Patents

Literature

36results about How to "Improved Impedance Control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

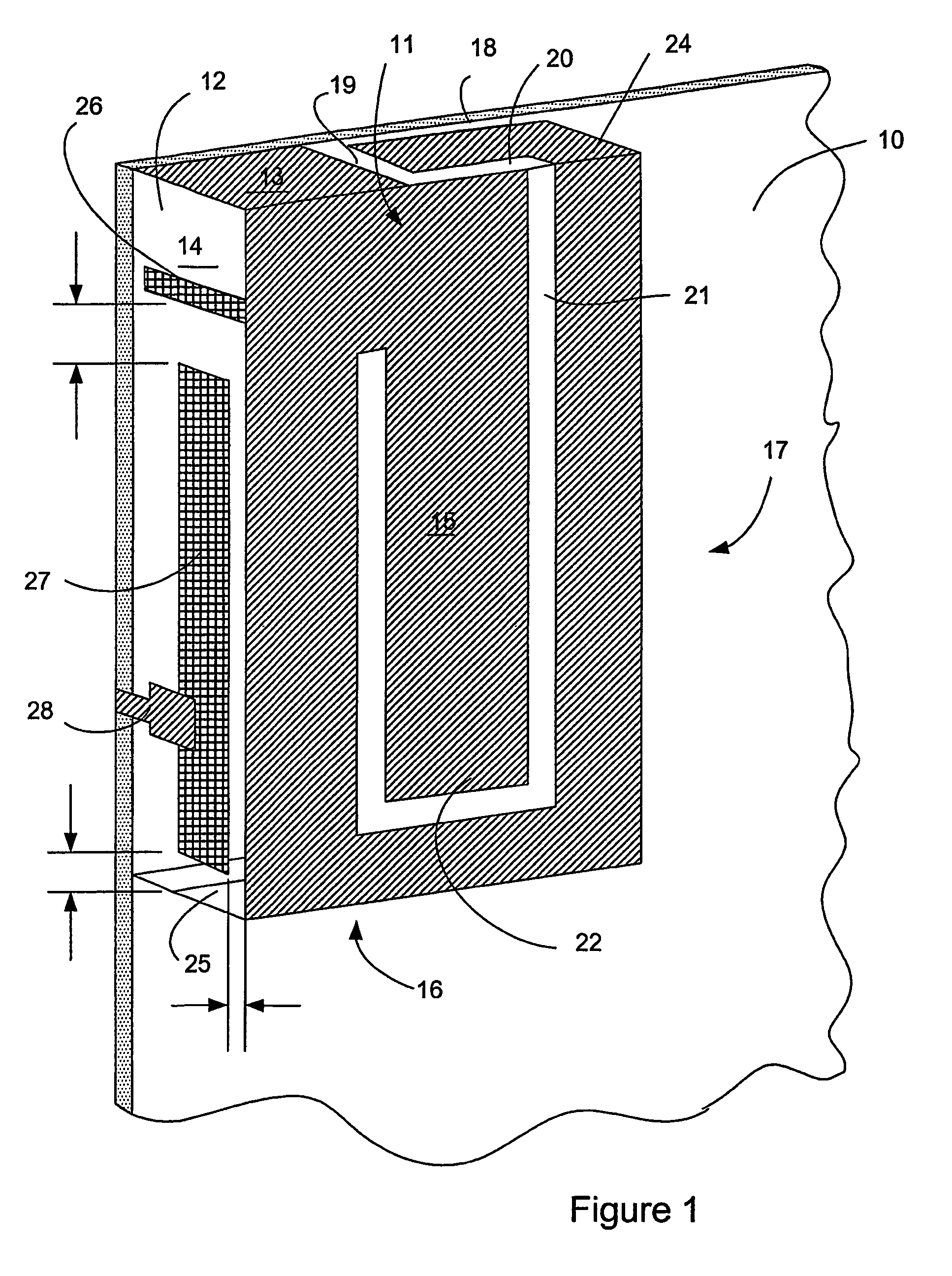

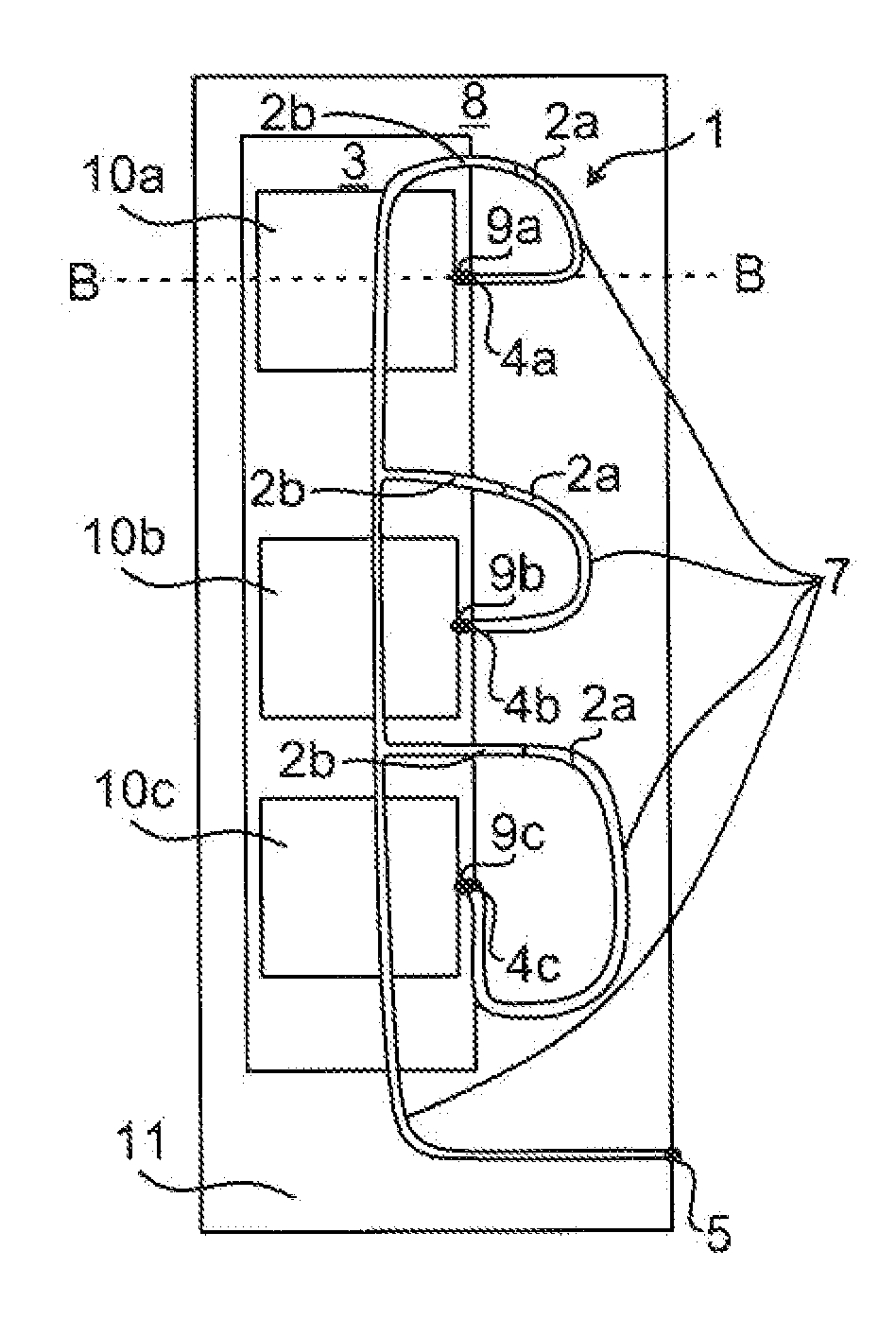

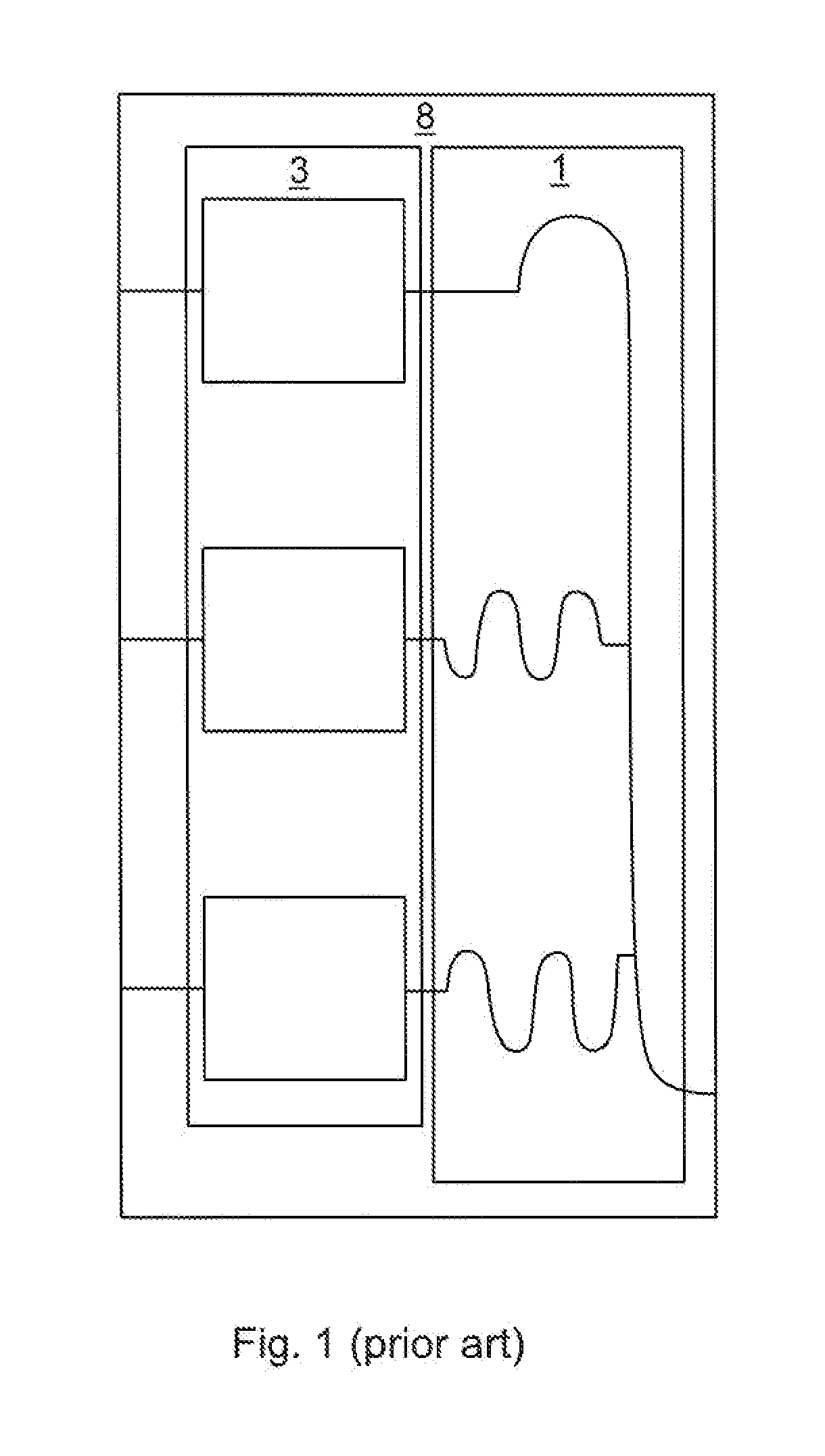

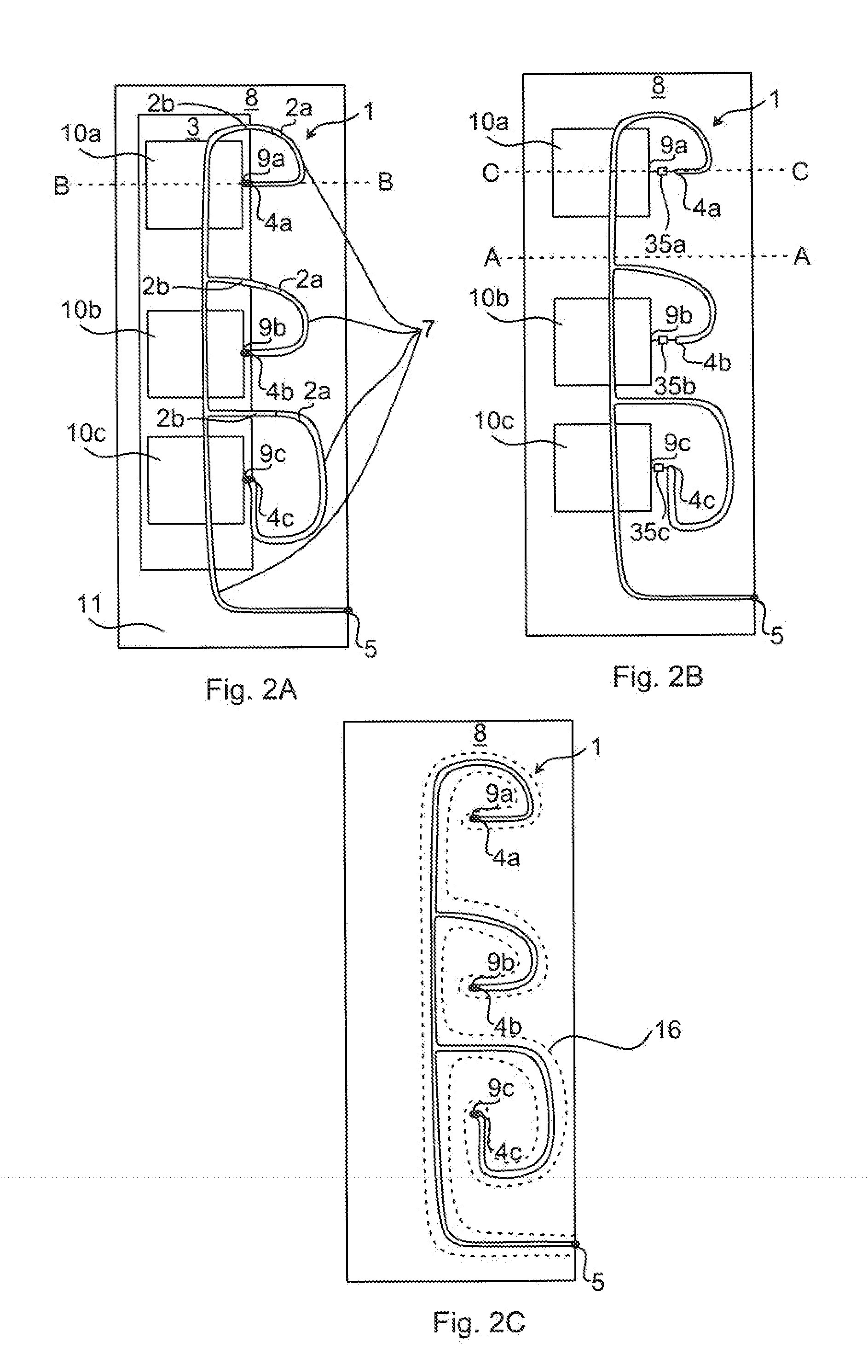

Controllable antenna arrangement

InactiveUS7339527B2Improved Impedance ControlEasy to tuneSimultaneous aerial operationsAntenna supports/mountingsCapacitanceCapacitive coupling

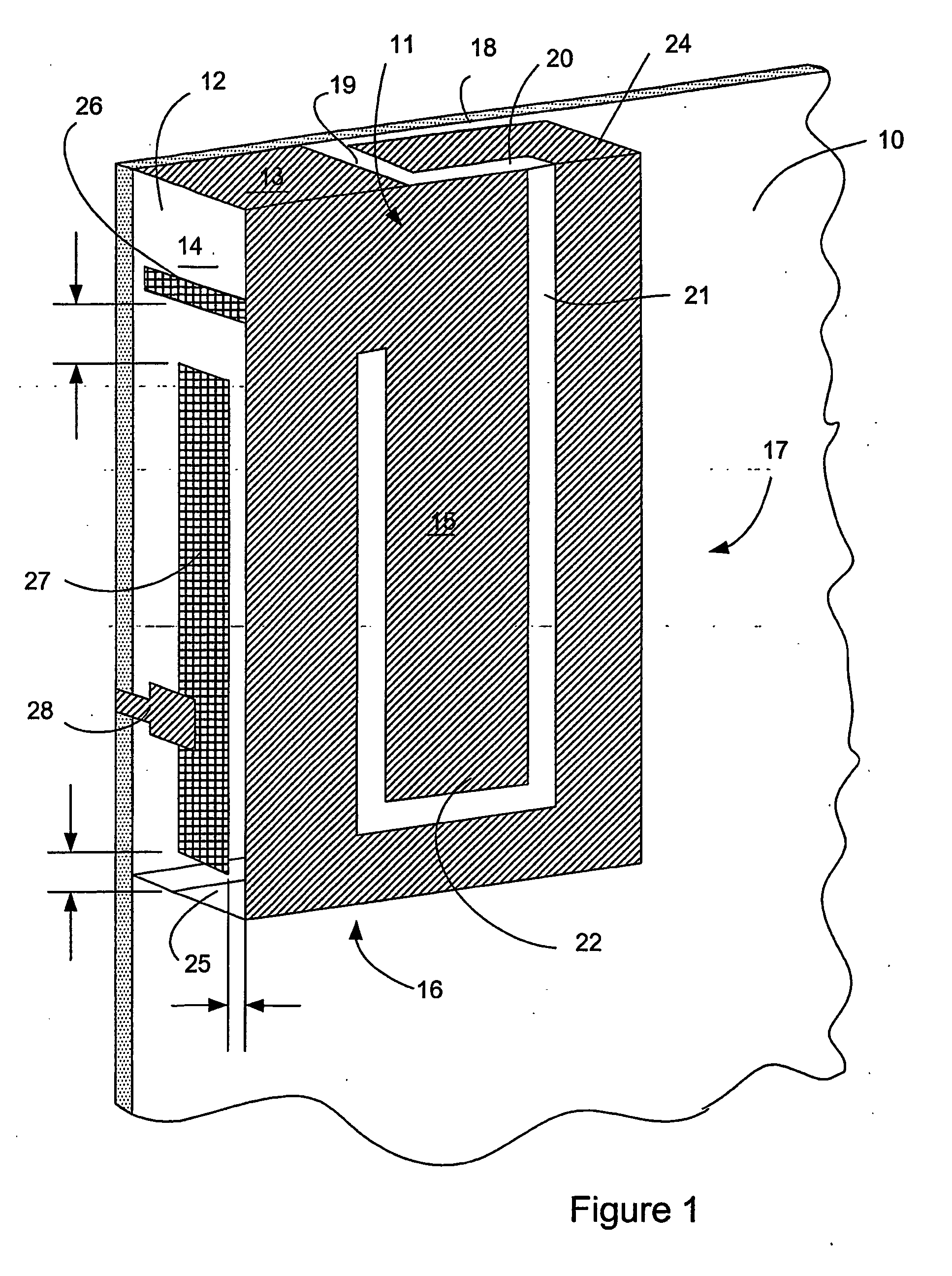

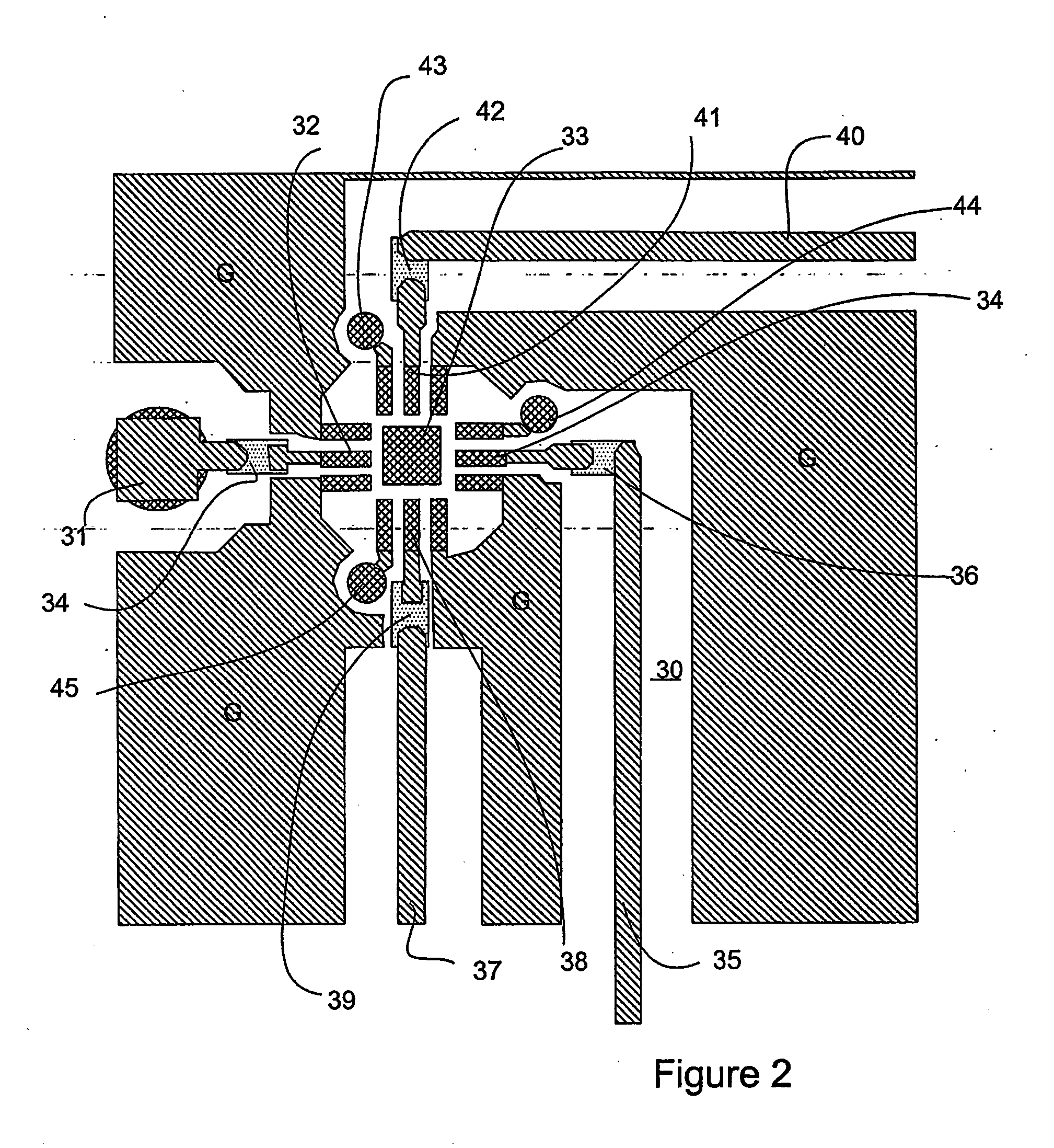

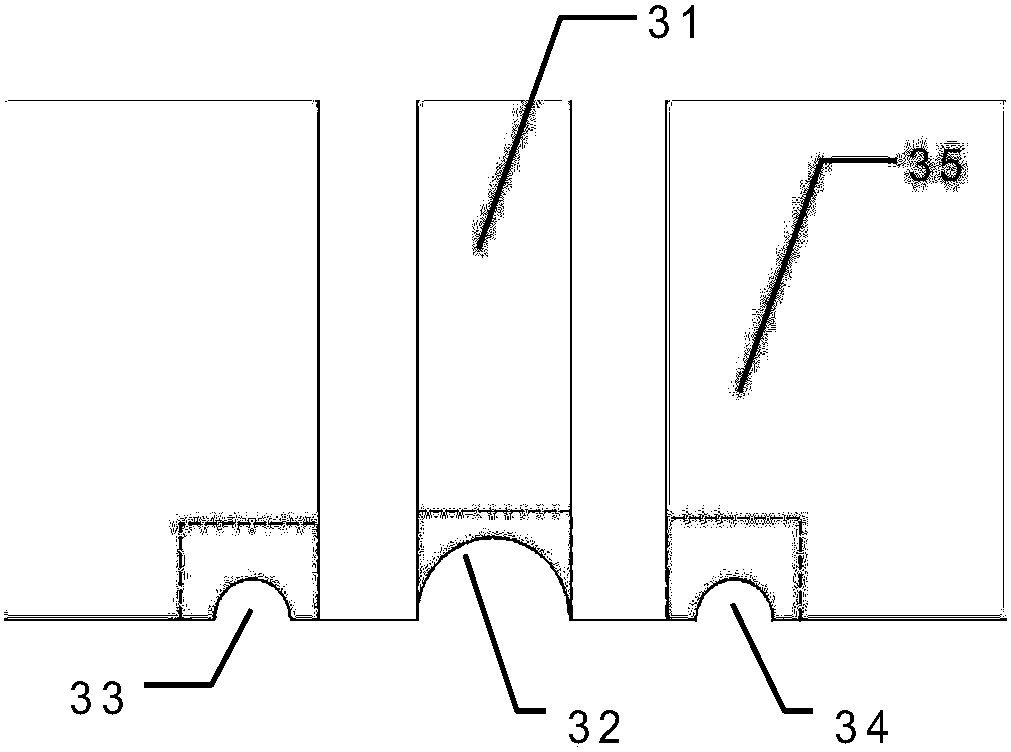

An antenna (11) includes a patch antenna element (22) capacitively coupled to a load patch (27). A switch (33) connects the load patch (27) to one of one or more strip lines (35, 37, 40), each of which has a different length. Each strip lines causes the load patch (27) to have a different impedance, with one causing a short circuit, one causing an open circuit, and one causing an impedance in between these extremes. Different impedances of the load patch (27) cause different frequencies of operation of the antenna patch (22) by virtue of the capacitive coupling therebetween. The antenna (11) is thereby tuneable to three separate frequencies. Other frequency bands are unaffected by virtue of the location of the load patch (27) relative to the antenna patch (22). By allowing tuning by way of controlling the impedance of the load patch (27), the antenna arrangement can be made smaller than a corresponding passive antenna operable at the same frequencies. By using an N throw switch, N strip lines of different lengths can be connected, each giving rise to a different operating frequency.

