Panel stamping die

A stamping die and panel technology, which is applied in the field of stamping dies, can solve the problems of complex production process and long development cycle, and achieve the effects of easy mold repair and mold modification, time-saving and labor-saving processing, and easy damage replacement or product change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

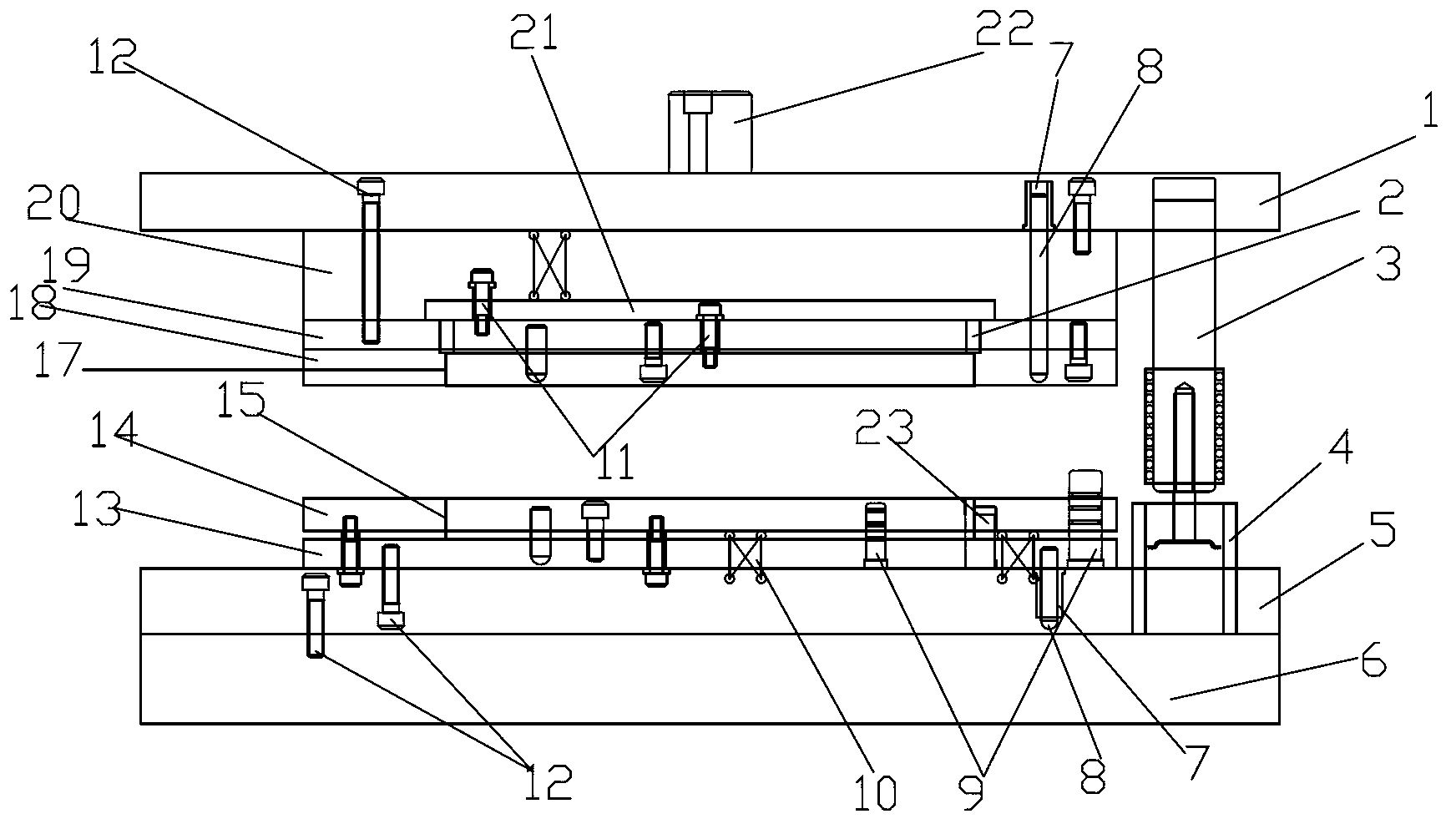

[0012] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the panel stamping die of the present invention includes a die handle 22, a patrix and a lower die, and the patrix includes an upper die base 1, an upper cushion block 20, an upper splint 19, an upper template 18, an upper beating plate 21 and a knock-off plate. Material plate 17; the formwork of described patrix is fixed by joint pin 8 and hexagonal countersunk head screw 12; Between described upper clamping plate 21 and upper clamping plate 19, between upper clamping plate 19 and stripping plate 17, also be fixed with equal height Sleeve 11, the contour sleeve has the advantages of simple assembly, adjustable length, high precision, etc. It has the functions of precise guidance and stable elastic pressure for structural stripping and forming stripping of the mold; there is also a punching rod 2 on the upper mold , to be convenien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com