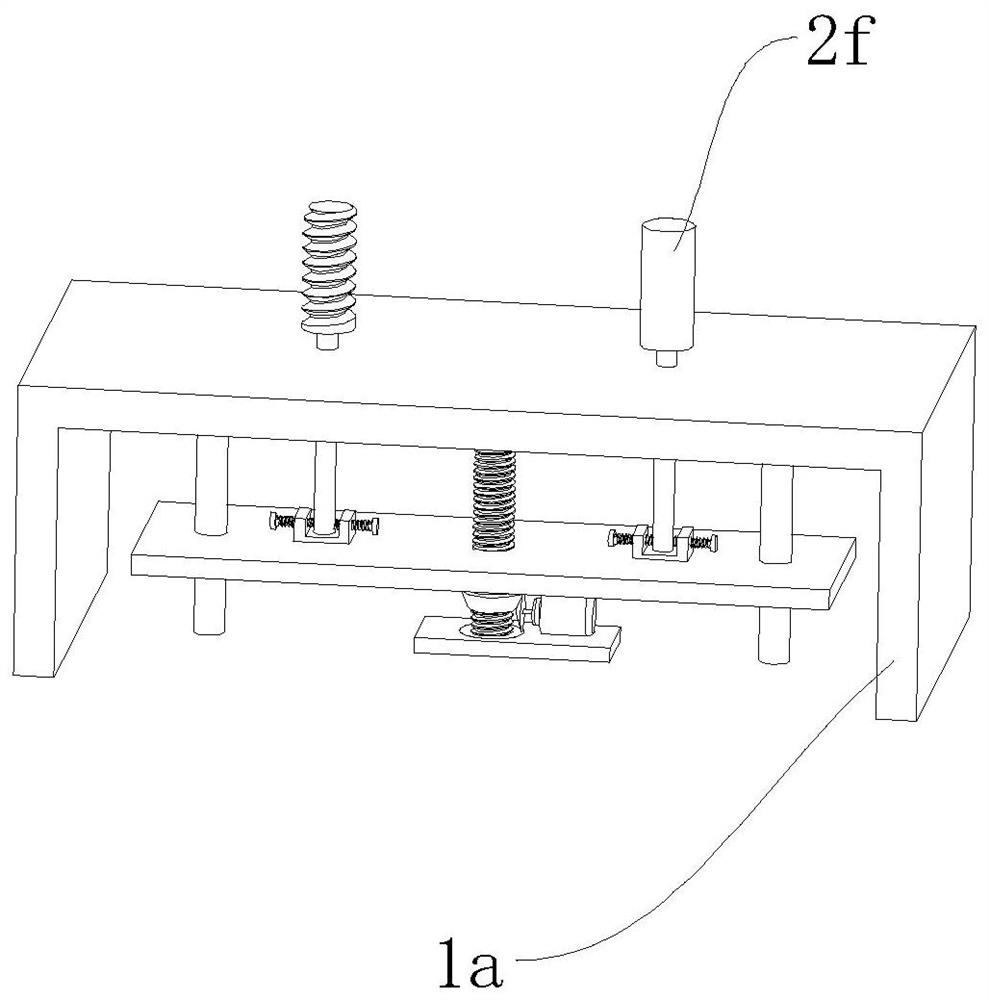

Forming and assembling equipment for decorative chain fastening members

ActiveCN103394923AQuality assuranceQuality improvementOther manufacturing equipments/toolsEngineeringSoldering

The invention belongs to the technical field of decoration processing equipment, and discloses forming and assembling equipment for decorative chain fastening members. The forming and assembling equipment for the decorative chain fastening members comprises a rack, a feeding device, a forming device, an assembling member clamping device and a fastening member clamping and transferring device, wherein the feeding device is used for feeding gold threads, the forming device is used for compressing the gold threads to form the fastening members, the assembling member clamping device is used for clamping assembling members, and the fastening member clamping and transferring device is used for clamping the fastening members and transferring the fastening members to the positions of the assembling members. The feeding device, the forming device, the assembling member clamping device and the fastening member clamping and transferring device are all arranged on the rack. The forming and assembling equipment for the decorative chain fastening members ensures the quality of decorative chains, the forming consistency of the fastening members is good, and assembling and soldering of the assembling members and the fastening members are easier to achieve. The degree of automation is high, and the complex degree of working of workers is reduced greatly. Further, time and labor are saved in a processing process, processing efficiency is high, a processing cycle is shortened, cost is lowered, and the forming and assembling equipment for the decorative chain fastening members can adapt to the modern production and manufacturing requirements of low cost, short cycles and high quality.

Owner:SHENZHEN INST OF ADVANCED TECH +1

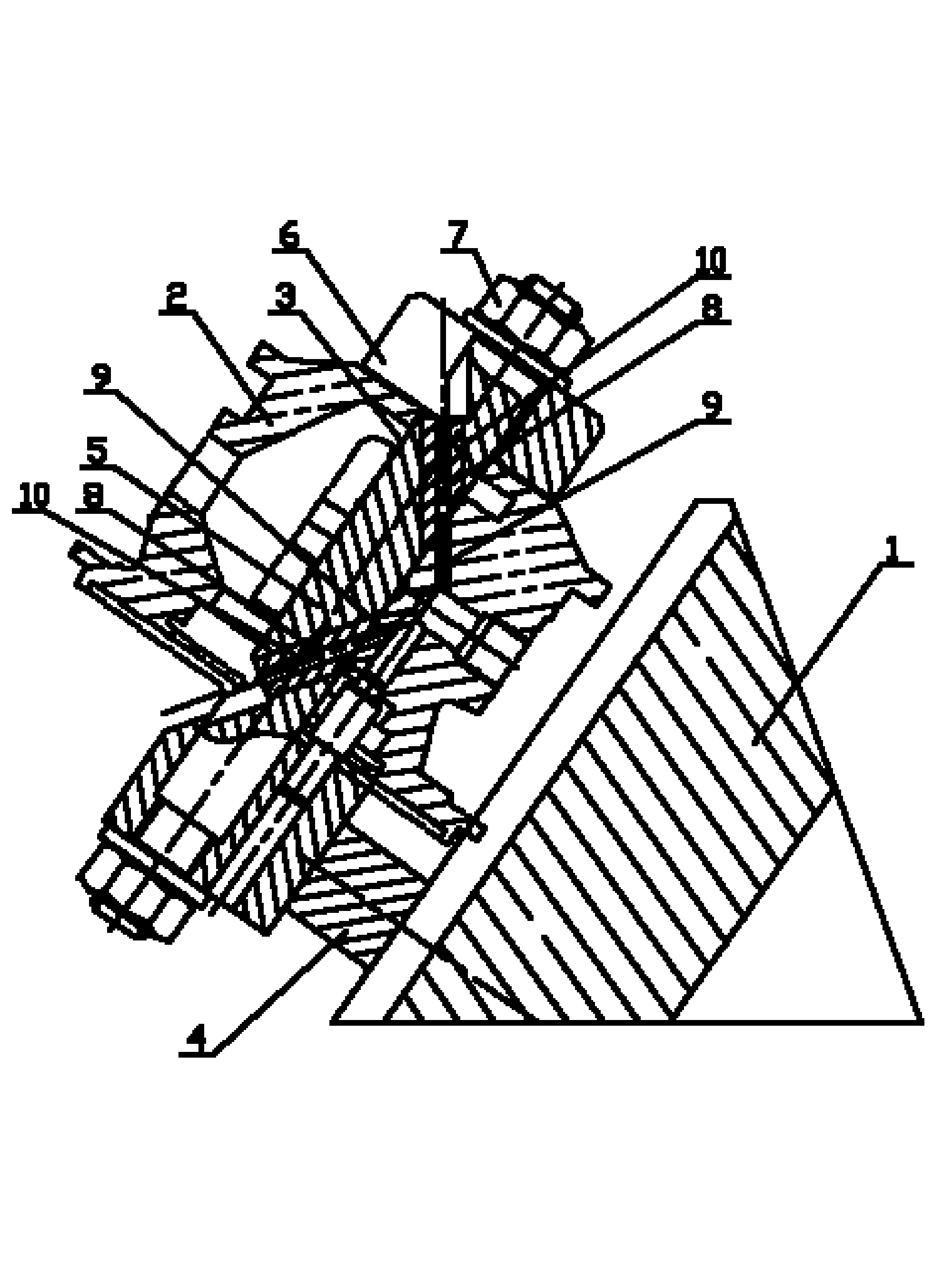

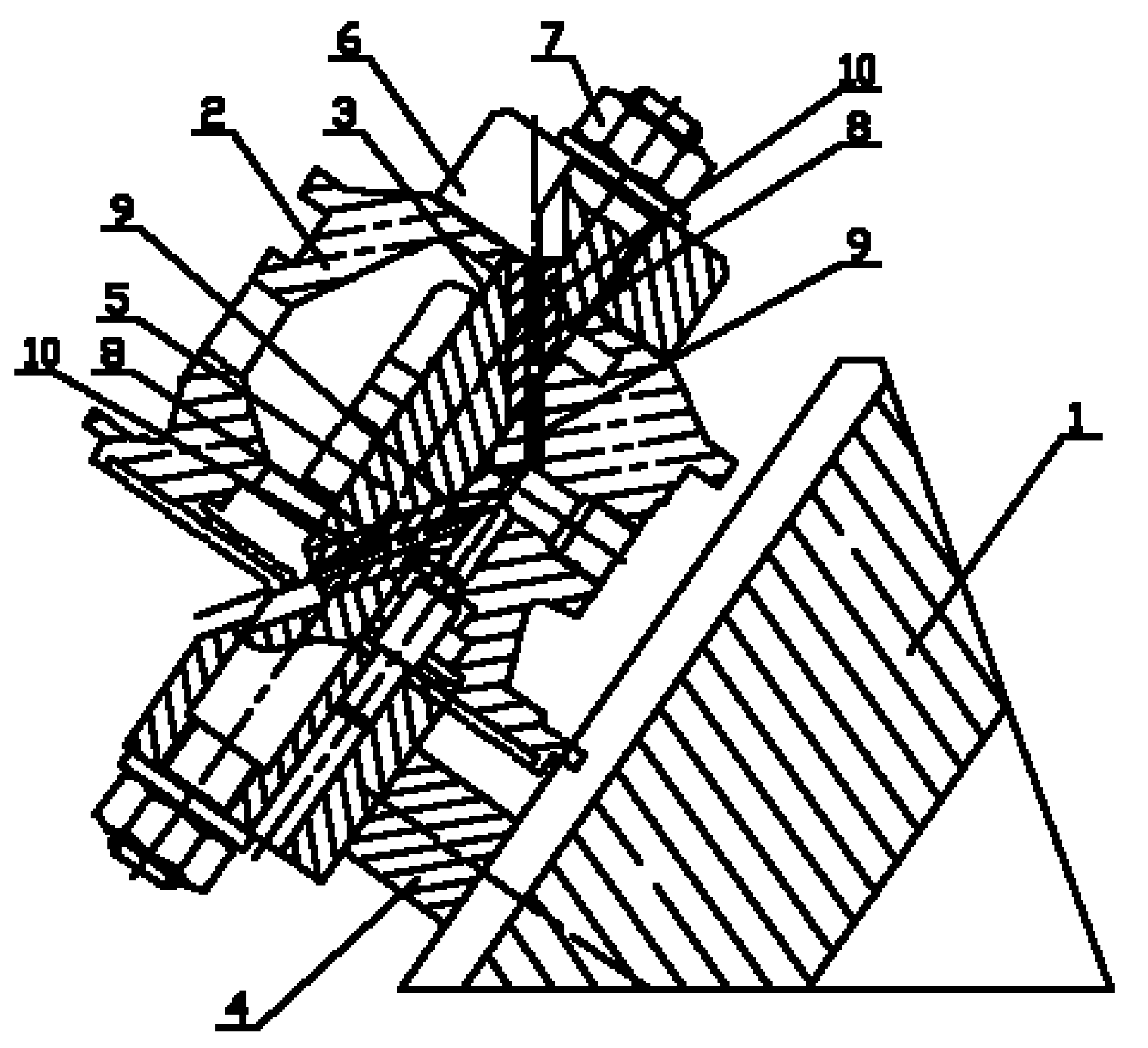

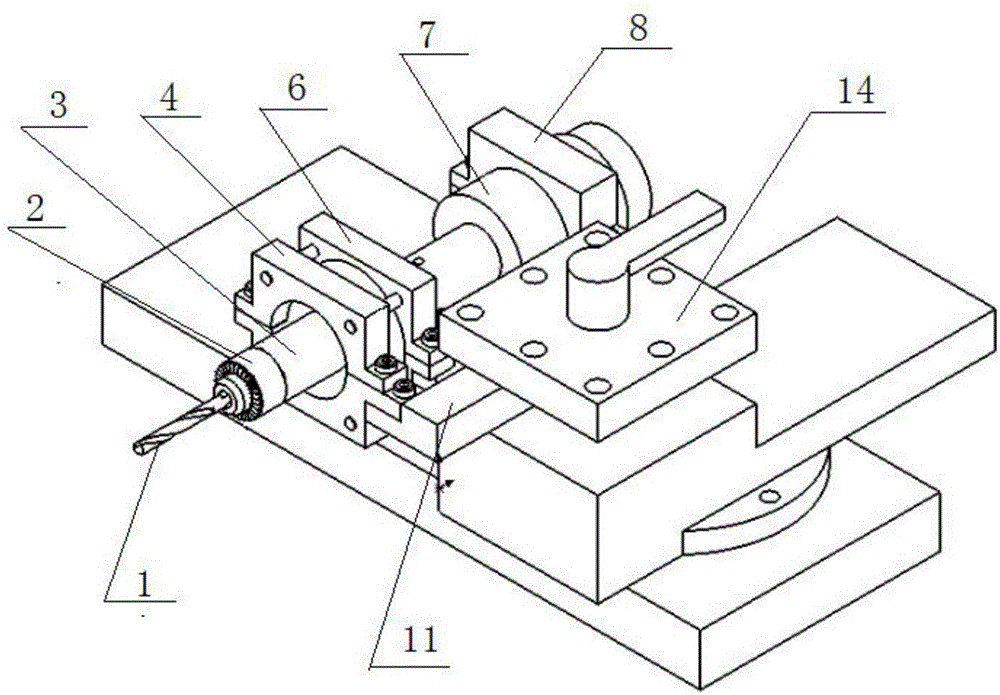

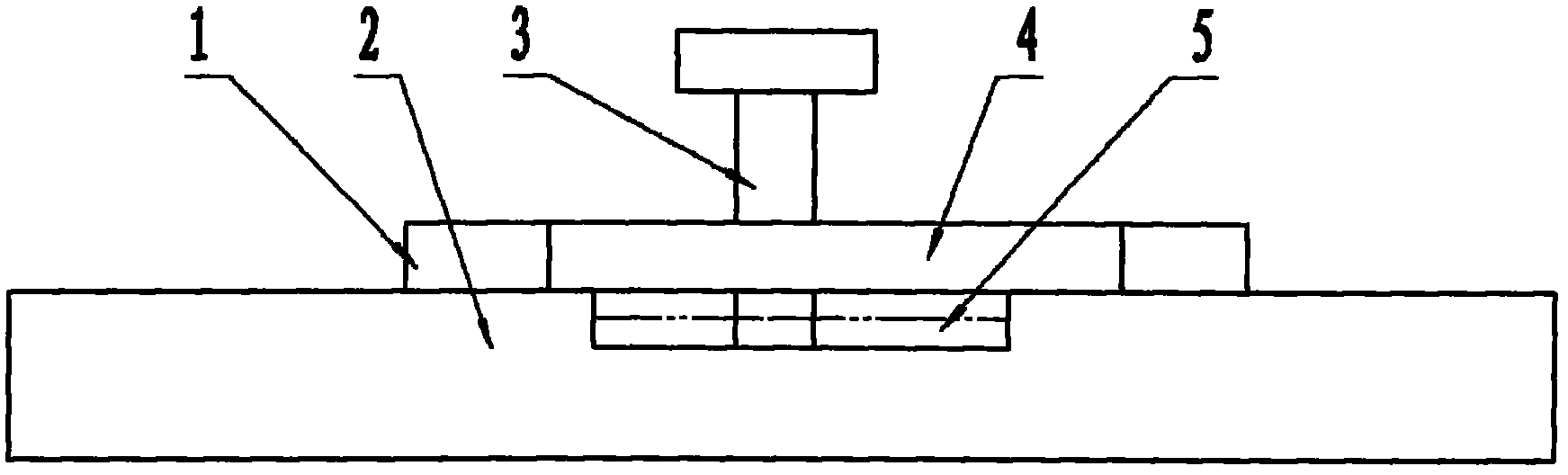

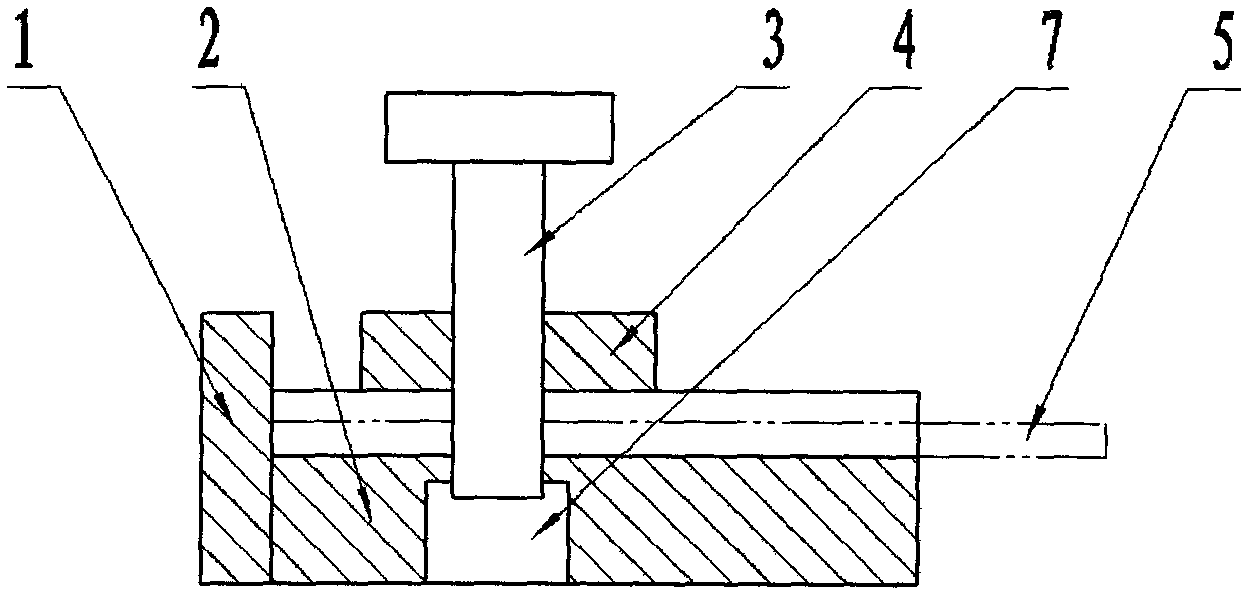

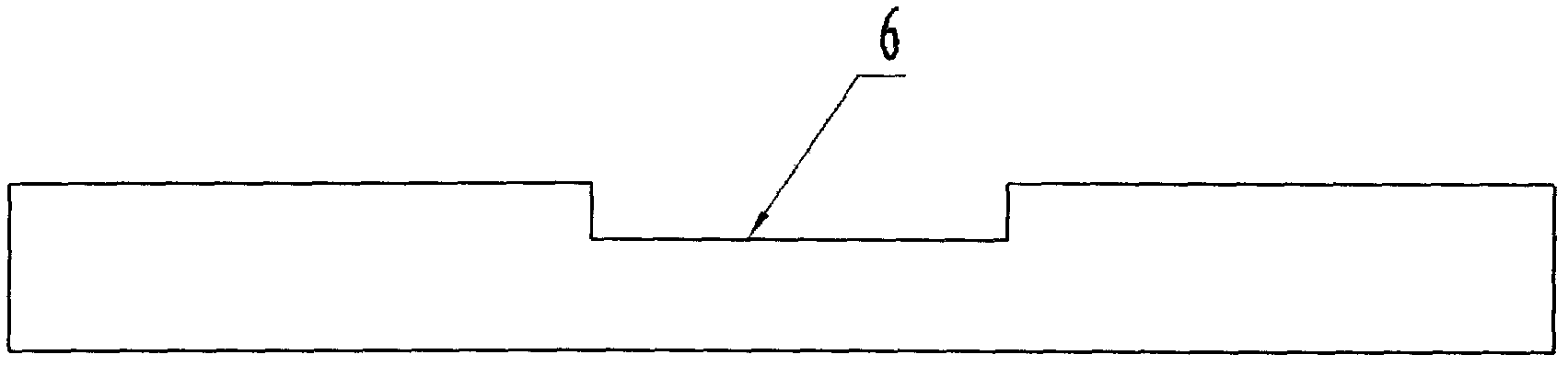

Die drilling clamp of two inclined connecting holes of middle shell

InactiveCN102000855AProcessing saves time and effortImprove efficiencyPositioning apparatusDrill jigsFastenerEngineering

The invention provides a die drilling clamp of two inclined connecting holes of a middle shell, which saves time and labor in machining and has high efficiency. The die drilling clamp of the two inclined connecting holes of the middle shell comprises a base, a clamping assembly and a middle shell with inclined holes to be machined, wherein a middle through hole of the middle shell with the inclined holes to be machined is processed. The die drilling clamp of the two inclined connecting holes of the middle shell is characterized in that the base is triangular, the clamping assembly is mounted on one lateral inclined surface of the base and comprises a connecting plate, a central shaft and an end fastening piece, the connecting plate is supported on the lateral inclined surface of the base and fastened on the central shaft which penetrates through the middle through hole of the middle shell with inclined holes to be machined, the end fastening piece is fixedly connected with the central shaft and the middle shell with the inclined holes to be machined, inclined through holes are respectively arranged on the central shaft close to the two end surfaces of the middle shell with the inclined holes to be machined, and the positions of the inclined through holes respectively align with the position of the inclined holes to be machined on the middle shell.