Owner:NOKIA TECH OY

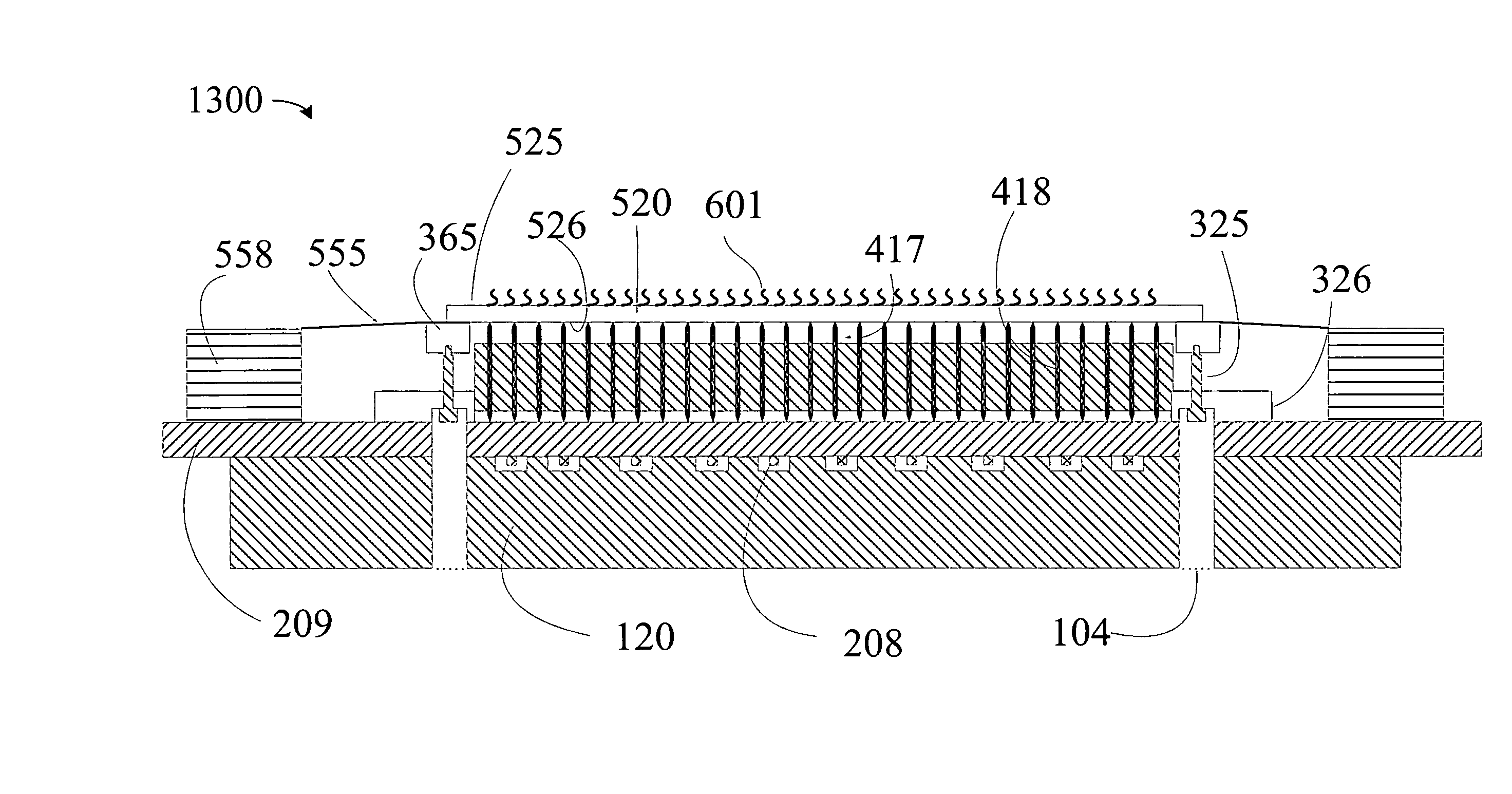

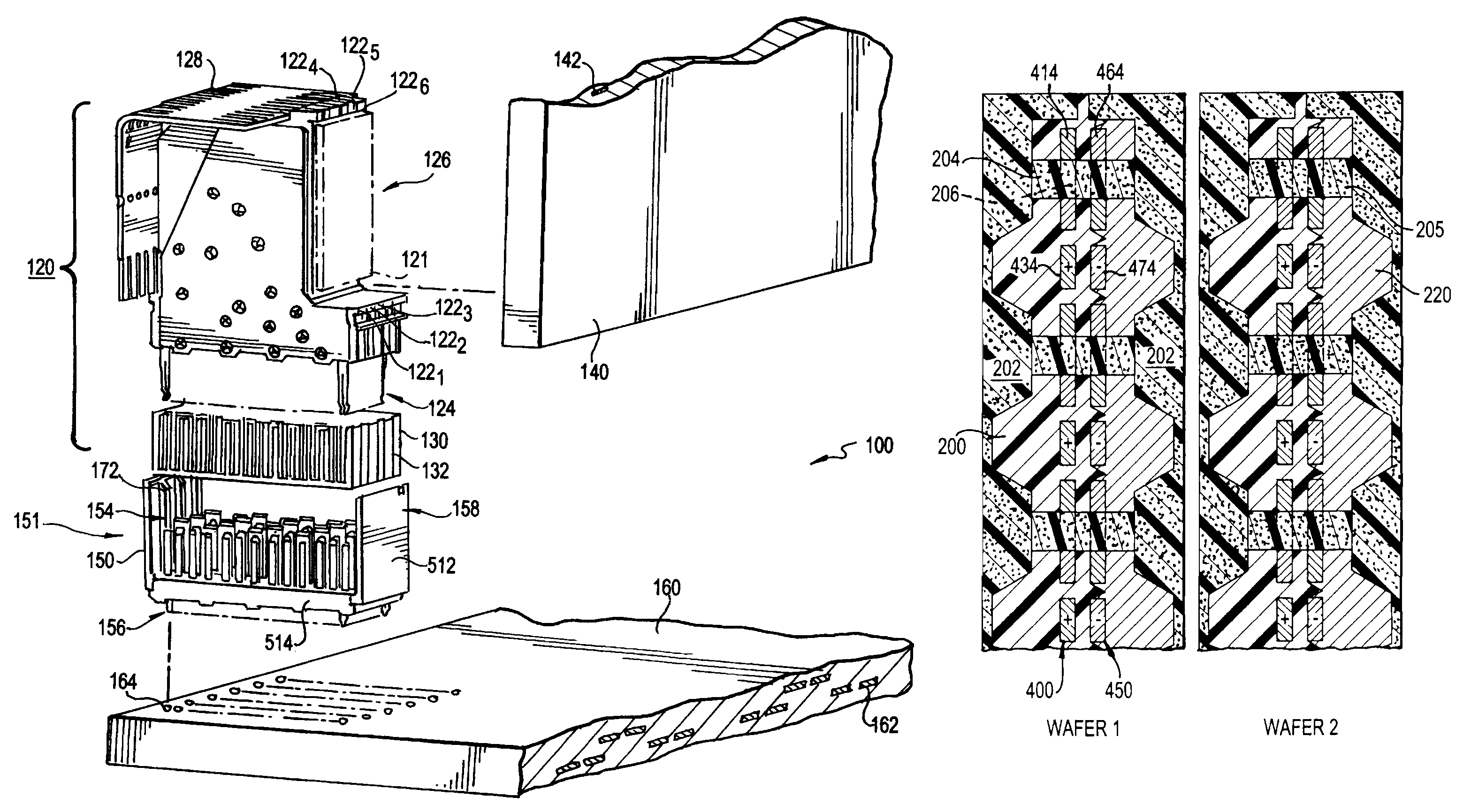

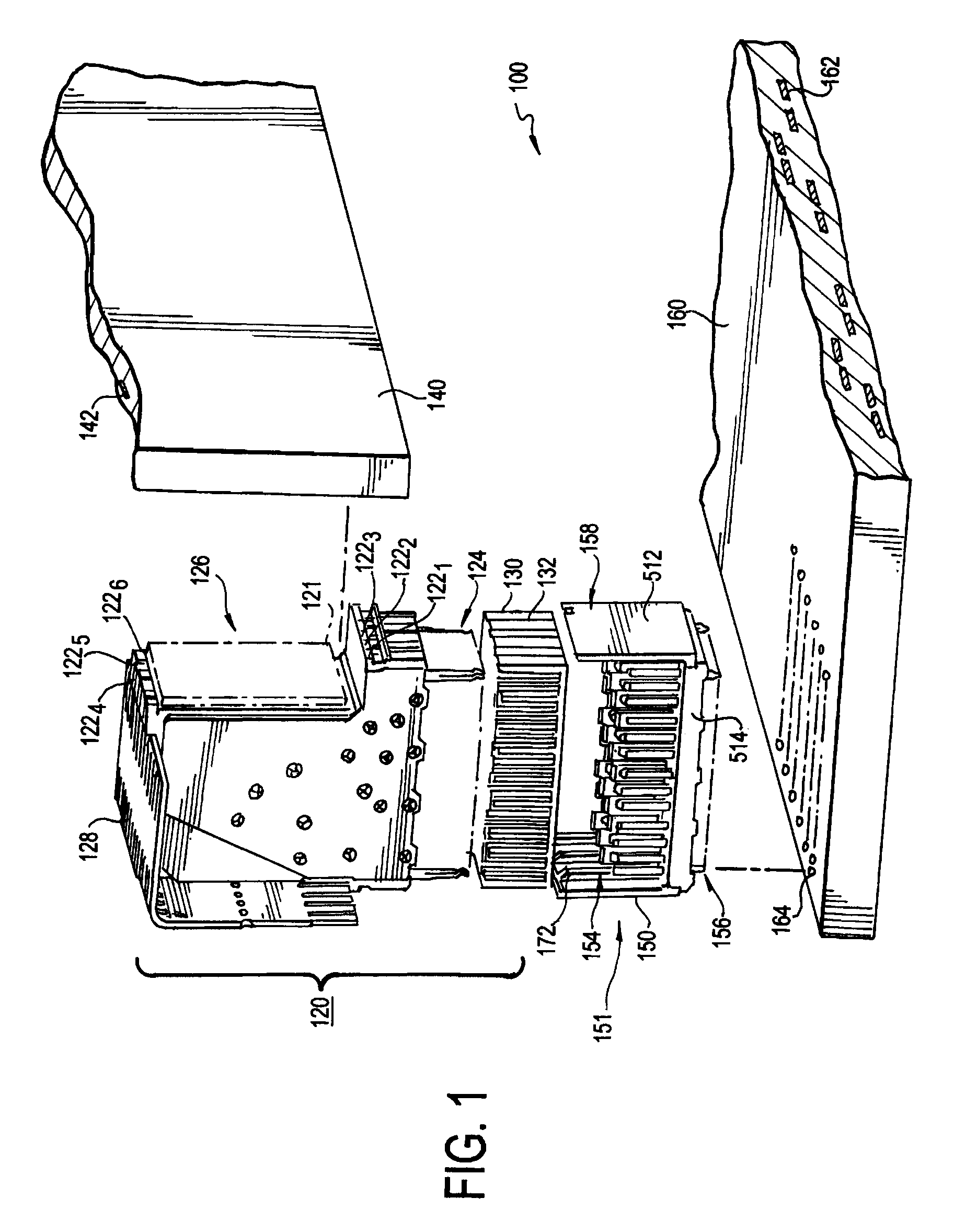

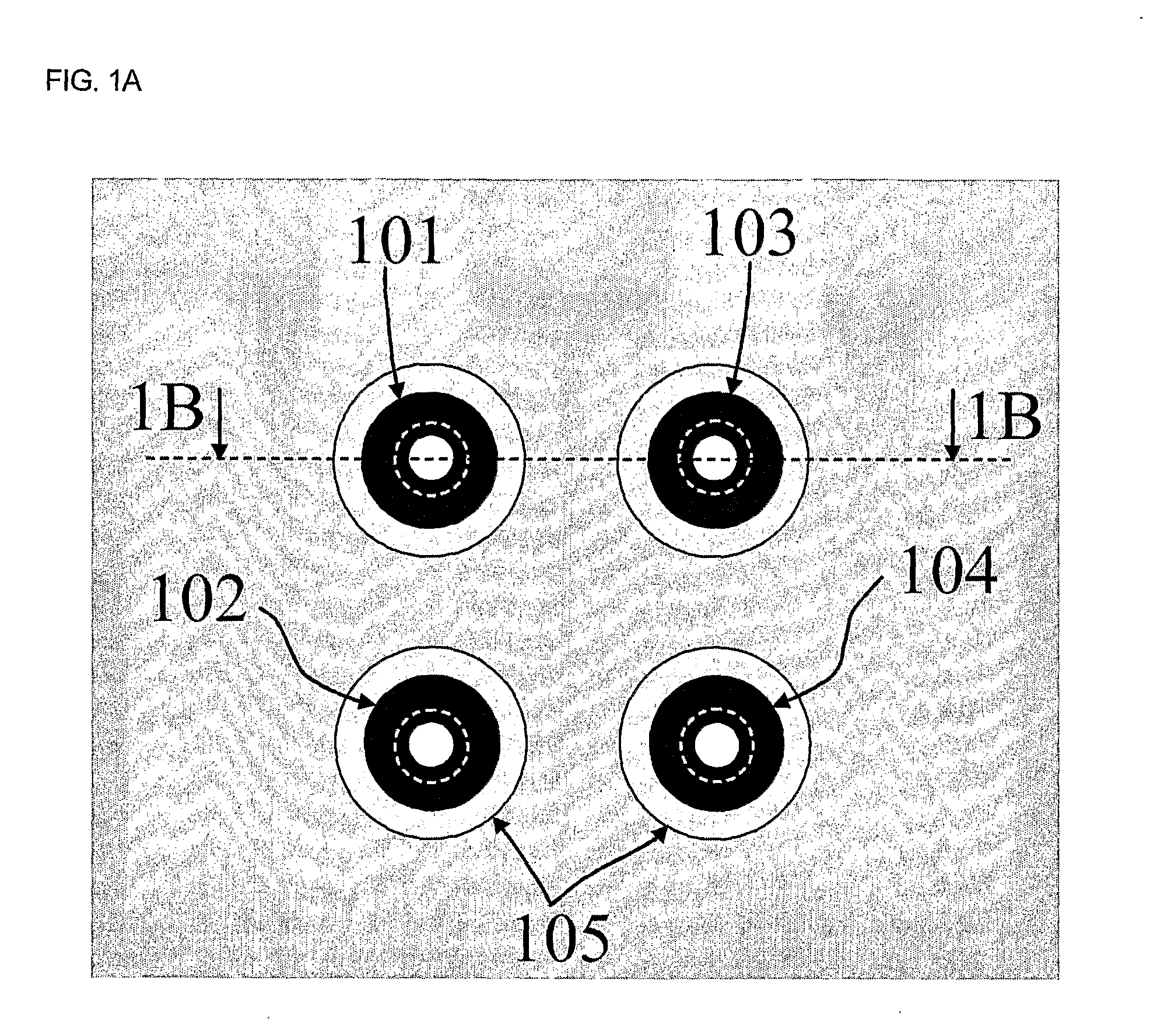

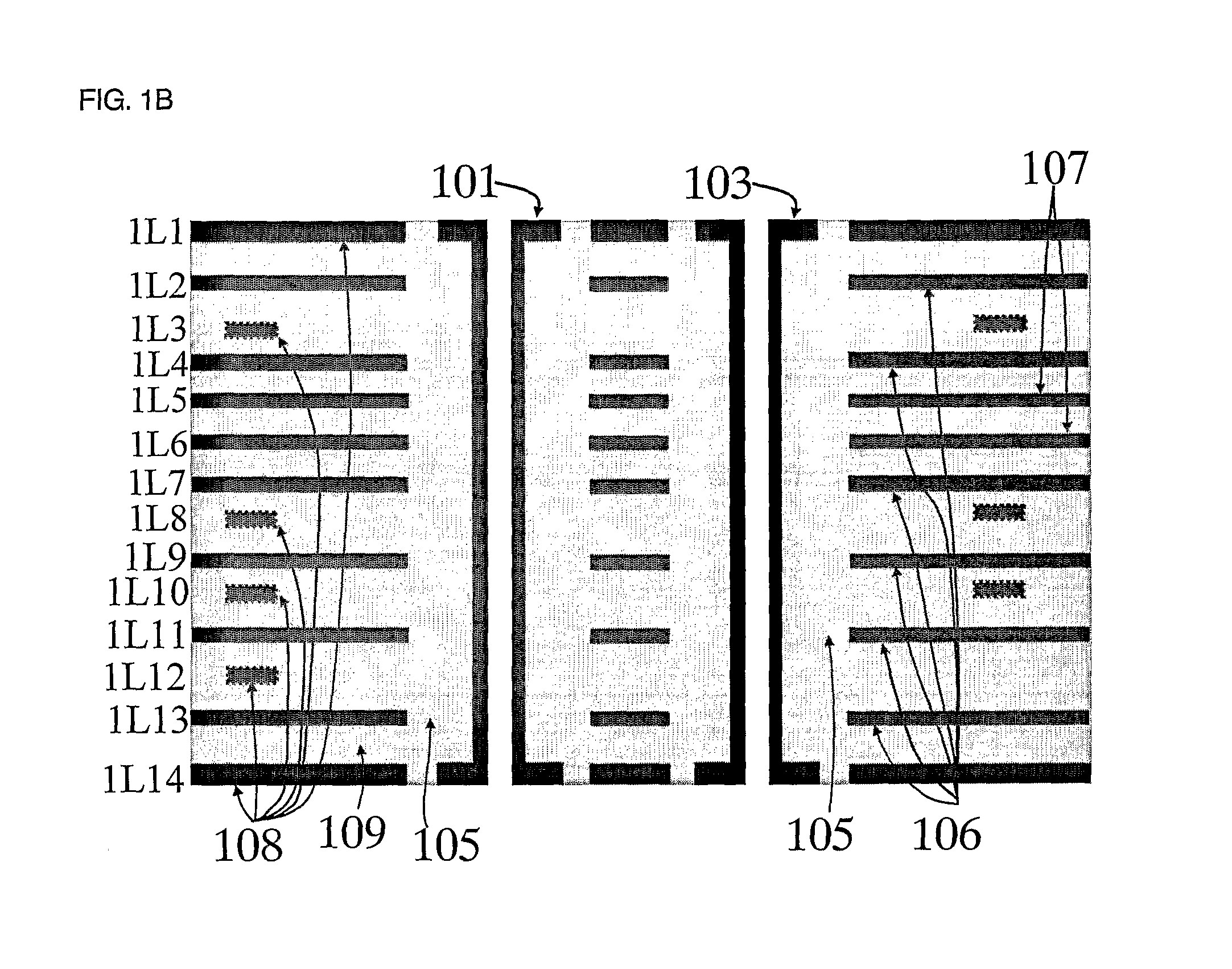

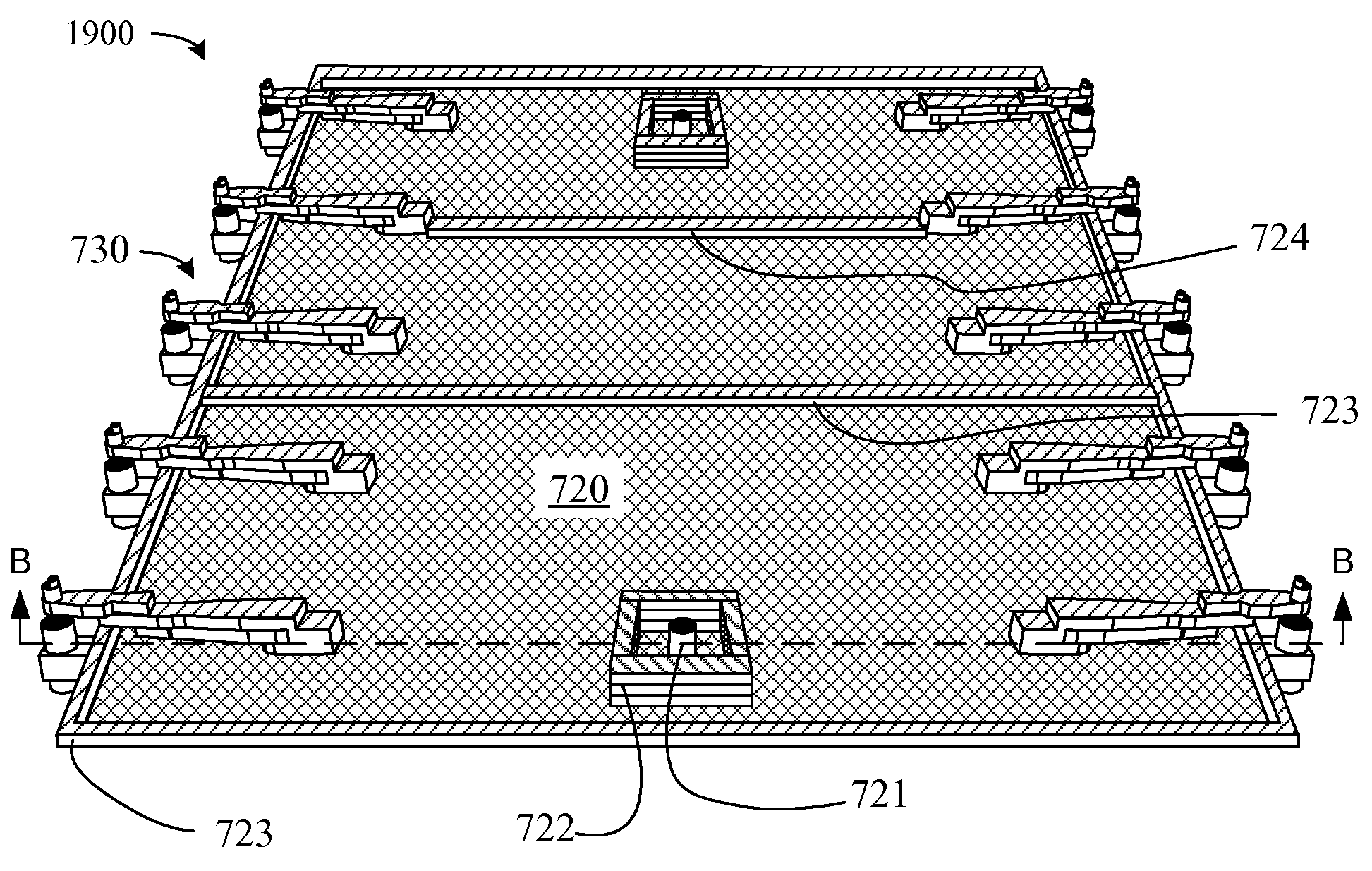

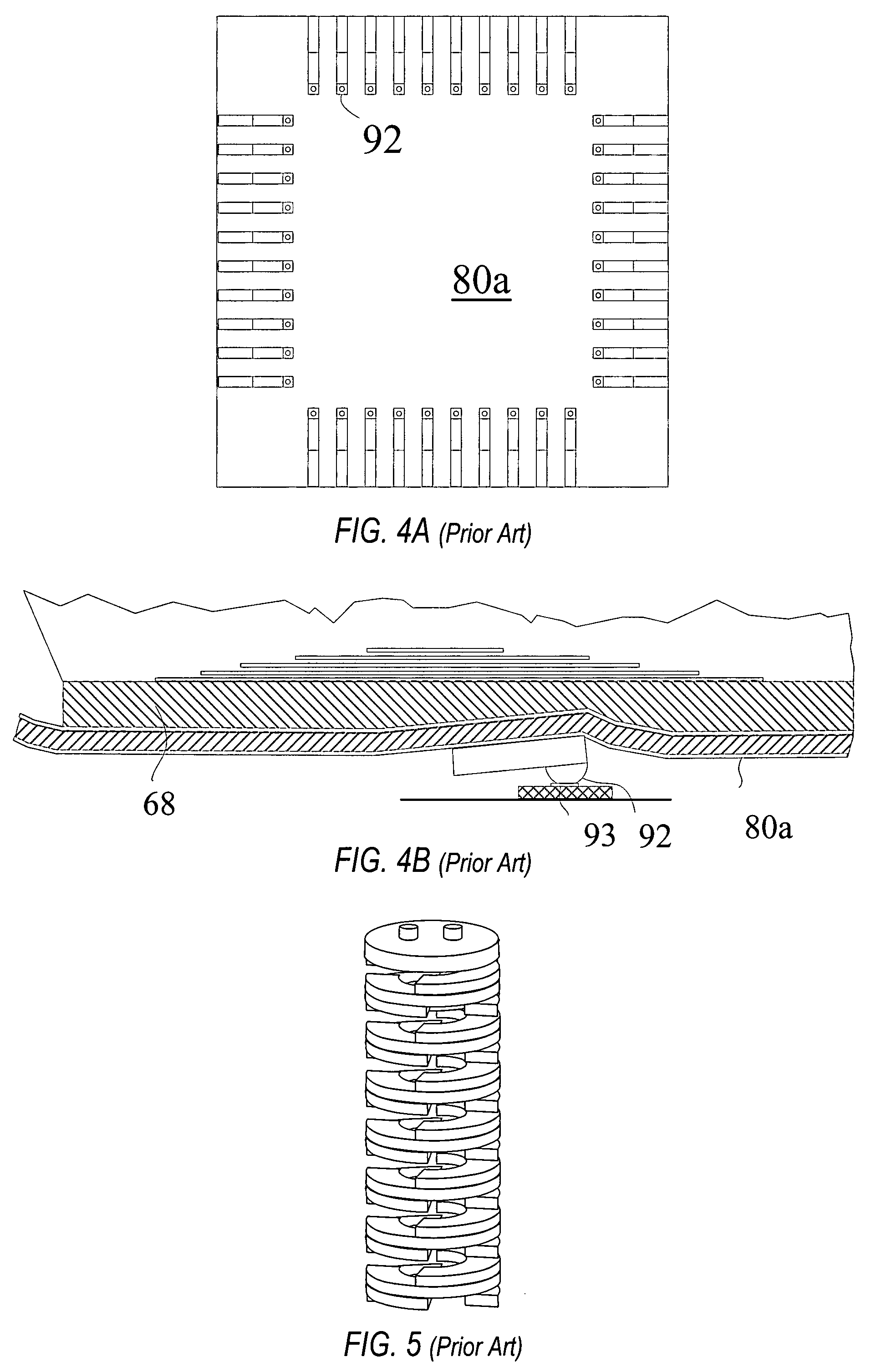

Compliance partitioning in testing of integrated circuits

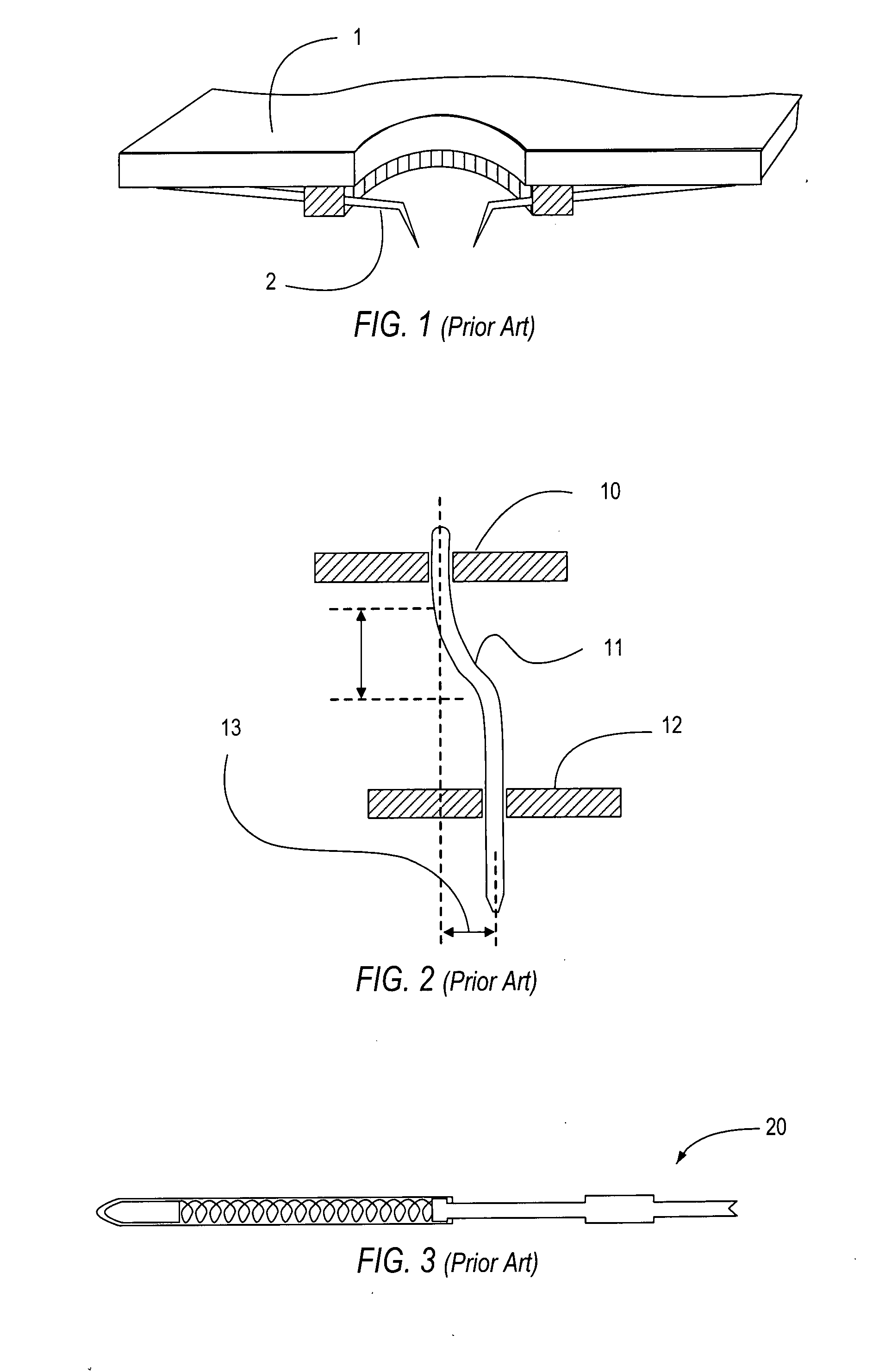

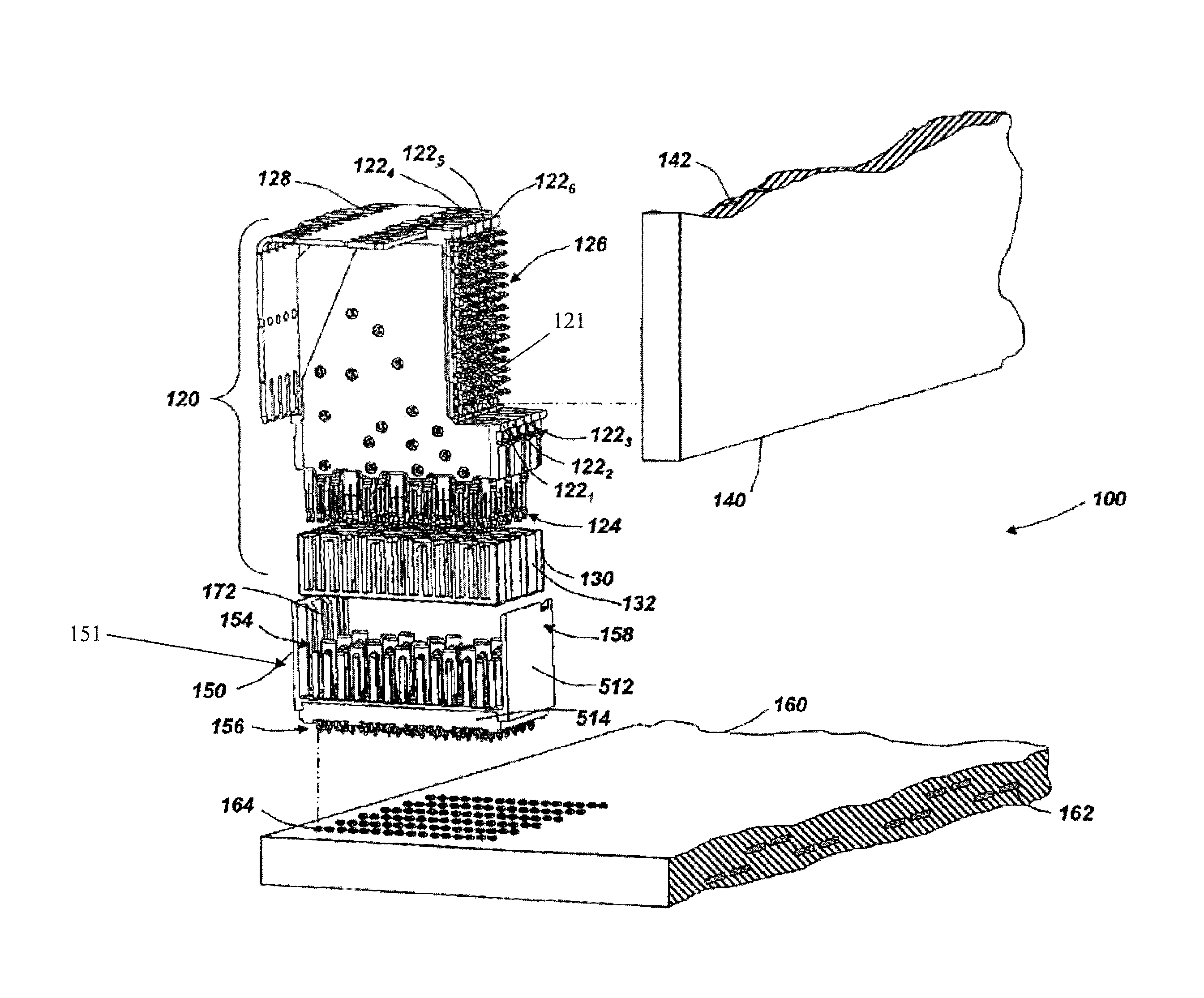

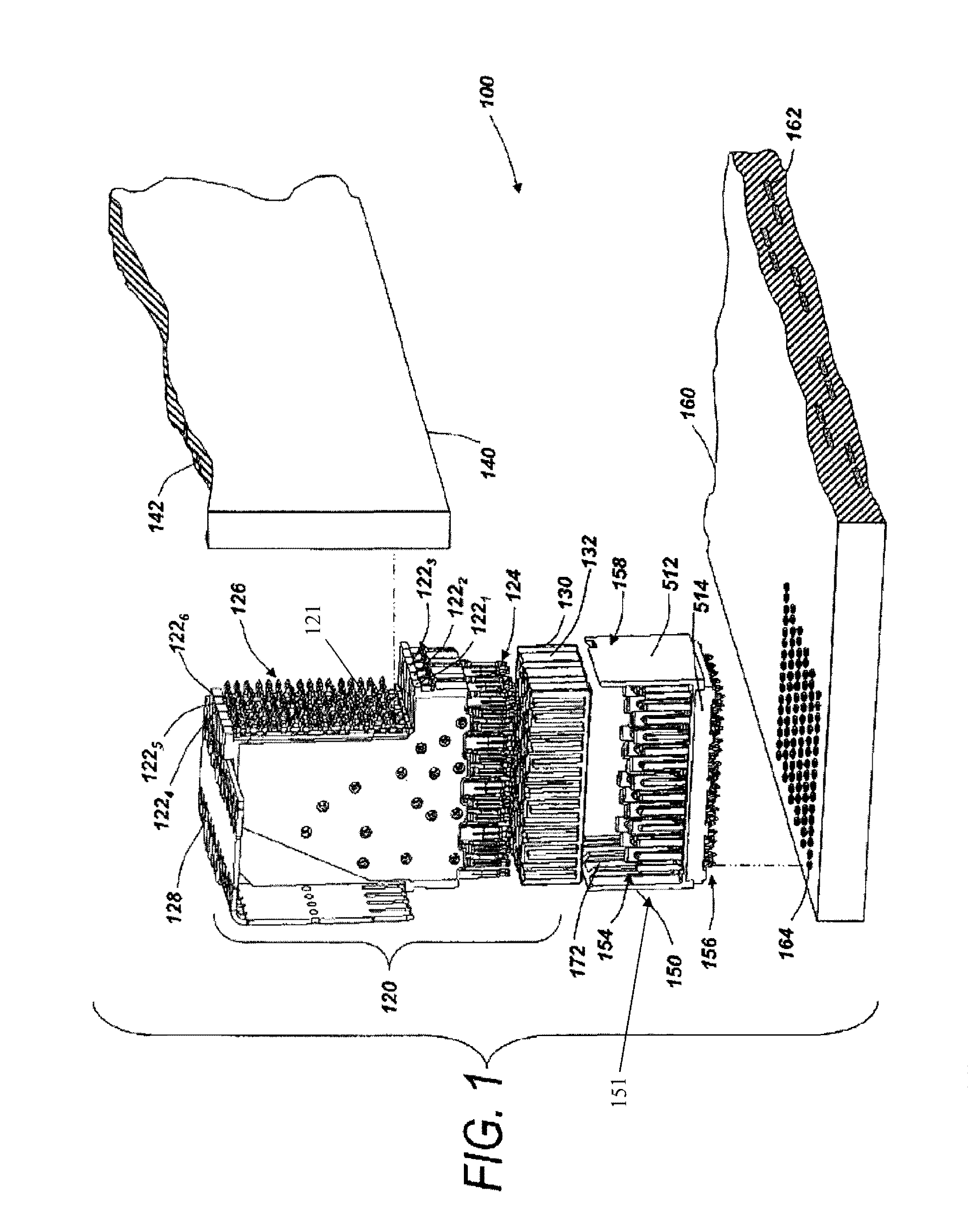

InactiveUS20080061808A1Low manufacturing costGood impedance controlPrinted circuit assemblingElectrical measurement instrument detailsMembrane configurationEngineering

Probecard architectures partition the spring compliance required for IC testing between several different components. Such architectures can provide shorter springs, better impedance control, improved power / ground distribution and more direct paths to tester electronics. The probecards can also use thinner interconnector substrates to conform to the planarity of a DUT and may suspend such a substrate by wires attached to a perimeter edge of the substrate to permit the substrate to tilt. Tilting can also be facilitated by positioning tester-side springs away from the perimeter of the substrate. Low compliance MEMS probes for such architectures can be provided on replaceable coupons having attachment points away from electrical connections, and a method for fabricating probe springs can plate spring material on a membrane deformed by contact with a bumped substrate.

