Multifunctional electric hydraulic pipe fitting machining tool

A technology for processing tools and hydraulic pipes, which is applied in the field of multifunctional electro-hydraulic pipe fittings processing tools, can solve the problems of unguaranteed product quality, low processing efficiency, and high cost of use, and achieve compact and reasonable space structure, improved oil absorption efficiency, and extended service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

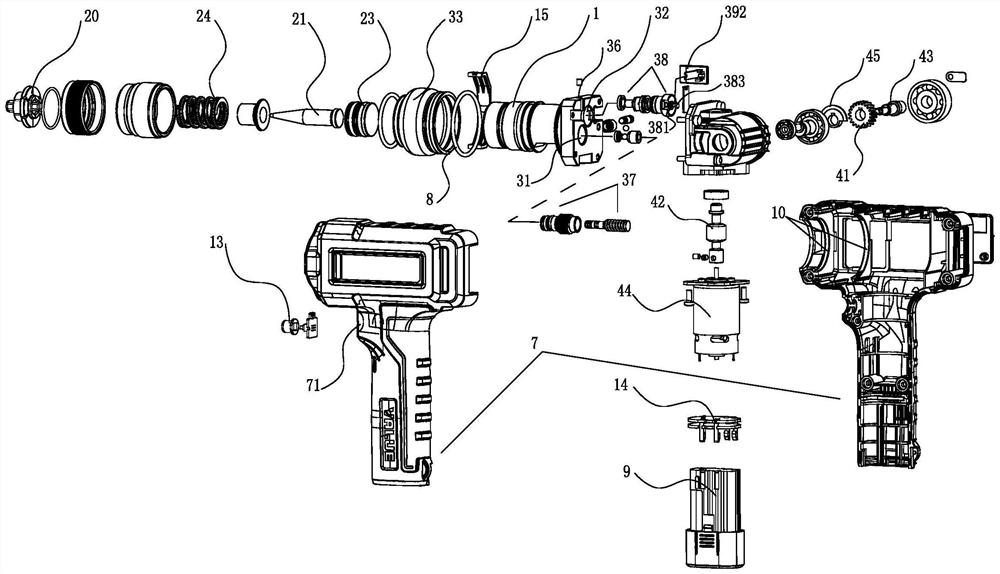

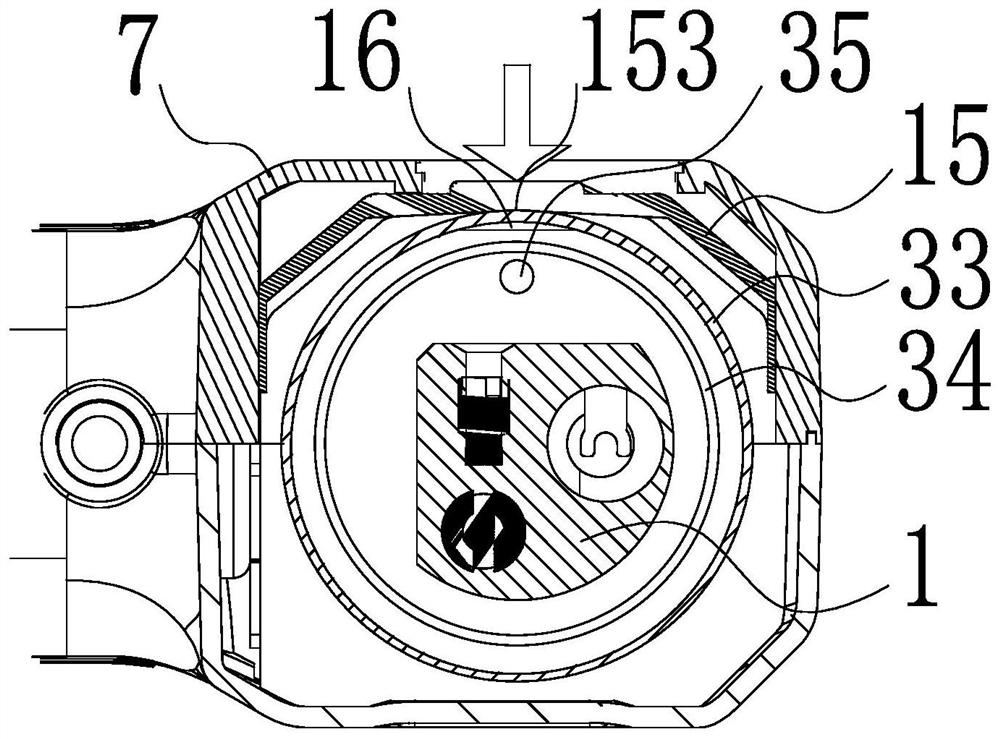

[0061] Such as figure 1 As shown, a multifunctional electro-hydraulic pipe fitting processing tool of the present invention includes a housing 7 similar to a "7" shape and a body 1 inside the housing 7. The front end of the body 1 has a feeding mechanism, and the rear end has a The hydraulic mechanism has a drive mechanism below the rear end, wherein the feed mechanism includes a drive chamber 22 located at the front end of the body 1, the port of the drive chamber 22 is externally screwed to the cone head cover ring 27, and the cone head cover ring 27 is coaxially docked and installed The pipe fitting chuck 20, the pipe fitting chuck 20 in this embodiment is the expansion head, the cone head 21 is the pipe expansion cone head, the cone head 21 is slidably connected in the drive chamber 22 through the piston 23, and the driving mechanism pushes the cone head through the hydraulic mechanism 21 move to the outside of the cone head cover ring 27, and process the pipe fittings cla...

Embodiment 2

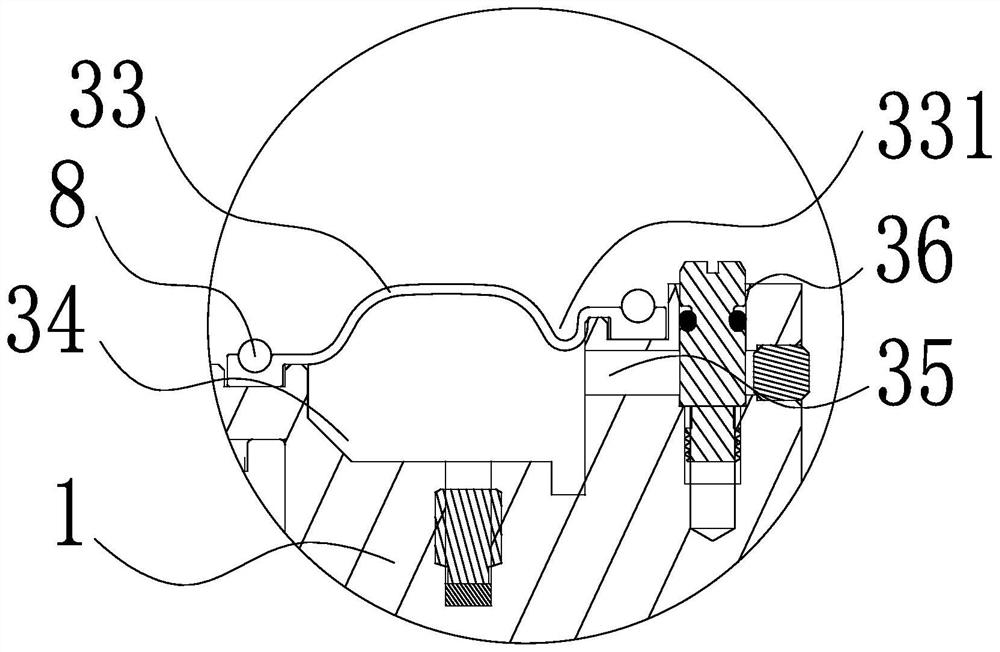

