Manual punching die

A punching die, punching die technology, applied in punching tools, metal processing, metal processing equipment and other directions, can solve the problems of inconvenient disassembly, low production efficiency, poor processing quality, etc., and achieves processing time and labor saving, simple structure, and manufacturing. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

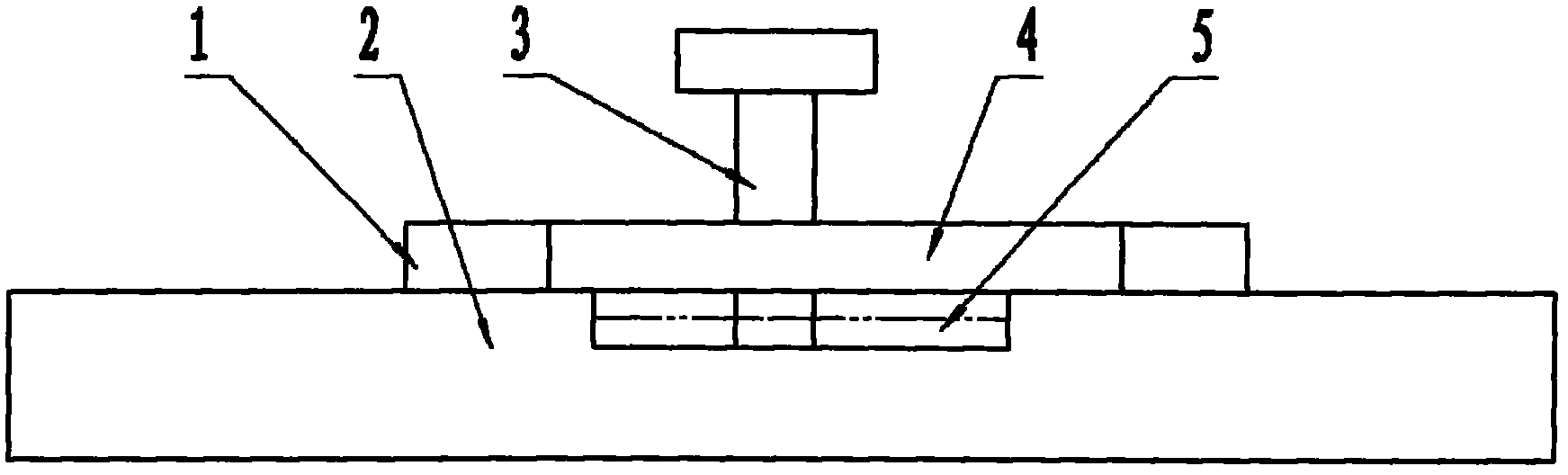

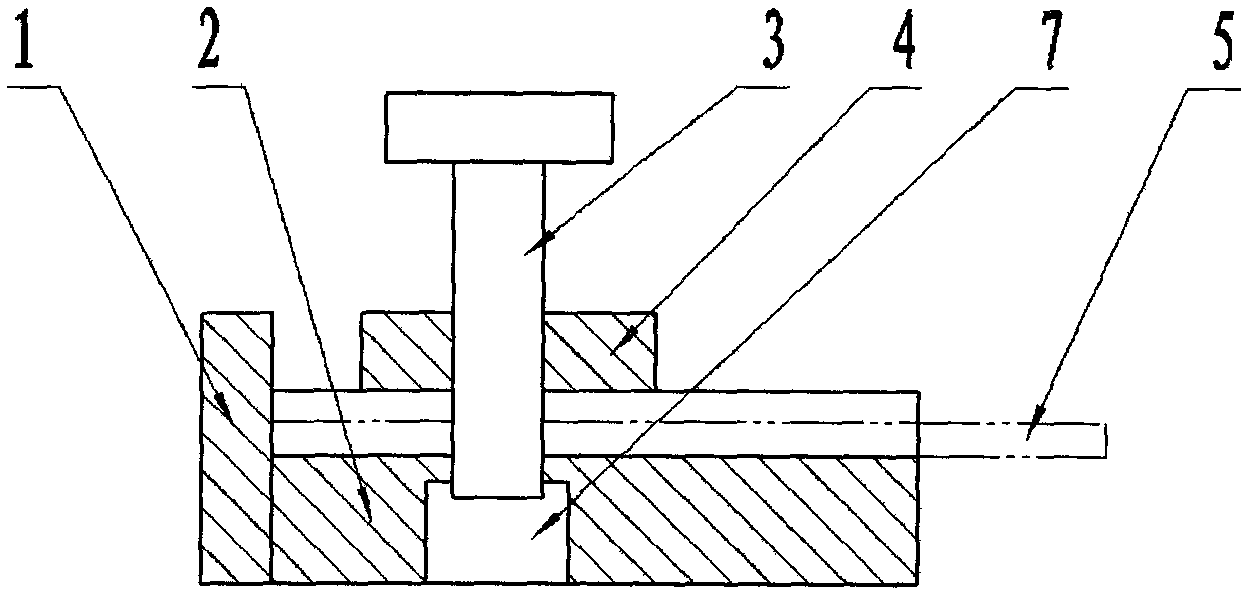

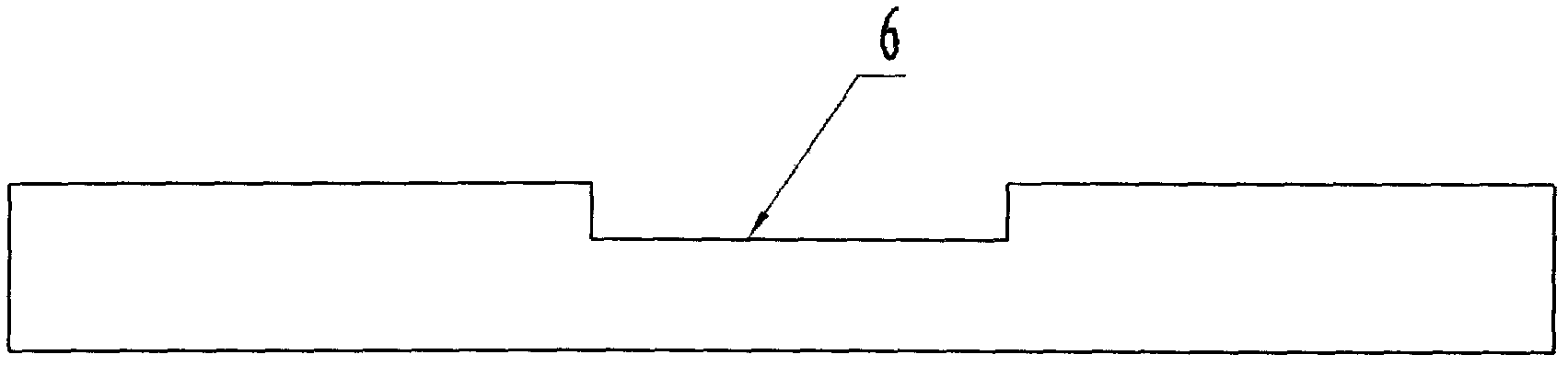

[0013] as attached figure 1 - attached Figure 4 As shown, a manual punching die is composed of a rear baffle, a lower die base, a punch, an upper punching plate, a workpiece, etc., and is characterized in that: before punching, the workpiece 5 is inserted into the limiting groove 6 of the lower die base 2 , relying on the limit groove 6 and the rear baffle plate 1 to limit the position without clamping, the punch 3 is inserted into the upper die hole of the upper punch plate 4, and the top of the punch 3 is lightly tapped with a hand hammer, and the punch 3 moves down into the anti-sinking In the die hole 7 under the head, the hole required by the design has just been punched on the workpiece 5.

[0014] The material of the workpiece 5 is a thinner copper plate, aluminum plate or thinner non-metallic material. The punch 3 does not punch down by mechanical power, but punches down after being lightly tapped with a hammer. big occasion.

[0015] The lower die base 2 is proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com