Owner:INNOCONNEX

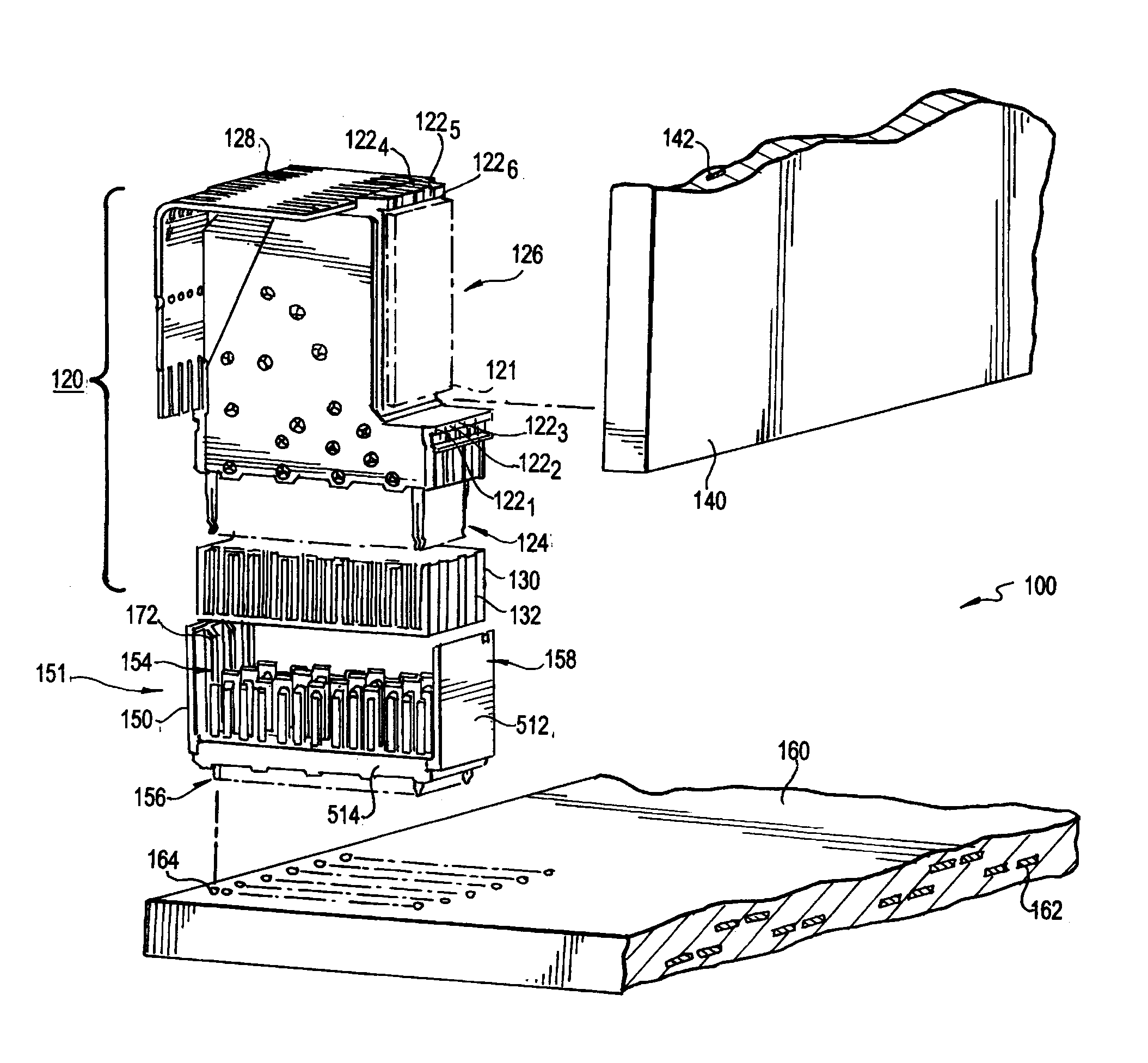

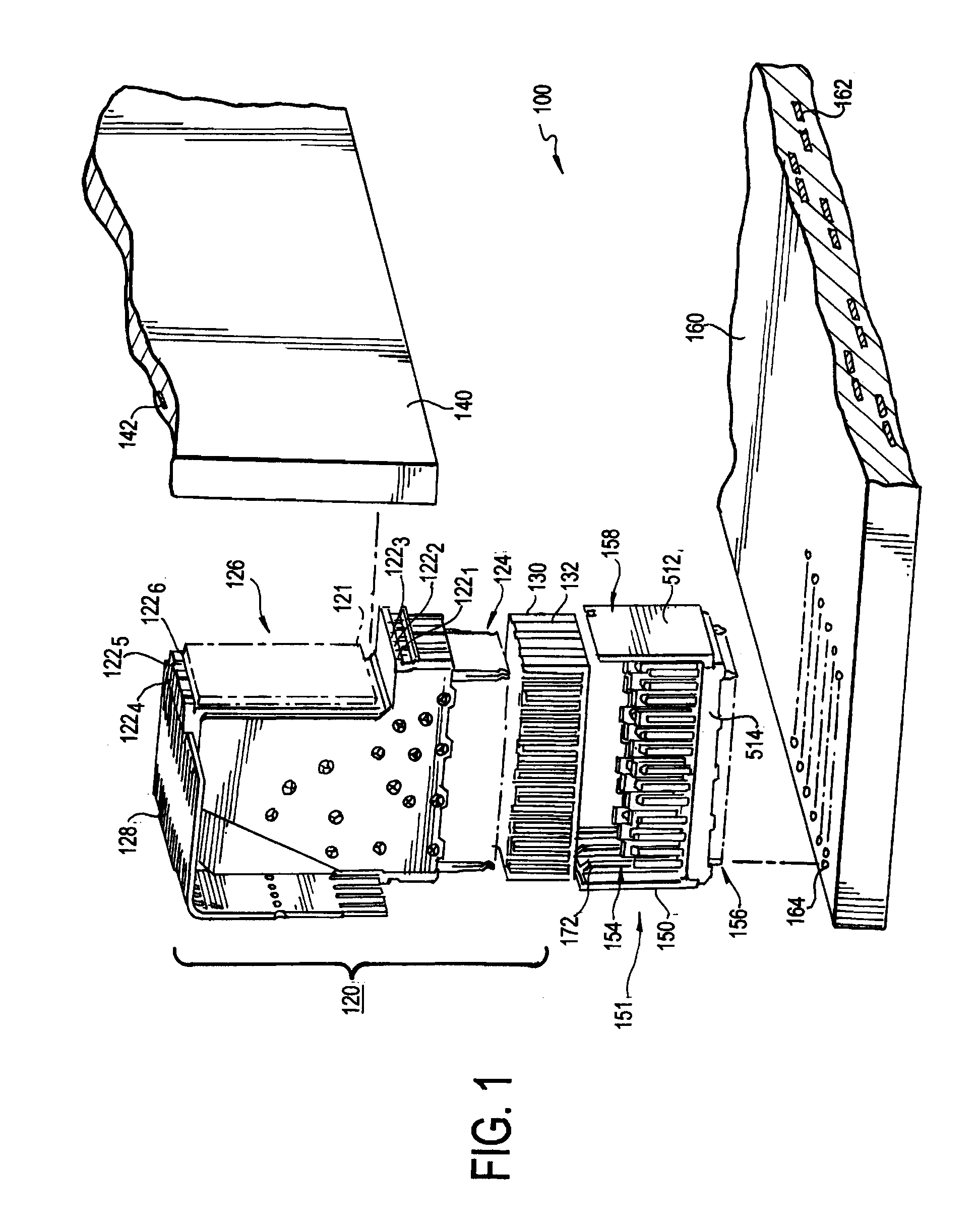

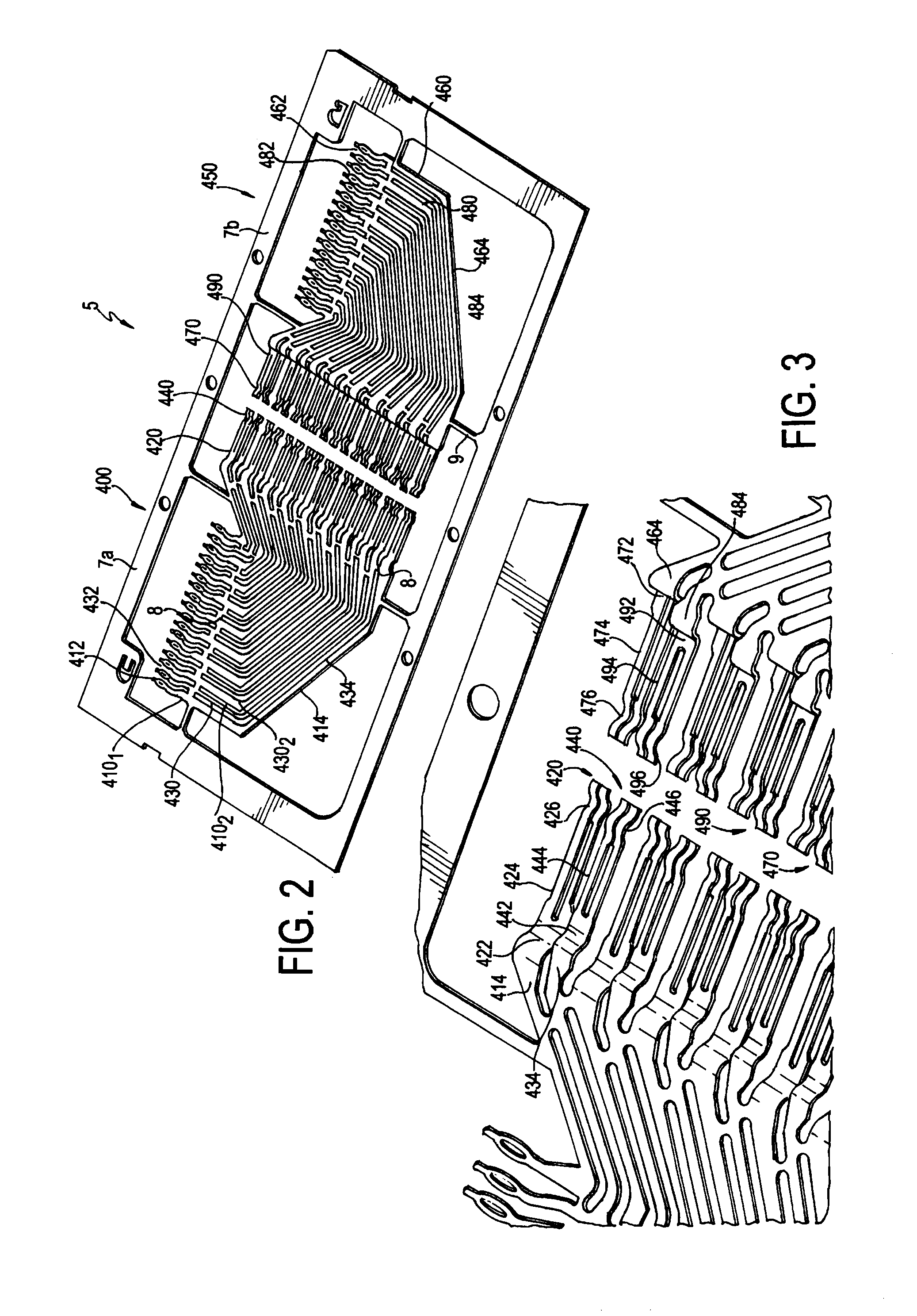

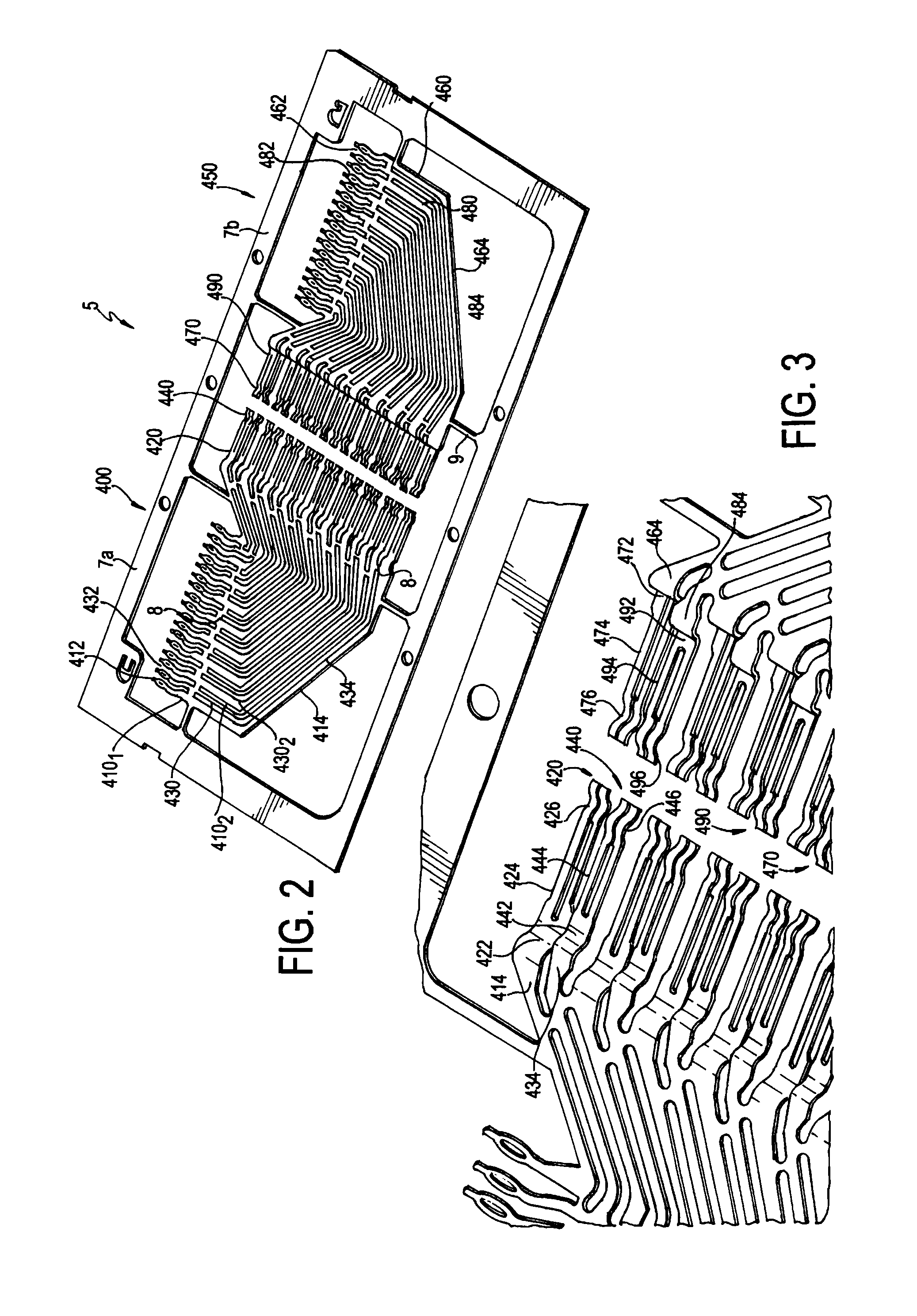

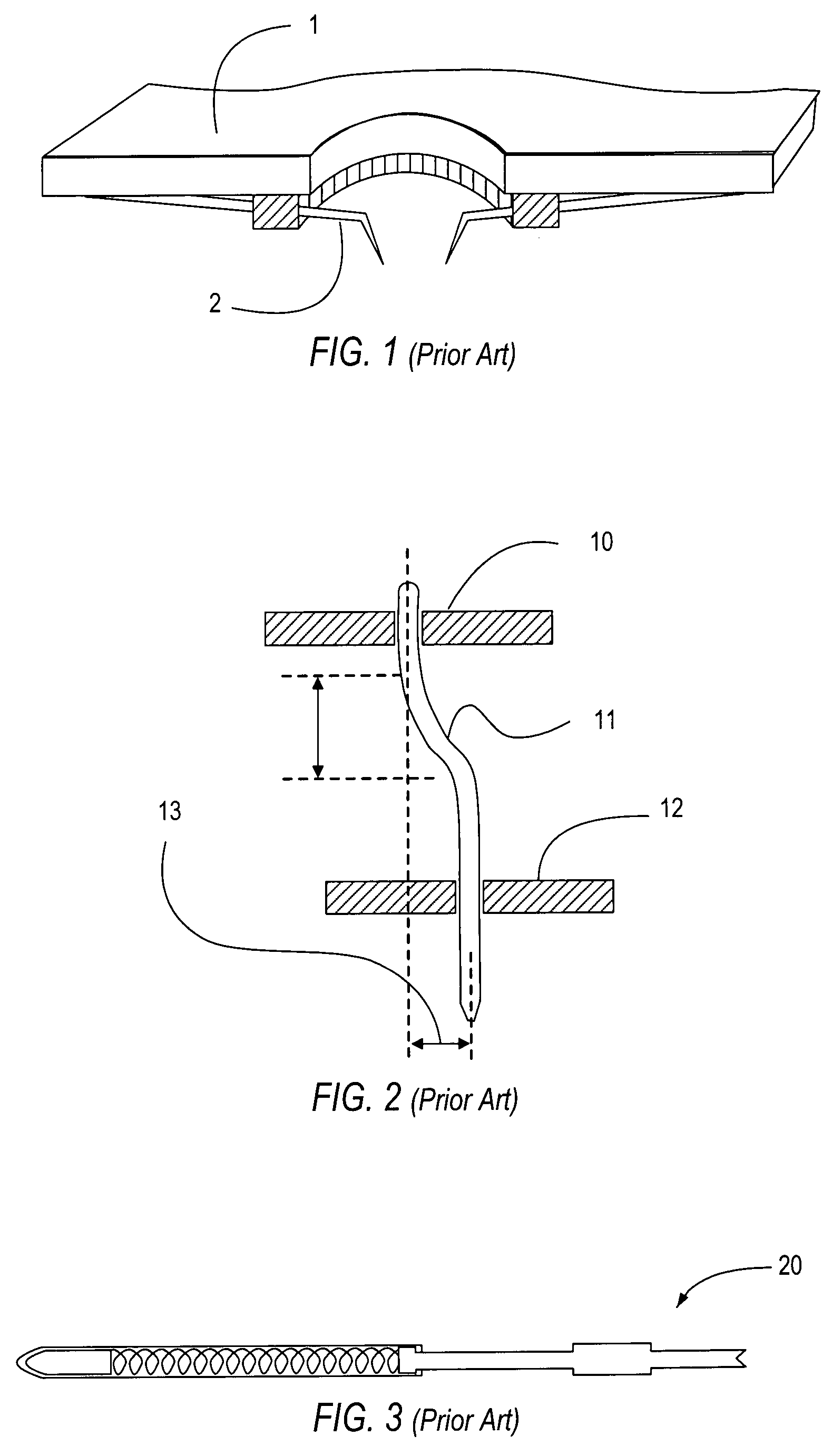

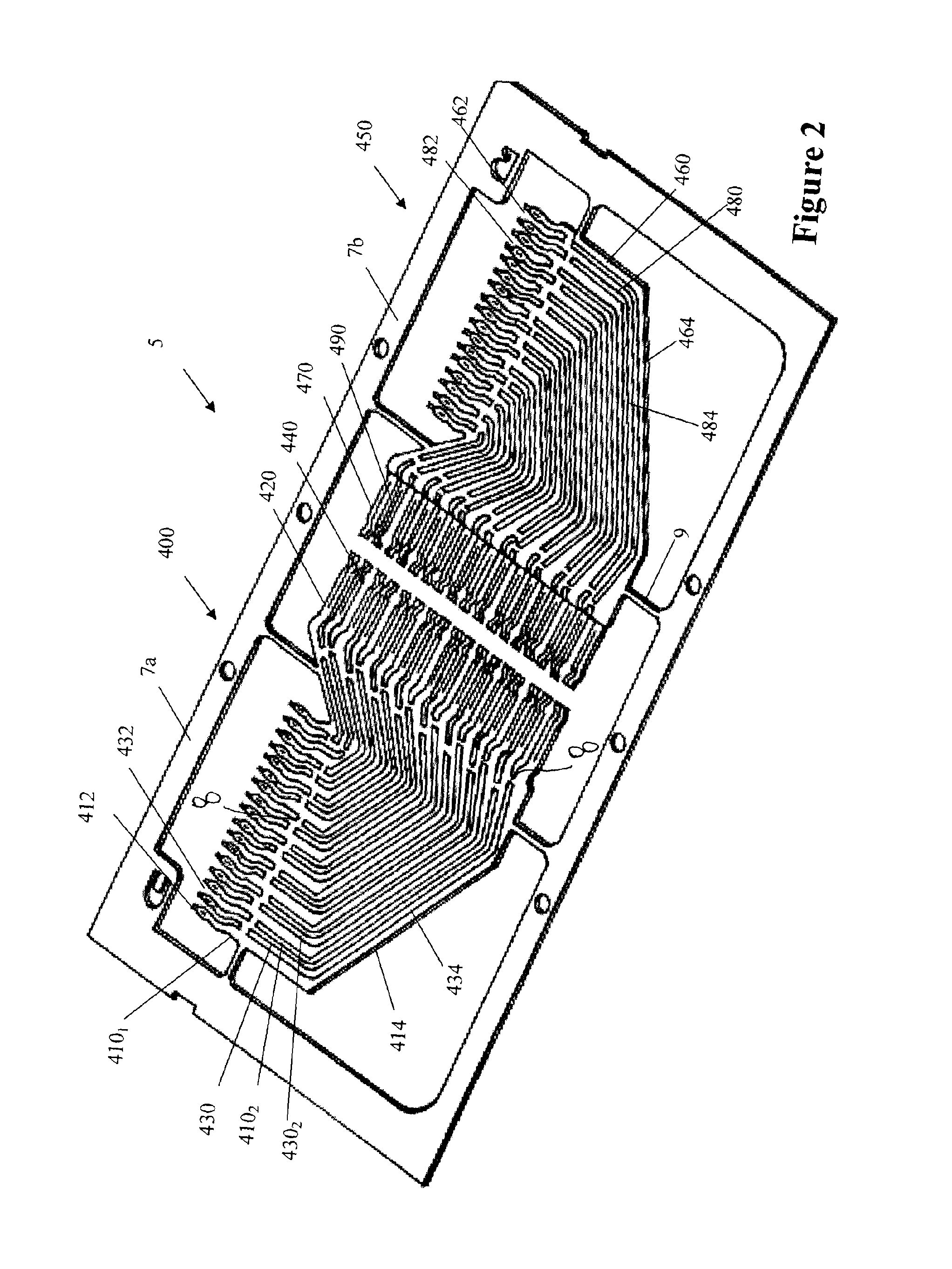

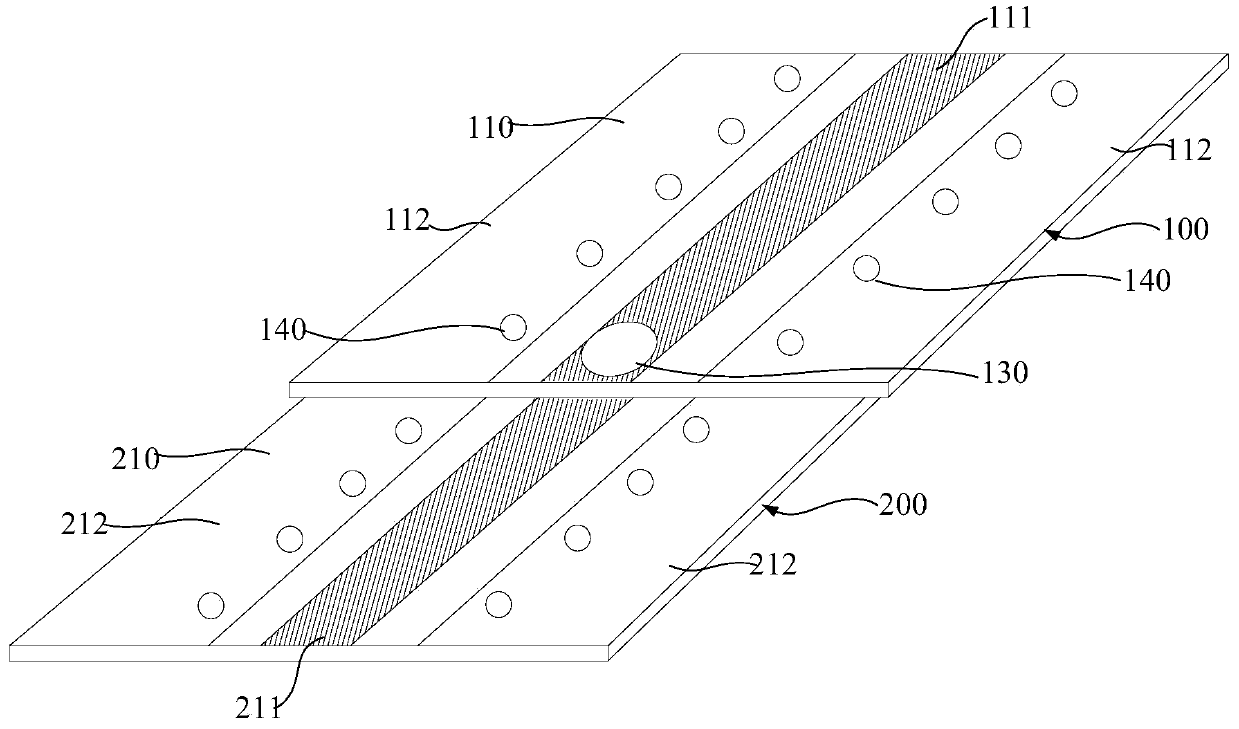

High speed, high density electrical connector

ActiveUS20120214344A1Smooth connectionLower insertion forceElectric discharge tubesCoupling contact membersPath lengthHigh density

A broadside coupled connector assembly has two sets of conductors, each separate planes. By providing the same path lengths, there is no skew between the conductors of the differential pair and the impedance of those conductors is identical. The conductor sets are formed by embedding the first set of conductors in an insulated housing having a top surface with channels. The second set of conductors is placed within the channels so that no air gaps form between the two sets of conductors. A second insulated housing is filled over the second set of conductors and into the channels to form a completed wafer. The ends of the first and second sets of conductors and the blades are jogged in both an x- and y-coordinate to reduce crosstalk and improve electrical performance.

Owner:AMPHENOL CORP

High speed, high density electrical connector

ActiveUS8814595B2Smooth connectionEnhanced couplingElectric discharge tubesCoupling contact membersElectricityPath length

A broadside coupled connector assembly has two sets of conductors, each separate planes. By providing the same path lengths, there is no skew between the conductors of the differential pair and the impedance of those conductors is identical. The conductor sets are formed by embedding the first set of conductors in an insulated housing having a top surface with channels. The second set of conductors is placed within the channels so that no air gaps form between the two sets of conductors. A second insulated housing is filled over the second set of conductors and into the channels to form a completed wafer. The ends of the first and second sets of conductors and the blades are jogged in both an x- and y-coordinate to reduce crosstalk and improve electrical performance.

Owner:AMPHENOL CORP

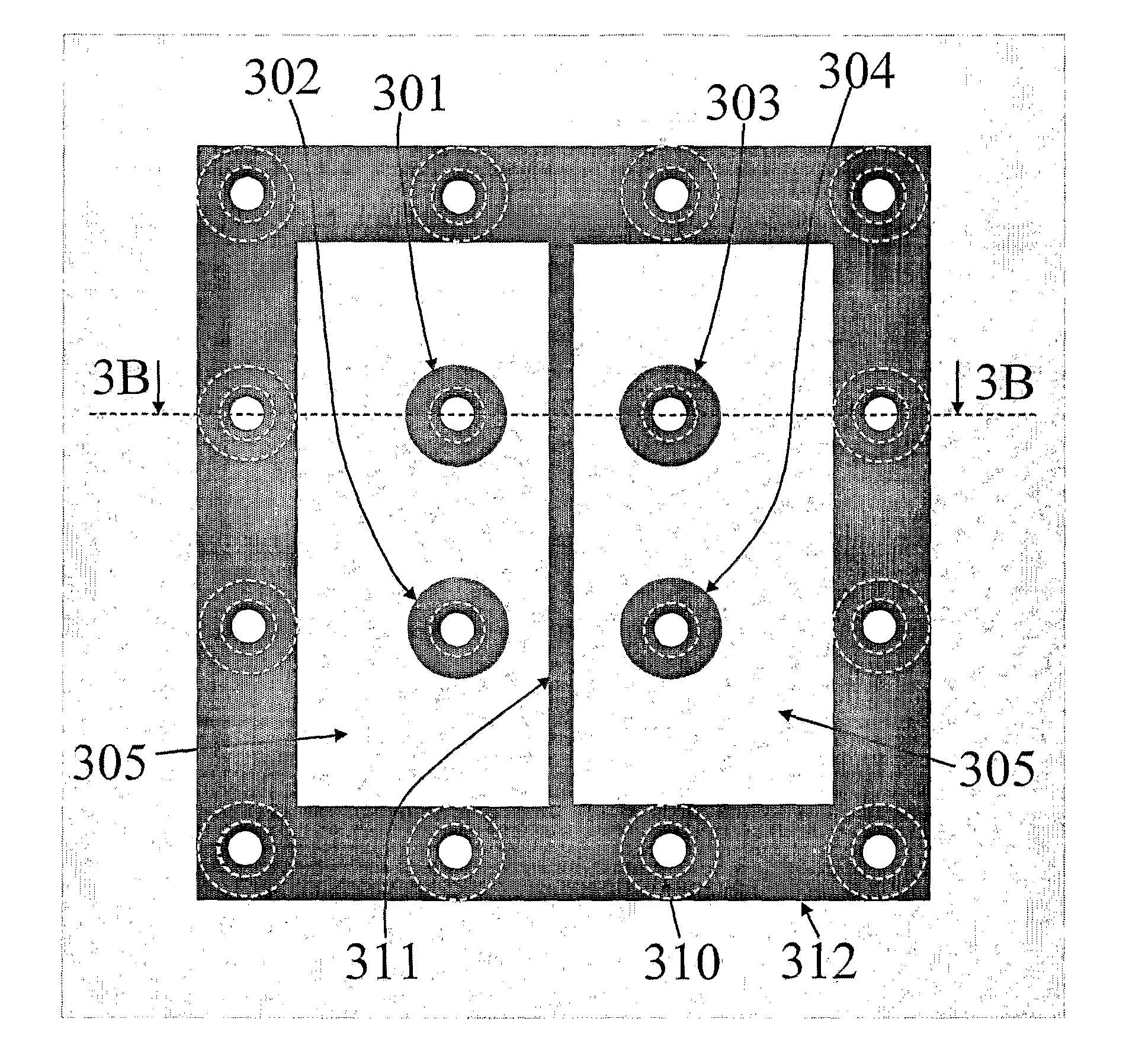

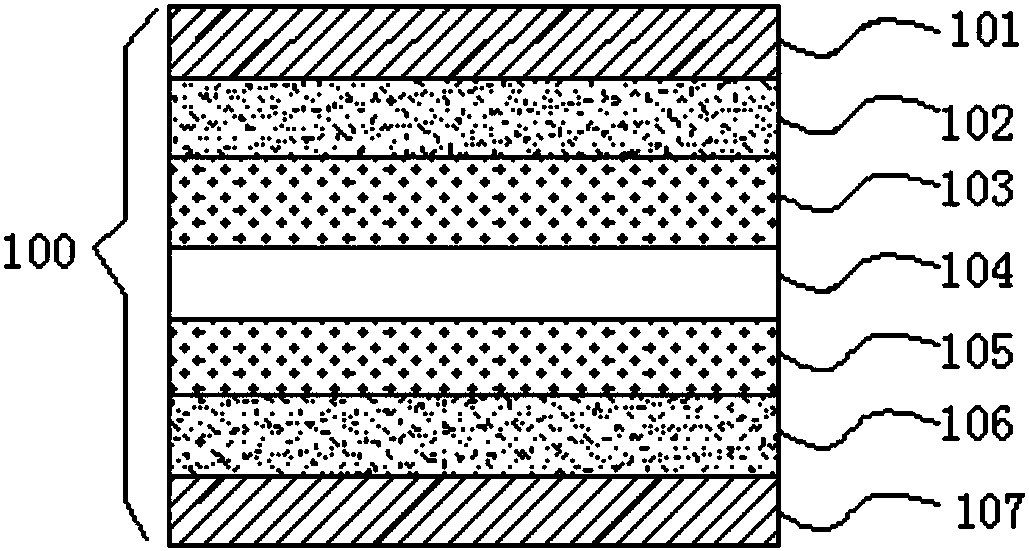

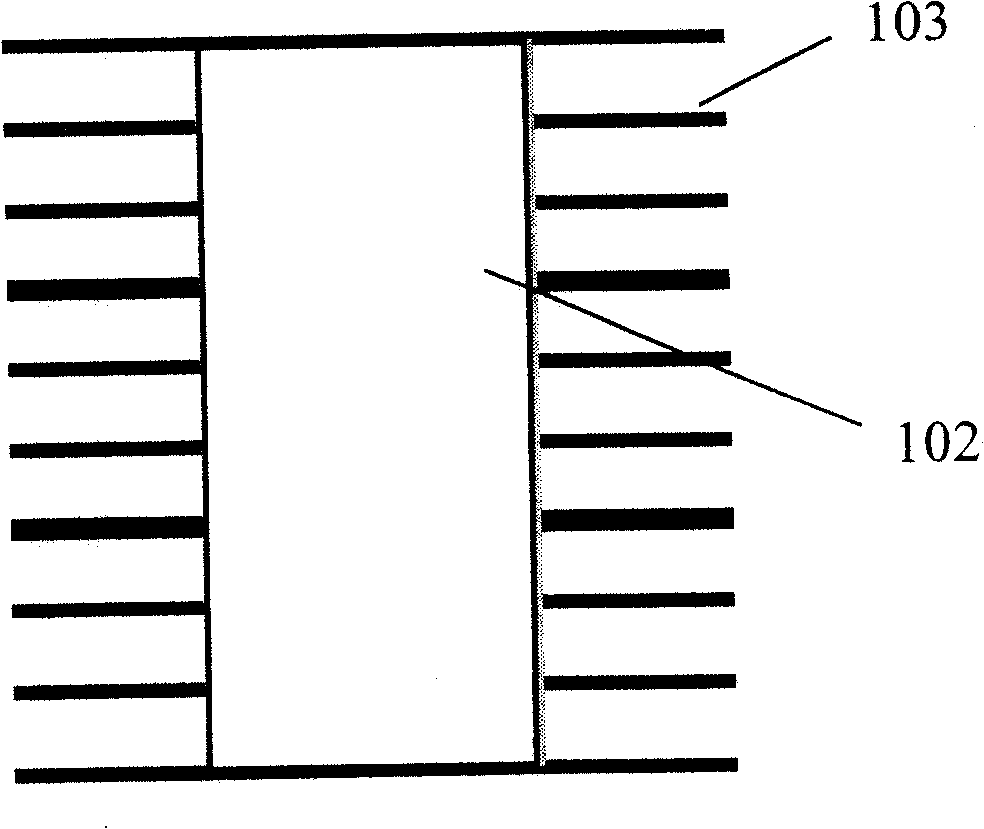

Multilayer substrate

InactiveUS20110203843A1Avoid leakage lossLeakage loss increaseMagnetic/electric field screeningCross-talk/noise/interference reductionCompact dimensionBroadband

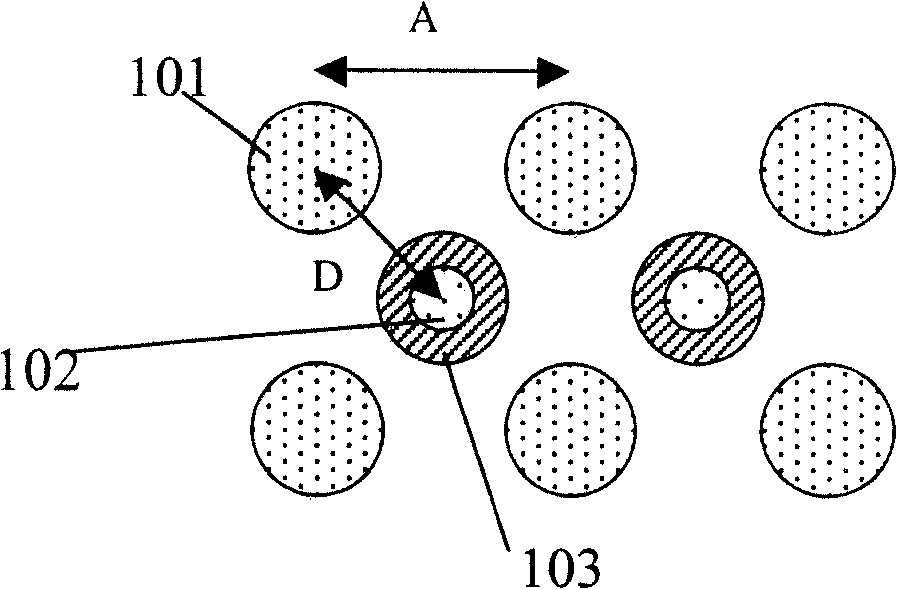

To provide more compact dimensions of a via structure formed by signal via pairs and ground vias in multilayer substrate. A multilayer substrate is provided such that the multilayer substrate comprising a high-isolated via cell wherein the high-isolated via cell comprises: two signal via pairs; a shield structure around two signal via pairs consisting of ground vias and ground strips connected to ground vias wherein the shield structure is formed symmetrically in respect to two via pairs to reduce the transformation between mixed modes and also leakage from two signal via pairs; a clearance hole separating signal via pairs from other conductive parts of the multilayer substrate and having predetermined dimensions to provide broadband operation of the high-isolated via cell; and the separating strip disposed symmetrically between said signal via pairs to provide crosstalk reduction between two signal via pairs and common mode decrease.