[0075] The pipe fitting chuck 20 is coaxially docked on the cone head cover ring 27. The pipe fitting chuck 20 in this embodiment is a pipe expansion head, and the cone head 21 is a pipe expansion cone head. The pressure relief shift fork 392 in the embodiment is removed, as Figure 4 As shown, one end of the L-shaped elastic fork 391 is slidably connected to the chuck groove 383, and the end of the elastic fork 391 corresponding to the bottom surface of the chuck groove 383 has a U-shaped notch groove that matches each other, and the elastic fork 391 passes through The U-shaped notch grooves are interfitted and clamped in the chuck groove 383, and there is a gap between the inner surface of the elastic shift fork 391 and the corresponding inner ring wall of the chuck groove 383, and the other end of the elastic shift fork 391 is located at the oil storage ring. 33, the body 1 close to the spool 381 extends outward to form a fork fulcrum 19 that can support the elastic fork 391...

Embodiment 3

[0077] The pipe fitting chuck 20 is coaxially docked on the cone head cover ring 27. The pipe fitting chuck 20 in this embodiment is a pressure pipe head, and the cone head 21 is a pressure pipe cone head, such as Figure 12As shown, a retaining ring 28 is sandwiched between the inner end of the return spring 24 and the outer end surface of the piston 23, the retaining rings 28 are matched with each other on the cone head 21, and the inner ring surface of the retaining ring 28 extends to the outside of the cone head 21. The ring surface, the outer ring surface of the retaining ring 28 extends forward along the outer ring surface of the return spring 24 to form an L shape, the outer side of the front end of the return spring 24 is equipped with a booster spring 25, and the direction of rotation of the return spring 24 and the booster spring 25 is opposite. And the rigidity of back-moving spring 24 is less than the rigidity of booster spring 25, and booster spring 25 is positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com