Owner:WUXI MINGZHU TURBOCHARGER MFG

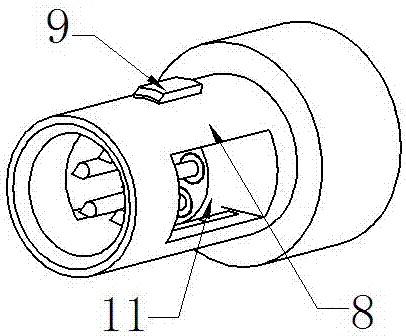

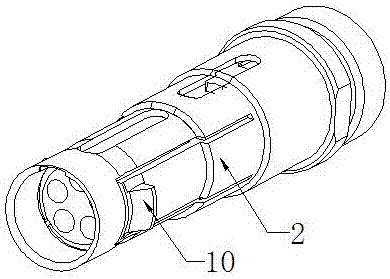

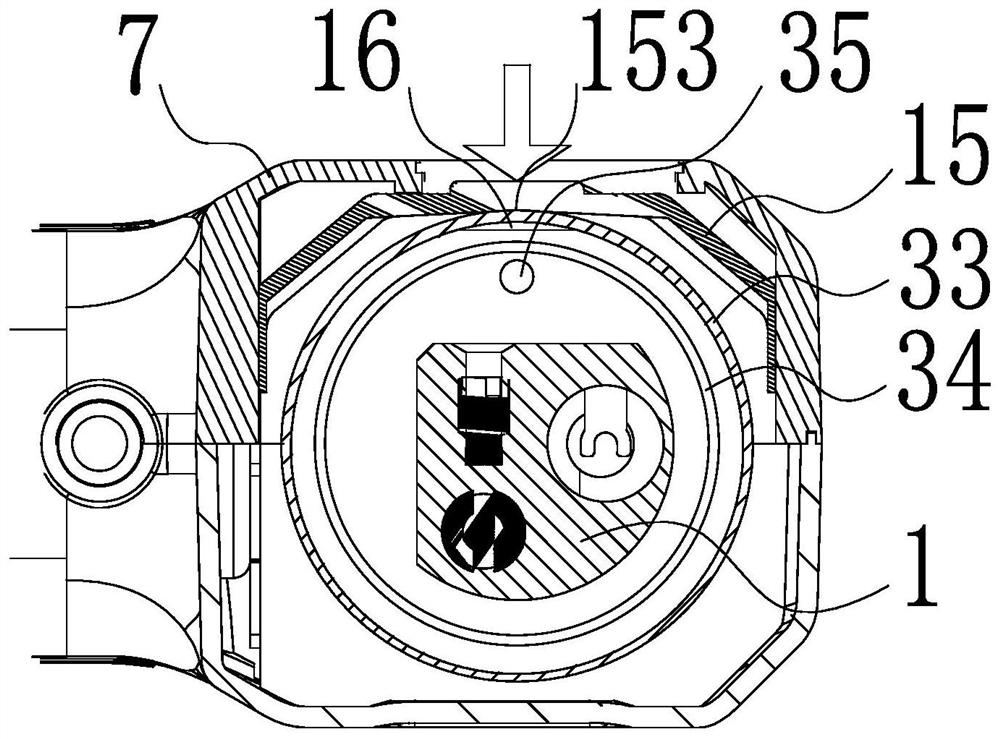

Push-pull self-locking multi-core connector

PendingCN107425360AEasy to installQuick to useCoupling contact membersEngineeringStructural engineering

The invention discloses a push-pull self-locking multi-core connector comprising a socket and a plug. A key sleeve is disposed in a socket housing, and the outer surface of the key sleeve is provided with a protruding key. A side wall of a plug housing is provided with a plurality of notches, and a middle front part of an elastic locking sleeve is provided with an elastic bolt. The inner wall of the elastic locking sleeve is provided with a guiding groove, and the inner wall of the socket housing is provided with a guiding inclined surface. Positioning guiding parts, which are cooperated with each other, are disposed between the elastic locking sleeve or the plug insulator of the plug and the key sleeve of the socket, and when the plug housing is inserted in the socket housing, the positioning guiding parts are used for alignment and positioning, and therefore the elastic bolt can be inserted successfully, and is limited in the guiding inclined surface. By adopting the above mentioned structure, a correct position can be found by rotation, and the in-place rotation is carried out, and therefore 360-degree blind plugging is realized, and clamping cannot be caused, and in addition, use is convenient and fast, and flexibility is strong; by adopting structural design of a wire clamp, the positioning is reliable, processing is time-saving and labor-saving, and installation is very convenient.

