Support device for fixing tower barrels of various models

A support device and tower tube technology, applied in the field of wind energy, can solve the problems of small application range, not wide application, low work efficiency, etc., and achieve the effects of improving support capacity, moving smoothly, and facilitating installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

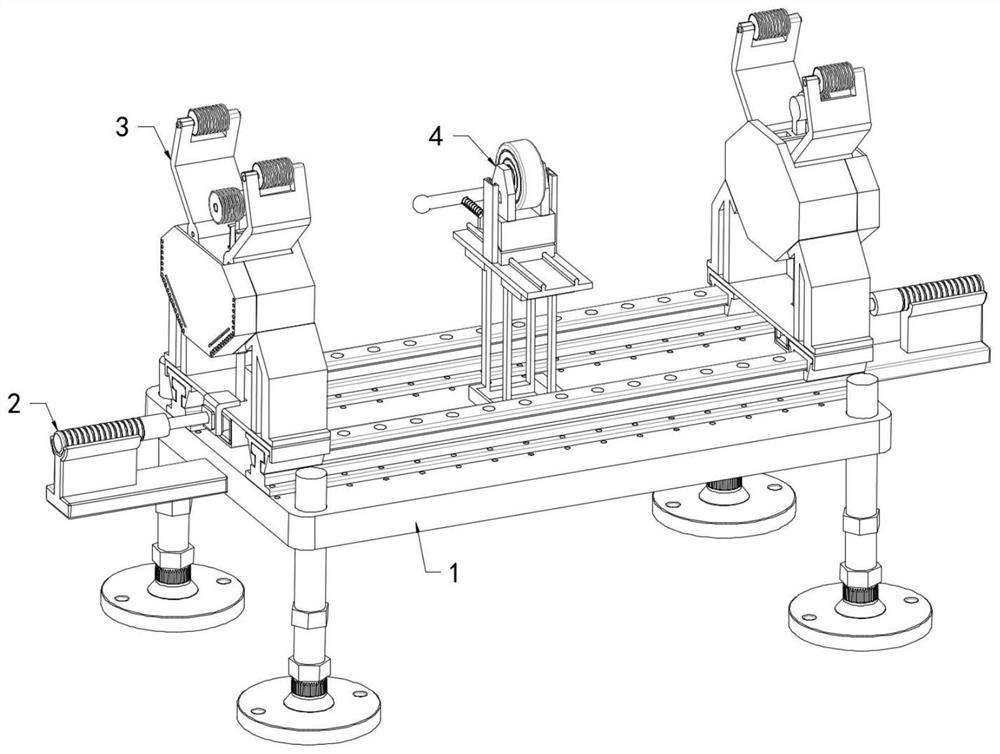

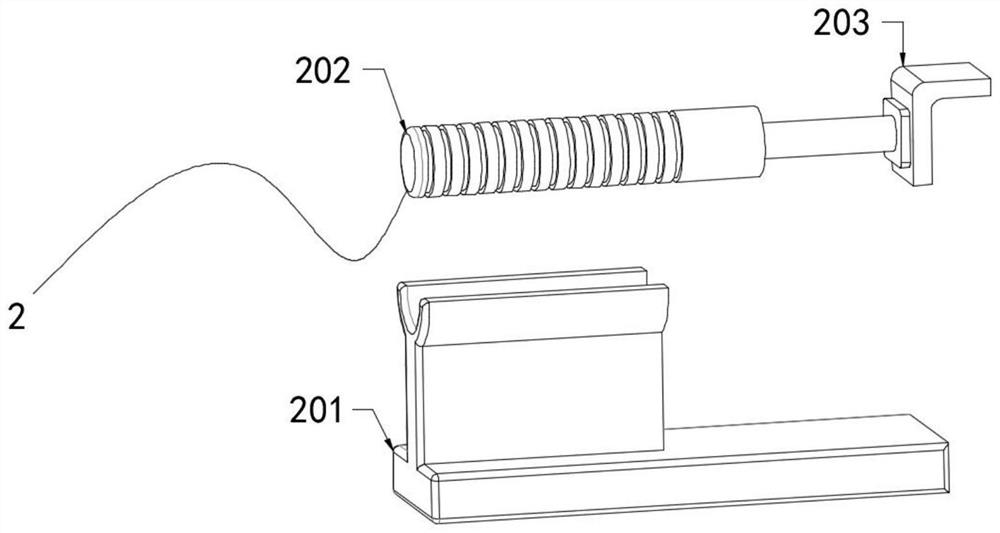

[0034] refer to Figure 1-7 , a bracket device for fixing various types of tower tubes, comprising a bearing part 1, two clamping parts 3 are symmetrically arranged on the top of the bearing part 1, and pushing parts 2 are arranged at both ends of the bearing part 1;

[0035] The bearing part 1 includes a bearing plate 102 arranged horizontally;