Owner:NEC CORP

Controllable antenna arrangement

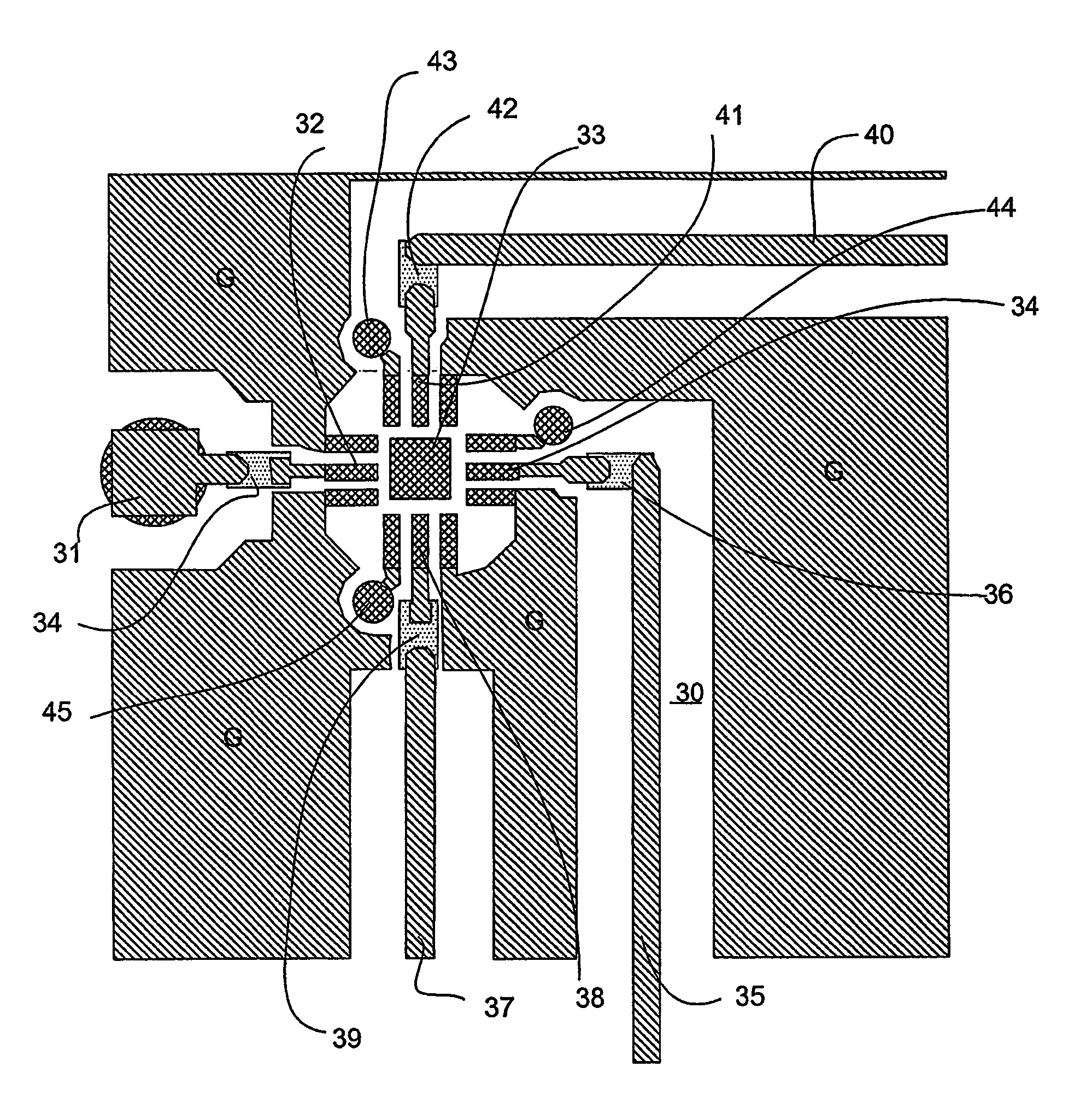

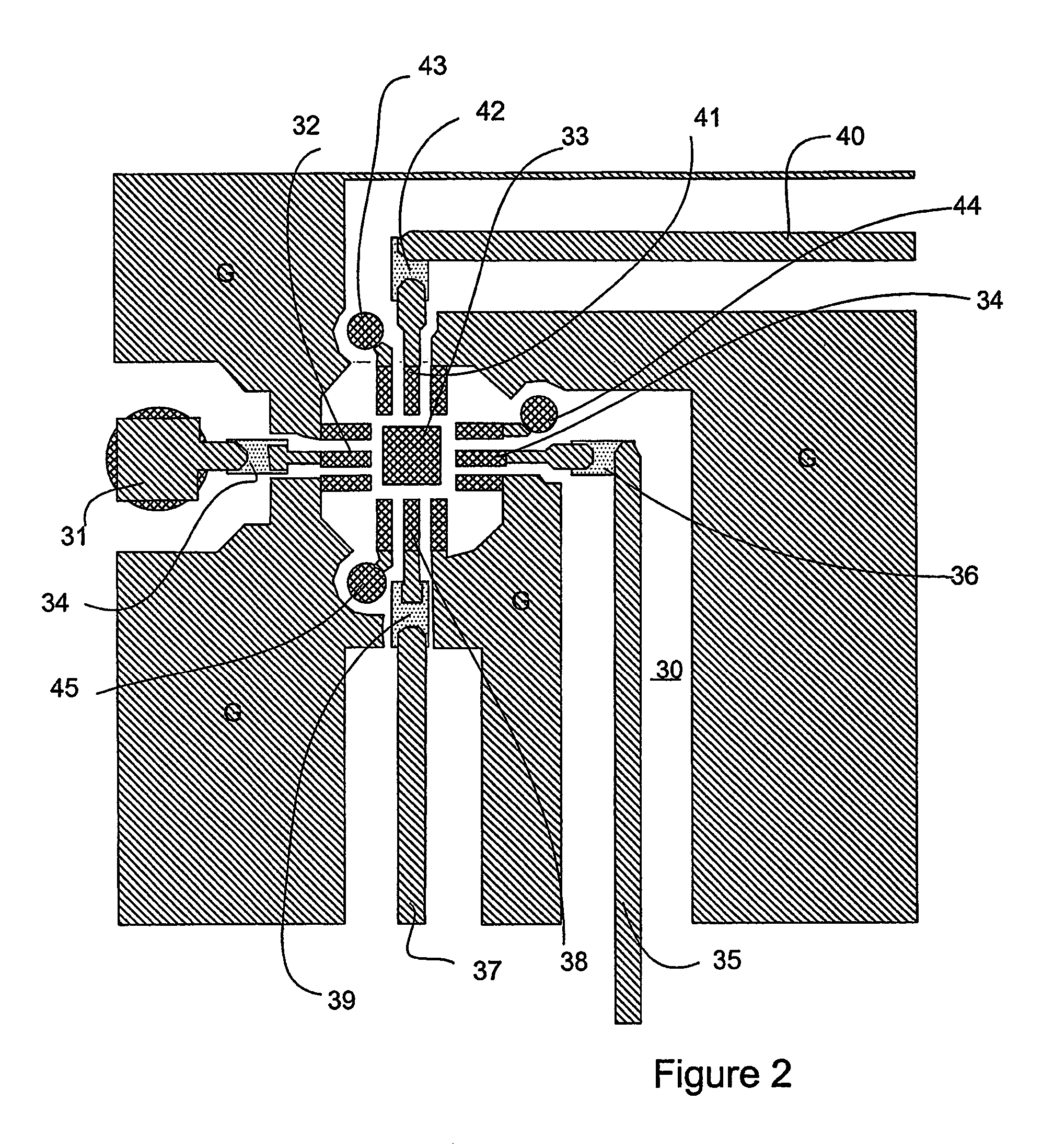

InactiveUS20060044187A1Improved Impedance ControlEasy to tuneSimultaneous aerial operationsAntenna supports/mountingsCapacitanceCapacitive coupling

An antenna (11) includes a patch antenna element (22) capacitively coupled to a load patch (27). A switch (33) connects the load patch (27) to one of one or more strip lines (35, 37, 40), each of which has a different length. Each strip lines causes the load patch (27) to have a different impedance, with one causing a short circuit, one causing an open circuit, and one causing an impedance in between these extremes. Different impedances of the load patch (27) cause different frequencies of operation of the antenna patch (22) by virtue of the capacitive coupling therebetween. The antenna (11) is thereby tuneable to three separate frequencies. Other frequency bands are unaffected by virtue of the location of the load patch (27) relative to the antenna patch (22). By allowing tuning by way of controlling the impedance of the load patch (27), the antenna arrangement can be made smaller than a corresponding passive antenna operable at the same frequencies. By using an N throw switch, N strip lines of different lengths can be connected, each giving rise to a different operating frequency.

Owner:NOKIA TECHNOLOGLES OY

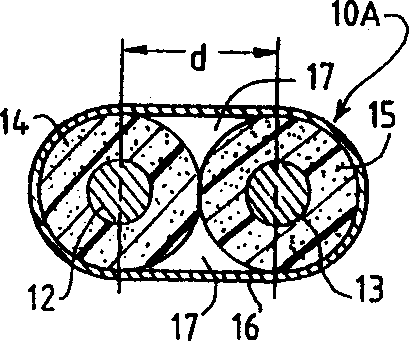

High performance data cable

InactiveCN1367930AImprove imbalanceEliminates trapped airInsulated cablesCable/conductor manufactureEngineeringTwisted pair

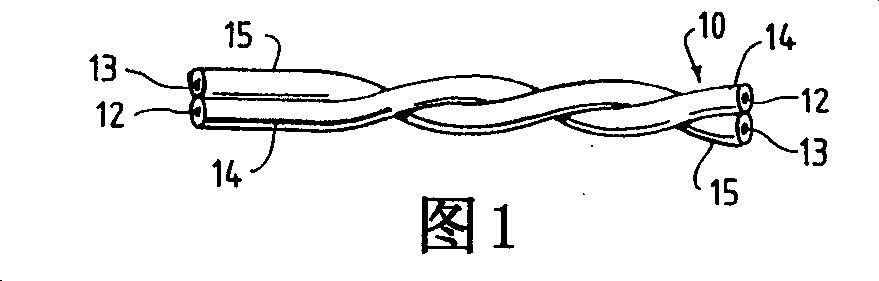

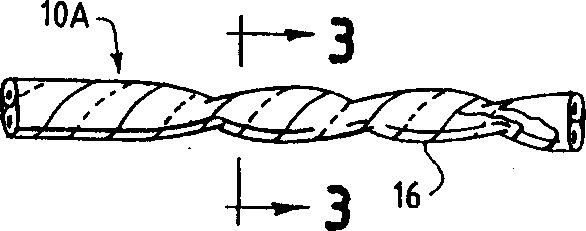

An improved high performance twisted pair data cable having a calculated impedance standard deviation of less than 3.5 at an average impedance of 50 to 200 ohms and a maximum of 90 to 110 ohms. The twisted pair is helically wrapped with metal shielding tape under a certain tension, which provides a shielded twisted pair with a cross-sectional void of less than 25%, preferably less than 18%. The tape is helically wrapped with an overlap of 30-45% and at 35-45 degrees to the longitudinal axis of the cable. This cable has a frequency up to 600MHz.

Owner:BELDEN WIRE & CABLE

Probe card repair using coupons with spring contacts and separate atachment points

InactiveUS7876087B2Shorten cycle timeShort springElectronic circuit testingElectrical measurement instrument detailsElectricityInterconnector

Owner:INNOCONNEX

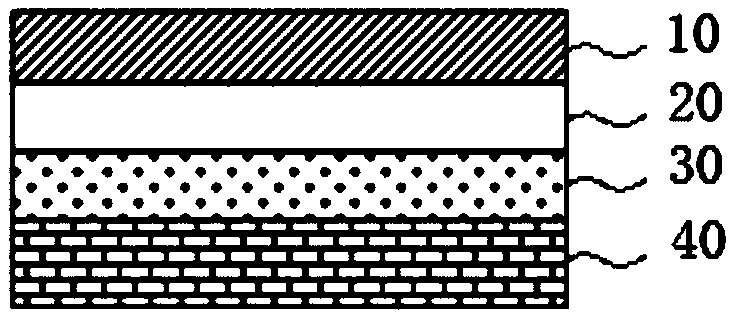

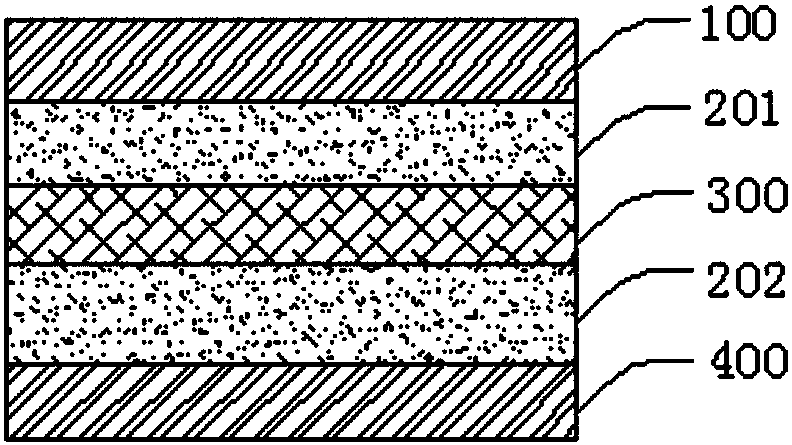

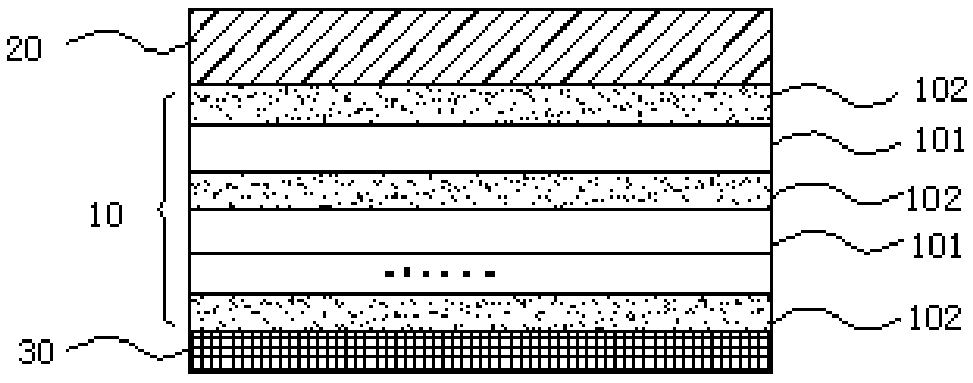

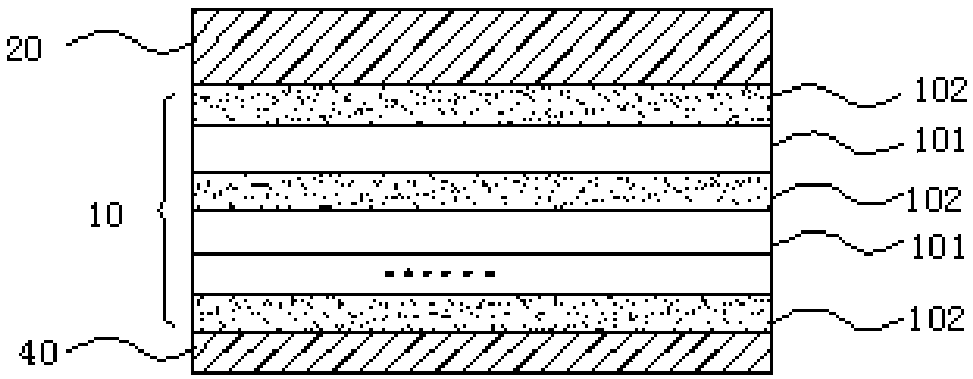

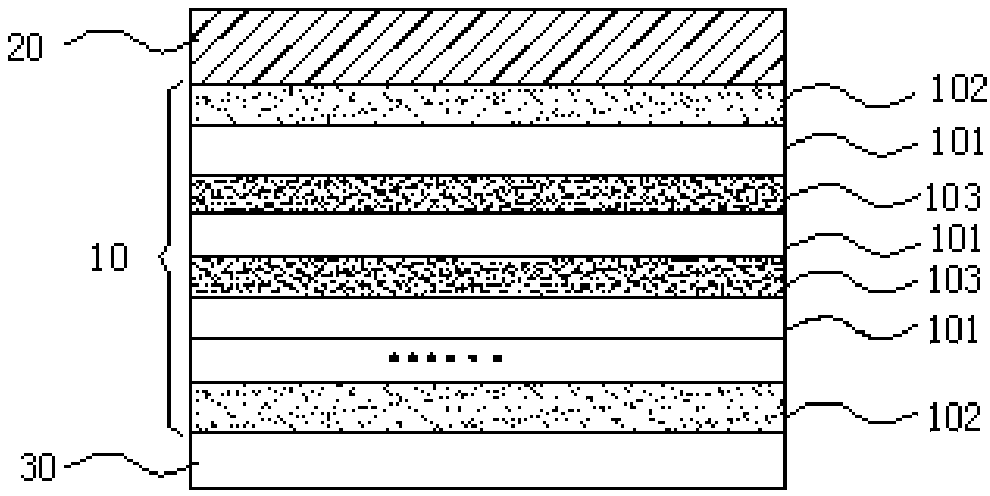

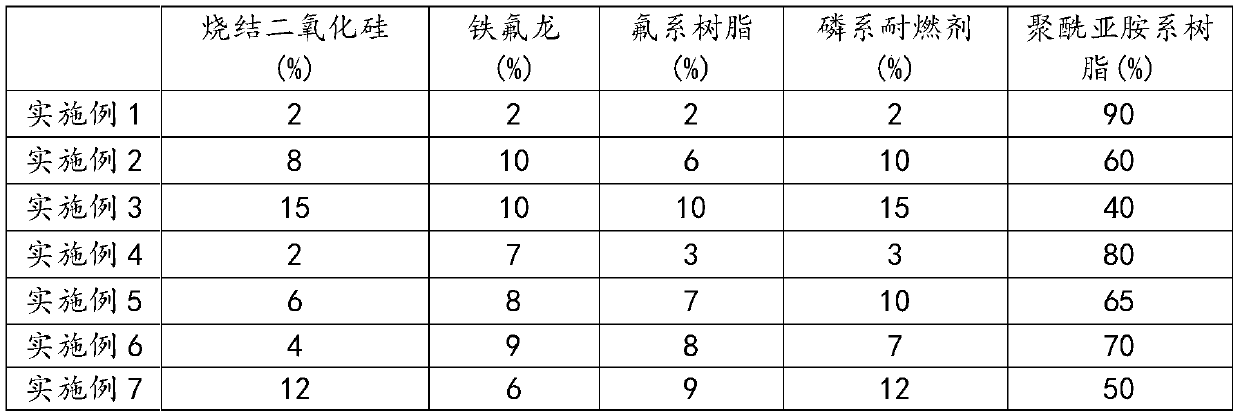

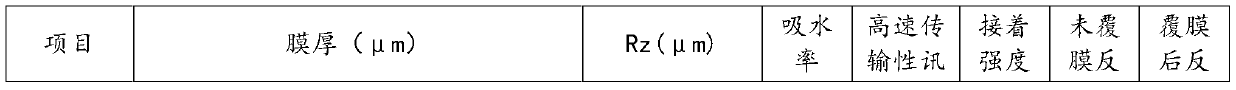

LCP high-frequency substrate having high-Dk and low-Df characteristic and fabrication method thereof

PendingCN110769594AExcellent high-speed transmissionReduce lossPrinted circuit aspectsCircuit susbtrate materialsUv laserHigh density

The invention discloses an LCP high-frequency substrate having the high-Dk and low-Df characteristic. The LCP high-frequency substrate comprises at least one copper foil layer, at least one high-dielectric LCP core layer and at least one high-dielectric glue layer, wherein the high-dielectric LCP core layer is arranged between the copper foil layer and the high dielectric layer, the high dielectric LCP core layer is a core layer with a Dk value being 6-100 and a Df value being 0.002-0.010, the high dielectric glue layer is a glue layer with a Dk value being 6-100 and a Df value being 0.002-0.010, the thickness of the copper layer is 1-35 micrometers, the thickness of the high dielectric LCP core layer is 12-100 micrometers, and the thickness of the high dielectric glue layer is 12-100 micrometers. The high dielectric LCP core layer and the high dielectric glue layer both have the high-Dk and low-Df characteristics, thus, the fabricated LCP high-frequency substrate has excellent high-speed transmission, low loss, high-Dk and low-Df performance, low roughness, the ultralow water absorption rate, low elastic force suitable for high-density assembly, favorable UV laser drilling capability and the excellent mechanical property.