Owner:镇江申庭电子科技有限公司

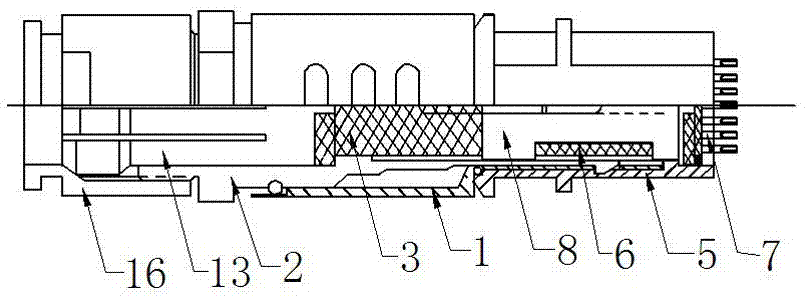

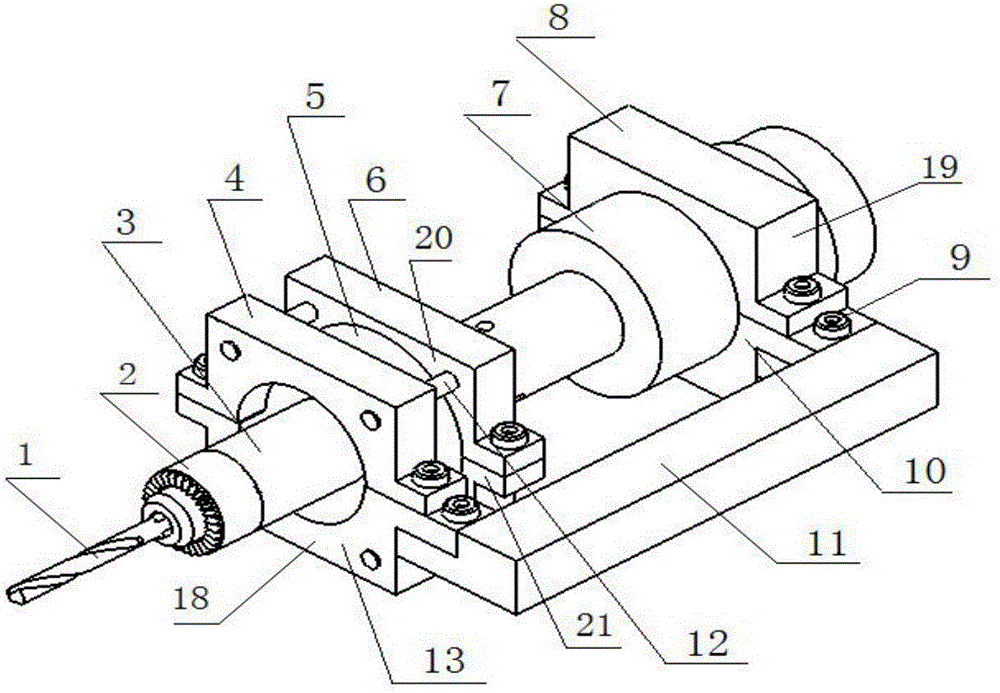

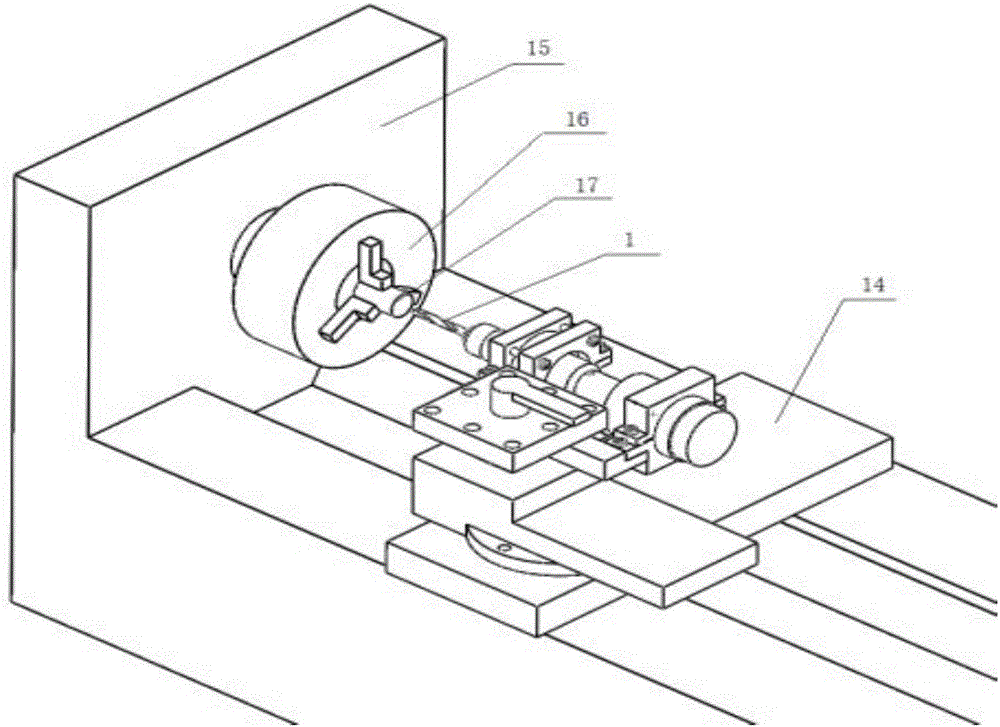

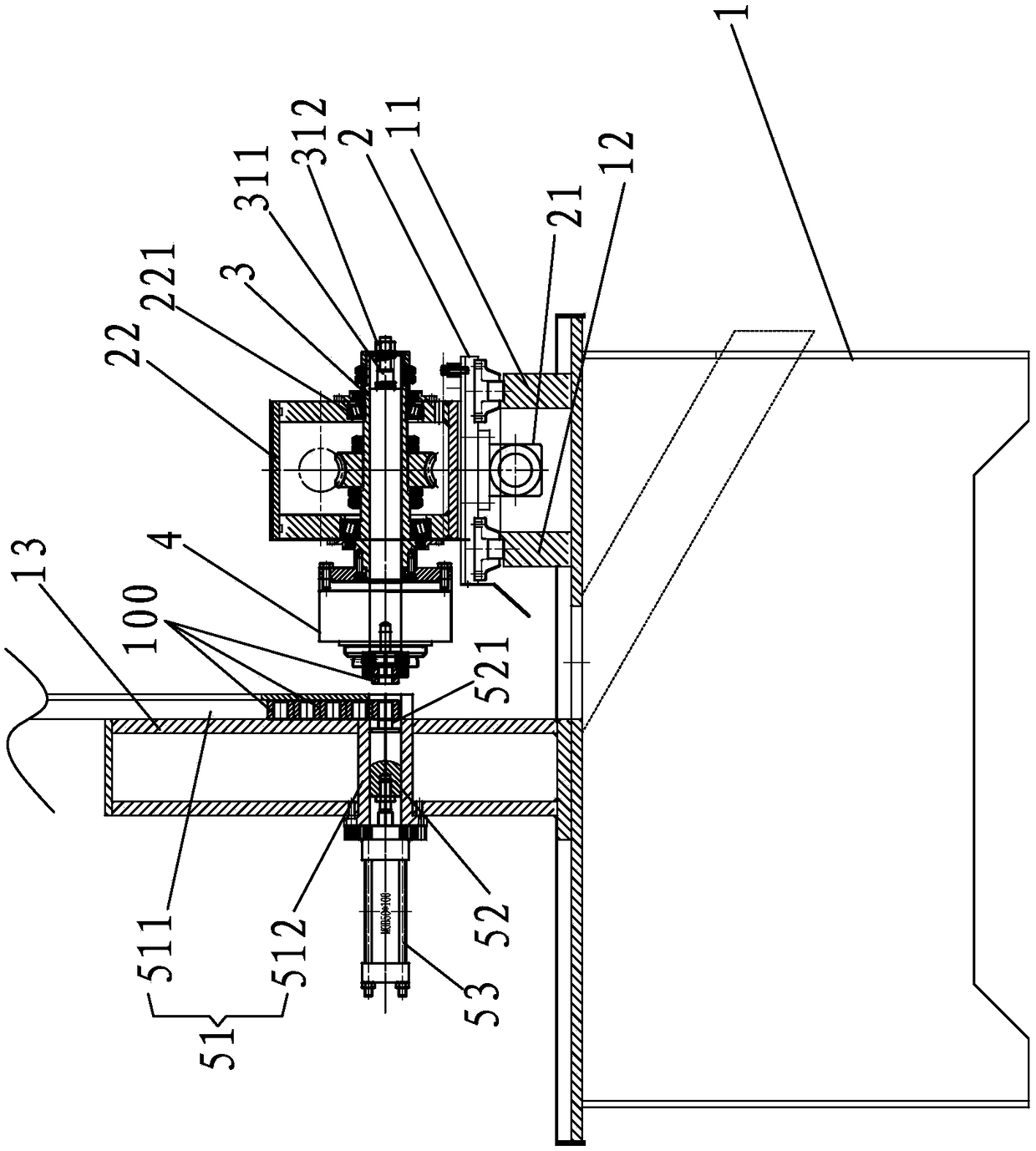

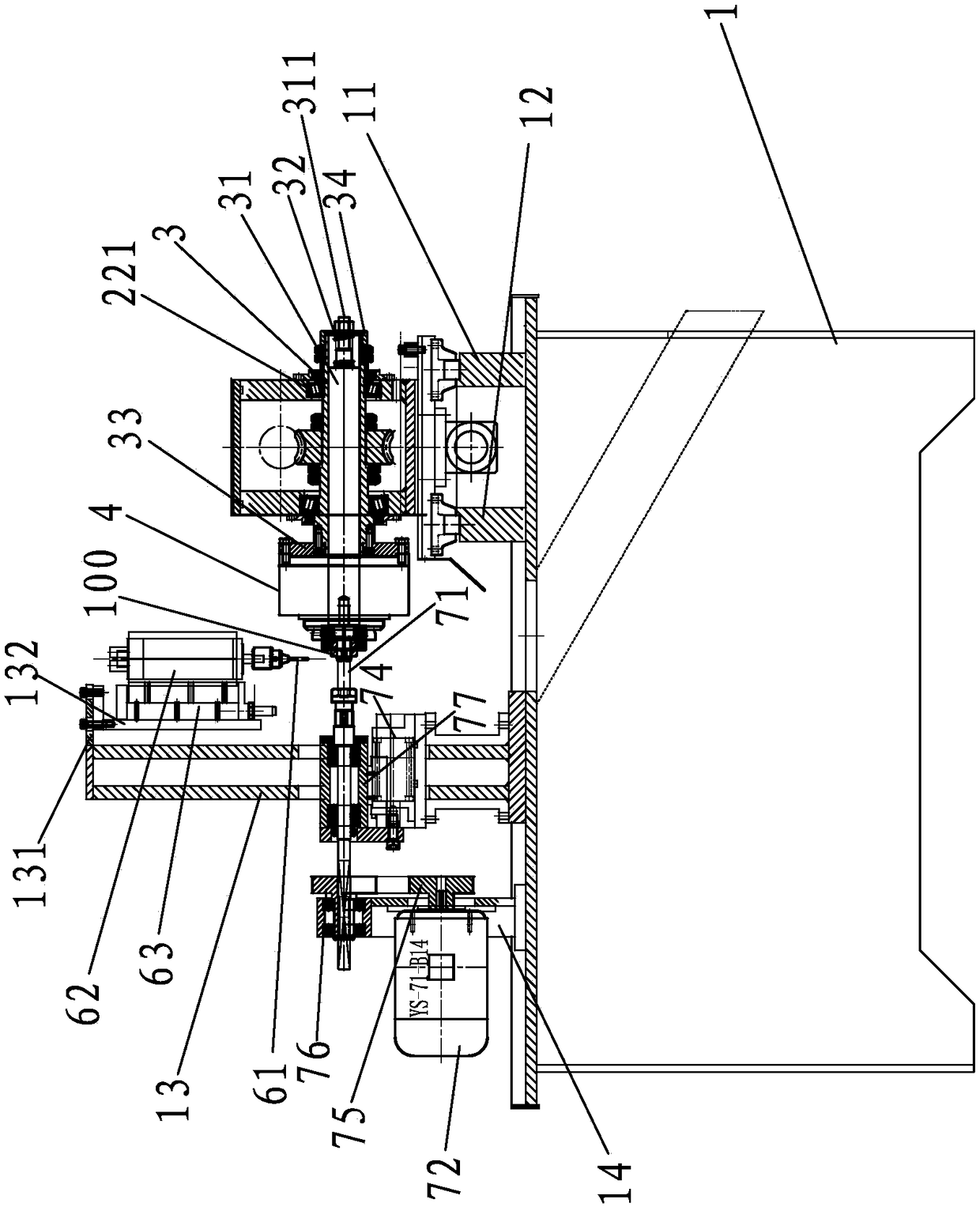

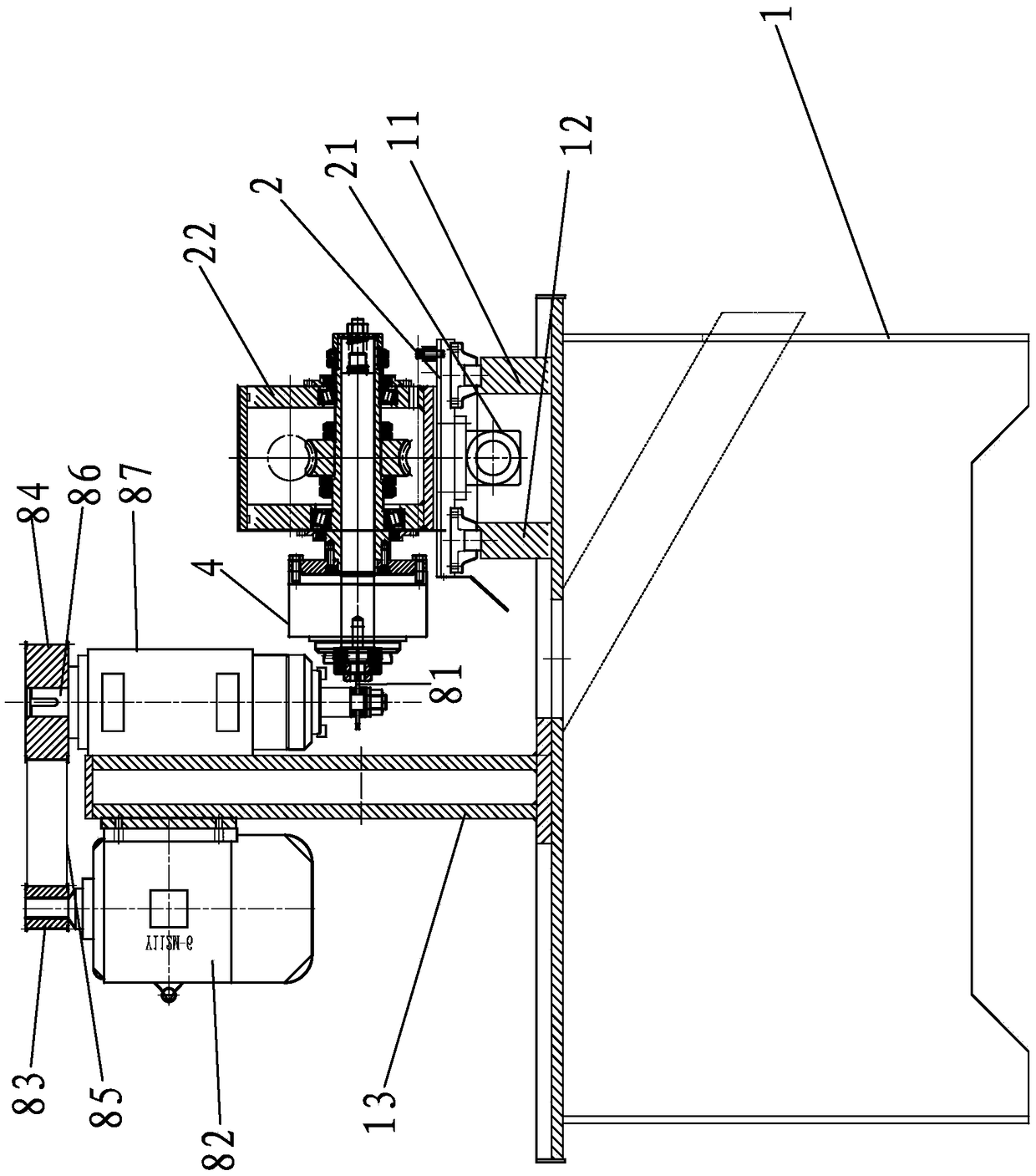

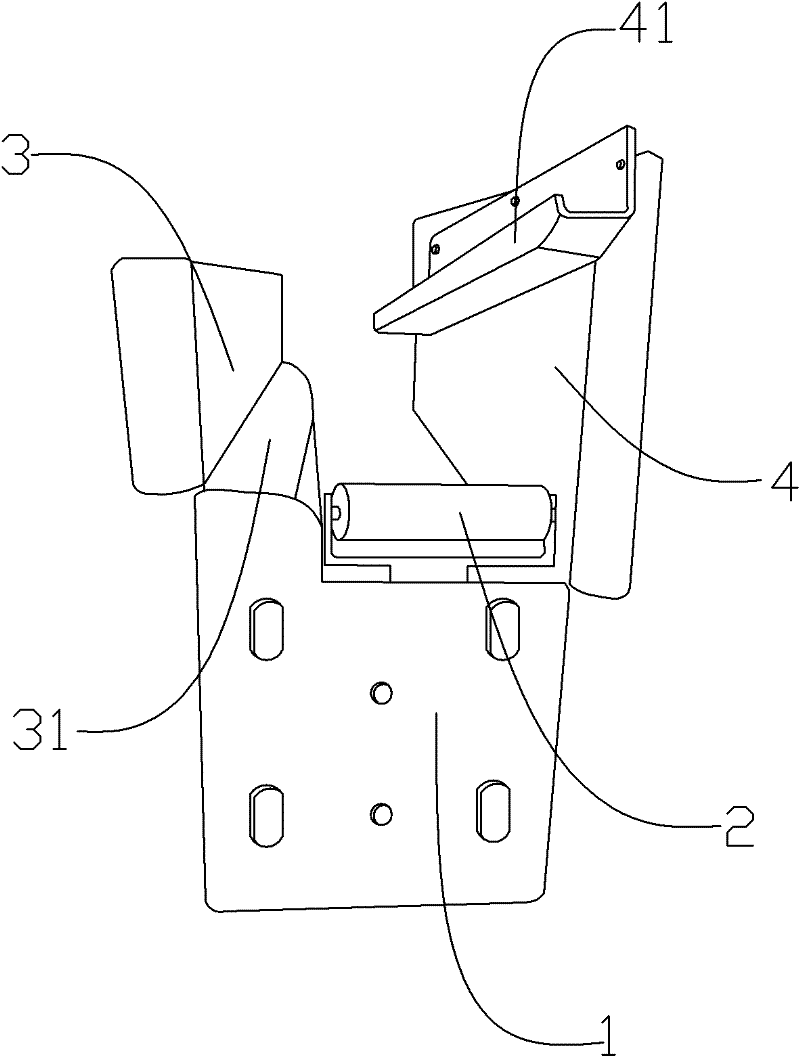

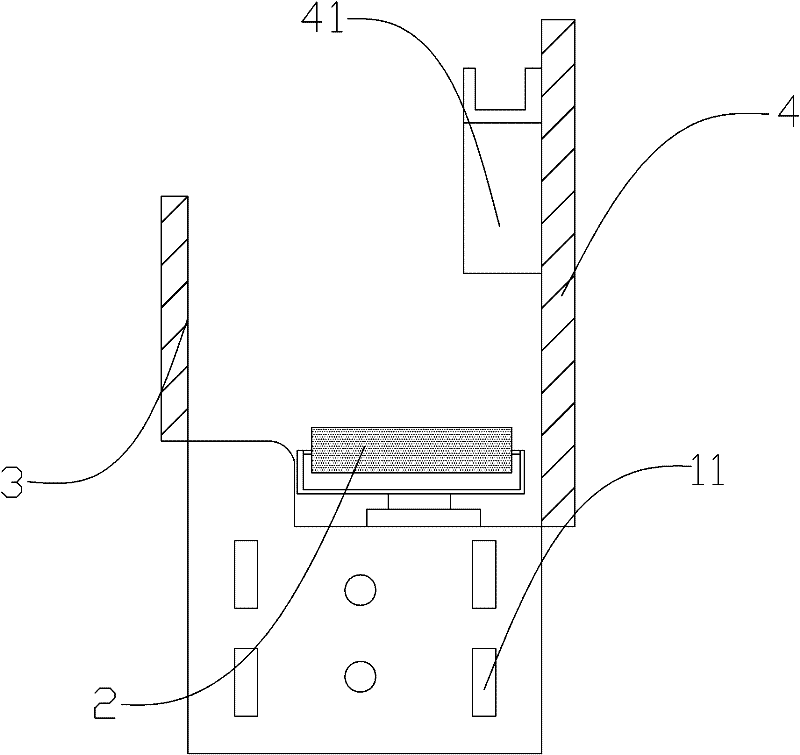

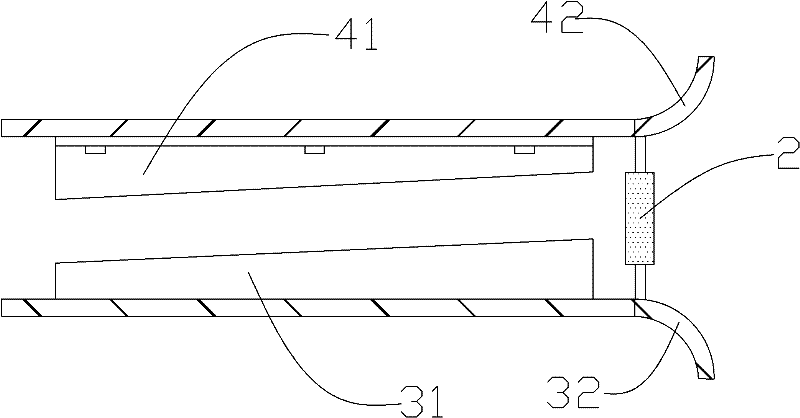

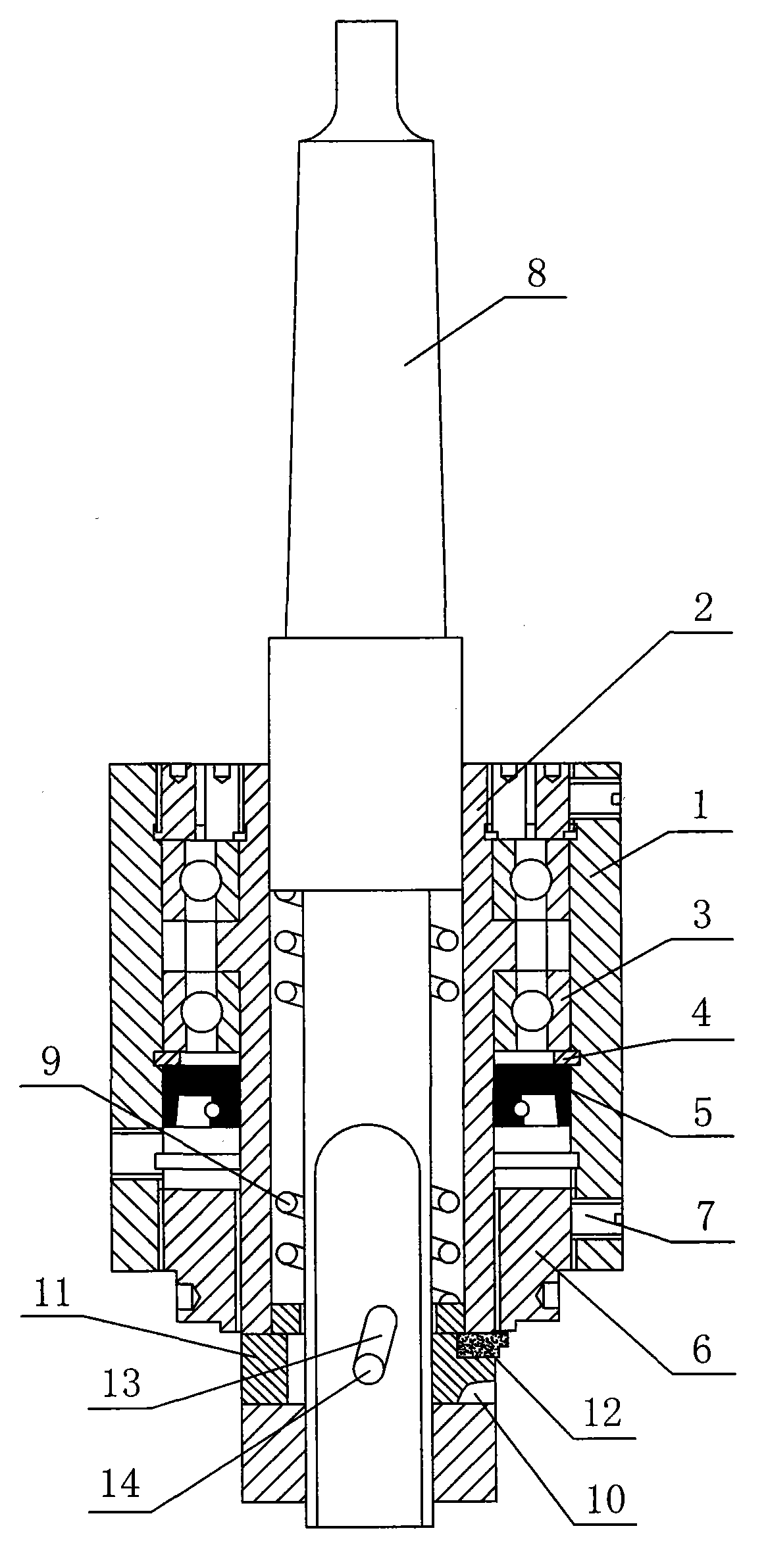

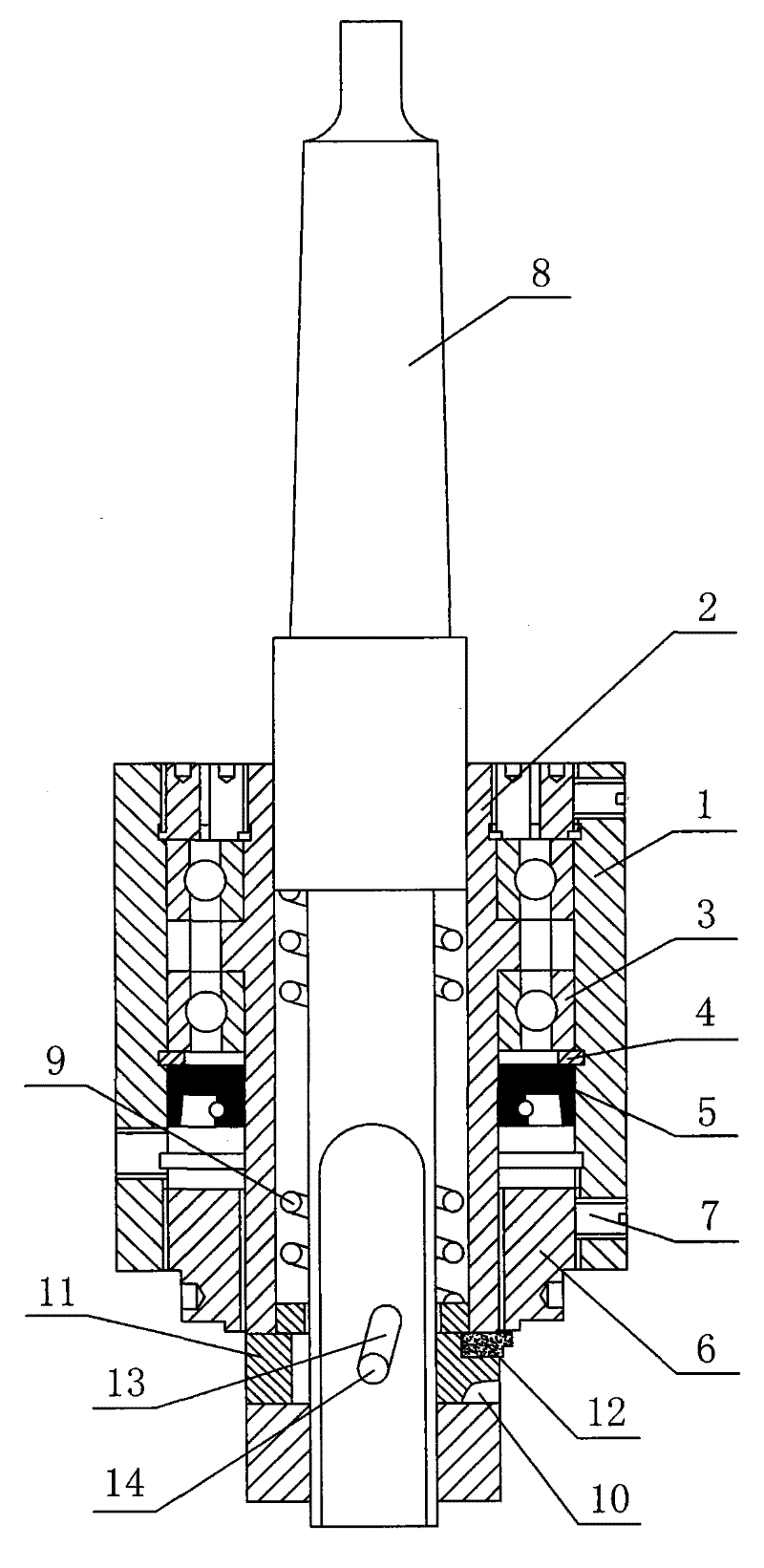

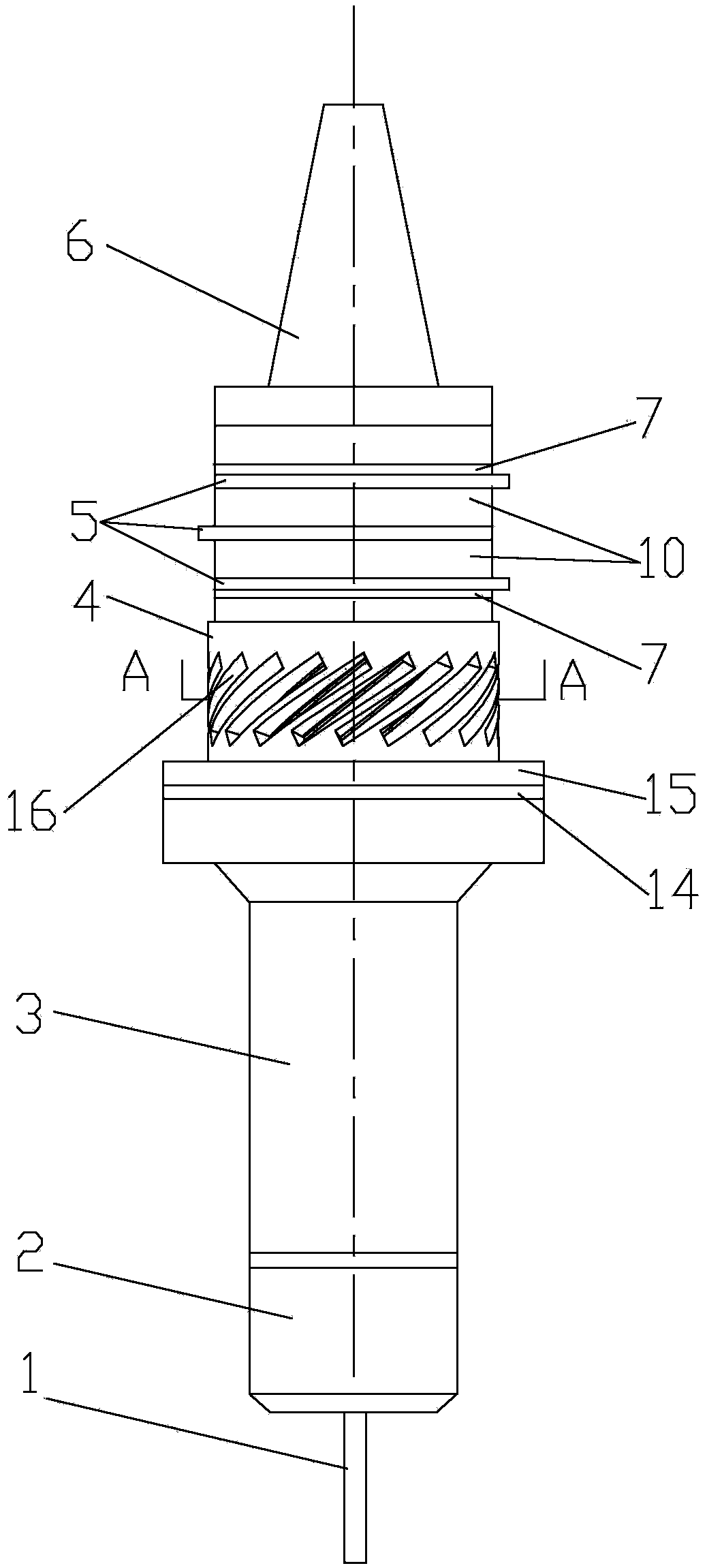

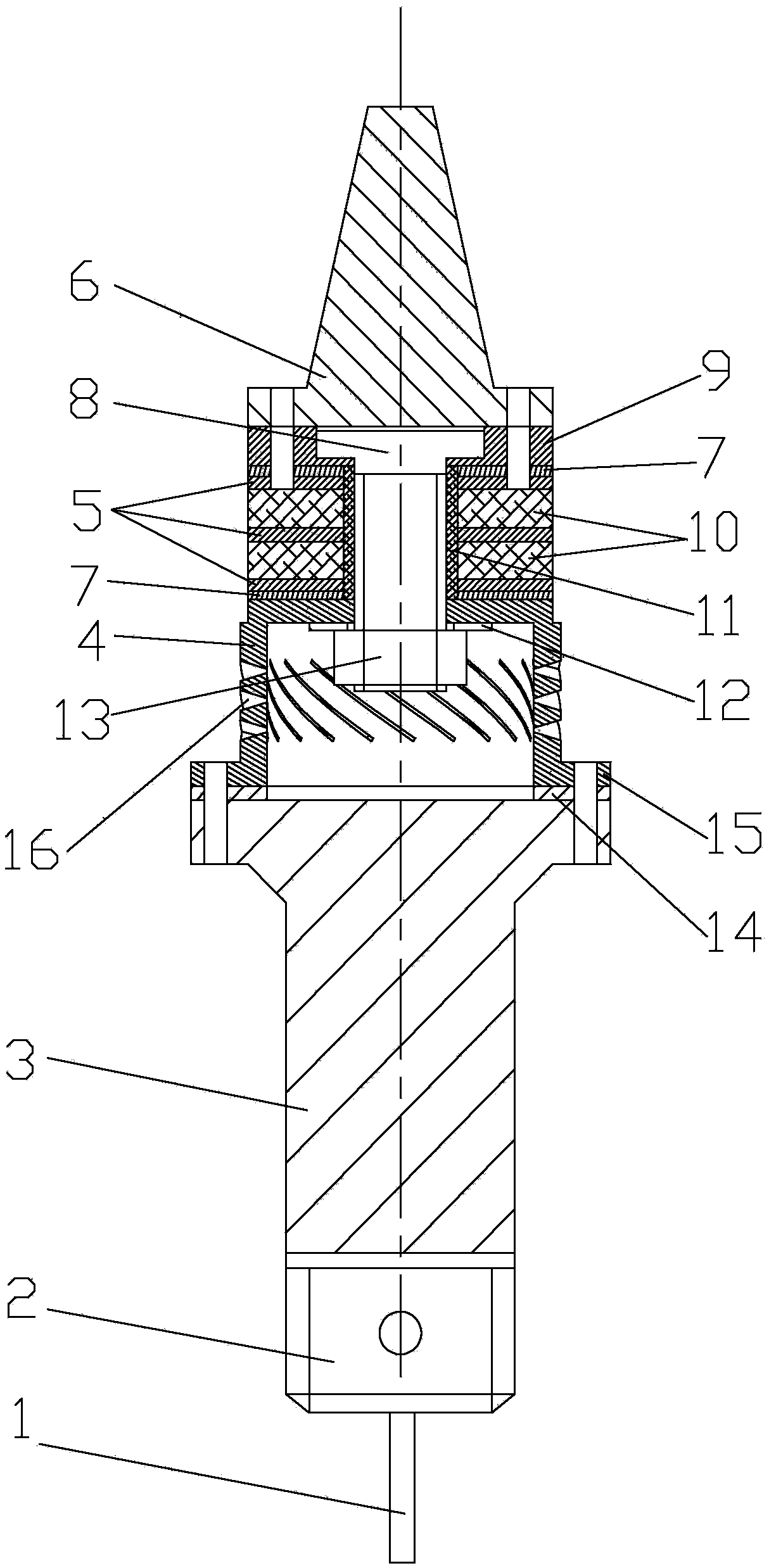

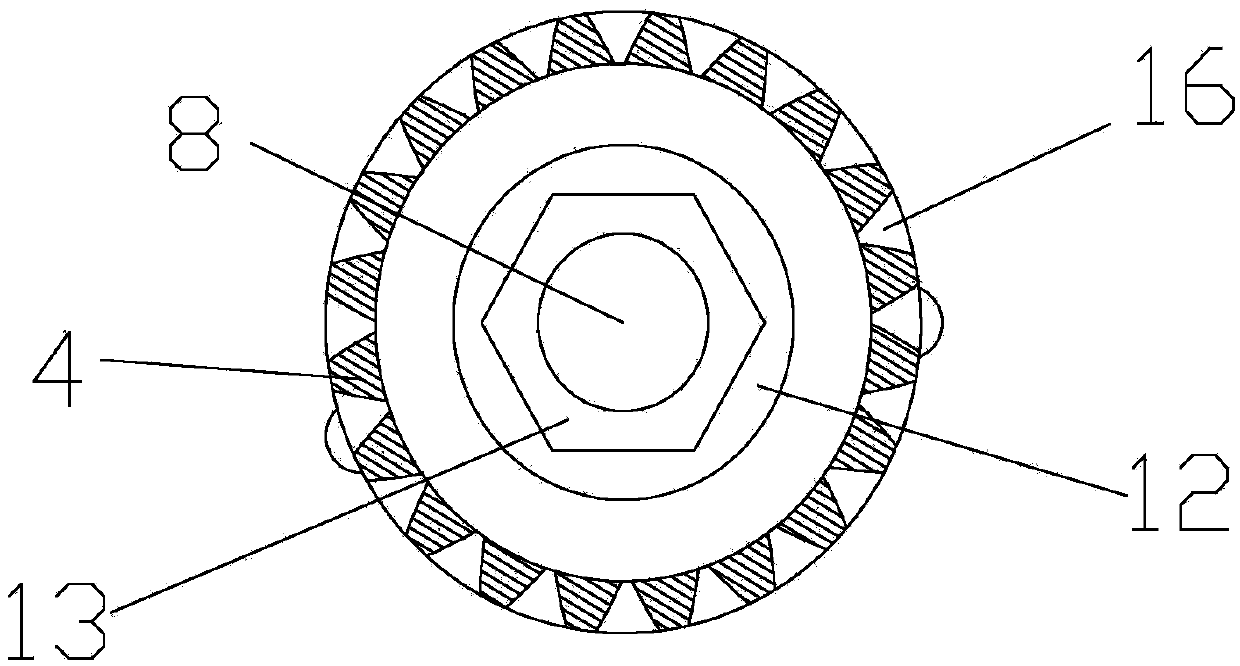

Axial ultrasonic vibration drilling device fixed by lathe carriage

InactiveCN106424836ASimple structureEasy to installMechanical vibrations separationBoring/drilling componentsTransducerEngineering

Provided is an axial ultrasonic vibration drilling device fixed by a lathe carriage. The axial ultrasonic vibration drilling device fixed by the lathe carriage comprises a drill, an amplitude-change pole, a transducer, a beam hanging type fixed device and an ultrasonic generator electrically connected to the transducer. The beam hanging type fixed device comprises a hanging beam fixed on the lathe carriage and a front pressing plate and a rear pressing plate, wherein the front pressing plate and the rear pressing plate are fixedly connected to the hanging beam, the front pressing plate fixes the front end of the amplitude-change pole, the rear pressing plate fixes the transducer, a fixed pressing plate fixes the middle part of the amplitude-change pole, and the front pressing plate, the rear pressing plate and the fixed pressing plate are all divided into upper and lower two parts and are assembled through bolts. Compared with a drilling device achieved on a drilling machine, there is no need to conduct any special refit on a machine tool; in addition, a method of workpiece revolution is adopted, there is no need to use assembly units such as a ring manifold or a carbon brush, thus the structure is simplified, the cost is saved, and the axial ultrasonic vibration drilling device fixed by the lathe carriage is convenient to disassemble and assemble and is beneficial to a proceeding of ultrasonic vibration drilling.

Owner:NORTHEASTERN UNIV

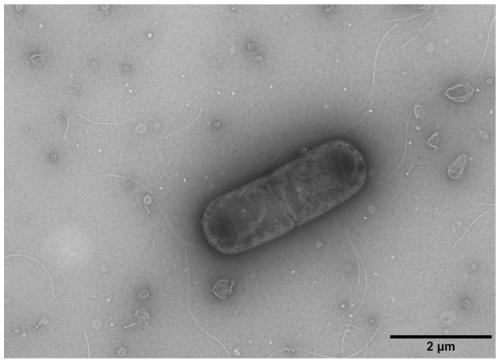

Bacillus siamensis, preparation method and usage thereof

ActiveCN110305813ASimple ingredientsProcessing saves time and effortBiocideBacteriaMicrobiologyPlant disease

The invention discloses Bacillus siamensis, a preparation method and the use thereof. The Bacillus siamensis is the Bacillus siamensis sp HY-075, and is preserved in Guangdong microbial culture preservation center, and the preservation number is GDMCC 60680. The Bacillus siamensis has the use of prevention and curing vegetable plant diseases.