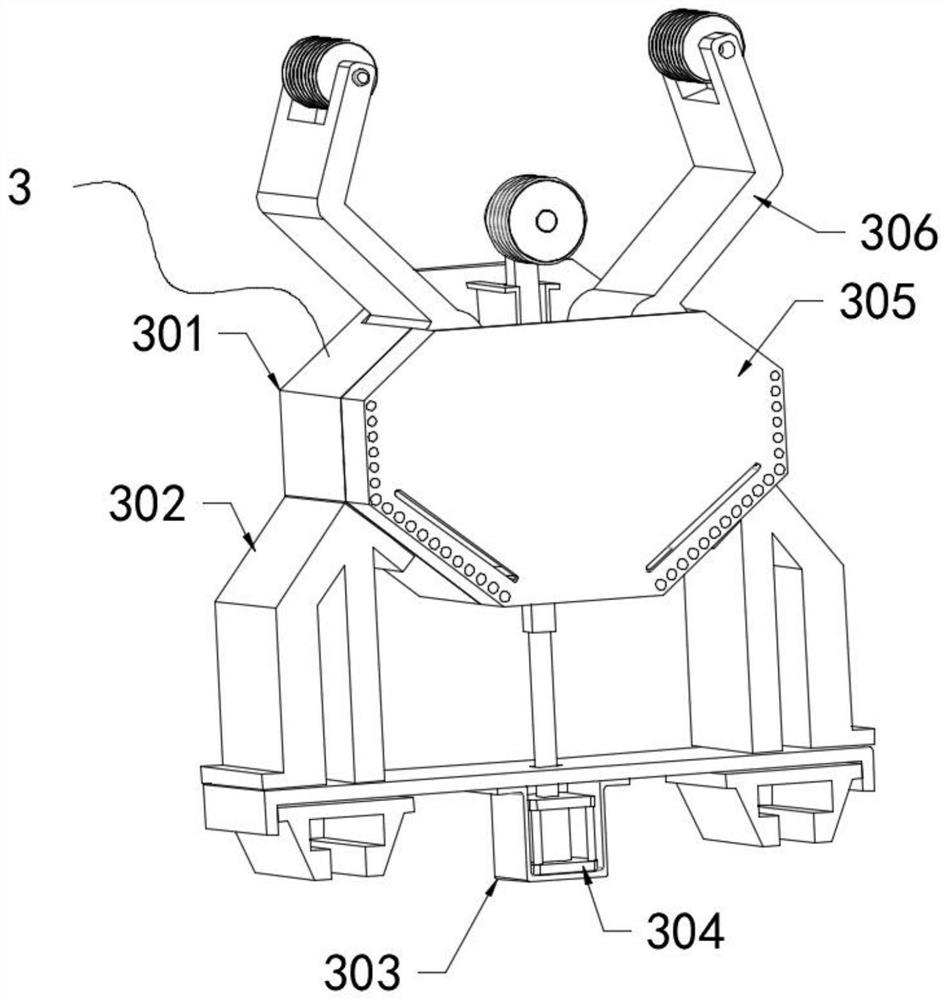

[0036] The clamping part 3 includes an installation bin 301 with an opening at the top, two movable rods 306 arranged symmetrically inside the installation bin 301 , and an adjustment rod 309 arranged between the two movable rods 306 and slidingly connected to the inner wall of the installation bin 301 One end of the two movable rods 306 close to the installation warehouse 301 is fixedly connected with an arc-shaped plate 314, and the ends of the two movable rods 306 far away from the installation warehouse 301 are connected with the side wall of the clamp rod 310 through the clamping rod 310 provided obliquely. Rotate the connected r...

Embodiment 2

[0040] refer to Figure 1-7 One side of the installation warehouse 301 is fixedly connected with a cover plate 305 by bolts, and one side of the cover plate 305 is provided with several connecting holes for the screw to pass through. Fixed plate 308, one end of two brackets 302 is fixedly connected with the top both sides of fixed plate 308 respectively, the top both sides of bearing plate 102 is all fixedly connected with slide rail 103, and the bottom both sides of fixed plate 308 is all fixedly connected with sliding rail 103. The sliding part 307 that the rail 103 is compatible, the top position of an inner wall of the installation warehouse 301 is fixedly connected with the sliding plate 311 that is compatible with the adjustment rod 309, the cylinder 304 is connected with the bottom center of the fixed plate 308 through the base 303, and the cylinder The output end of 304 passes through the fixed plate 308 through the sliding sleeve and is fixedly connected with one end ...

Embodiment 3

[0042] refer to Figure 1-7 The support legs 101 are fixedly connected to the four corners of the bottom of the carrying plate 102, and the support portion 4 is arranged at the center of the top of the carrying plate 102. The support portion 4 includes a horizontal moving plate 407 and two A lifting guide plate 406 symmetrically arranged on both sides of the top of the horizontal moving plate 407, a roller 5 is arranged at the center of the top of the horizontal moving plate 407 and between the two lifting guide plates 406, and the bottom of the roller 5 is provided with two sides and two respectively. The second wedge block 405 that is slidingly connected to the side wall of the lifting guide plate 406 is provided with a wedge block one 404 that is slidably connected to the top of the horizontal moving plate 407 and adapted to the bottom of the second wedge block 405, and both sides of the roller 5 rotate A mounting plate that is fixedly connected to the top of the wedge-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com