Owner:KUSN APLUS TEC CORP

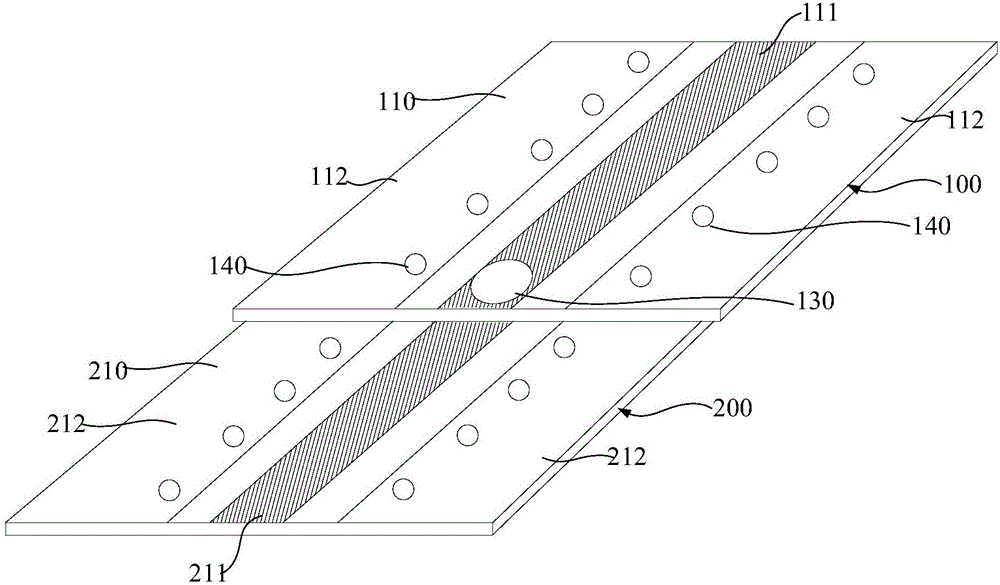

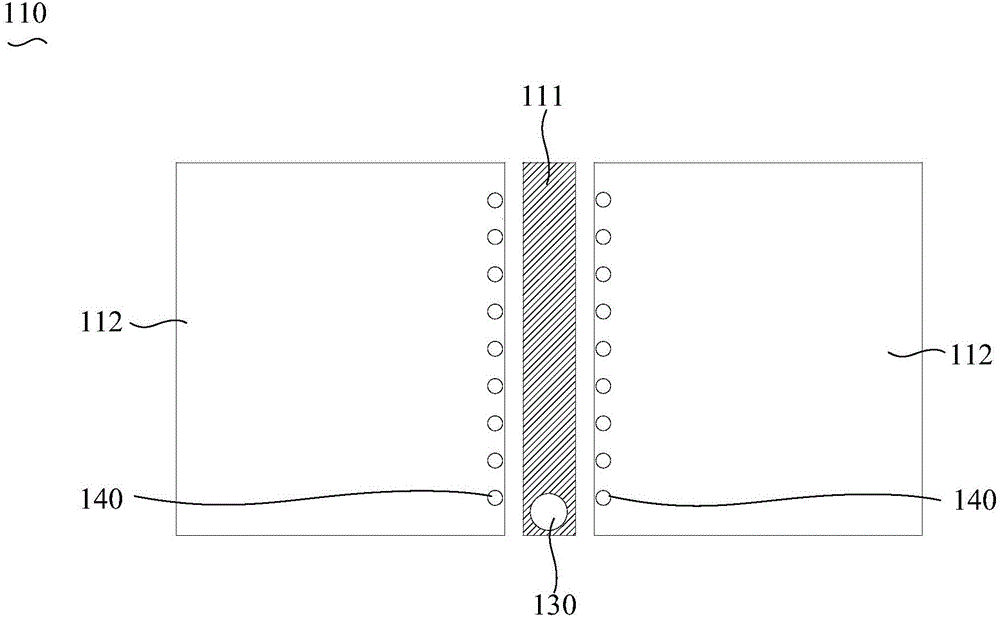

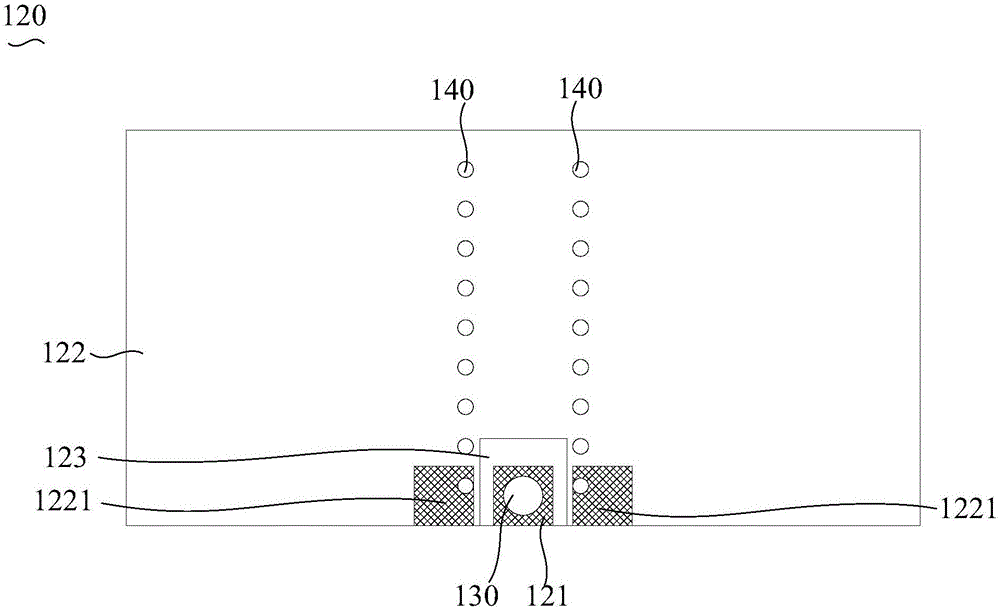

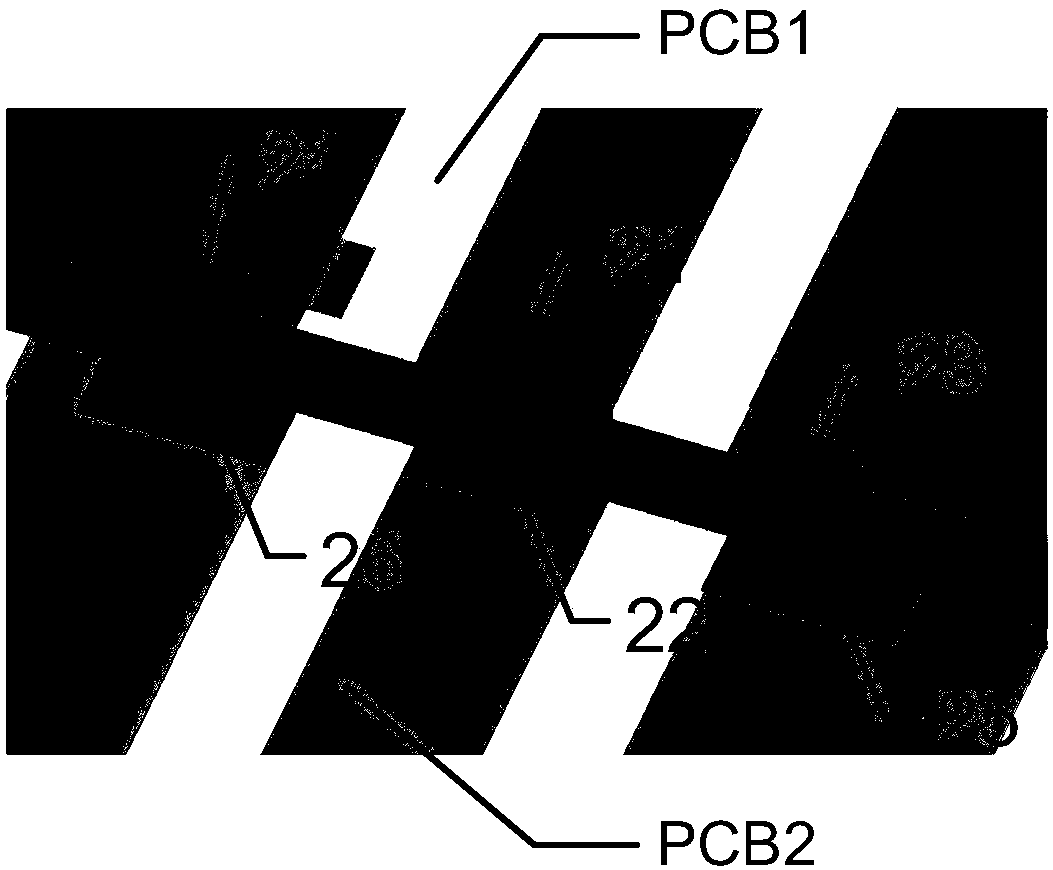

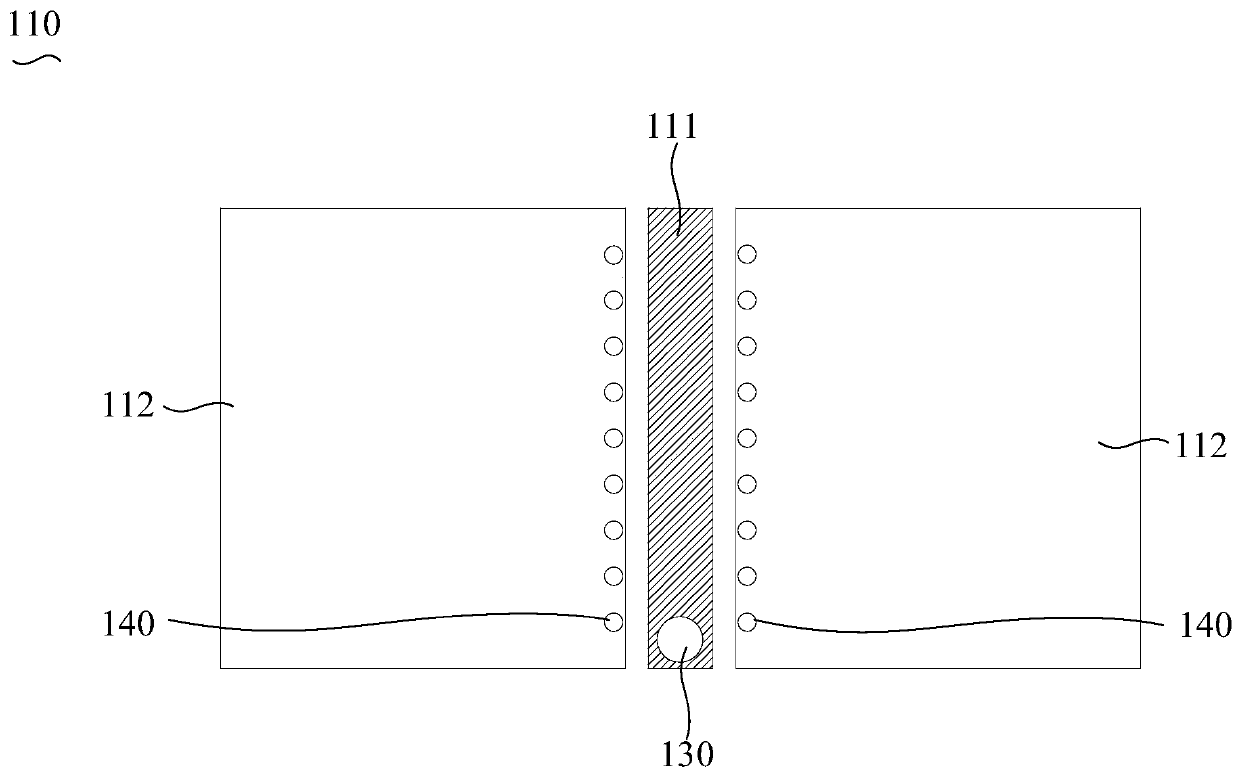

Radio frequency PCB connecting structure and connecting method

ActiveCN106211570ATo achieve signal connectivitySignal connectivity satisfiesStacked PCBsElectrical connection printed elementsEngineeringRadio frequency circuits

The invention discloses a radio frequency PCB connecting structure and connecting method. The radio frequency PCB connecting structure comprises a first PCB and a second PCB. The first PCB is arranged above the second PCB, a first radio-frequency circuit is arranged on the top layer of the first PCB, a first signal welding disc is arranged on the bottom layer of the first PCB, and the first radio-frequency circuit is electrically connected with the first signal welding disc through a signal through hole; a second radio-frequency circuit is arranged on the top layer of the second PCB, a second signal welding disc corresponding to the first signal welding disc is arranged on the second radio-frequency circuit, and the first signal welding disc and the second signal welding disc are welded. According to the radio frequency PCB connecting structure and connecting method, the first radio-frequency circuit is communicated with the first signal welding disc through the signal through hole, then the first signal welding disc and the second signal welding disc located on the second radio-frequency circuit are welded, and signal communication between the first radio-frequency circuit and the second radio-frequency circuit is achieved.

Owner:COMBA TELECOM SYST CHINA LTD

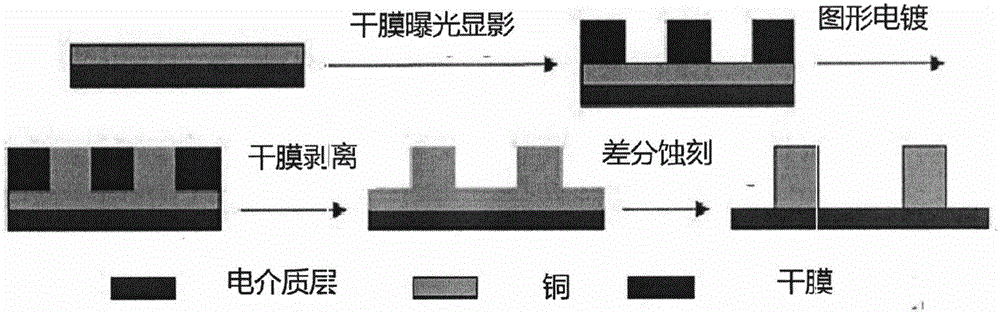

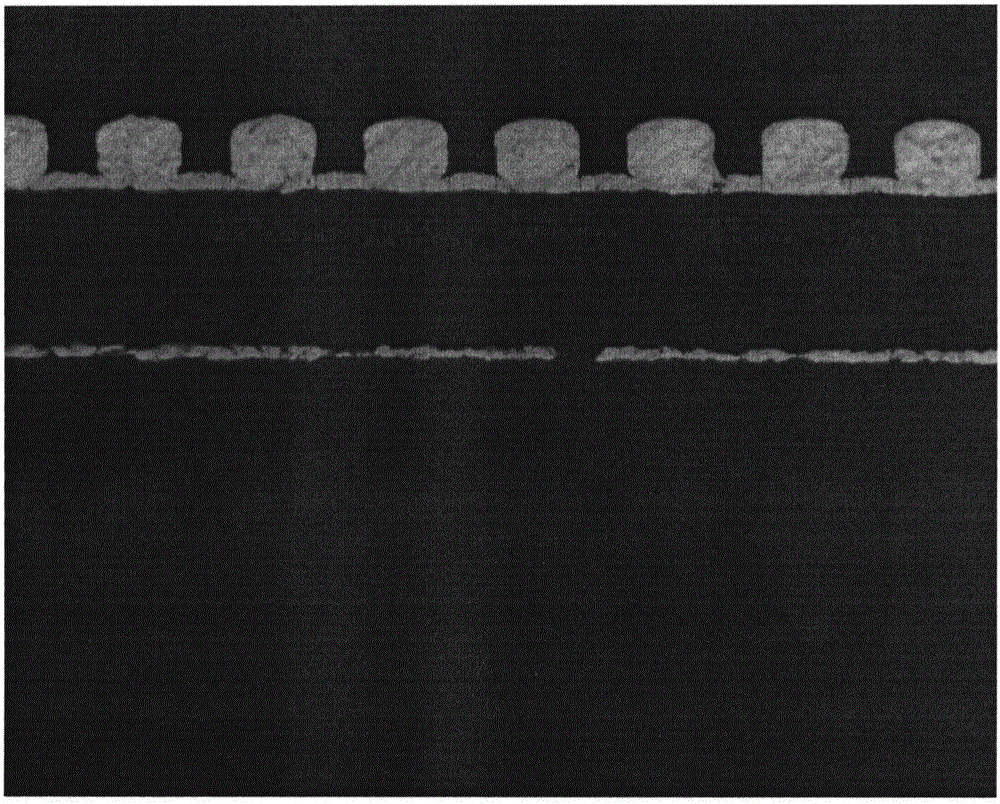

Difference etching solution for semi-additive process preparation fine line

InactiveCN105848421ANo pollution in the processImprove side erosion effectConductive material chemical/electrolytical removalFine lineEtching

The present invention provides a difference etching solution for a semi-additive process preparation fine line. The difference etching solution comprises two parts: basic solution and difference etching additive, wherein the basic solution is vitriol and hydrogen peroxide, and the difference etching additive includes a hydrogen peroxide stabilizer, a flat etchant protective agent, a gloss agent and a roughness control agent. Compared with the prior art, the difference etching solution for semi-additive process preparation fine line is able to effectively remove the base copper and effectively reduce the lateral erosion. The difference etching solution for a semi-additive process preparation fine line employs a lateral erosion protective agent so as to greatly reduce the generation of Undercut, improve the line yield rate, effectively protect the line corner angle and maintain the rectangular morphology of the line cross section; and the difference etching solution for the semi-additive process preparation fine line employs additives such as a microetching detergent, a roughness control agent and the like so as to perform further control of the line microscopic morphology of the line after difference etching, obtain visual sense shine and cleaning and facilitate subsequent process connection because of the roughness of 0.2-0.5[Mu]m in the microscopic scale.

Owner:杭州乐芙新材料科技有限公司

High speed, high density electrical connector

ActiveUS20140335735A1Smooth connectionEnhanced couplingCoupling contact membersTwo-part coupling devicesElectricityElectrical conductor

Owner:AMPHENOL CORP

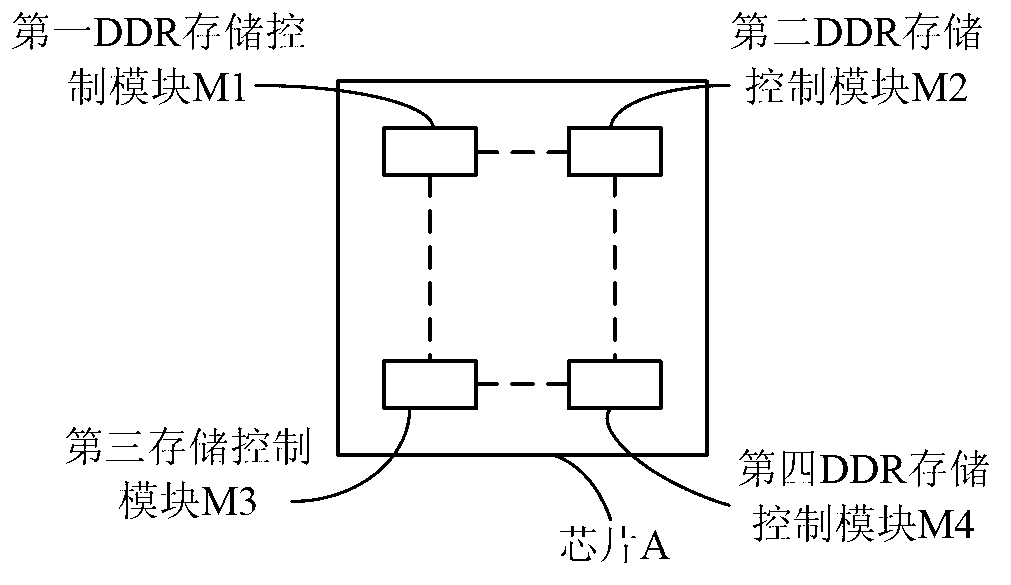

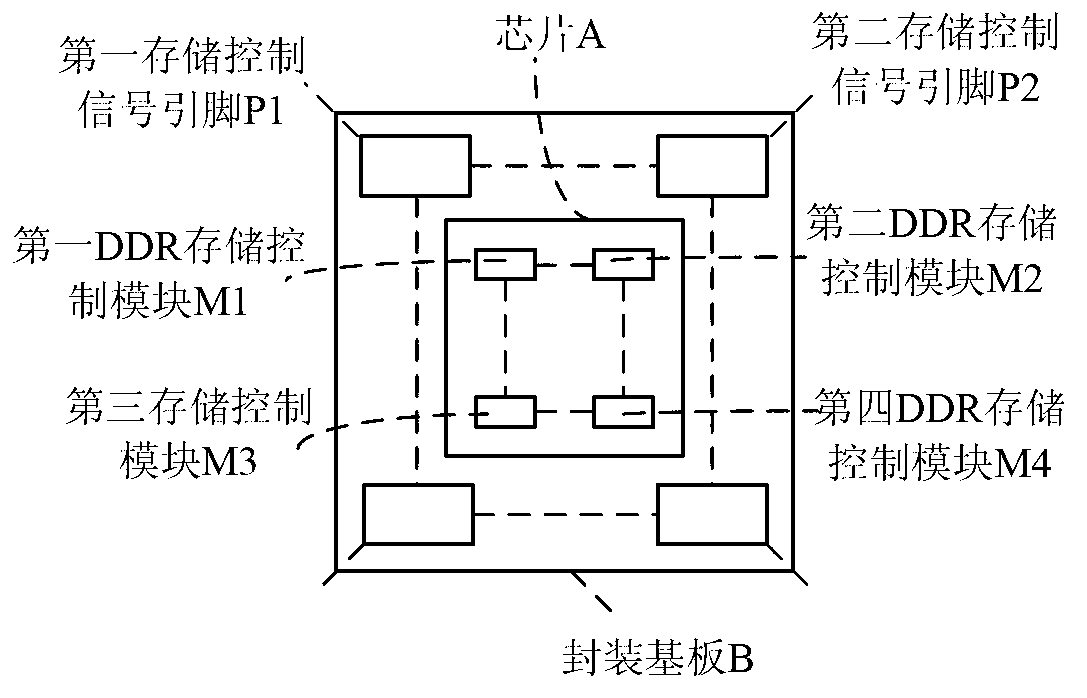

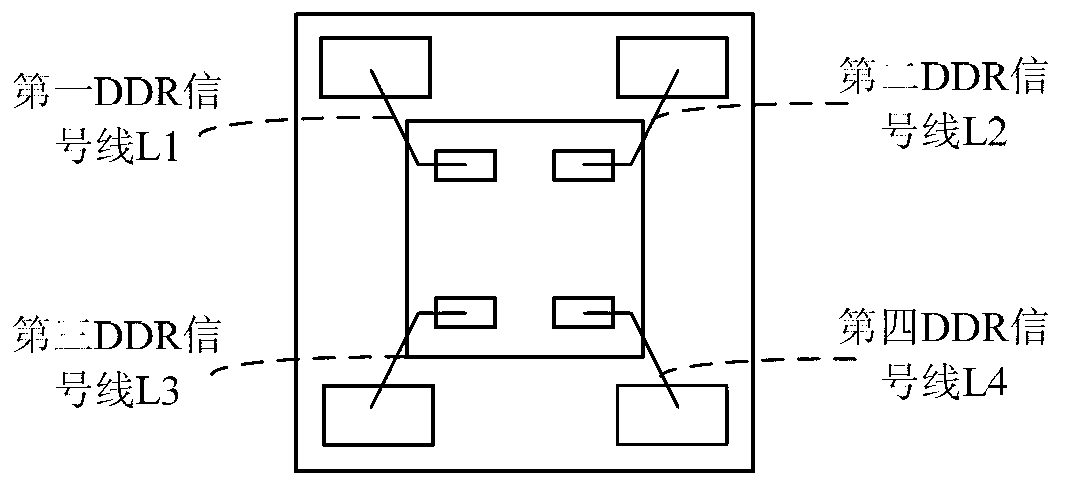

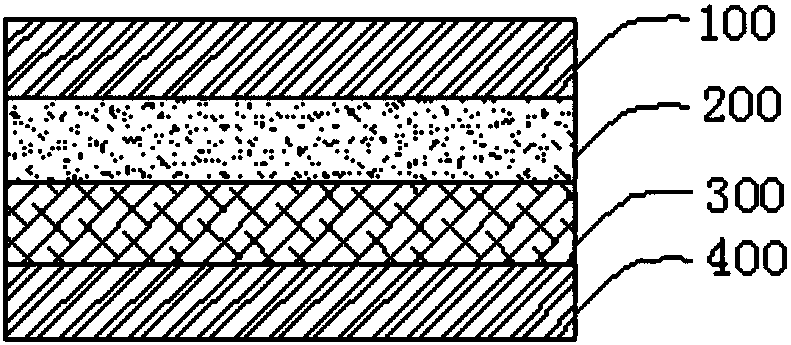

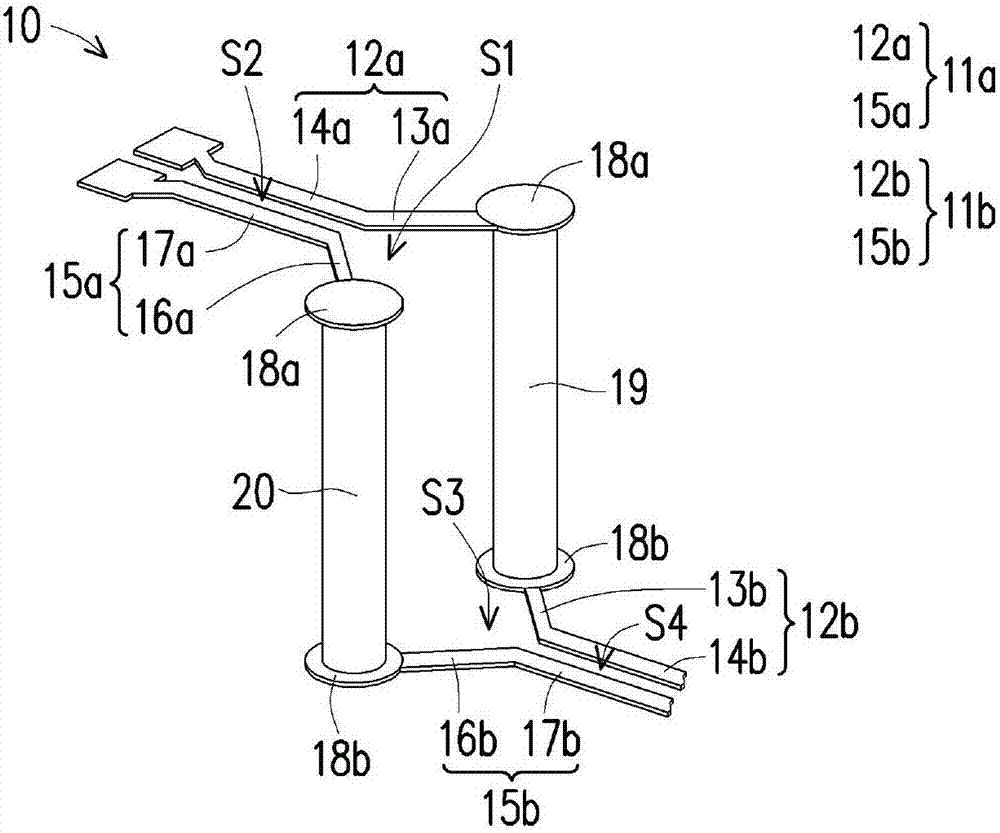

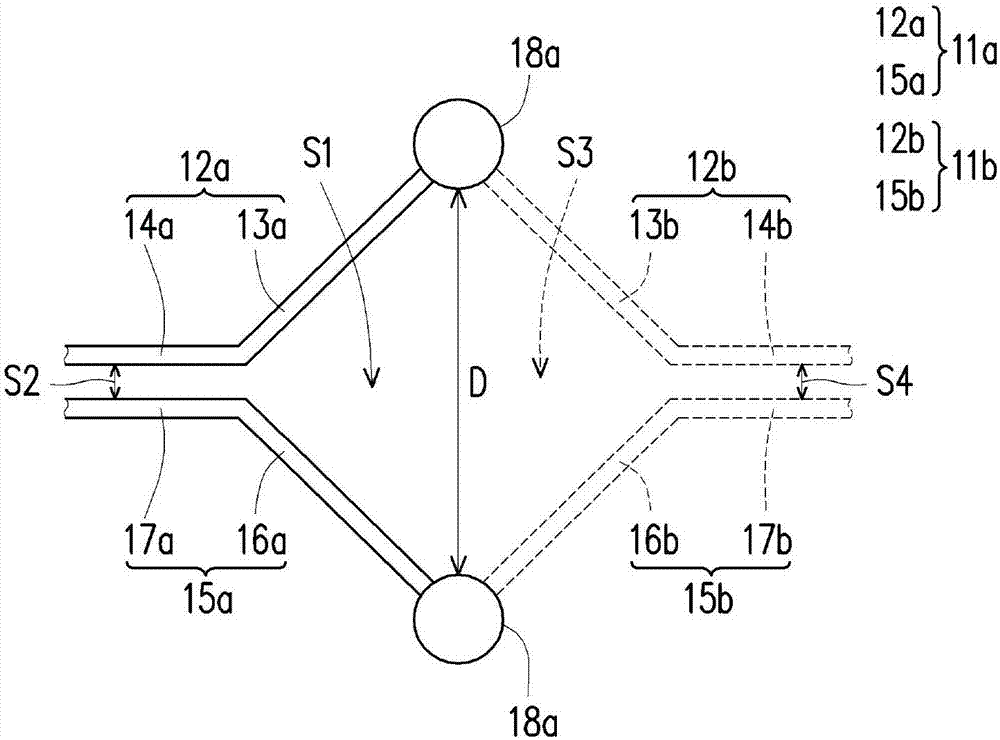

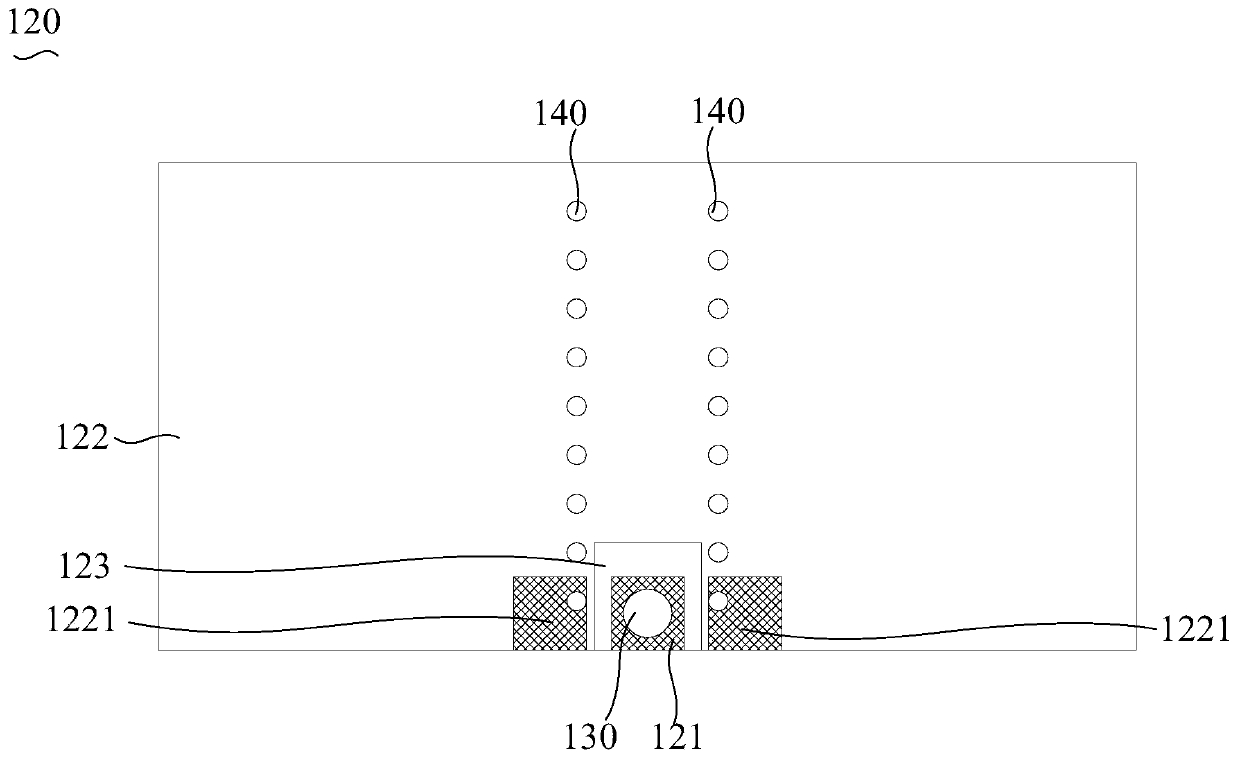

Double data rate (DDR) signal wiring encapsulation substrate and DDR signal wiring encapsulation method

ActiveCN102800644AReduce complexityShorten return current pathSemiconductor/solid-state device detailsSolid-state devicesDouble data rateControl signal

The invention provides a double data rate (DDR) signal wiring encapsulation substrate and a DDR signal wiring encapsulation method. A plurality of DDR storage control modules are symmetrically arranged on a chip. A plurality of storage control signal pins corresponding to the DDR storage control module are symmetrically arranged in the area outside the chip. A plurality of DDR signal wires which are symmetrically distributed are used for respectively and correspondently joining one of the DDR storage control modules to one of the storage control signal pins. The DDR signal wiring encapsulation substrate comprises a ground plane layer, a first medium layer, a DDR signal layer, a second medium layer and a DDR interface power supply plane layer; and the DDR interface power supply plane layer and the ground plane layer are simultaneously selected as a reference plane layer of a DDR signal. The DDR storage control modules are respectively and correspondently connected to the storage control signal pins through a plurality of DDR signal holes which are symmetrically distributed. A plurality of ground holes are correspondently and symmetrically distributed referring to the positions of the DDR signal holes.