Owner:SUBTROPICAL CROPS INST OF FUJIAN PROVINCE

Anti-cracking treatment method for rattan

InactiveCN106393369APrevent peelingAvoid breakingElectric wood treatmentWood treatment detailsWarm waterLow temperature plasma

The invention discloses an anti-cracking treatment method for a rattan. The method comprises the following steps: treating the rattan in a dark environment of which the humidity is 65% to 68% and the temperature is 8 to 10 DEG C, and irradiating twice; subsequently soaking the rattan in warm water and putting in cold storage; dissolving chitosan in a saturated carbon dioxide water solution to prepare a solution for soaking the rattan; and treating the rattan by utilizing low-temperature plasma generated by dielectric barrier discharge at atmospheric pressure. In comparison with an existing rattan treatment method, the method disclosed by the invention has the advantages that a knitted product made from the rattan treated by the method disclosed by the invention is not deformed, free of cracks and very comfortable to skin in use; the bearing capacity is increased; the dimensional stability is good; decrustation of the rattan can be effectively prevented; after the rattan is knitted, the strength of the rattan is gradually restored and is increased by 2% to 3% in comparison with the original strength; the treated rattan is quite good in corrosion prevention effect, good in rattan softening effect and harder to mildew and damage in use; the knitted product prepared by the rattan treated by the method disclosed by the invention is free of mildew and worm damages and can be kept in the original color within at least 8 years.

Owner:阜南县环宇柳木工艺制品有限公司

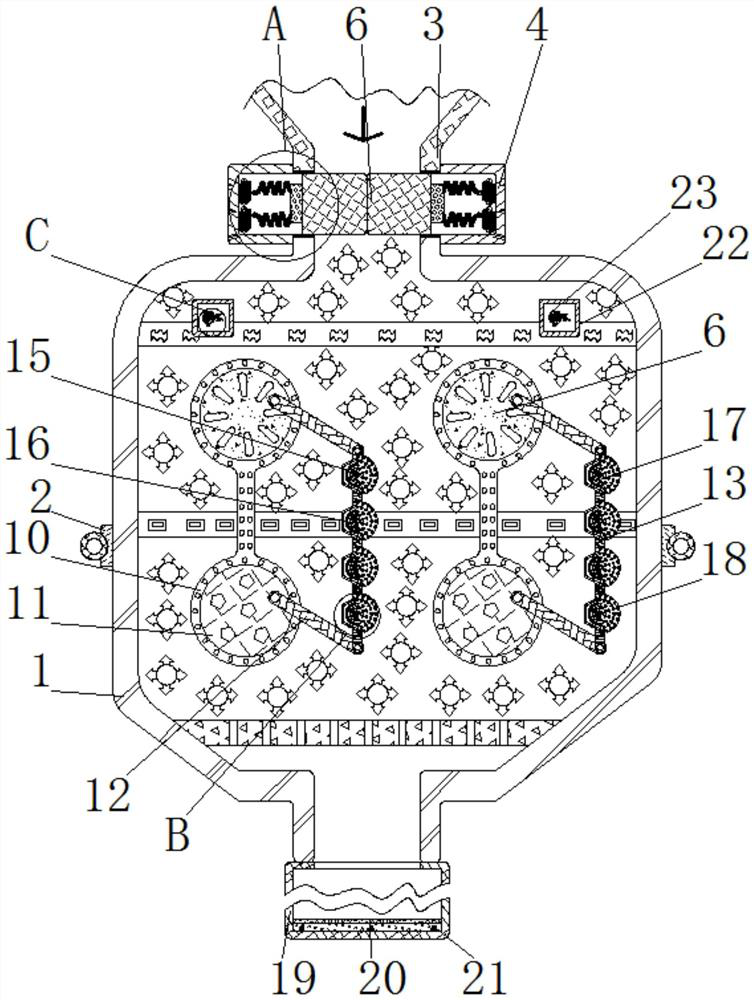

CNC machining all-in-one machine for high precision slotted nuts

PendingCN109014931AImprove machining accuracyGuaranteed machining accuracyOther manufacturing equipments/toolsMachiningAutomation

The invention discloses a CNC machining all-in-one machine for high precision slotted nuts. The CNC machining all-in-one machine for the high precision slotted nuts comprises a machine base and a sliding base sliding left and right. The sliding base is rotatably provided with a hollow rotating rod, a compressed air chuck for clamping a nut is installed at the rear end of the hollow rotating rod, and the hollow rotating rod is internally provided with a pushing rod and a tension spring tensioned between the hollow rotating rod and the pushing rod. A feeding mechanism for conveying the nut ontothe compressed air chuck to be clamped, a milling groove mechanism for milling the nut on the compressed air chuck, a boring cutter mechanism for punching the nut on the compressed air chuck, and an air blowing mechanism for air blowing and cleaning the compressed air chuck are installed on the top face, located on the rear portion of the sliding base, of the machine base. The milling groove mechanism is located at the left side of the feeding mechanism, the boring cutter mechanism is located below the milling groove mechanism, and the air blowing mechanism is located at the left side of the boring cutter mechanism. Compared with the prior art, not too much participation of workers is required in the whole process, the automation degree is high, the machining working efficiency is greatlyimproved, machining is time saving and labor saving, the machining precision of the nut is accuracy and high, and machining is fine.

Owner:泉州宇诺机械有限公司

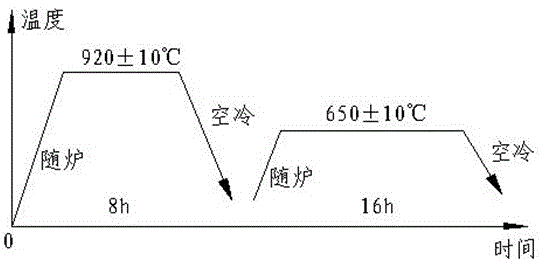

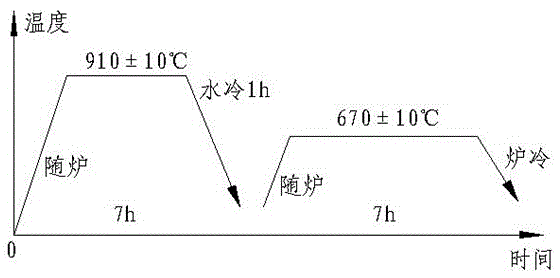

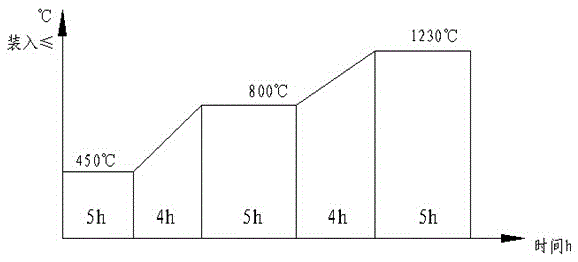

High-performance steam cylinder cover for large low-speed diesel engine and manufacturing process

ActiveCN105586533AProcessing saves time and effortControl rising production costsCylinder headsCylindersLow speedEngineering

The invention relates to a high-performance steam cylinder cover for a large low-speed diesel engine and a manufacturing process. According to the high-performance steam cylinder cover and the manufacturing process, after steam cylinder cover forge pieces are produced, the phenomena of segregation, loosening, uneven grain distribution and the like cannot occur inside, the performance difference in the same plane is extremely small, performance is stable, and the material utilization rate is high. The high-performance steam cylinder cover is prepared from, by mass percent, 0.17%-0.22% of C, 0.45% of Si or less, 0.95%-1.1% of Mn, 0.03% of P or less, 0.03% of S or less, 0.9%-1.1% of Cr, 0.4%-0.5% of Mo, 0.4% of Ni or less, 0.08%-0.12% of V and 0.005% of Nb or less. The high-performance steam cylinder cover has the beneficial effects that the workpiece structure is uneven, and internal stress is extremely small; production cost increase is effectively controlled; the subsequent workpiece cutting machining amount is small, and time and labor are saved during machine tool machining; and after ultrasonic testing, the internal grains are stable in state, and no coarse grain phenomenon exists.

Owner:宝鼎重工有限公司

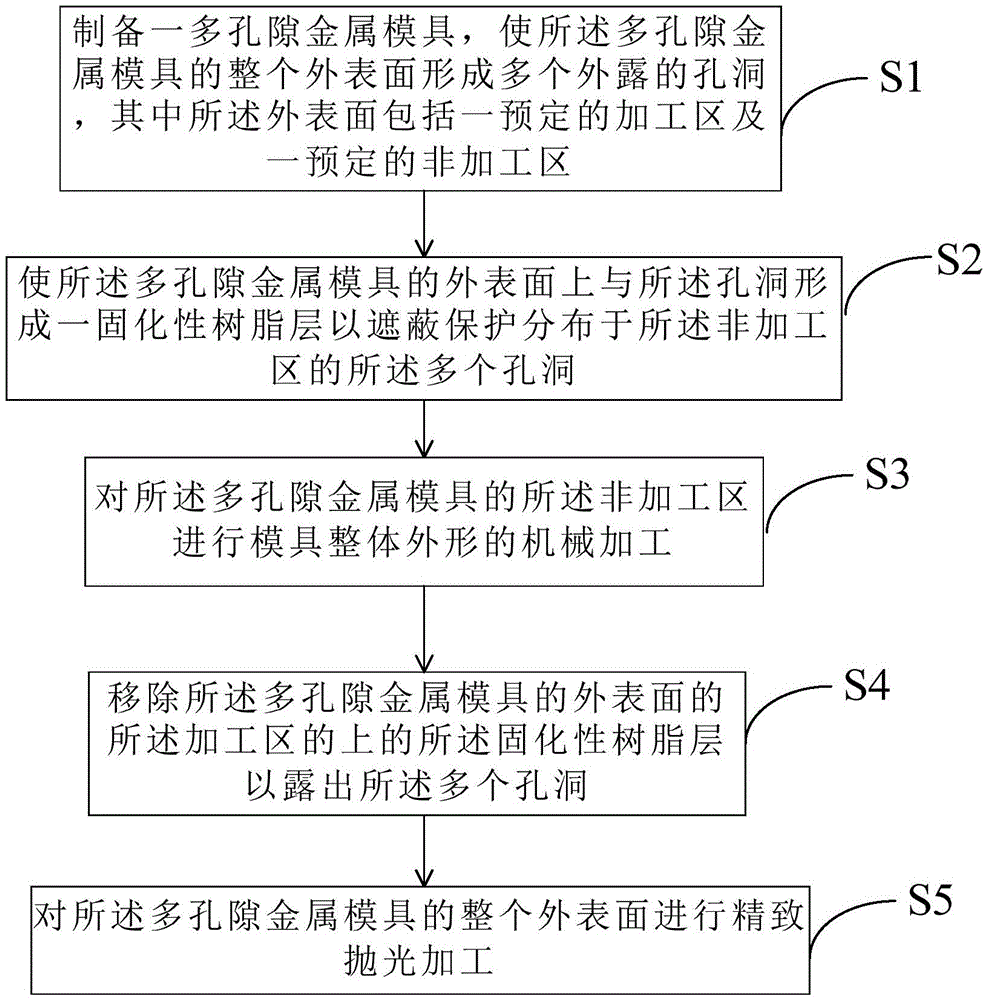

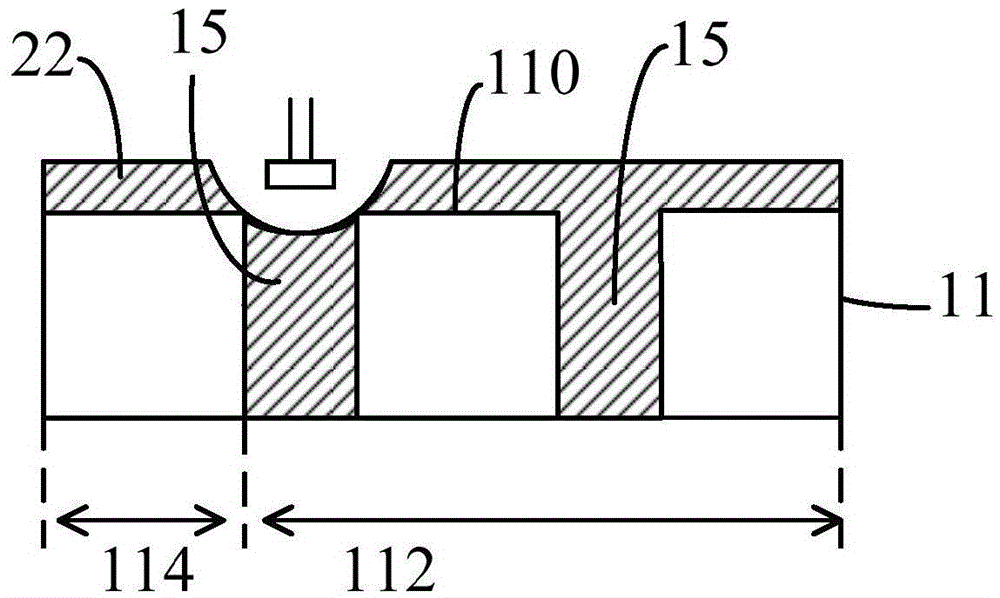

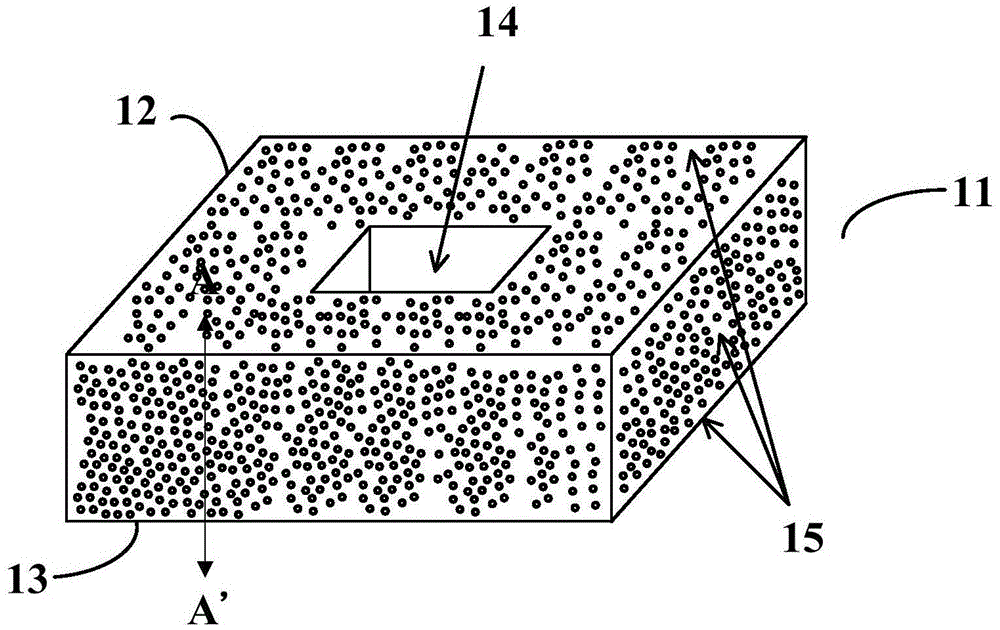

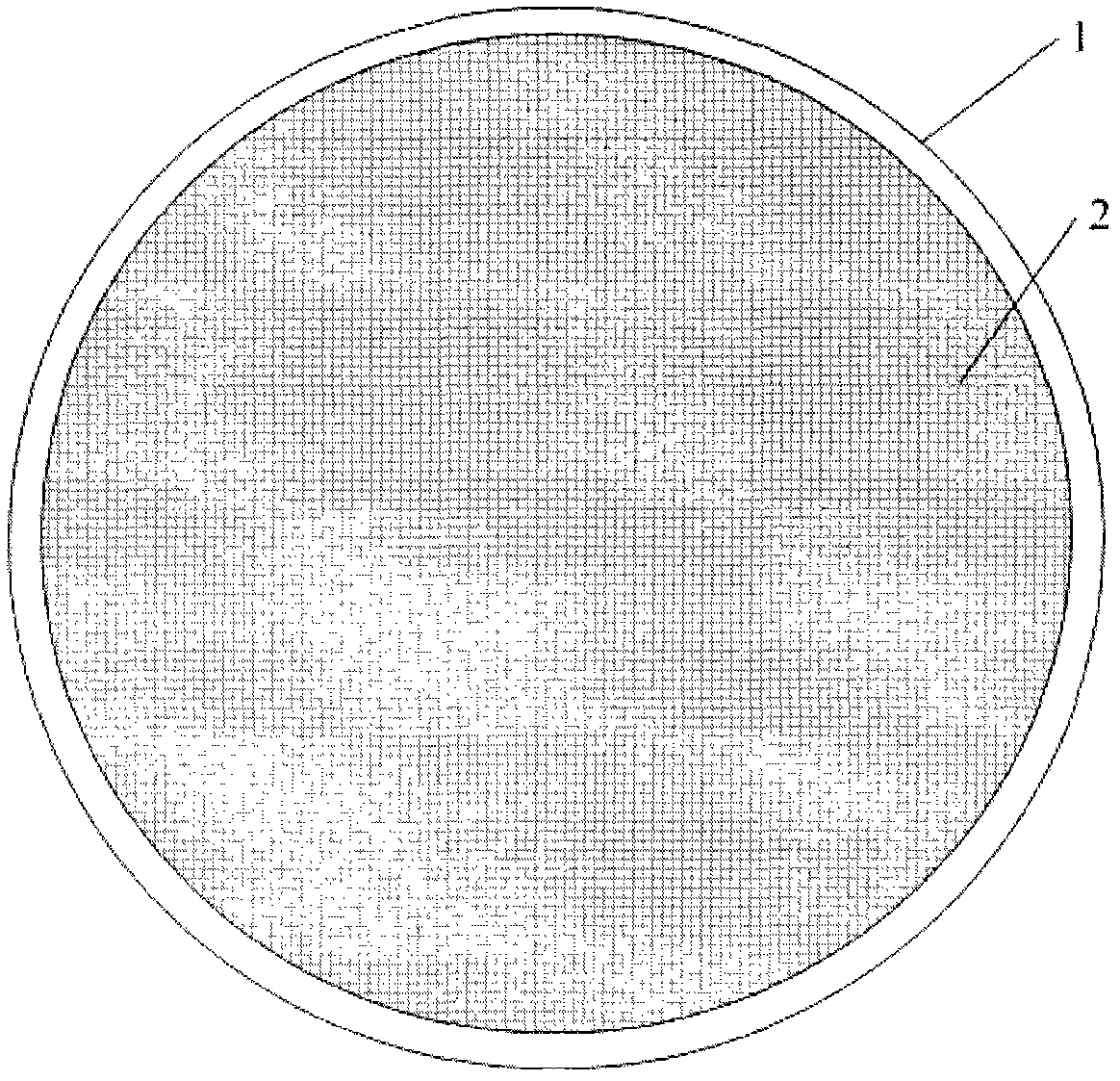

Method of manufacturing porous metal mold for wet pulp molding process

A method of manufacturing a porous metal mold for a wet pulp molding process is disclosed herein. The method comprises the steps of (1) preparing a porous metal mold, an outer surface of which and a pore form a plurality of exposed pores, wherein the outer surface comprises a machining area and a non-machining area; (2) forming a solidified resin layer on the outer surface of the porous metal mold and the pore to shield and protect the plurality of pores distributed in the non-machining area; (3) machining the machining area of the porous metal mold; (4) removing the solidified resin layer on the surface of the porous metal mold to expose the plurality of pores; and (5) delicately polishing and machining the outer surface of the porous metal mold.

Owner:GOLDEN ARROW PRINTING

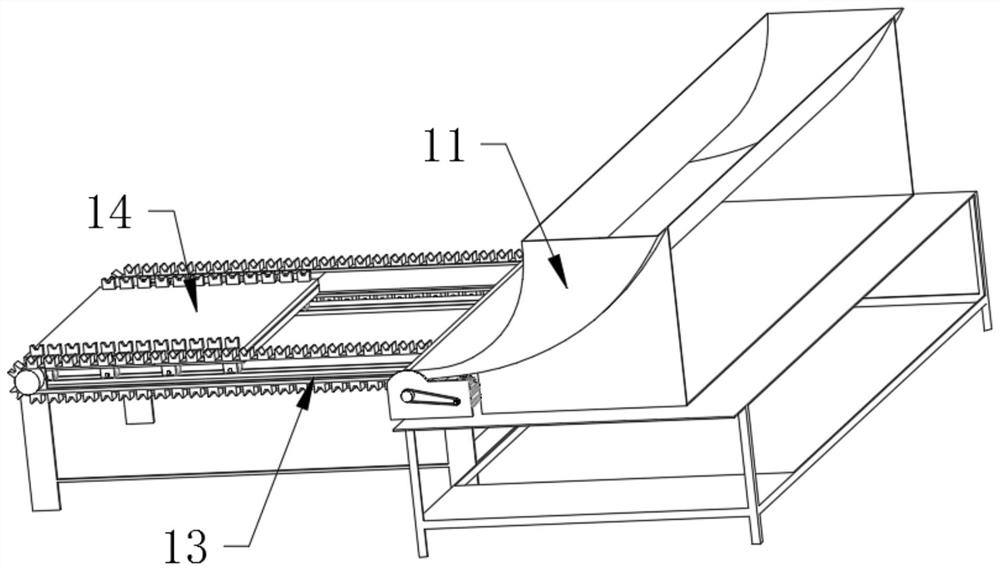

Tobacco turning device of efficient hoisting machine

ActiveCN102205884ASimple structureProcessing saves time and effortPackagingEngineeringMechanical engineering

The invention discloses a tobacco turning device of an efficient hoisting machine. The tobacco turning device has a groove-shaped structure with an open bottom part and two open ends; the groove-shaped structure comprises a tobacco rod entrance end and a tobacco rod turning end; a fixing plate used for fixing the tobacco turning device is arranged at the tobacco rod entrance end; a roller is also arranged at the tobacco rod entrance end to convey tobacco rods; the tobacco turning device is provided with two side walls, one of the side walls is provided with a baffle plate, and the bottom of other one of the side walls is provided with an arc-shaped surface; the conveyance of the tobacco rods is performed between the two side walls; the arc-shaped surface plays a role in supporting the bottom parts of the tobacco rods; the baffle plate controls the advancing direction of the tobacco rods; and in the process of advancing from the tobacco rod entrance end to the tobacco rod turning end, the tobacco rods can automatically fall down from a gap between the side walls to realize side turning. The tobacco turning device is reasonable in structure, can effectively realize automatic turning of the tobacco rods, overcomes the defects of blockage and poor turning in the conveying process of the tobacco rods, and improves the smoothness and convenience of tobacco package and conveyance.

