A method and device for producing refined brine using bromine-extracting brine

A technology for refining brine and brine, which is applied in the purification of alkali metal halides, etc., can solve the problems of high dependence on weather conditions, large floor space, and large manpower consumption, so as to realize waste utilization, reduce refining costs, and avoid leakage loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

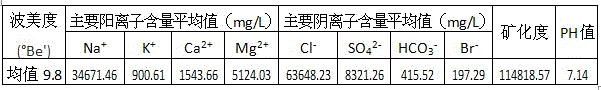

[0045] In this example, the various components and indicators in the bromine-extracting brine: the pH value is 2.67, the oxide content is 1.95 ppm, the calcium ion content is 1120 mg / L, the magnesium ion content is 5562 mg / L, and the sulfate content is 11087 mg / L.

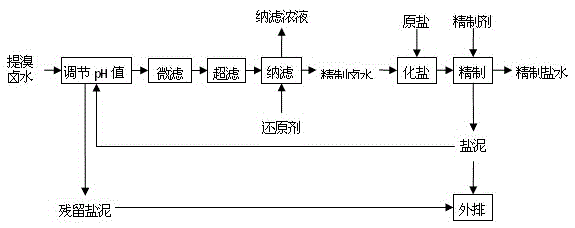

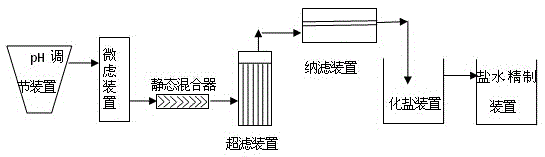

[0046] refer to figure 1 , the above-mentioned brine is sent into the pH value adjustment bucket, and the salt mud with a solid content of 9.95% is added therein, and the addition amount is 0.353g / L bromine-extracting brine in equivalent dry basis. After reacting for 20min, the pH value of the bromine-extracting brine is adjusted to 5.52, the overflow liquid from the upper part of the pH adjustment tank was clarified by the clarification tank, and the turbidity was 7.65NTU. After being filtered by the sand filter device filled with quartz sand and activated carbon, the turbidity was reduced to 2.87NTU, and the membrane material was PVDF ultrafiltration. After the device is filtered, the turbidity drops to 0.93NTU. ...

Embodiment 2

[0049] In this example, the various components and indicators in the bromine-extracting brine: the pH value is 2.78, the oxide content is 0.69 ppm, the calcium ion content is 950 mg / L, the magnesium ion content is 5250 mg / L, and the sulfate content is 10206 mg / L.

[0050] Put the above-mentioned brine into the pH adjustment bucket, add salt mud with a solid content of 9.91% to it, and add 0.426g / L bromine brine in equivalent dry basis, and adjust the pH value of the bromine brine to 7.10 after reacting for 16 minutes , After the overflow from the upper part of the pH value adjustment tank is clarified by the clarification tank, the turbidity is 8.59NTU. After being filtered by the screen type self-cleaning filter device, the turbidity is reduced to 2.69NTU. After being filtered by the ultrafiltration device whose membrane material is stainless steel, The turbidity dropped to 0.90NTU.

[0051] Add 2.80ppm of sodium bisulfite to the ultrafiltration product water, and completely ...

Embodiment 3

[0053] In this example, various components and indicators in the bromine-extracting brine: the pH value is 2.30, the oxide content is 3.20 ppm, the calcium ion content is 1000 mg / L, the magnesium ion content is 5100 mg / L, and the sulfate content is 9486 mg / L.

[0054] Put the above-mentioned brine into the pH adjustment bucket, add salt mud with a solid content of 9.95% to it, and add 0.301g / L bromine brine in equivalent dry basis, and adjust the pH value of the bromine brine to 5.22 after reacting for 20 minutes , After the overflow liquid from the upper part of the pH value adjustment barrel is clarified by the clarifier, the turbidity is 6.25NTU, and after being filtered by the sand filter device filled with pebbles, quartz sand and anthracite, the turbidity is reduced to 2.11NTU, and the membrane material is ceramic ultra-thin After filtering by the filter device, the turbidity dropped to 0.68NTU.

[0055] Add 15.57ppm of sodium bisulfite to the ultrafiltration product wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com