Owner:JIANGNAN INST OF COMPUTING TECH

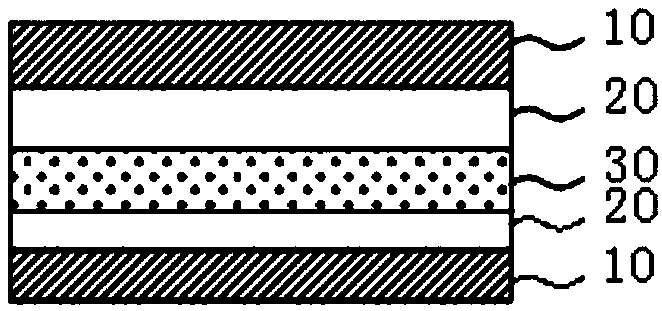

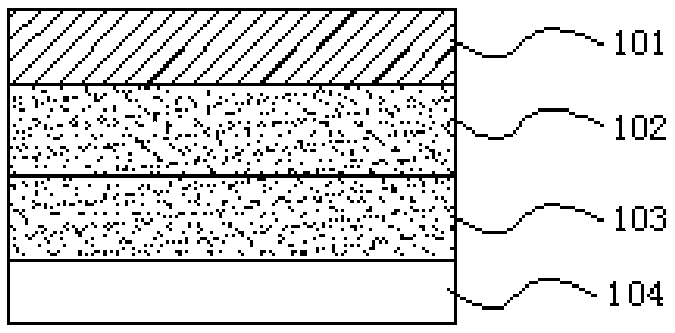

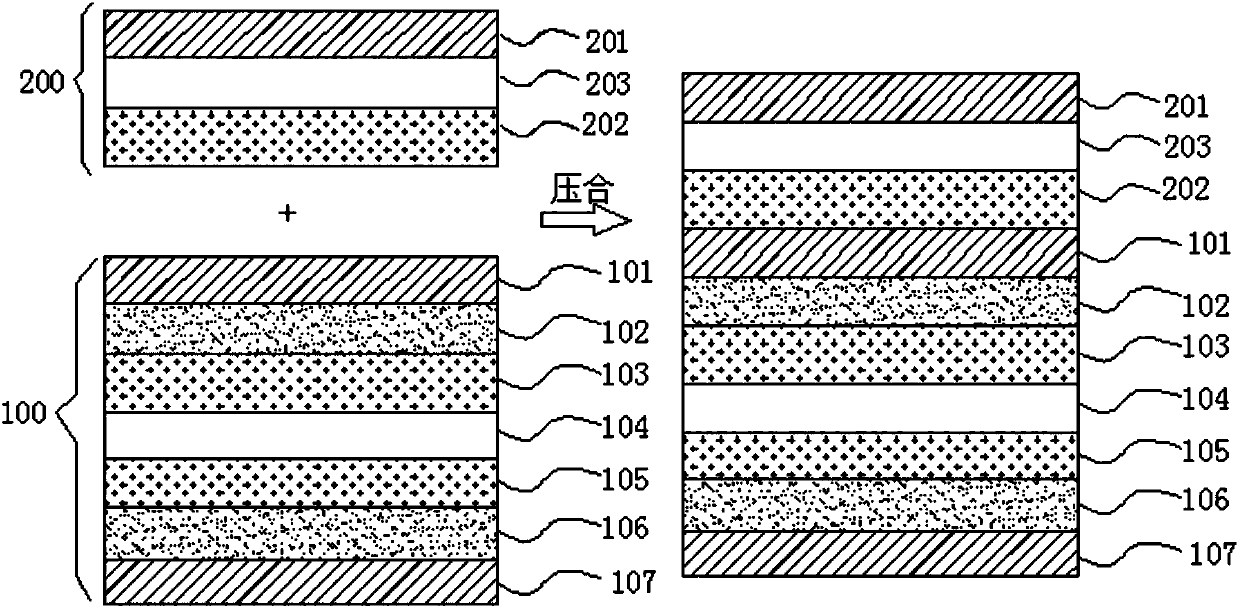

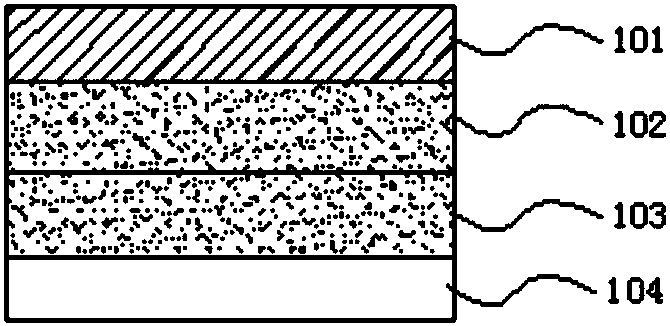

Compound type LCP (Liquid-Crystal Polymer) high-frequency high-speed double-sided copper foil substrate and preparation method thereof

ActiveCN108859316ALow and stable Dk/Df performanceReduce skin effectLamination ancillary operationsDielectric materialsCopper foilAbsorption rate

The invention discloses a compound type LCP (Liquid-Crystal Polymer) high-frequency high-speed double-sided copper foil substrate. The compound type LCP high-frequency high-speed double-sided copper foil substrate comprises one or more LCP core layer, one or more extremely-low dielectric adhesive layer and two copper foil layers, the LCP core layer and the extremely-low dielectric adhesive layer are arranged between the two copper foil layers, wherein the thickness of the each LCP core layer is 5 to 50 micronmeters; the thickness of the each extremely-low dielectric adhesive layer is 2 to 50 micrometers; the thickness of the each copper foil layer is 1 to 35 micrometers, the extremely-low dielectric adhesive layers are adhesive layers of which Dk values are 2.0 to 3.0 (10GHz) and Df valuesare 0.002 to 0.010 (10GHz). The compound type LCP high-frequency high-speed double-sided copper foil substrate disclosed by the invention has the advantages of good electricity, low roughness, stabledk / df performance under a high-temperature moisture environment, ultra-low water absorption rate, good UV laser drilling ability, low rebounding force for high-density assembly and excellent mechanical performance; in addition, based on a current coating technology, the coating thickness of about 50 micrometers at most only can be required. According to the preparation method disclosed by the invention, the substrate, of which the thickness is 100 micrometers or above, can be easily obtained.

Owner:KUSN APLUS TEC CORP

Multi-layer circuit structure

ActiveCN107222970AImproved Impedance ControlReduced Impedance DiscontinuitiesPrinted circuit detailsPrinted circuit aspectsTransmission lineEngineering

The invention discloses a multi-layer circuit structure which includes a differential transmission line pair and at least one conductive pattern. The differential transmission line pair includes first and second transmission lines disposed side by side. Each of the first and second transmission lines includes first and second segments connected to each other. An spacing between the two first segments is non-fixed, and an spacing between the two second segments is fixed. A first zone is located between the two first segments, a second zone is opposite to the first zone and located outside the first segment of the first transmission line, and a third zone is opposite to the first zone and located outside the first segment of the second transmission line. The conductive pattern is coplanar with the differential transmission line pair and disposed on at least one of the first, second and third zones. The conductive pattern is electrically connected to a reference potential and electrically insulated from the differential transmission line pair.

Owner:IND TECH RES INST +2

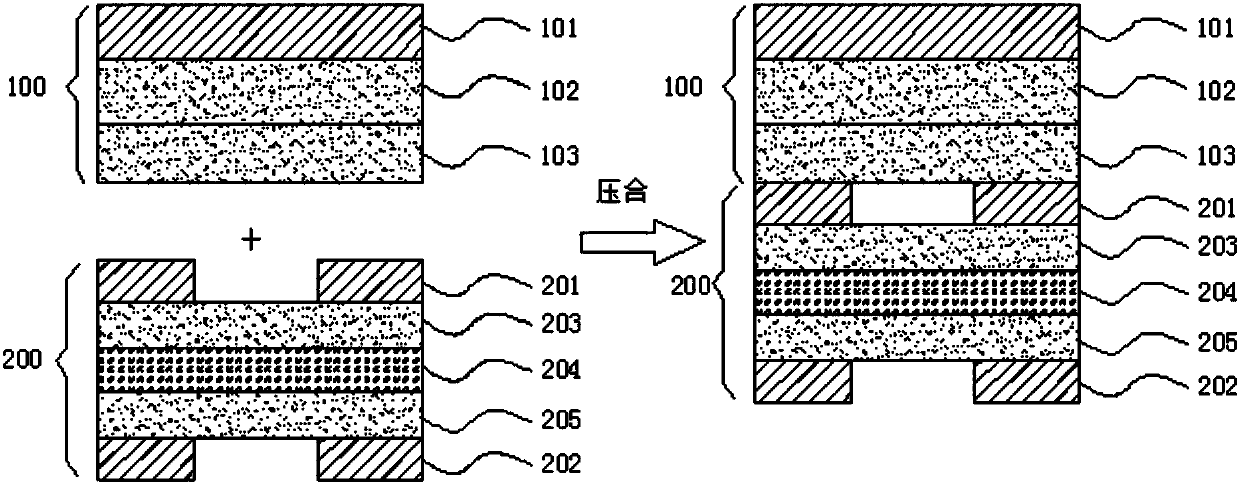

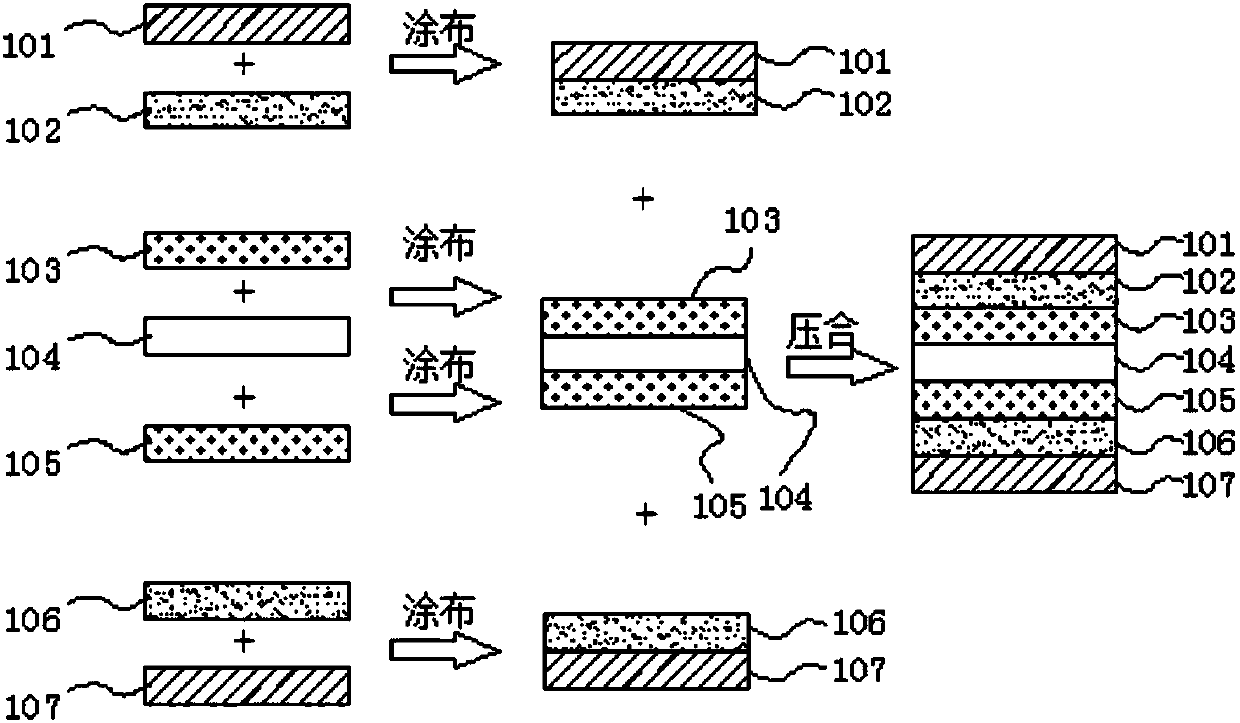

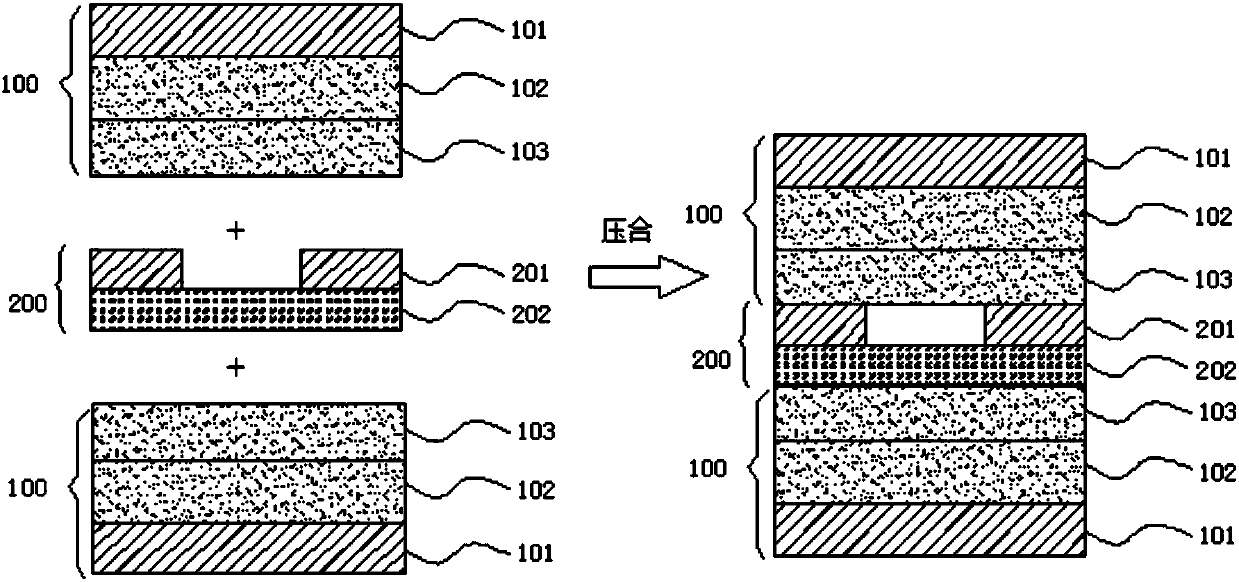

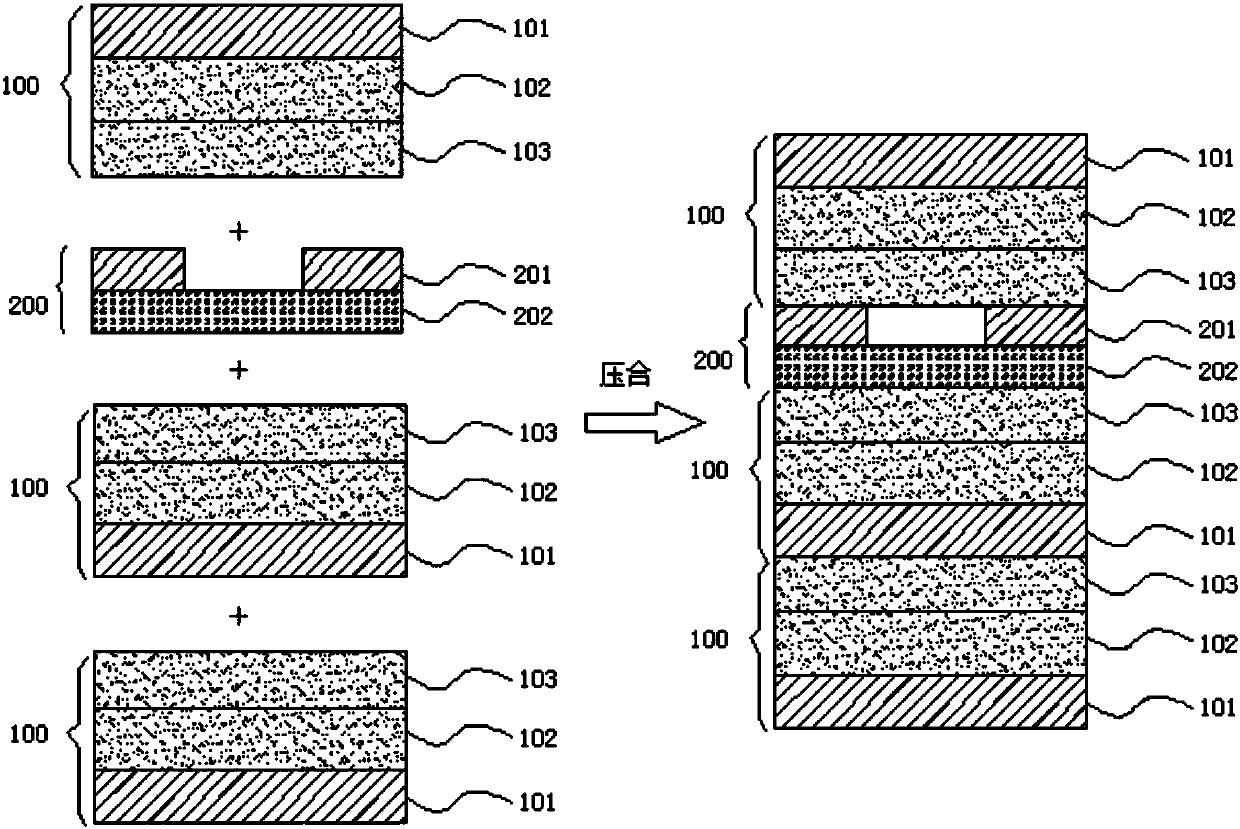

FPC multilayer board based on high-frequency FRCC and high-frequency double-sided board and manufacturing process thereof

PendingCN110366330AConditions that are not easy to retractLaser drilling process is easy to implementCircuit susbtrate materialsMultilayer circuit manufacturePressure transmissionManufacturing technology

The invention discloses an FPC (Flexible Printed Circuit) multilayer board based on a high-frequency FRCC and a high-frequency double-sided board. The FPC multilayer board comprises at least one FRCCand at least one double-sided board, wherein the FRCC and the double-sided board are pressed together; the FRCC comprises a first copper foil layer, a first low dielectric glue layer and a second lowdielectric glue layer; the double-sided board is at least one of a PI type double-sided board and an LCP type double-sided board. According to the invention, the FRCC without the LCP layer is matchedwith the high-frequency PI type double-sided board or the LCP type double-sided board to manufacture a three-layer to six-layer FPC, the process flow for manufacturing the FPC is simple, the laser drilling process is better, the situation of retraction is not easy to occur, the FPC has lower hygroscopicity and lower Dk and Df electrical properties, fast press equipment or pressure transmission equipment can be matched, the FPC has the cost advantage, the thick film manufacturing technology is provided, and meanwhile, the FRCC with the simpler interface and the lower cost is used in the FPC multilayer board structure based on the high-frequency FRCC and the high-frequency double-sided board.

Owner:KUSN APLUS TEC CORP

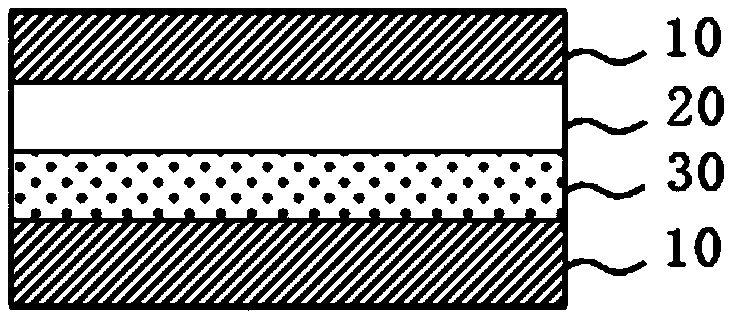

Composite fluorine polymer high-frequency high-transmission dual-side copper foil substrate and fabrication method thereof

PendingCN110062520ALow dielectric constantLow dielectric lossLiquid surface applicatorsDielectric materialsUv laserInsulation layer

The invention discloses a composite fluorine polymer high-frequency high-transmission dual-side copper foil substrate and a fabrication method thereof. The dual-side copper foil substrate sequentiallycomprises a first copper foil layer, a first insulation polymer layer, a first extremely-low dielectric glue layer, a core layer, a second extremely-low dielectric glue layer, a second insulation polymer layer and a second copper foil layer from top to bottom, wherein the first insulation polymer layer and the second insulation polymer layer both are fluorine polymer layers, the first insulationpolymer layer and the second insulation polymer layer both are insulation layers with Dk values being 2.0-3.50 and Df values being 0.0002-0.001, and the first copper foil layer and the second copper foil layer both are low-profile copper foil layers with Rz values being 0.1-1.6 micrometers. The dual-side copper foil substrate and an FPC have favorable electricity and also have the advantages of cost, relatively short processing flow, low thermal expansion coefficient, stable dk / df performance under a high-temperature humidity environment, ultralow water absorption rate, favorable UV laser drilling capability, low elastic force, high-density assembly and excellent mechanical property.