Owner:SHENZHEN TOBACCO IND

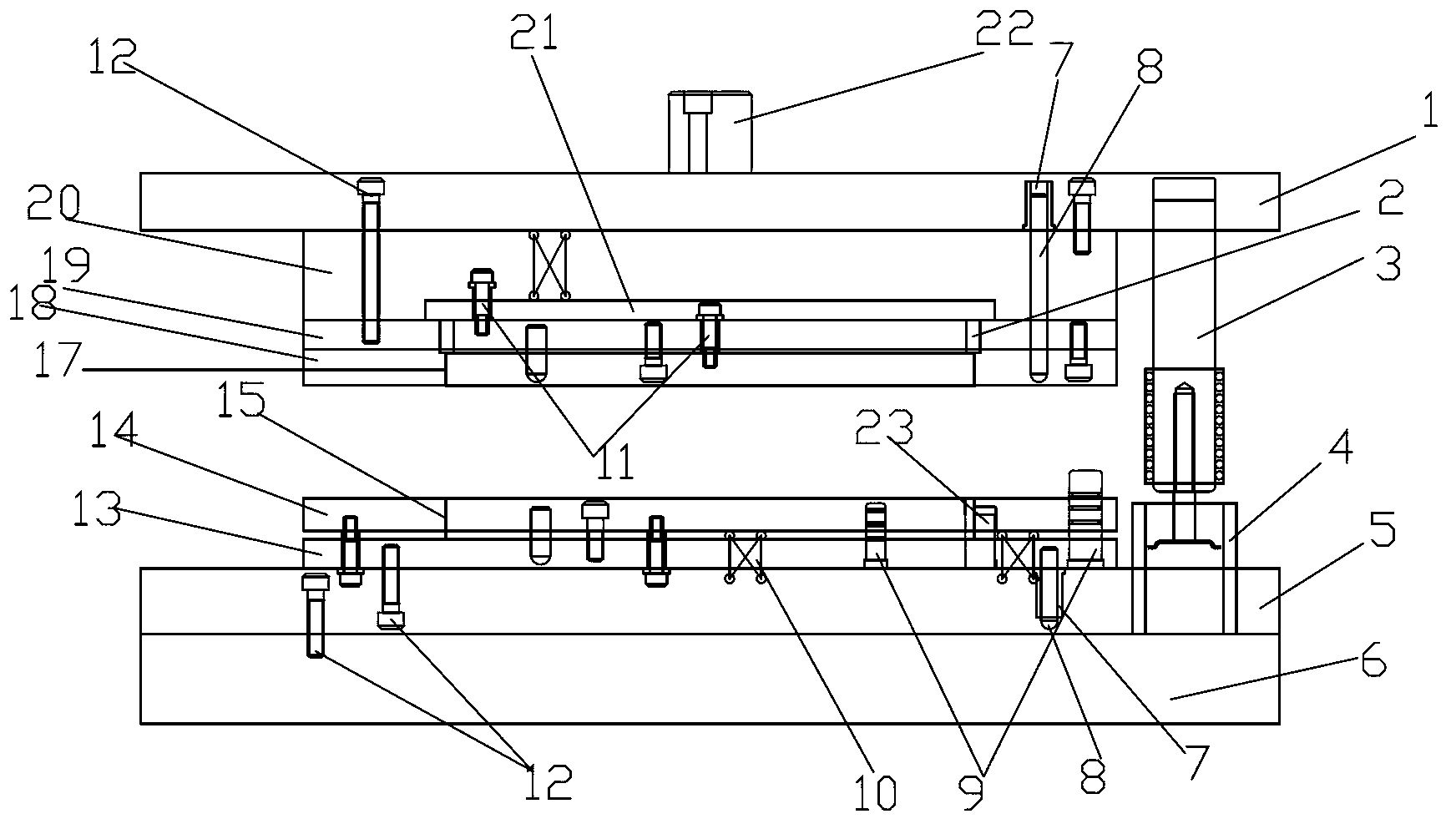

Panel stamping die

The invention discloses a panel stamping die which comprises a shank, an upper die and a lower die. The upper die comprises a punch set, a punch pad block, a punch holder, an upper plate, an up striking plate and a stripper plate, wherein the upper plate of the upper die is fixed through a dowel pin and a hexagonal sink screw, and a stripping rod is arranged on the upper die; the lower die comprises a male die, a lower stripping plate, a die holder, a die set and a die pad block, wherein a lower plate of the lower die is fixed through a dowel pin and a hexagonal sink screw, and an auxiliary guide pillar is arranged on the lower die; an elastic interval is arranged between the die holder and the lower stripping plate through a spring; and an external guide pillar is arranged between the upper die and the lower die. The die has the advantages that the positioning and guide are accurate, the die is convenient to repair and modify, the processing is time and labor saving, replacement of a damaged die and change of a finished die are facilitated, and the working efficiency can be improved.

Owner:昆山威安精密模具有限公司

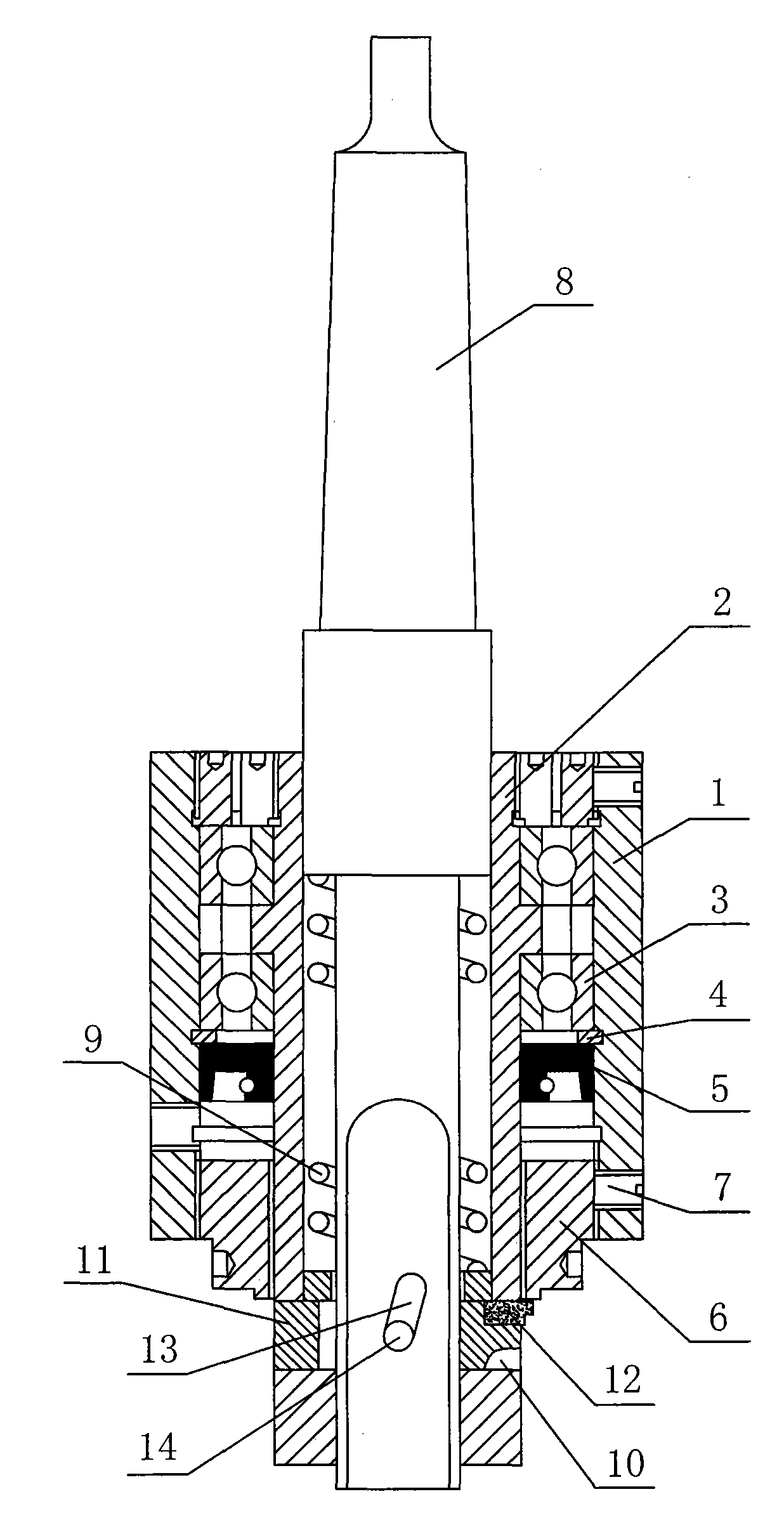

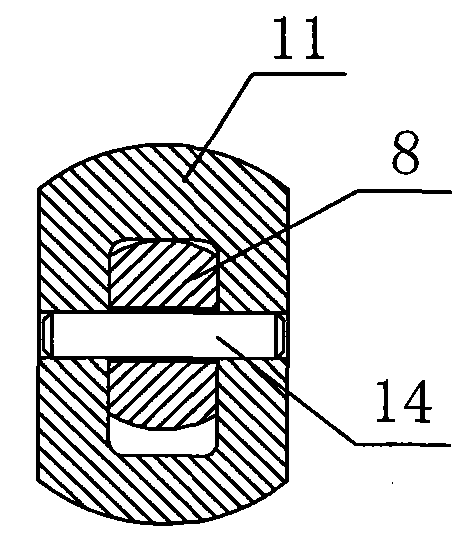

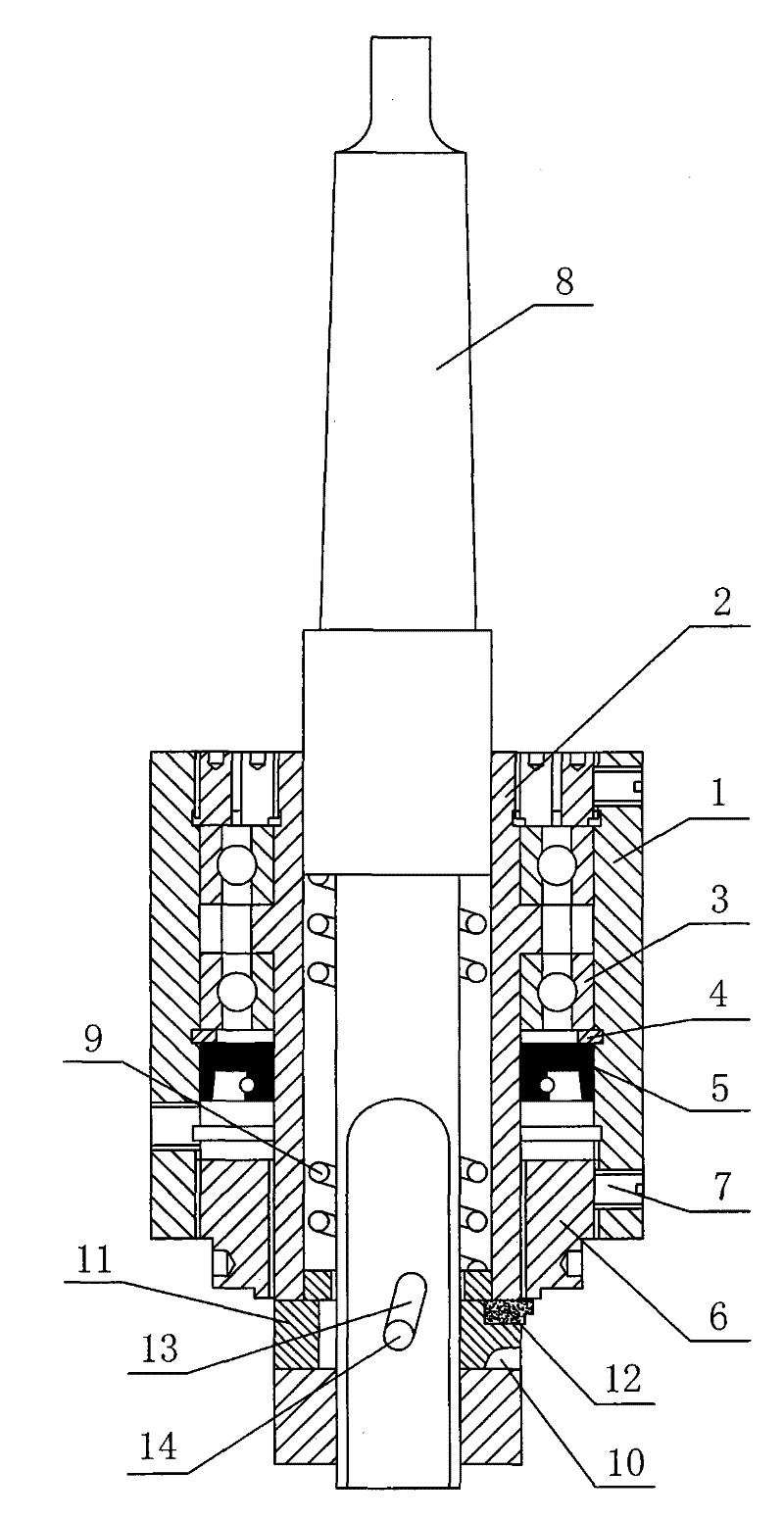

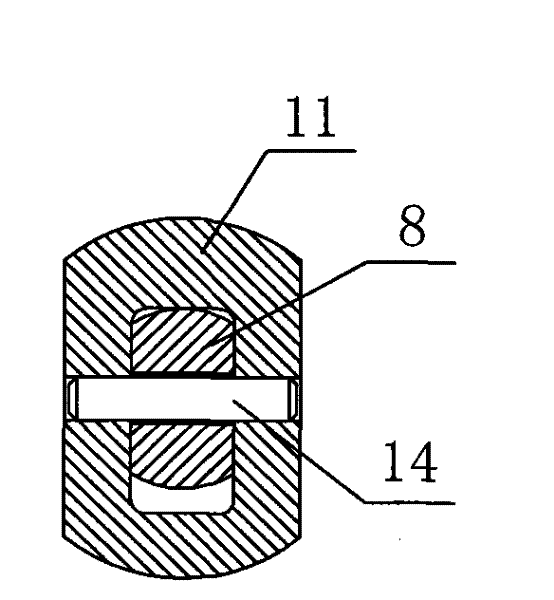

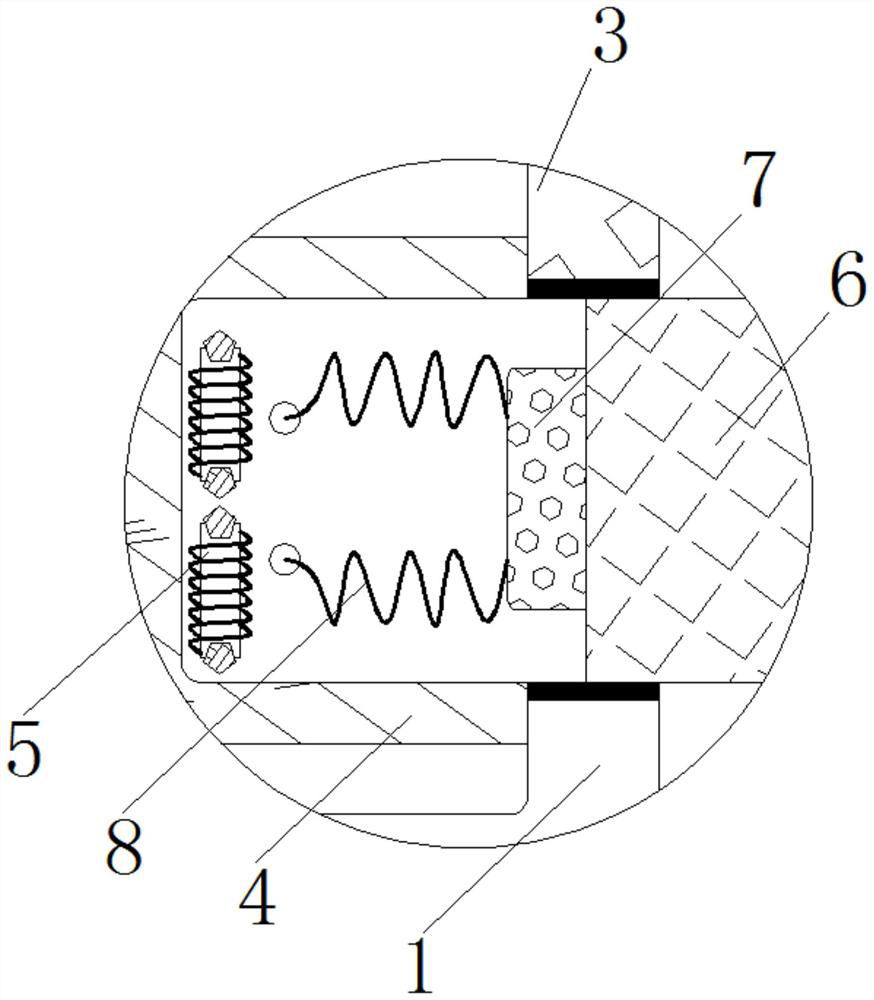

Dedicated tool for machining clamp spring slot

InactiveCN101767215ASimple structureEasy to operateTransportation and packagingTrepanning drillsJackscrewEngineering

The invention relates to a machining tool, in particular to a dedicated tool for machining a clamp ring slot. The tool comprises an outer fixed sleeve and an inner fixed sleeve, a bearing, a clamp spring and a sealing ring are sequentially arranged between the outer fixed sleeve and the inner fixed sleeve from top to bottom, a screw nut for fixing the bearing is arranged above the bearing, the outer fixed sleeve below the sealing ring is connected with an adjustment sleeve in a threading way, and a positioning jackscrew is arranged at a place, which is corresponding to the adjustment sleeve, on the outer fixed sleeve; the inner fixed sleeve is internally sheathed with a core shaft which can move up and down, a reset spring is arranged between the lower part of the core shaft and the inner fixed sleeve, a chute at the lower end of the inner fixed sleeve is internally provided with a movable tool embedding block, the outer end of the tool embedding block is fixed with a tool head the position of which is next to the lower end of the adjustment sleeve, the lower end of the core shaft is provided with an oblique slot which leans to the tool head side, and the core shaft passes through the tool embedding block and is pin-connected with the tool embedding block by a positioning pin which pass through the oblique slot. The dedicated tool has the advantages of simple structure, convenient operation, time and labor saving, safety, reliability and high production efficiency.

Owner:山东光岳转向节有限责任公司

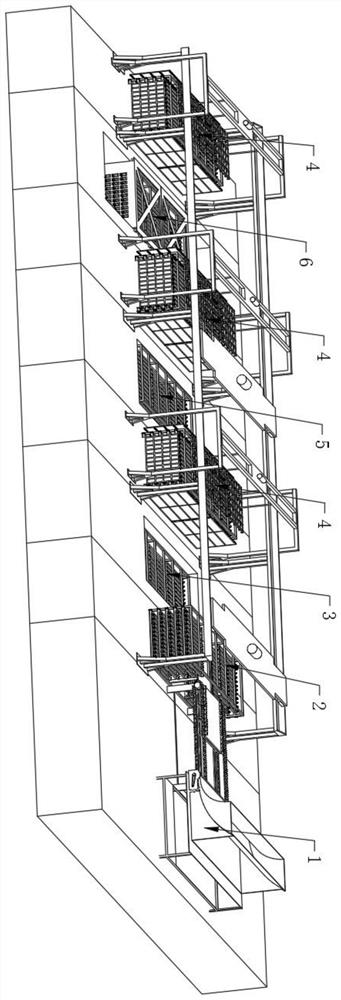

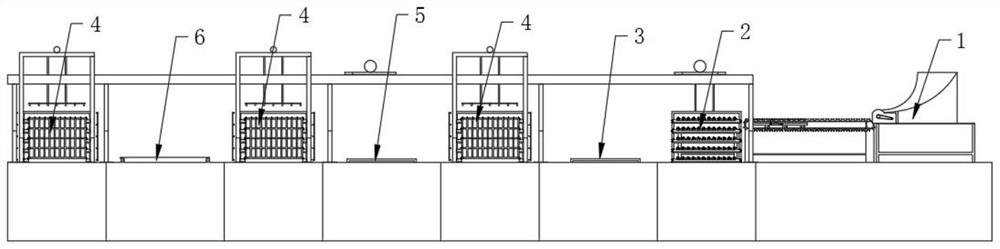

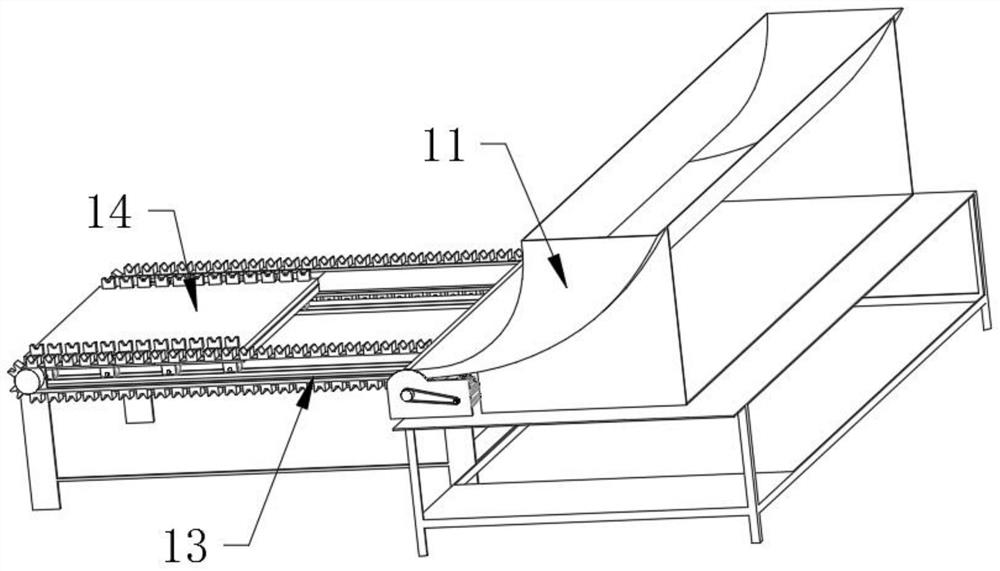

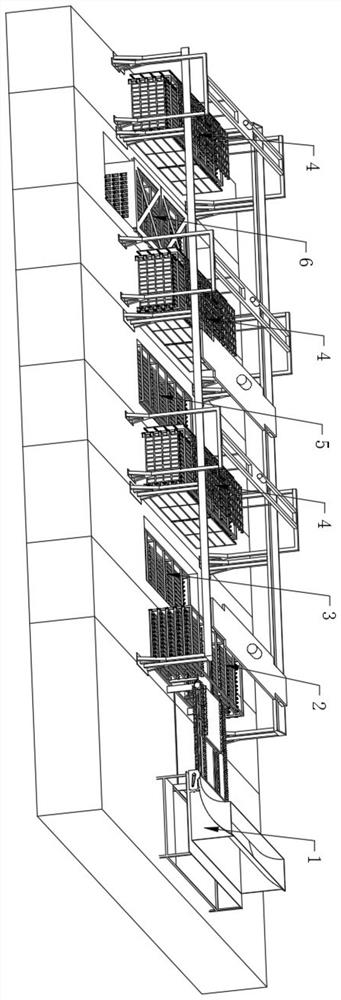

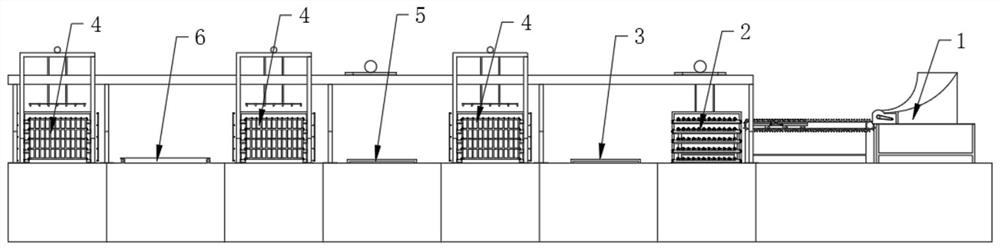

Steel pipe conveying, degreasing, cleaning and electrophoresis automatic production line

InactiveCN112458517AGood processing effectReduce labor intensityConveyorsHollow article cleaningElectrophoresesProcess engineering

The invention discloses a steel pipe conveying, degreasing, cleaning and electrophoresis automatic production line which comprises a sorting mechanism, a feeding mechanism, a degreasing pool, sprayingmechanisms, a silane pool and an electrochemical treatment device; the sorting mechanism, the feeding mechanism, the degreasing pool, the spraying mechanisms, the silane pool and the electrochemicaltreatment device are sequentially and transversely arranged side by side, and the spraying mechanisms are arranged on the front side and the rear side of the electrochemical treatment device; the sorting mechanism is used for sorting and conveying steel pipes, the feeding mechanism is used for stacking, fixing and conveying the steel pipes to a subsequent procedure, the degreasing pool is used fordegreasing the surfaces of the steel pipes, the spraying mechanisms are used for washing the surfaces of the steel pipes, and the silane pool is used for carrying out silane treatment on the surfacesof the steel pipes; and the electrochemical treatment device is used for electrochemically treating the surfaces of the steel pipes. The steel pipe conveying, degreasing, cleaning and electrophoresisautomatic production line is reasonable in design, the automation degree is improved, the labor intensity of workers is reduced, the production efficiency is effectively improved, and the steel pipetreatment effect is better.

