Dividing feeding mechanism

A feeding mechanism and indexing technology, which is applied to metal processing machinery parts, precision positioning equipment, metal processing equipment, etc., can solve the problems of troublesome operation, wasteful handling, no feeding design structure, etc., and achieve low cost and good structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

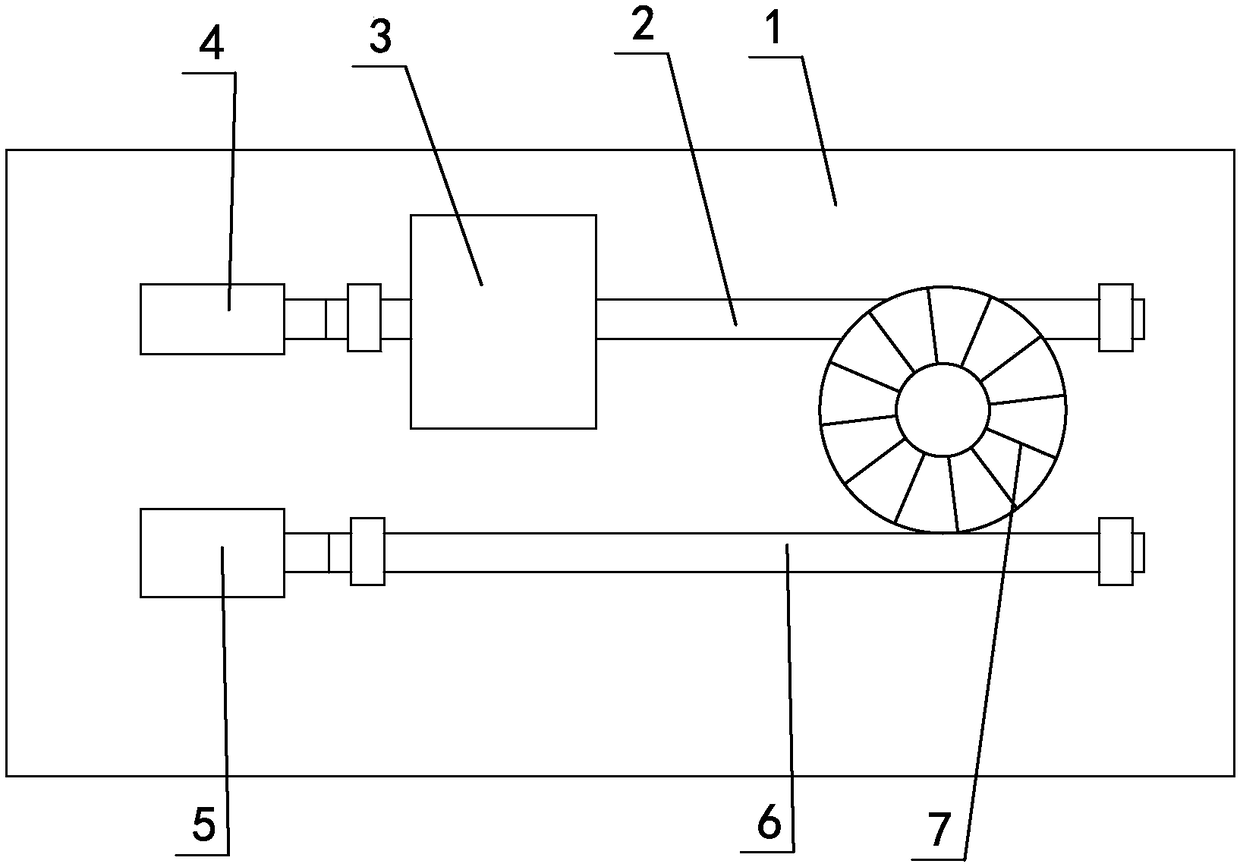

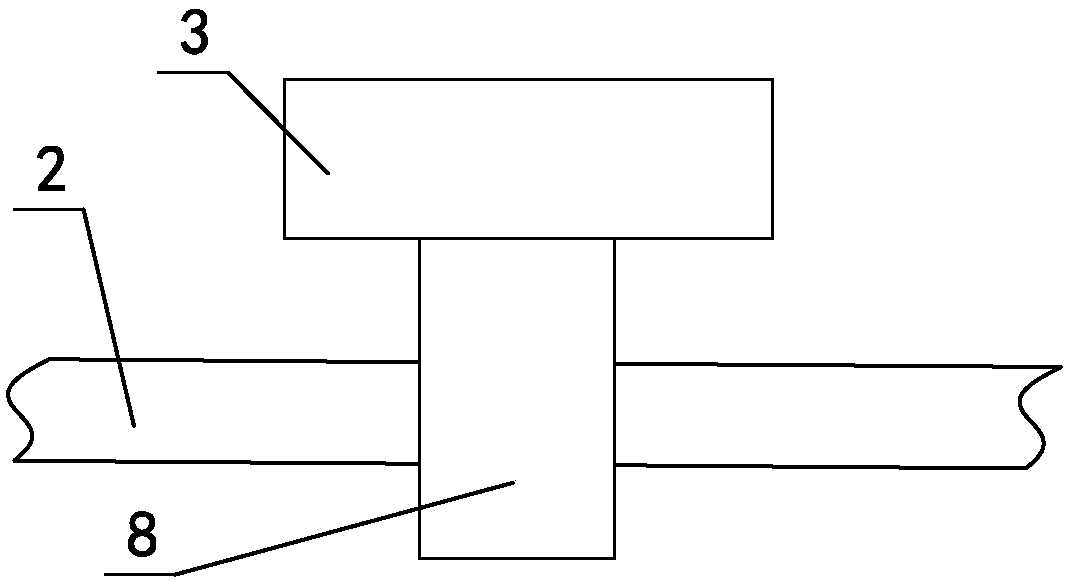

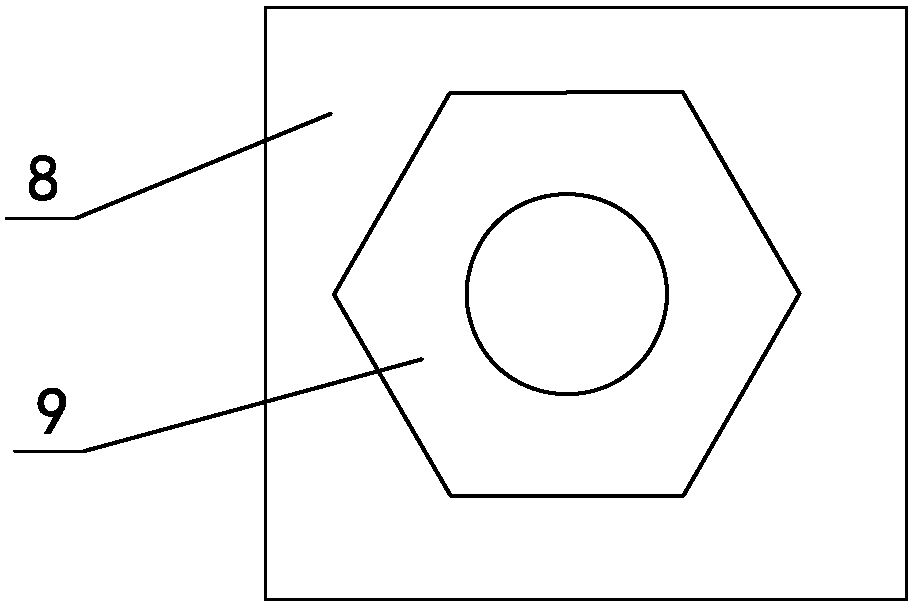

[0016] Such as figure 1 , figure 2 As shown, the indexing feeding mechanism includes a base 1, on which a feed screw 2 and an index screw 6 are arranged in parallel, and the feed screw 2 and the index screw 6 are installed on the On the base 1, a material advance motor 4 is connected to the left end of the feed screw 2, the material advance motor 4 is installed on the base 1, the feed screw 2 is covered with a nut 9, and the nut 9 is covered with a nut mounting seat 8. The feed plate 3 is fixed on the top of the screw nut mounting base 8, and a left and right sliding assembly is arranged between the screw nut mounting base 8 and the base 1; an indexing progressive motor 5 is connected to the left end of the indexing screw rod 6, and the indexing progressive motor 5 is installed on the base 1, and the indexing worm gear 7 matched with the indexing screw 6 is installed on the base 1, and the indexing worm gear 7 is installed on the base 1 through the rotating shaft.

[0017] ...

Embodiment 2

[0020] On the basis of Embodiment 1, the parallel spacing between the feed screw 2 and the indexing screw 6 is changed to 35 cm; the nut mount 8 is a rectangular structure with a length of 30 cm. The width is 25cm.

[0021] Others are the same as embodiment one.

Embodiment 3

[0023] Change on the basis of Embodiment 1, the parallel spacing between the feed screw mandrel 2 and the indexing screw mandrel 6 is 20cm; the screw mother mounting seat 8 is a rectangular body structure, its length is 15cm, and its width is 15cm. It is 10cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com