Die drilling clamp of two inclined connecting holes of middle shell

A technology of connecting holes and inclined holes, which is applied in the direction of drilling dies, clamping, and manufacturing tools for workpieces, can solve the problems of low efficiency, time-consuming and labor-intensive processing, etc., and achieve the effect of high efficiency, time-saving and labor-saving processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

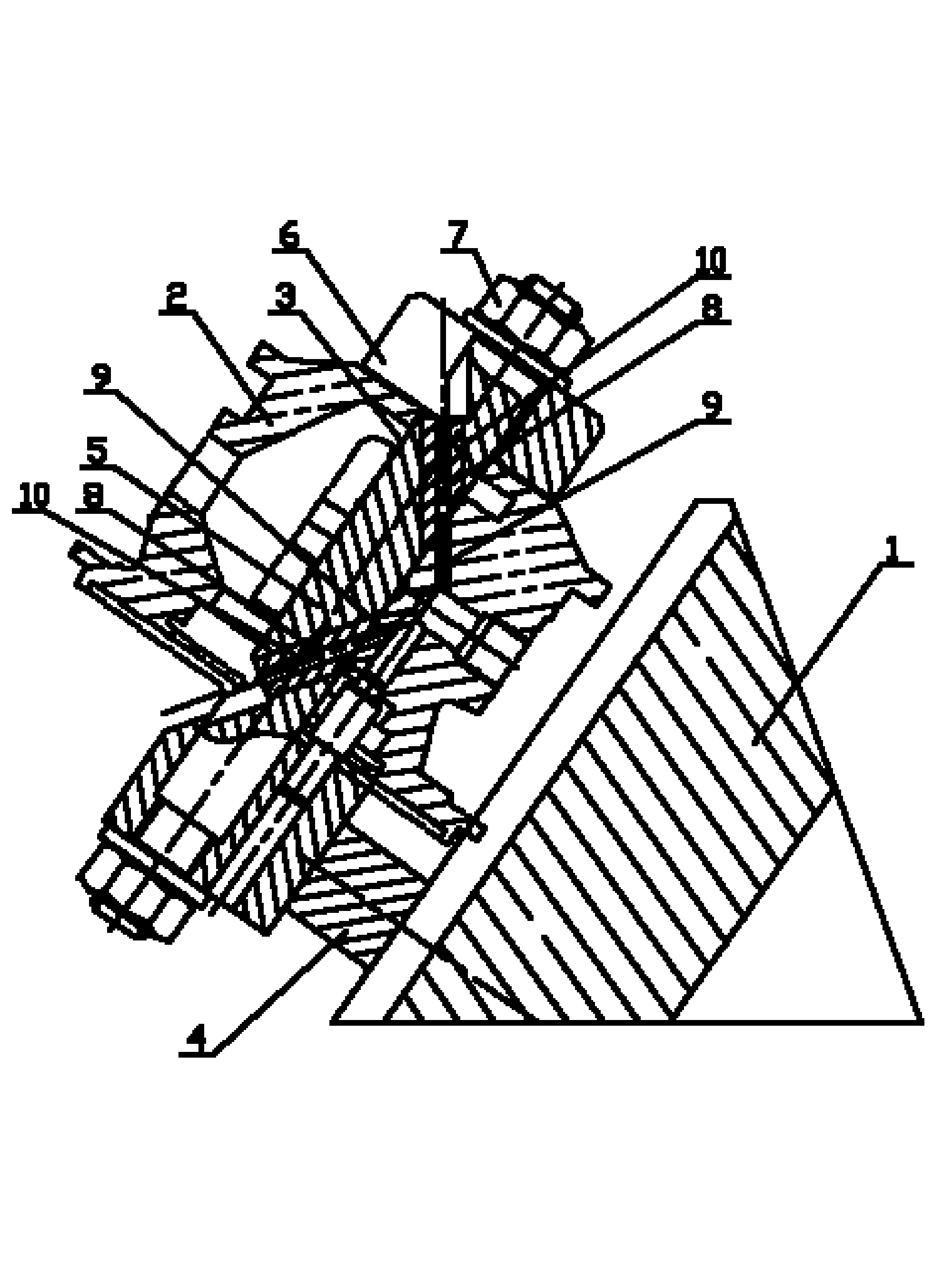

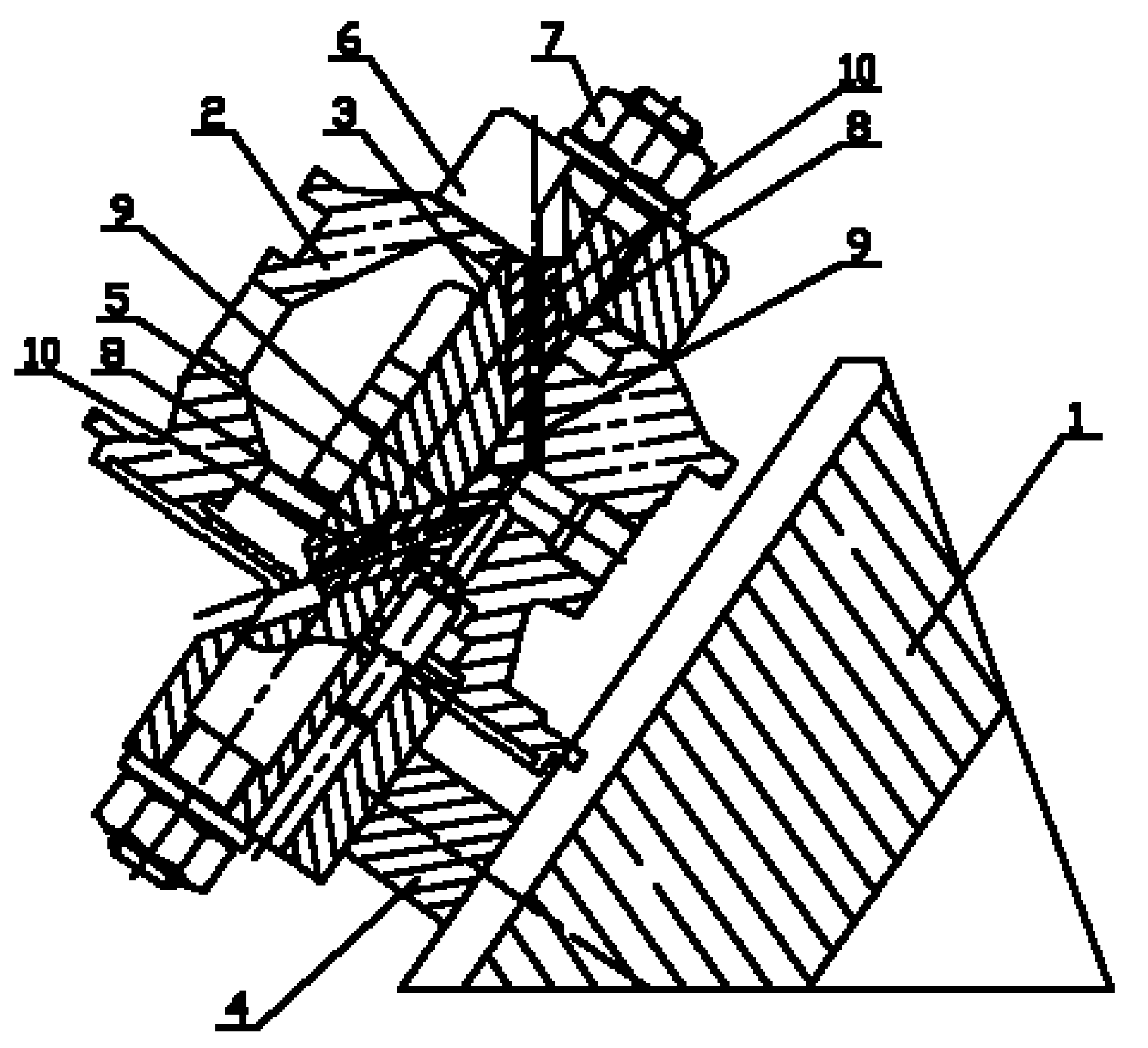

[0009] See figure 1 , which includes a base 1, a clamping assembly, and an intermediate shell 2 with a slanted hole to be processed. The middle through hole 3 of the intermediate shell 2 with an slanted hole to be processed has been processed. The base 1 is a triangular surface. Clamping assembly, the clamping assembly includes a connecting plate 4, a central shaft 5, a gland 6, and a nut 7, the connecting plate 4 is supported on a side slope of the base, the connecting plate 4 is fastened with a central shaft 5, and the central shaft 5 passes through the The middle through hole 3 of the middle shell 2 for processing the inclined hole, the gland 6 is set on the top of the central shaft 5, the inner side of the gland 6 is pressed against the end face of the middle shell 2 to be processed with the inclined hole, the nut 7 is set on the central shaft 5, and The inner side is pressed against the outer side of the gland 6. On the central axis 5, the two ends of the middle shell 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com