Owner:XINGTAI POLYTECHNIC COLLEGE

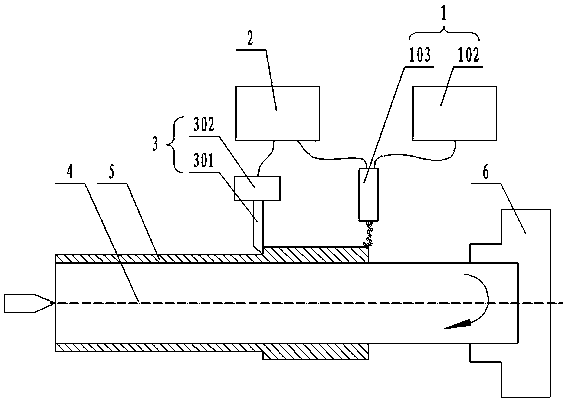

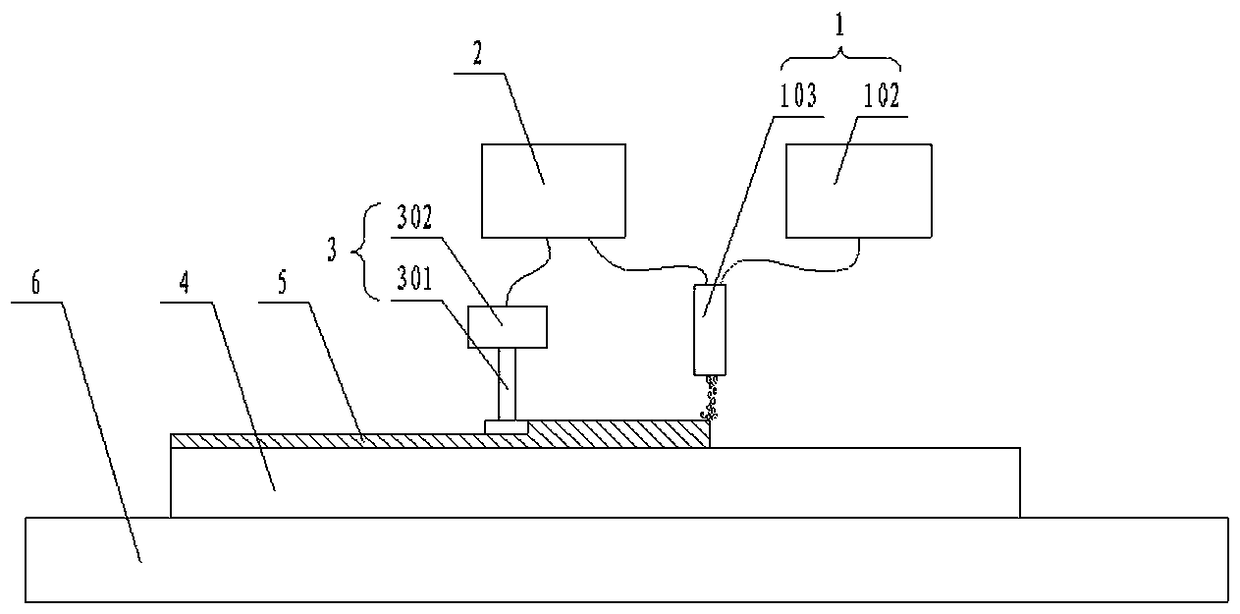

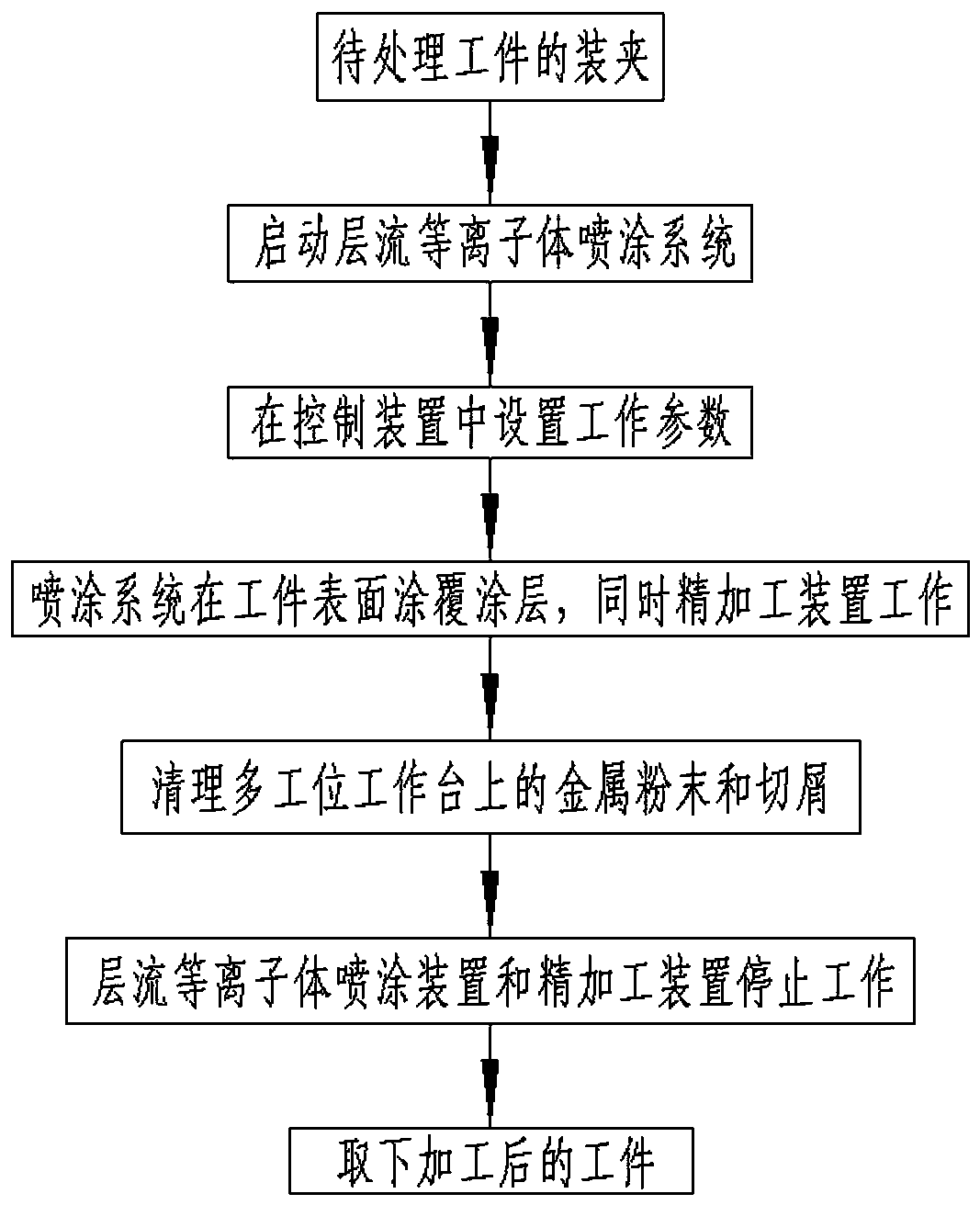

Metal surface strengthening combined machining device and method of laminar plasmas

The invention provides a metal surface strengthening combined machining device and method of laminar plasmas. The device comprises a laminar plasma spraying system (1), a control device (2) and a finish machining device (3); the control device (2) is electrically connected with the laminar plasma spraying system (1) and the finish machining device (3); a laminar plasma generator (101) of the laminar plasma spraying system (1) is parallel to a cutter (301) of the finish machining device (3); and the cutter (301) synchronously follows the laminar plasma generator (101) to axially move along workpieces to be treated. The method comprises the steps of: clamping of the workpieces on a worktable; resetting of the machining device; operation of the finish machining device during spraying by the laminar plasma generator; completion of the surface spraying of the workpieces and finish machining of coating layers; recovery of metal powder and chips; parking and taking down of the workpieces. Thedevice has the advantages of good controllability, high stability, good quality of the coating layers and high surface precision of the coating layers.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

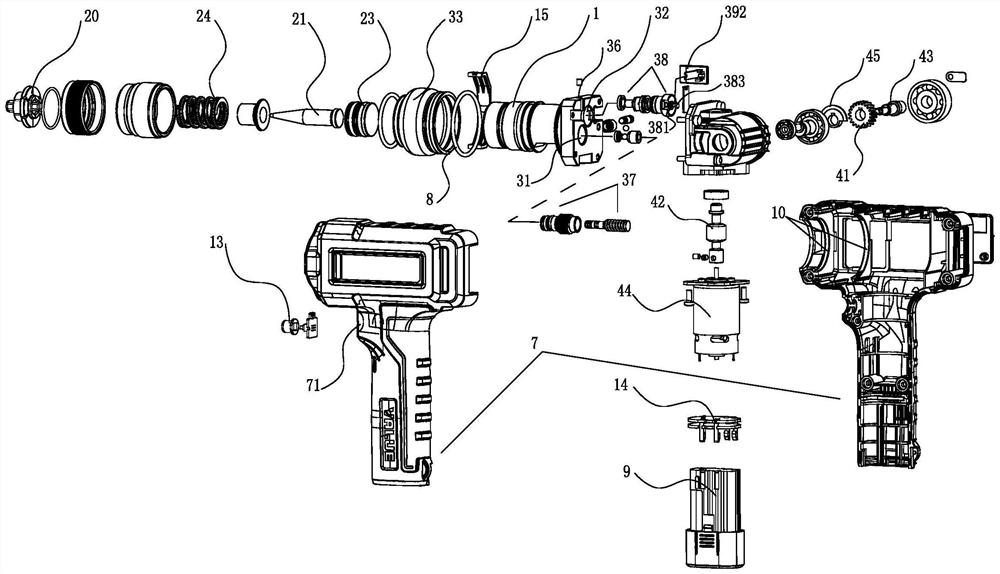

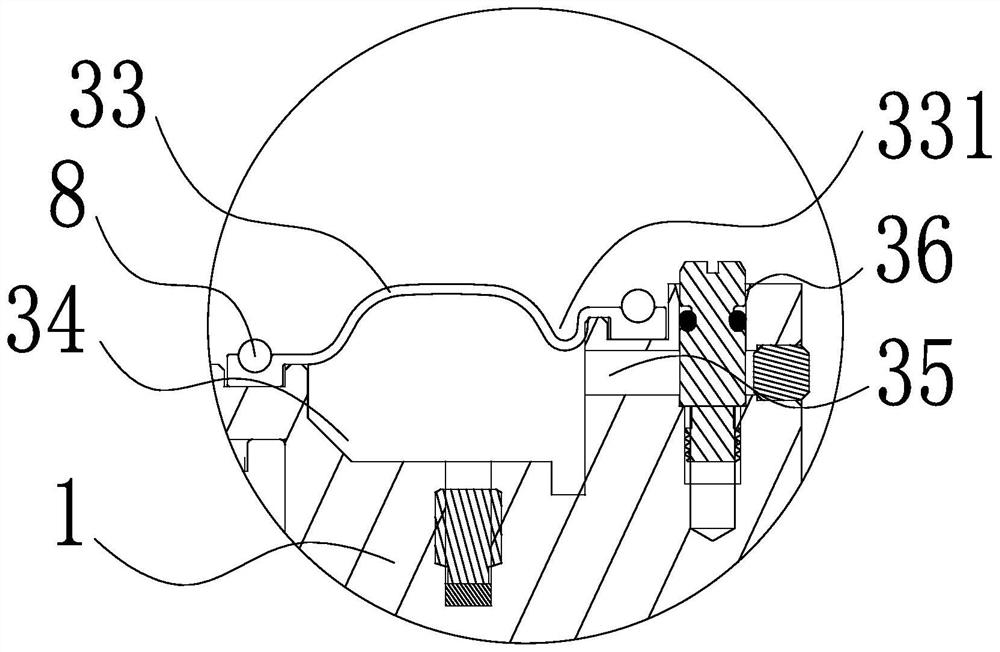

Multifunctional electric hydraulic pipe fitting machining tool

PendingCN113649483AImprove oil absorption efficiencyWon't hurtShaping safety devicesPress ramElectrical batteryPipe fitting

The invention discloses a pipe fitting machining tool, and provides a multifunctional electric hydraulic pipe fitting machining tool which can be used for machining various types of pipe fittings, is good in universality, saves time and labor in machining and is convenient to carry and use. The technical problems that in the prior art, a pipe fitting machining tool is single in function and high in use cost, generally manual operation is used, the machining process wastes time and consumes labor, the machining efficiency is low, and the product quality cannot be guaranteed are solved. The multifunctional electric hydraulic pipe fitting machining tool comprises a body, and a feeding mechanism, a hydraulic mechanism and a driving mechanism that are arranged on the body, a driving motor on the driving mechanism is electrically connected to a battery pack, the driving mechanism pushes a conical head in the feeding mechanism to move outwards through the hydraulic mechanism to be matched with a pipe fitting chuck, the hydraulic mechanism comprises a plunger cavity and a pressure relief cavity which are in communication with the rear end of the conical head, the plunger cavity and the pressure relief cavity are in communication with an oil storage ring covering the body, and the strength of the oil storage ring wall face close to an inlet of the plunger cavity is increased.

Owner:ZHEJIANG VALUE MECHANICAL & ELECTRICAL PROD CO LTD

Assembling equipment for built-in soldering lug of two-way joint

ActiveCN113182740AGood for industrial processingRealize automatic feeding operationWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringManual handling

The invention provides assembling equipment for a built-in soldering lug of a two-way joint, and belongs to the technical field of metal part machining. A base feeding mechanism, a visual grabbing mechanism, a direction adjusting mechanism, an automatic base discharging mechanism, a copper ring piece machining mechanism, a bamboo joint piece placing mechanism, an assembling and pressing mechanism and an automatic discharging mechanism are sequentially arranged beside a rotary disc. Automatic feeding operation of a base and automatic adjustment of the direction of a welding hole in the base are achieved, automatic machining and installation of a copper ring piece can be achieved at the same time, the problem that machining, transferring and manual placing are needed in advance is solved, the workload is relieved, automatic feeding of a bamboo joint piece can be achieved, the base and the bamboo joint piece are automatically and temporarily fixed, automatic discharging is conducted on the base and the bamboo joint piece which are temporarily fixed, the automation degree is higher, the machining efficiency is improved, potential safety hazards caused by manual operation are avoided, and industrialization machining of the two-way joint is facilitated.

Owner:宁波亚大自动化科技有限公司

Automatic punching device for cylindrical neodymium iron boron

InactiveCN112935321AProcessing saves time and effortImprove work efficiencyFeeding apparatusMetal working apparatusPunchingStructural engineering

The invention discloses an automatic punching device for cylindrical neodymium iron boron and belongs to the technical field of neodymium iron boron machining. The automatic punching device comprises an operation table, a feeding mechanism, a conveying mechanism, a fixing mechanism, a pushing mechanism, a cleaning mechanism, a punching mechanism, a collecting mechanism and a control device, wherein the feeding mechanism is fixedly connected to the left side wall of the operation table through bolts, the conveying mechanism is arranged above the operation table, the fixing mechanism is fixedly connected to the periphery of the outer side wall of the conveying mechanism through bolts, and the pushing mechanism is fixedly connected to the front side of the left side of the top of the operation table through bolts. For the automatic punching device for the cylindrical neodymium iron boron, by replacing manual punching with automatic punching, more time and more labor can be saved during neodymium iron boron machining, and the working efficiency is improved at the same time; and the punching process is completely automatic, so that the yield is increased while the qualified rate is increased, chips produced during punching are prevented from being scattered at will, damages to the machine are avoided, and the production and machining cost is reduced while the economic loss is avoided.

Owner:安徽新科磁业有限公司

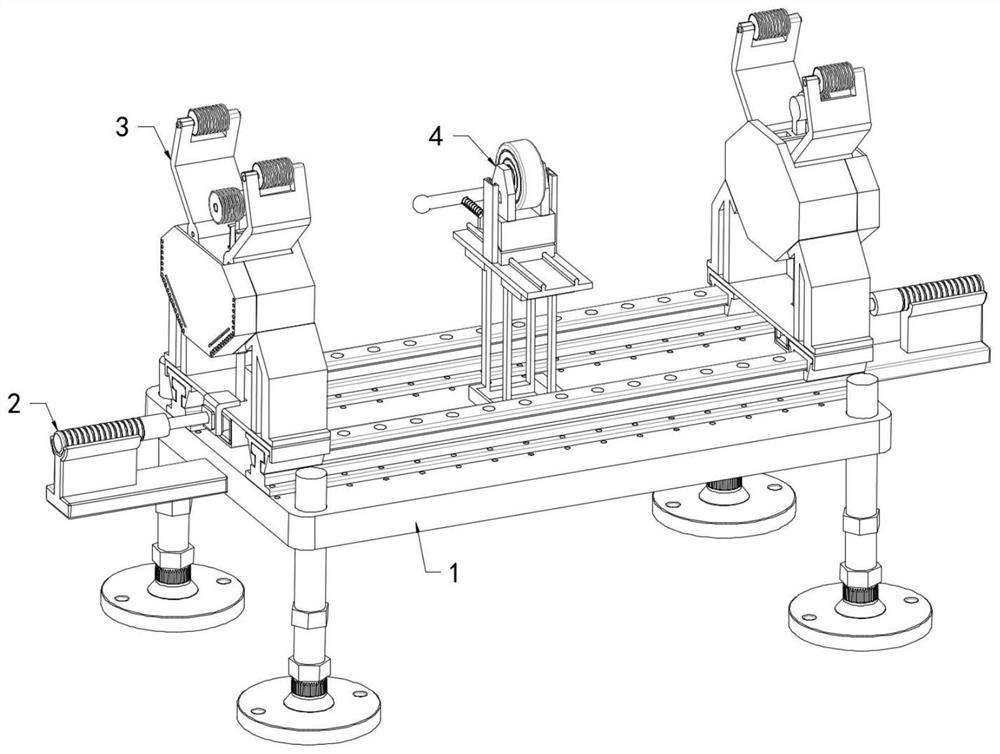

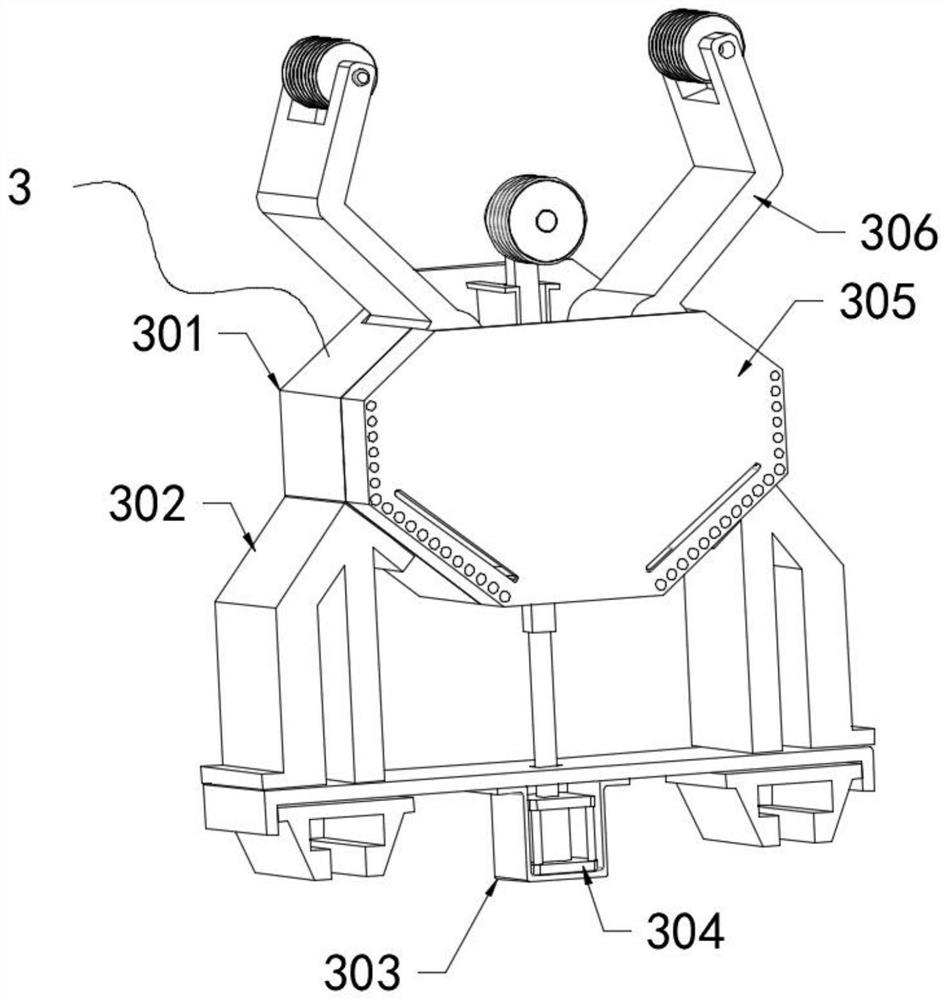

Support device for fixing tower barrels of various models

PendingCN114178773AEasy to moveStable supportWelding/cutting auxillary devicesAuxillary welding devicesWind powerIndustrial engineering

The invention relates to the technical field of wind energy, in particular to a support device for fixing tower barrels of various models, and solves the problems that in the prior art, only one tower barrel of one size model can be applied, the application range is small, and the application range is not wide; the problems that in the welding process, a welding worker needs to weld around the tower drum, time and labor are consumed, the labor intensity is large, and the working efficiency is low are solved. A support device for fixing tower barrels of various models comprises a bearing part, and two clamping parts are symmetrically arranged at the top of the bearing part. According to the device, the structure is reasonable, automatic adjustment can be conveniently achieved, rapid adaptive adjustment can be conducted according to tower barrels with different sizes and specifications and different diameters at the two ends, the tower barrels can be stably supported and can rotate, the use range of the device is widened, meanwhile, the practicability of the device is improved, time and labor are saved during machining, and the machining efficiency is improved. Labor intensity is reduced, and working efficiency is improved.

Owner:江苏长风海洋装备制造有限公司

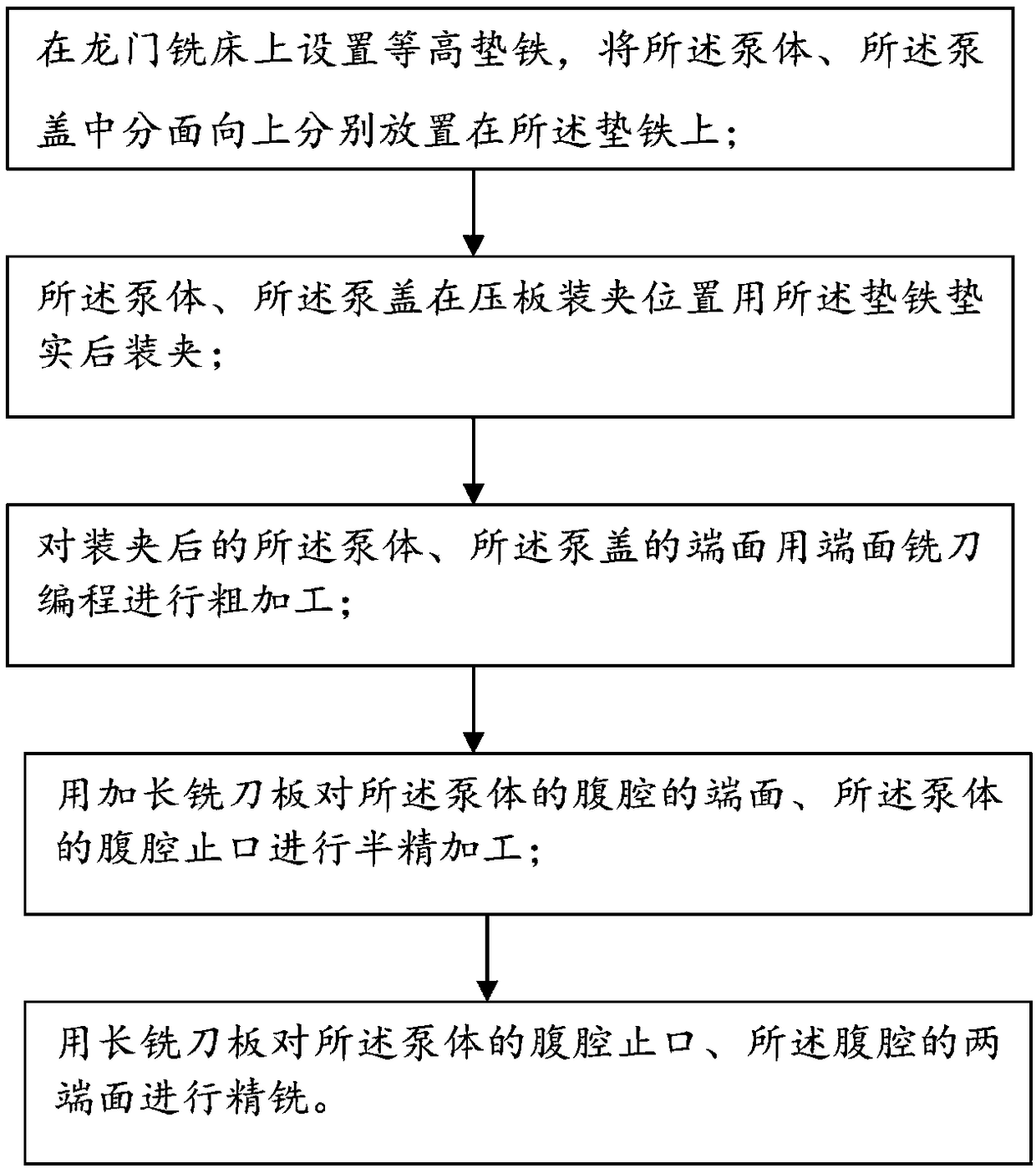

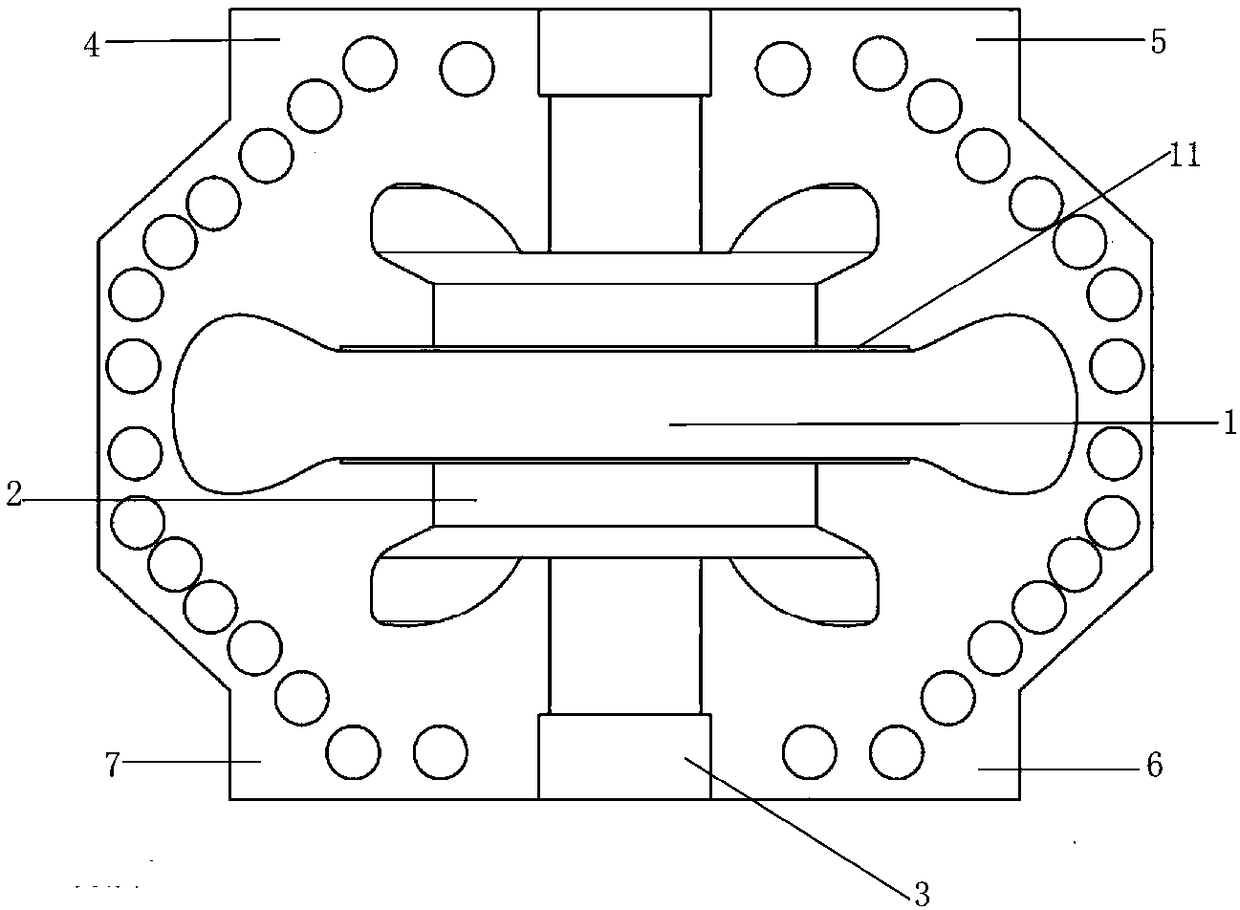

Pipeline pump abdominal cavity machining method

ActiveCN108145221AEasy and fast processingProcessing saves time and effortMilling equipment detailsAbdominal cavityRapid processing

The invention discloses a pipeline pump abdominal cavity machining method and relates to the technical field of turbine machinery machining technique design. The pipeline pump abdominal cavity machining method is used for rapidly machining a pipeline pump abdominal cavity structure and comprises the steps that equal-height shim plates are arranged on a plano milling machine, and a pump body and apump cover are placed on the shim plates in the mode that the association planes are upward correspondingly; the pump body and the pump cover are compactly cushioned through the shim plates on the pressing plate clamping position and then clamped; the end faces of the pump body and the pump cover which are clamped are subjected to coarse machining through an end face milling tool program; the endface of an abdominal cavity of the pump body and an abdominal cavity spigot of the pump body are subjected to semi finish machining through a lengthened milling tool plate; and through a long millingtool plate, the abdominal cavity spigot of the pump body and the two end faces of the abdominal cavity are subjected to finish milling. By adopting the pipeline pump abdominal cavity machining method,overall machining of a pipeline pump product is developed into split machining, simple and rapid effects are achieved, the time and labor are saved, the blank of abdominal cavity split machining in the pump industry is filled up, a traditional machining mode is broken through, and the high popularization value is achieved.

Owner:SHENYANG TURBO MASCH CORP

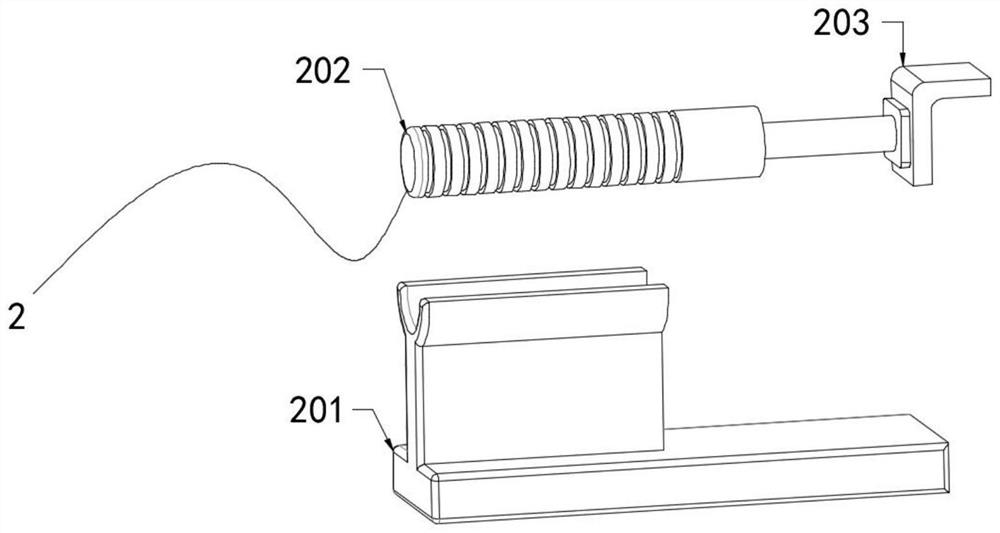

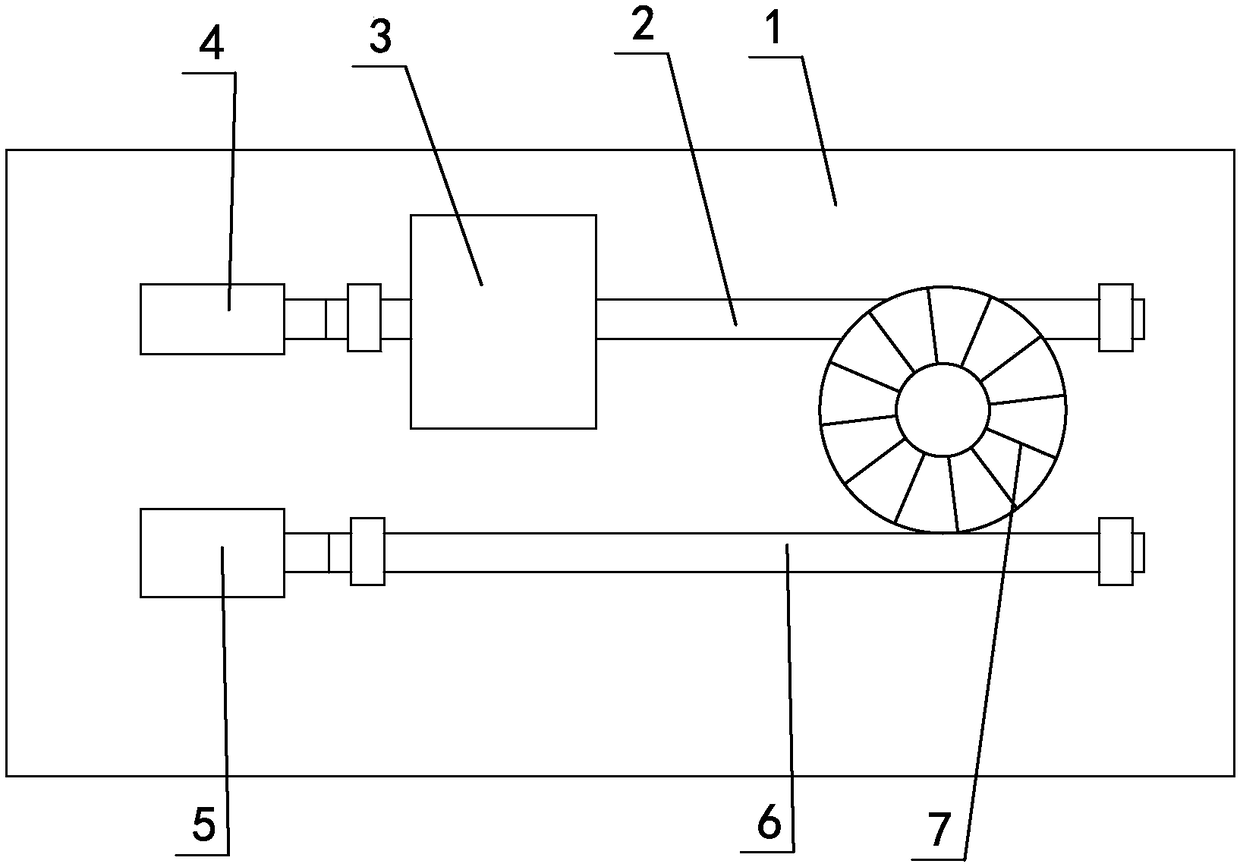

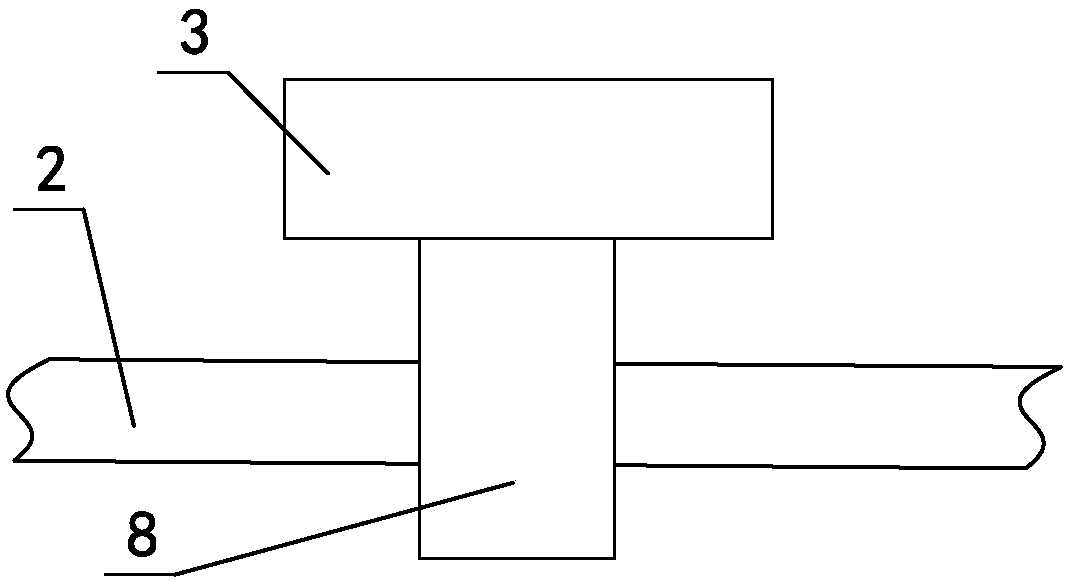

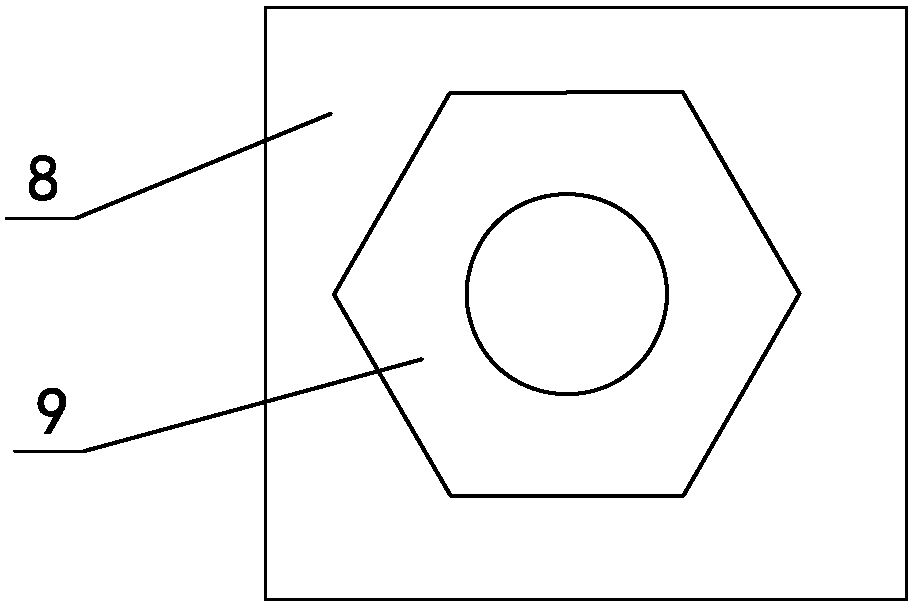

Dividing feeding mechanism

InactiveCN108081008ASimple structureProcessing saves time and effortPrecision positioning equipmentFeeding apparatusMachiningDrilling machines

The invention relates to a dividing feeding mechanism and belongs to the technical field of dividing feeding. The dividing feeding mechanism comprises a base, a feeding lead screw and a dividing leadscrew are parallelly arranged on the base, and the feeding lead screw and the dividing lead screw are mounted on the base through bearings. The left end of the feeding lead screw is connected with a material stepping motor, and the material stepping motor is mounted on the base. The feeding lead screw is sleeved with a nut, and the nut is sleeved with a nut mounting seat. A feeding plate is fixedto the top of the nut mounting seat, and a left-right sliding assembly is arranged between the nut mounting seat and the base. The left end of the dividing lead screw is connected with a dividing stepping motor, and the dividing stepping motor is mounted on the base. A dividing worm wheel which is in dividing fit with the dividing lead screw is mounted on the base, and the dividing worm wheel is mounted on the base through a rotary shaft. According to the dividing feeding mechanism, a workpiece feeding system and a workpiece dividing system are designed simultaneously, the dividing feeding mechanism is the improvement on the basis of an original drilling machine, the dividing feeding mechanism is very suitable for conducting circumferential porous machining on a workpiece, the time and labor are saved during machining, and the cost is low.

Owner:CHONGQING JIANGJIN HUAMAO MACHINERY CO LTD

Steel pipe surface treatment production line

InactiveCN113881996AEasy to handleReduce labor intensityConveyorsHollow article cleaningProcess engineeringElectrochemistry

The invention discloses a steel pipe surface treatment production line. The steel pipe surface treatment production line comprises a sorting mechanism, a feeding mechanism, a degreasing pool, spraying mechanisms, a silane pool and an electrochemical treatment device; the sorting mechanism, the feeding mechanism, the degreasing pool, the spraying mechanisms, the silane pool and the electrochemical treatment device are sequentially and transversely arranged side by side, and the spraying mechanisms are arranged on the front side and the rear side of the electrochemical treatment device correspondingly; and the sorting mechanism is used for sorting and conveying the steel pipes, the feeding mechanism is used for stacking, fixing and conveying the steel pipes to a subsequent process, the degreasing pool is used for degreasing the surfaces of the steel pipes, the spraying mechanisms are used for washing the surfaces of the steel pipes, the silane pool is used for performing silane treatment on the surfaces of the steel pipes, and the electrochemical treatment device is used for performing electrochemical treatment on the surfaces of the steel pipes. The steel pipe surface treatment production line is reasonable in design, the automation degree is improved, the labor intensity of workers is reduced, the production efficiency is effectively improved, and the steel pipe processing effect is better.

Owner:XINGTAI POLYTECHNIC COLLEGE

Dedicated tool for machining clamp spring slot

InactiveCN101767215BEasy to operateProcessing saves time and effortTransportation and packagingTrepanning drillsFixed bearingJackscrew

The invention relates to a machining tool, in particular to a dedicated tool for machining a clamp ring slot. The tool comprises an outer fixed sleeve and an inner fixed sleeve, a bearing, a clamp spring and a sealing ring are sequentially arranged between the outer fixed sleeve and the inner fixed sleeve from top to bottom, a screw nut for fixing the bearing is arranged above the bearing, the outer fixed sleeve below the sealing ring is connected with an adjustment sleeve in a threading way, and a positioning jackscrew is arranged at a place, which is corresponding to the adjustment sleeve, on the outer fixed sleeve; the inner fixed sleeve is internally sheathed with a core shaft which can move up and down, a reset spring is arranged between the lower part of the core shaft and the innerfixed sleeve, a chute at the lower end of the inner fixed sleeve is internally provided with a movable tool embedding block, the outer end of the tool embedding block is fixed with a tool head the position of which is next to the lower end of the adjustment sleeve, the lower end of the core shaft is provided with an oblique slot which leans to the tool head side, and the core shaft passes throughthe tool embedding block and is pin-connected with the tool embedding block by a positioning pin which pass through the oblique slot. The dedicated tool has the advantages of simple structure, convenient operation, time and labor saving, safety, reliability and high production efficiency.

Owner:山东光岳转向节有限责任公司

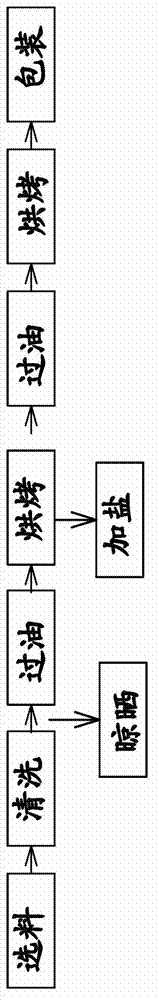

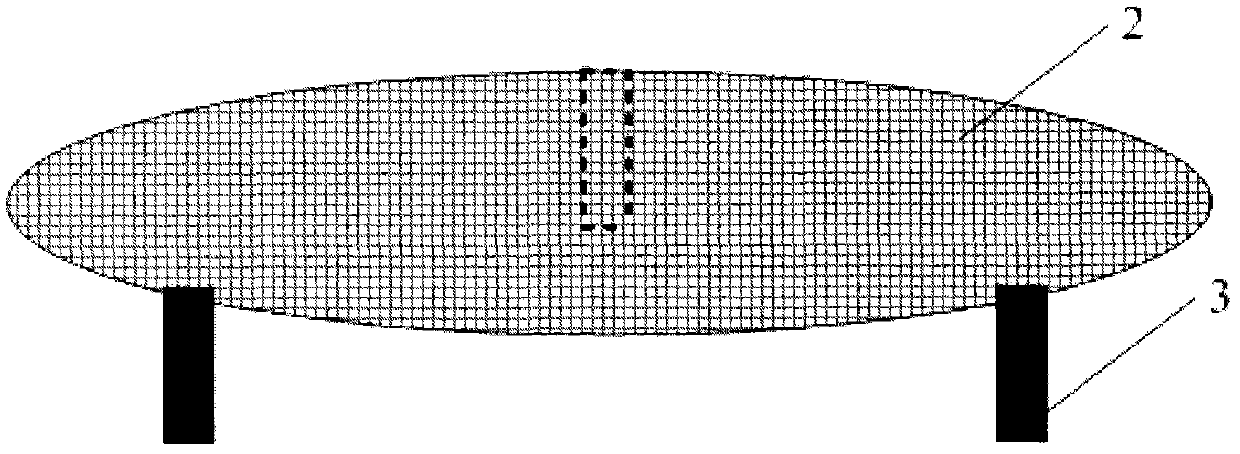

Processing technology of trchosanthes kiriowii maxim

InactiveCN103202500AGreat tasteProcessing saves time and effortFood preparationCooking & bakingComputer science

The invention provides a processing technology of trchosanthes kiriowii maxim, aiming at solving the problem that the existing trchosanthes kiriowii maxim can not be reasonably utilized. The processing technology of the trchosanthes kiriowii maxim comprises the steps of: A. selecting material; B. cleaning; C. soaking in hot oil; D. baking; and E. packaging. The trchosanthes kiriowii maxim processed by the technology has certain fragrance, thus being directly eaten and having better mouthfeel. Furthermore, according to the processing technology of the trchosanthes kiriowii maxim, an oven is driven to rotate by a driving part, so that the processing process is time-saving and labor-saving, and the processing technology has higher practical value.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Traditional Chinese medicine preparation for treating rhinitis and use method thereof

InactiveCN114699375ASignificant effectEasy to usePowder deliveryHydroxy compound active ingredientsCassiaCurative effect

The invention discloses a traditional Chinese medicine preparation for treating rhinitis and a use method. The traditional Chinese medicine preparation is prepared from 13g of fructus xanthii (stir-fried to be scorched and deburring), 9g of flos magnoliae, 10g of radix angelicae, 20g of herba menthae, 10g of spica prunellae, 3g of borneol, 3g of herba asari, 10g of herba centipedae, 6g of cassia twig, 3g of fructus gleditsiae and 6g of fructus arctii. And grinding the 11 medicinal powder into superfine powder, sieving, and storing in a closed bottle for later use. The externally applied nasal plug has the advantages of remarkable curative effect, convenience in use, extremely small side effect, small medical risk, capability of treating both symptoms and root causes, simplicity, convenience, feasibility and convenience, is very suitable for common patients and has high popularization value.

Owner:讷河市忠海中医医院

Asexual propagation method of liverwort

The invention provides a novel method for propagating liverwort. According to the method, the liverwort is propagated by using a liquid culture medium; a plastic bracket is arranged in the liquid culture medium, so that tissue blocks of the liverwort cannot be immersed in the culture medium; and the tissue blocks of the liverwort are managed respectively before or after the rhizoids grow, and therefore, the aim of the rapid and efficient propagation of the liverwort is achieved.

Owner:LIYANG AOGU INFORMATION TECH

Bearing bush inner hole milling and grinding integrated equipment

InactiveCN112476657AProcessing saves time and effortImprove processingGrinding drivesMulti-purpose machinesPhysicsElectric machinery

The invention relates to the field of bearing bush machining, in particular to bearing bush inner hole milling and grinding integrated equipment which comprises a supporting seat, a milling and grinding assembly and a clamping, moving and rotating assembly. The milling and grinding assembly comprises a first motor, a lifting plate, a first threaded rod, a first clamp, a milling cutter and a grinding rod. The clamping, moving and rotating assembly comprises a supporting rod, an electric sliding table, a second motor and a second clamp. When the device is used, after the surface of an inner holeof a bearing bush is attached to the grinding rod, the second motor drives the second clamp to drive the bearing bush to rotate, and after grinding is completed, the second clamp can be opened to collect the ground bearing bush. Milling and grinding are carried out on the same equipment, the bearing bush does not need to be frequently disassembled and fixed, then the bearing bush does not need tobe carried, the machining of the inner hole of the bearing bush is labor-saving and time-saving, and the machining efficiency of the inner hole of the bearing bush can be improved.

Owner:丽水市盛裕机械制造有限公司

A Longitudinal-Torsion Compound Ultrasonic Vibration Cutting Device

InactiveCN104014836BSimple structureEasy to controlFine working devicesMilling equipment detailsEngineeringUltrasonic vibration

Owner:NORTHEASTERN UNIV LIAONING

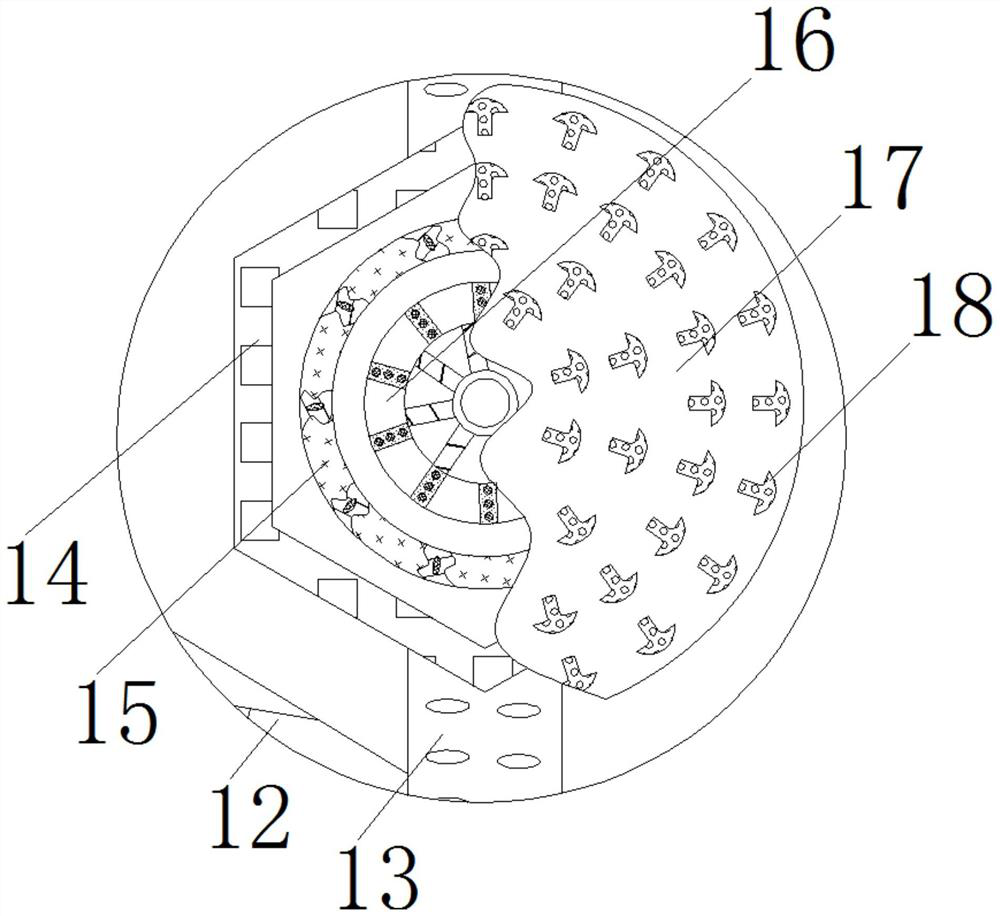

Automatic crushing full-load alarm integrated device for traditional Chinese medicinal material processing

InactiveCN113731578AProcessing saves time and effortShorten the timeMeasurement devicesGrain treatmentsMedical equipmentMechanical engineering

The invention relates to the technical field of medical equipment, and discloses an automatic crushing full-load alarm integrated device for traditional Chinese medicinal material processing. The automatic crushing full-load alarm integrated device for traditional Chinese medicinal material processing comprises an outer shell, the exterior of the outer shell is fixedly connected with a buzzer, the exterior surface of the outer shell is fixedly connected with a feeding nozzle, and the exterior of the outer shell is fixedly connected with a protective cover. Through interaction of the buzzer, the feeding nozzle, the protective cover, a coil, a baffle, an iron plate, a first spring, a first rotating wheel, a connecting plate, a second rotating wheel, a first connecting rod, a second connecting rod, a sleeve, a magnetic ring, an electromagnet, a sealing plate, a blade, a storage tank, a bearing plate, a detection assembly, a cover body and a timing assembly, processed traditional Chinese medicine can be automatically loaded and stored in the traditional Chinese medicine processing process, meanwhile, an alarm is automatically given to remind an operator when the device is fully loaded, so that intelligence of traditional Chinese medicine processing is achieved, the yield of traditional Chinese medicine processing can be effectively increased, the cost of traditional Chinese medicine processing can be effectively reduced, and clinical application of traditional Chinese medicine is effectively promoted.

Owner:上海旎丽美医药科技有限公司

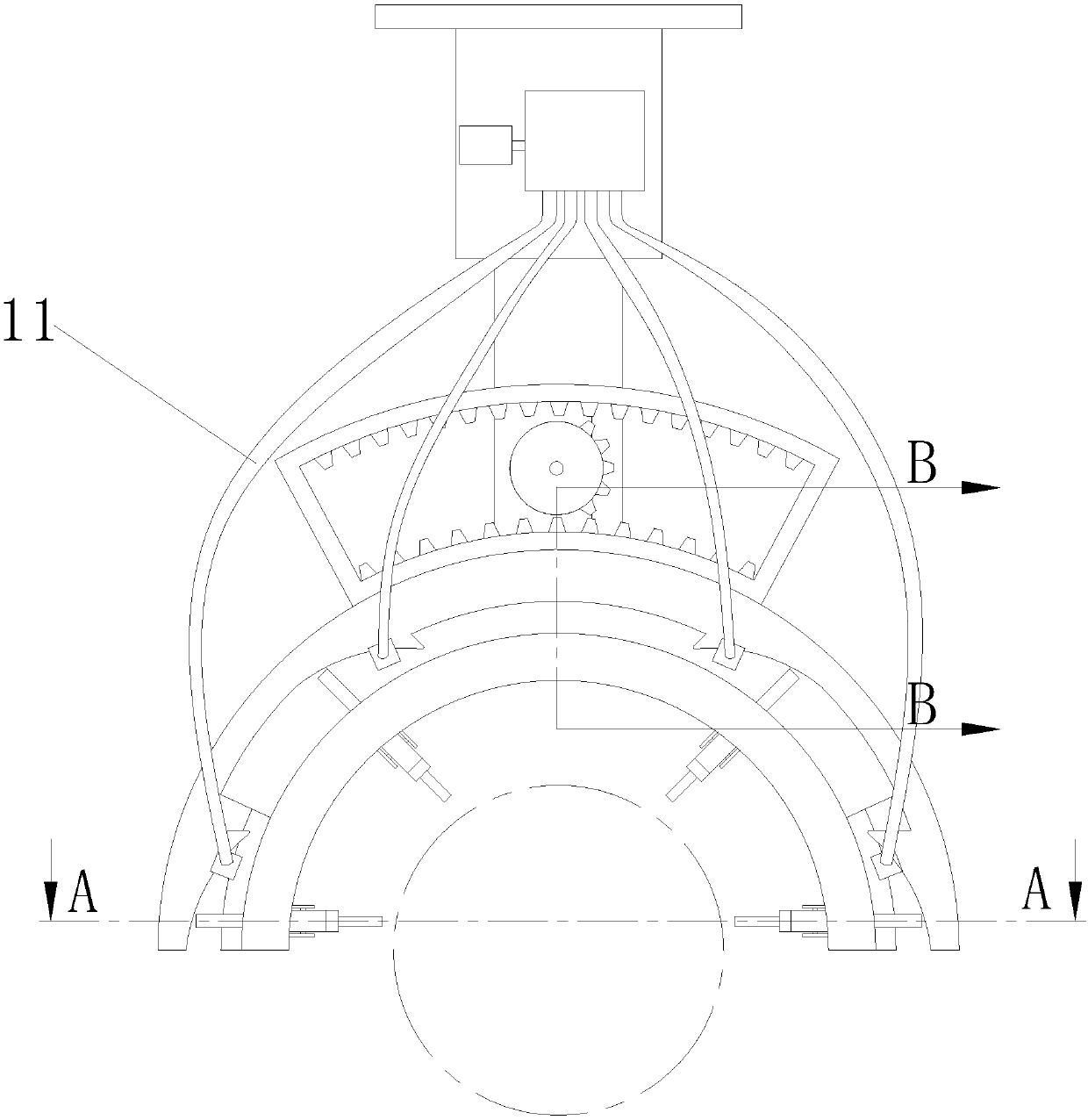

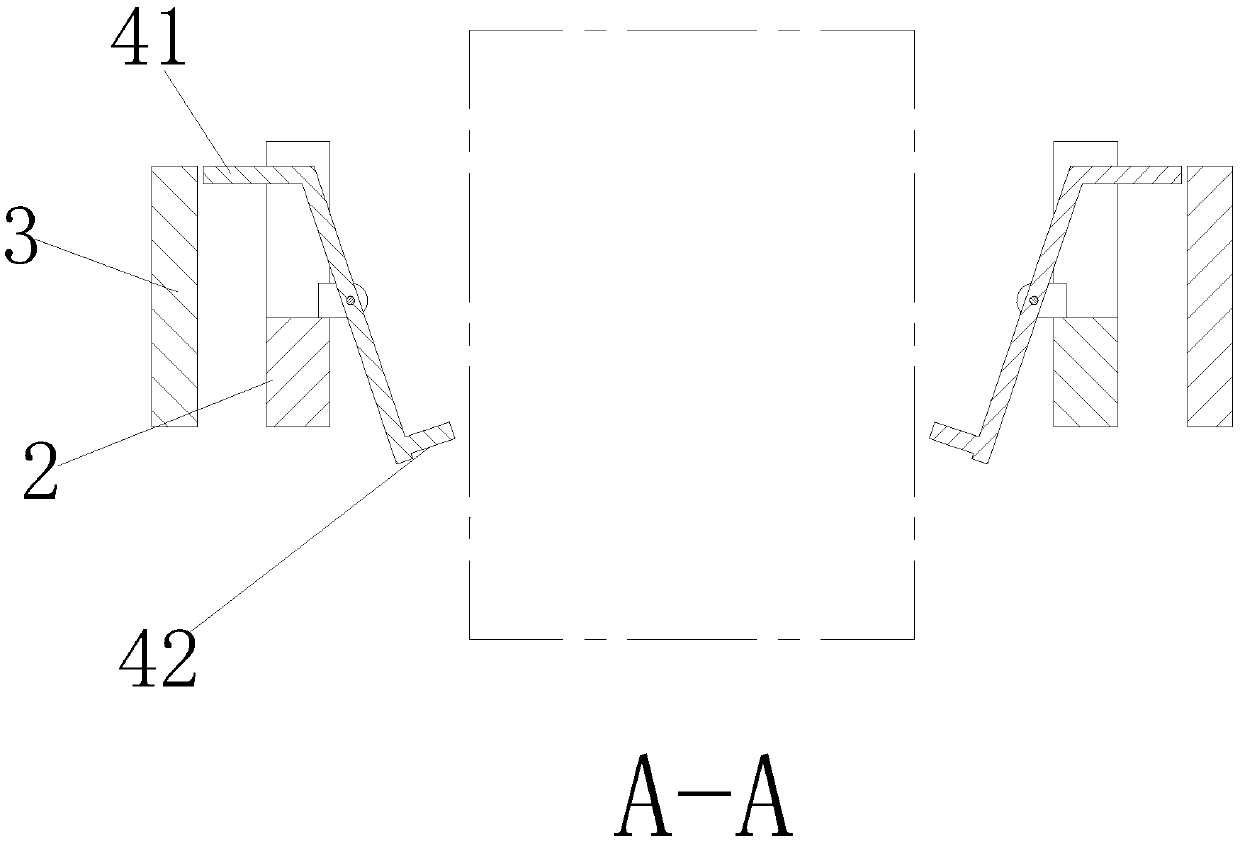

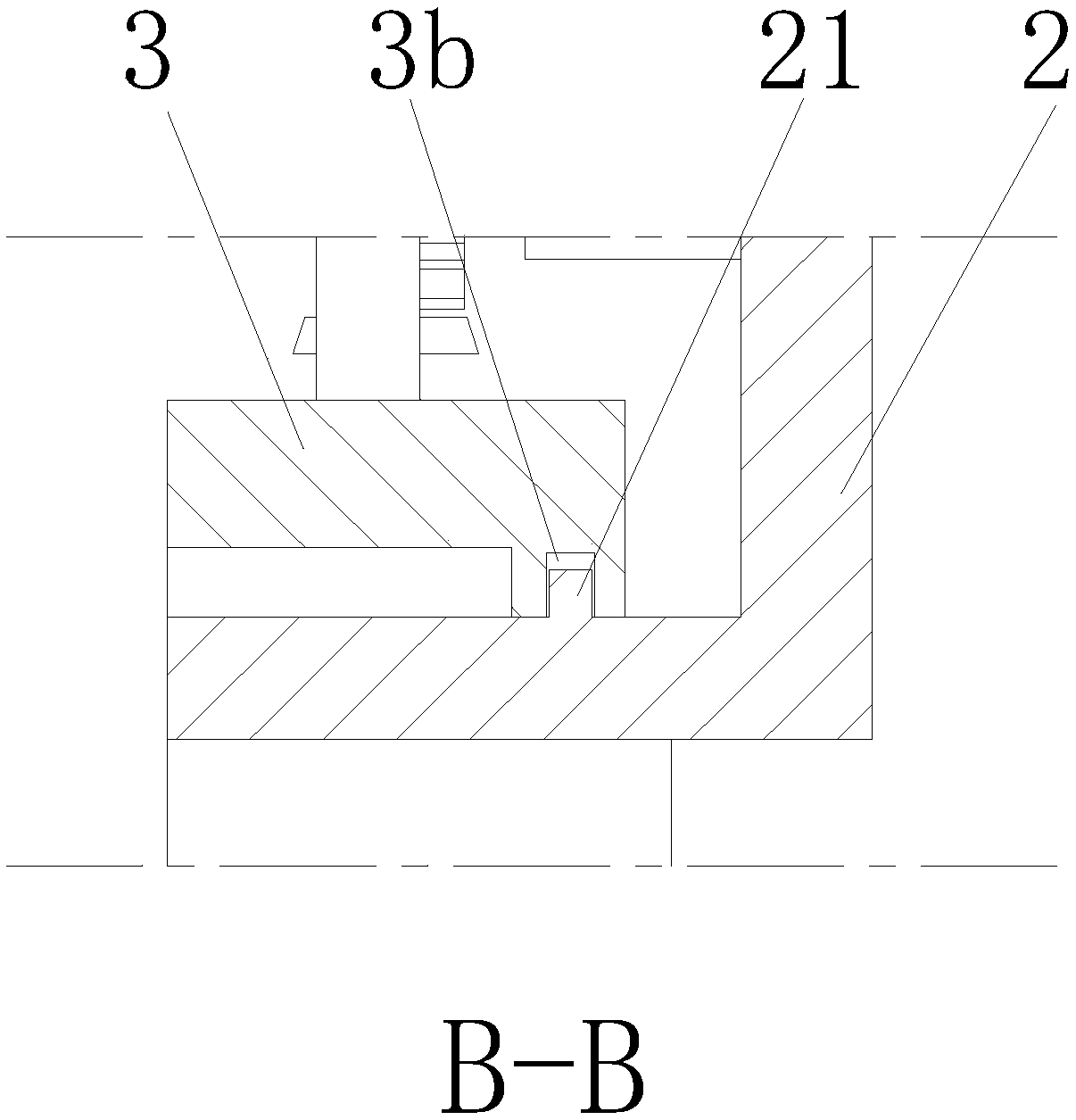

A surrounding multi-point melting debris removal device for laser cladding

ActiveCN107338439BReduce laborReduce manufacturing costMetallic material coating processesReciprocating motionEngineering

The invention relates to a surrounding multi-point-position melting chip removing device for laser cladding. The device comprises a mounting frame fixed on a laser cladding device; the mounting frame is connected with a semicircular plate; the semicircular plate is peripherally provided with a beating device moving back and forth; and the semicircular plate is provided with an air blowing device on the beating device. The beating device comprises a semicircular slide block slidingly mounted on the semicircular plate, a beating plate hinged to the inner side surface of the semicircular plate and matched with the semicircular slide block, and a driving mechanism connected with the semicircular slide block. The air blowing device comprises multiple air blowing nozzles formed in the beating place and uniformly distributed, an air blower fixed on the mounting frame, and a hose connected with the air blower by one end and connected with the air blowing nozzles by the other end. The device adopts mechanical automatic operation to replace manual operation for melting chip treatment, is more thorough in removing effect through vibration beating and air blowing, can prevent quality defects, saves both time and labors, and improves the machining efficiency.

Owner:WUHU DINGHAN REMFR TECH

Manual punching die

InactiveCN103101079ASimple structureEasy to manufacturePerforating toolsMetal working apparatusPunchingEngineering

A manual punching die is mainly composed of parts including a rear baffle, a lower punching die base, an upper punching die plate, a punch, a workpiece and the like. The manual punching die is characterized in that the rear baffle is welded together with the lower punching die base, the lower punching die base is provide with a limiting groove, the workpiece is located through the limiting groove formed in the lower punching die base and the rear baffle, the workpiece is only located but not clamped, so that the workpiece can be quickly replaced. A reversed countersunk head lower punching die hole is formed in the lower punching die base, wherein the upper end of the reversed countersunk head lower punching die hole is matched with the punch in size, the hole at the lower end is large, so that blanking of flushing cinder and plug-out of the punch are convenient. The upper punching die plate is welded on the upper plane of the lower punching die base, and a punching die hole in the upper punching die plate facilitates guide of the punch and location rectification of the punch hole in the workpiece. The manual punching die has the advantages of being simple in structure, convenient to manufacture, time-saving and labor saving in machining, low in cost, capable of being widely used in the field of machining, and particularly suitable for materials such as copper boards and aluminum boards or nonmetal, wherein the copper boards, the aluminum boards or the nonmetal are thin in material, and the manual punching die is suitable for occasions of small-number machining holes of a single part and small-batch machining.

Owner:HENAN BENMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com