Owner:KUSN APLUS TEC CORP

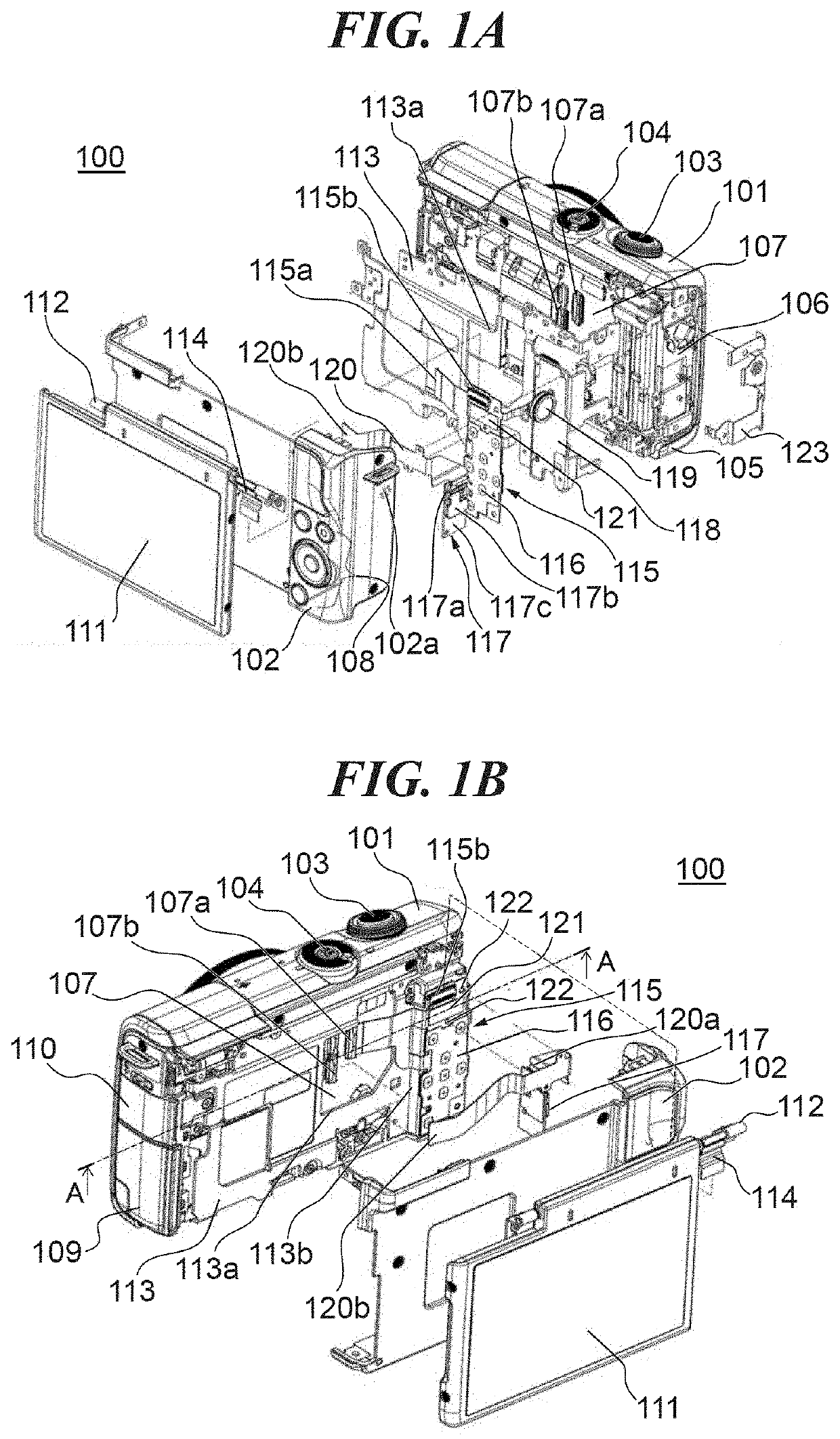

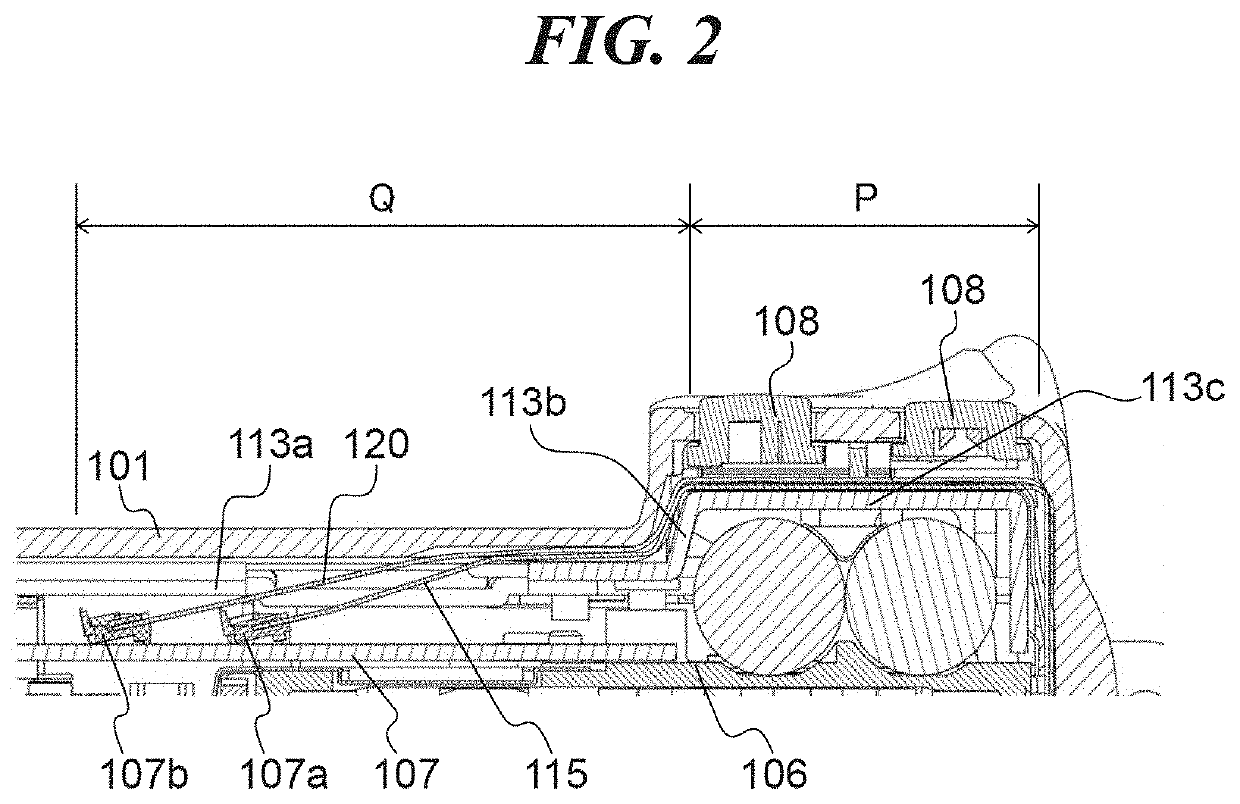

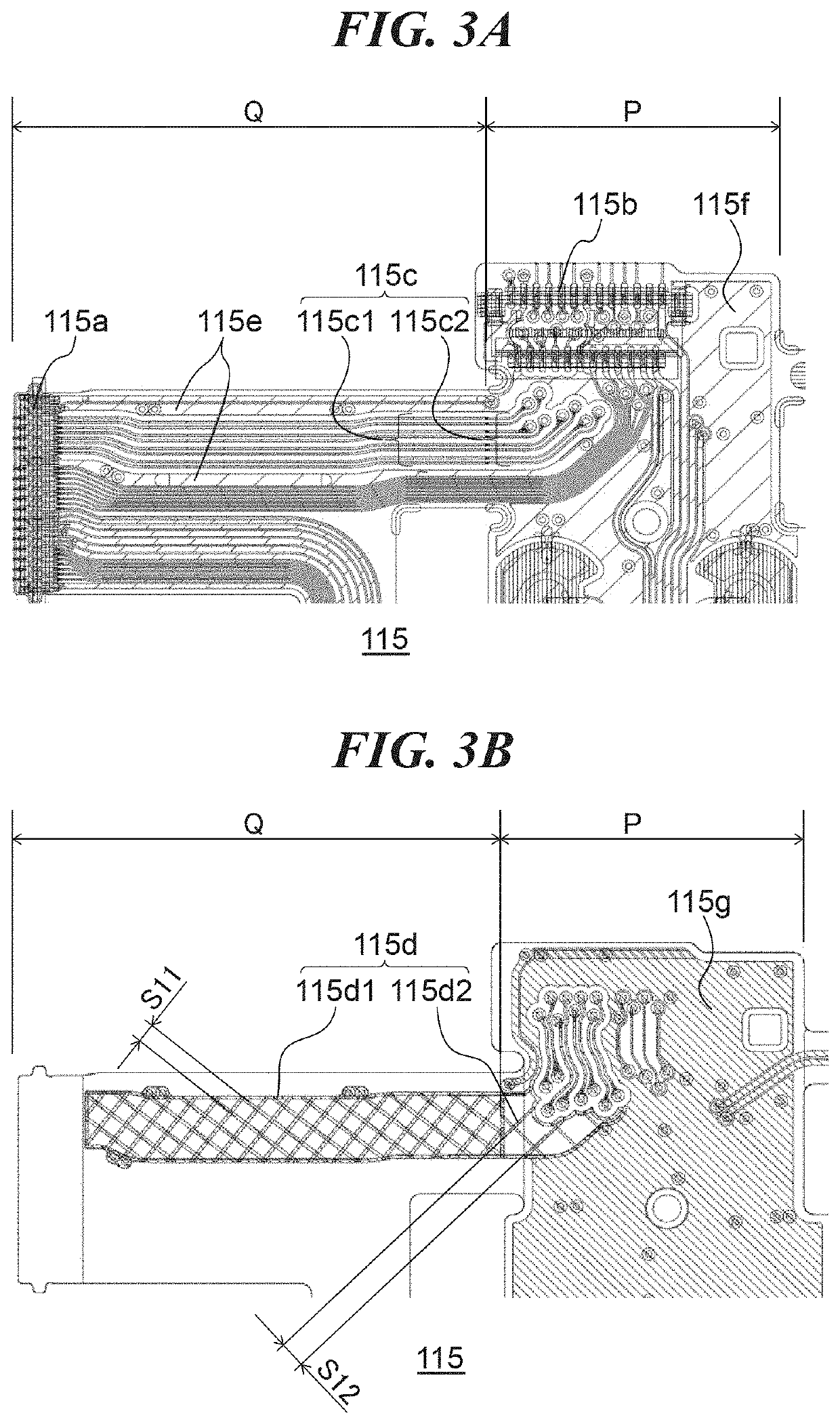

Electronic apparatus equipped with flexible boards

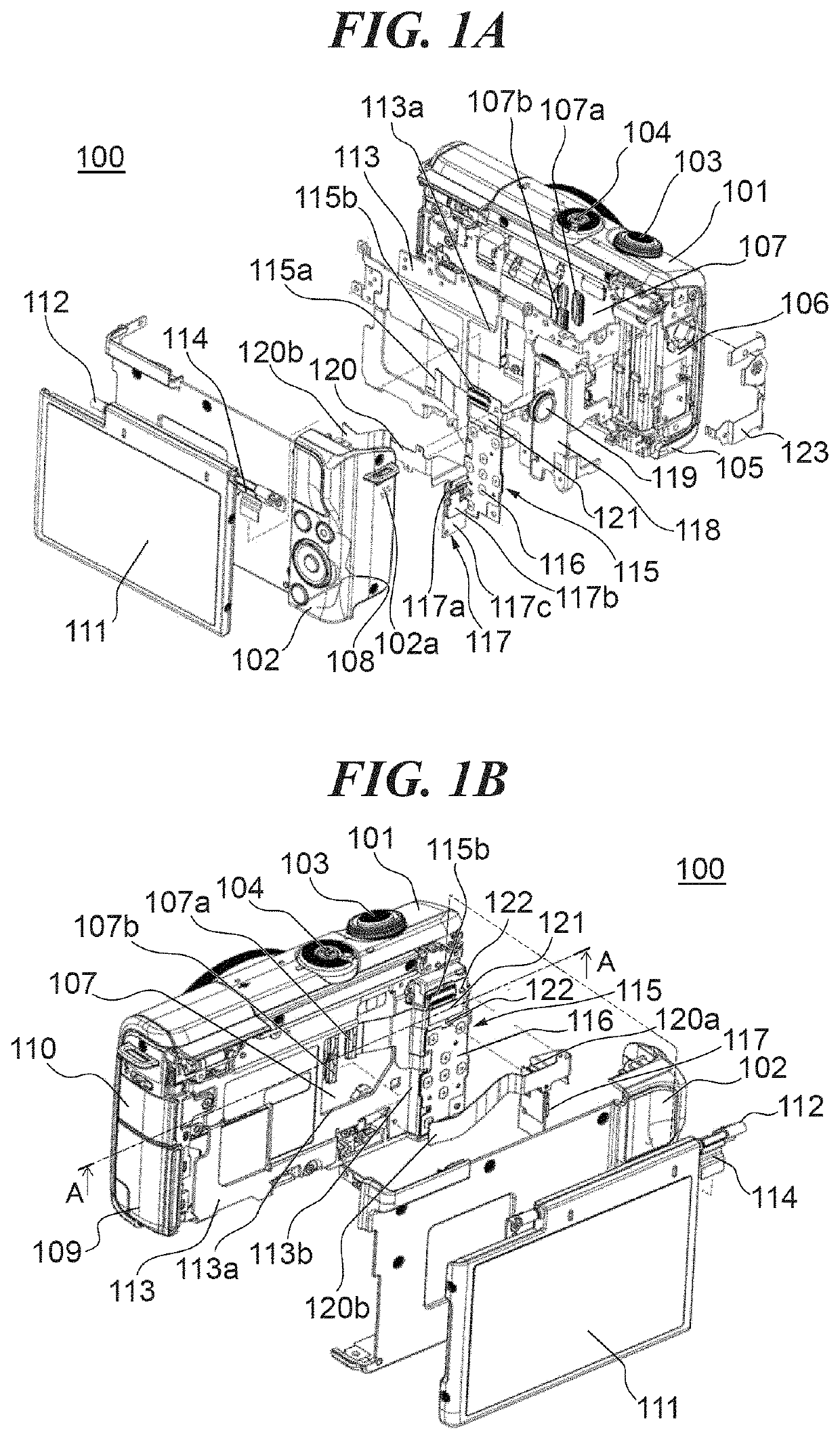

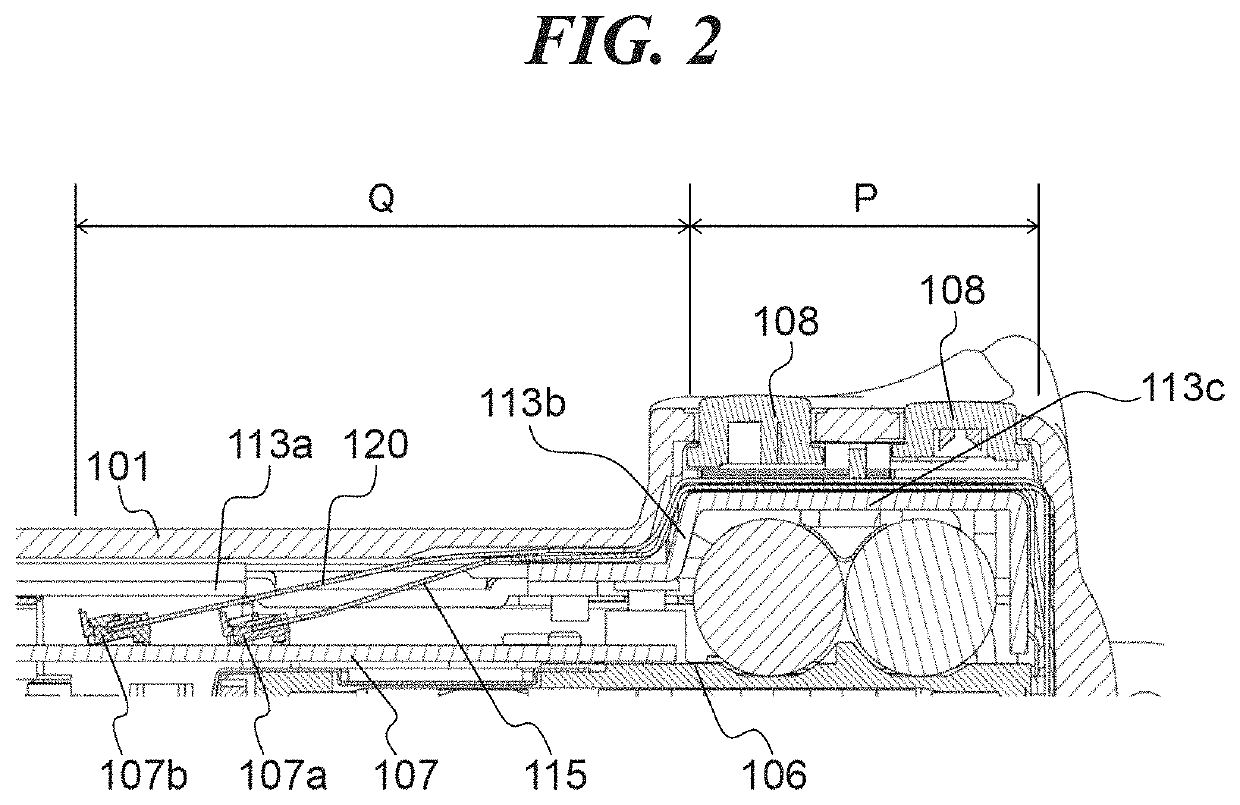

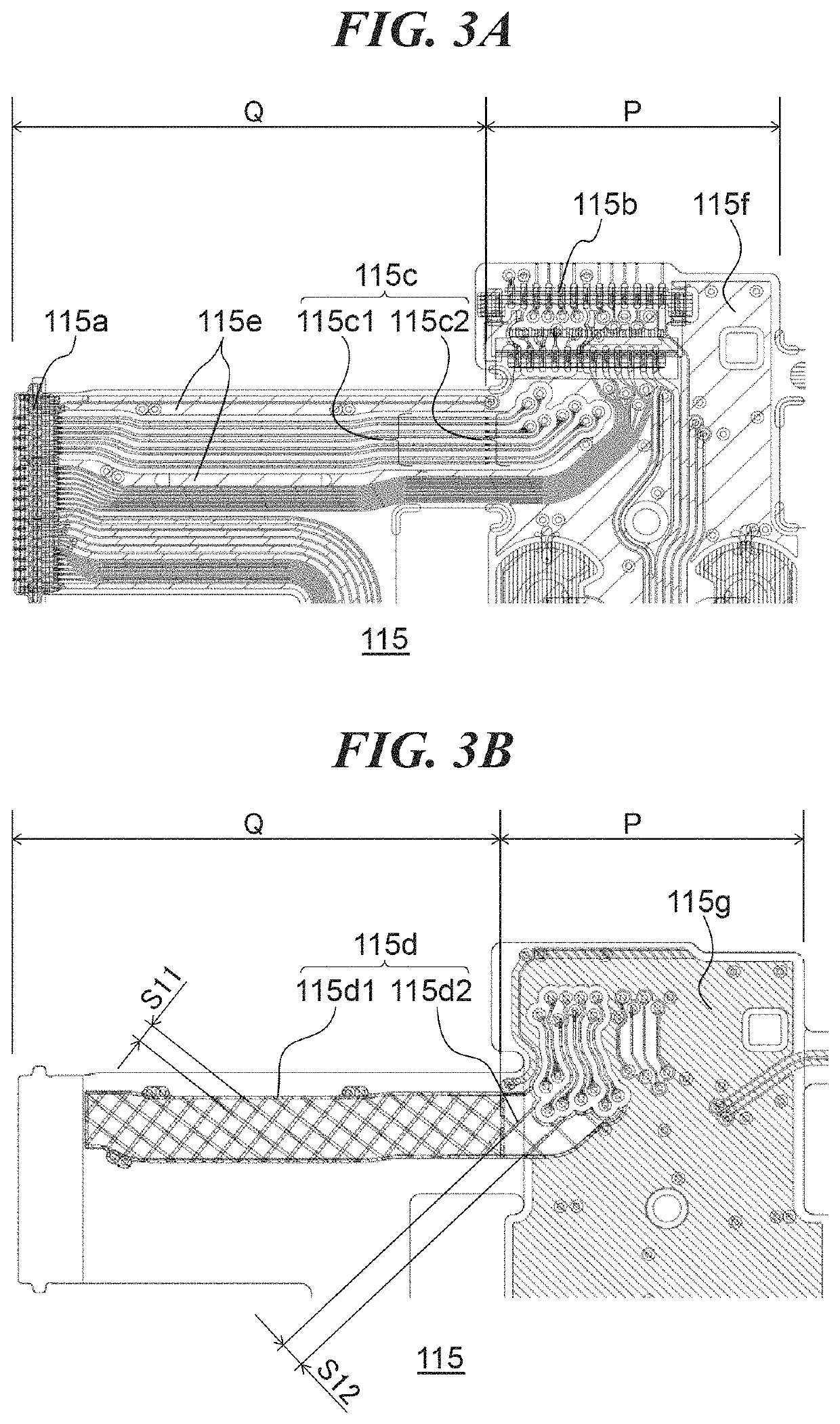

ActiveUS20200344871A1Ease of incorporating a flexible boardImproved Impedance ControlTelevision system detailsCross-talk/noise/interference reductionEngineeringStructural engineering

An electronic apparatus which achieves ease of incorporating flexible boards into the electronic apparatus and ease of impedance control at the same time. A first flexible board and a second flexible board are placed along a structure having a bent portion and a flat portion. Differential signal wires are wired on one surface of the first flexible board placed between the structure and the second flexible board, and first ground wires for impedance control of the differential signal wires are wired on the other surface and on a rear side of the differential signal wires. Second ground wires for impedance control of the differential signal wires are wired on one surface of the second flexible board the one surface of the first flexible board faces. A wiring density of the first and second ground wires differs between an area along the bent portion and an area along the flat portion.

Owner:CANON KK

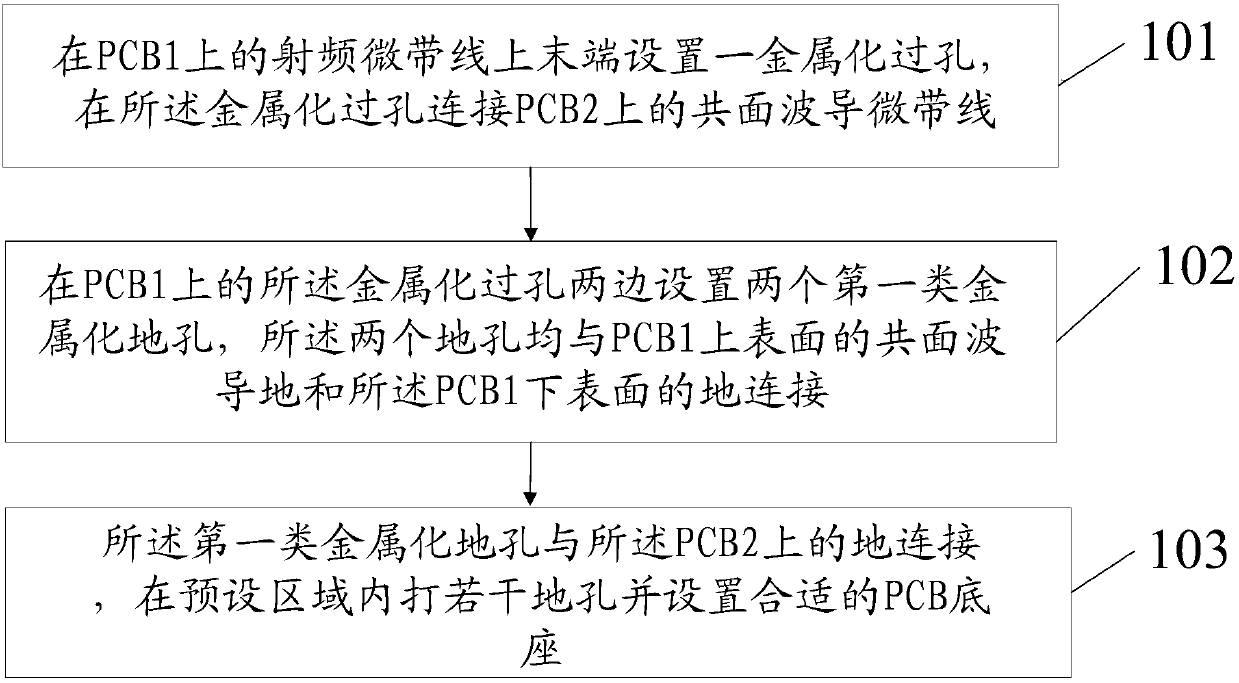

Connection method and connection structure of radio frequency PCB

PendingCN107949154ALow costImproved Impedance ControlCross-talk/noise/interference reductionPrinted circuit aspectsRadio frequencyStanding wave

The present invention proposes a connection method and a connection structure of a radio frequency PCB. A metalized via of the appropriate size is designed at the end of a PCB1 radio frequency microstrip line. One end of the metalized via is connected to the end of a radio frequency microstrip transmission line on the PCB1, and the other end is connected to a first signal pad on the lower surfaceof the PCB1. There is also a second signal pad on a PCB2 at a position corresponding to the first signal pad of the PCB1. The PCB1 and the PCB2 are soldered together by two pads. Both the PCB1 and PCB2 on both sides of a radio frequency microstrip via are provided with ground pads soldered together. With the technical scheme of the present invention, the two connected PCBs can be grounded with good standing wave, and the beneficial effect of small insertion loss can be achieved.

Owner:COMBA TELECOM SYST CHINA LTD

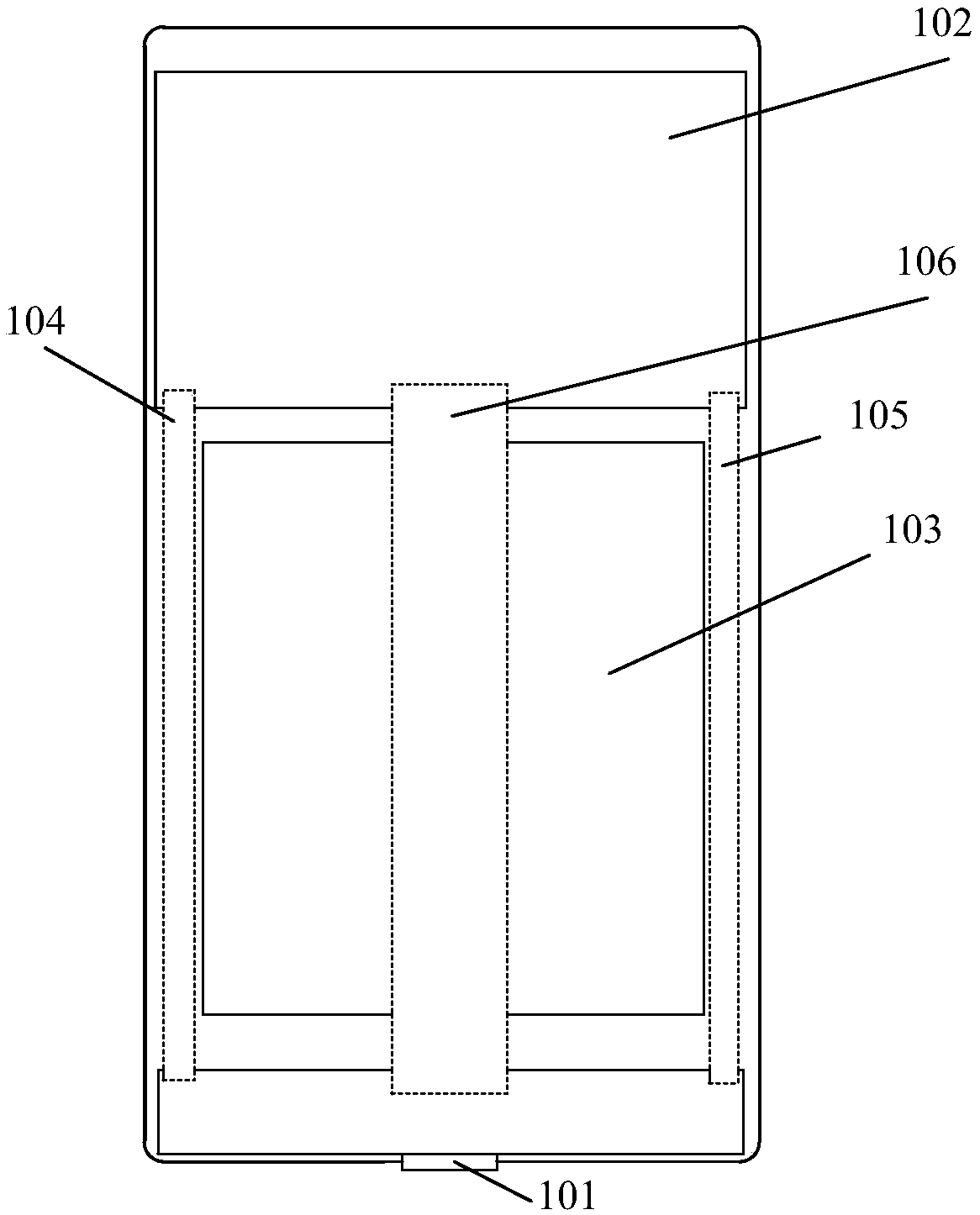

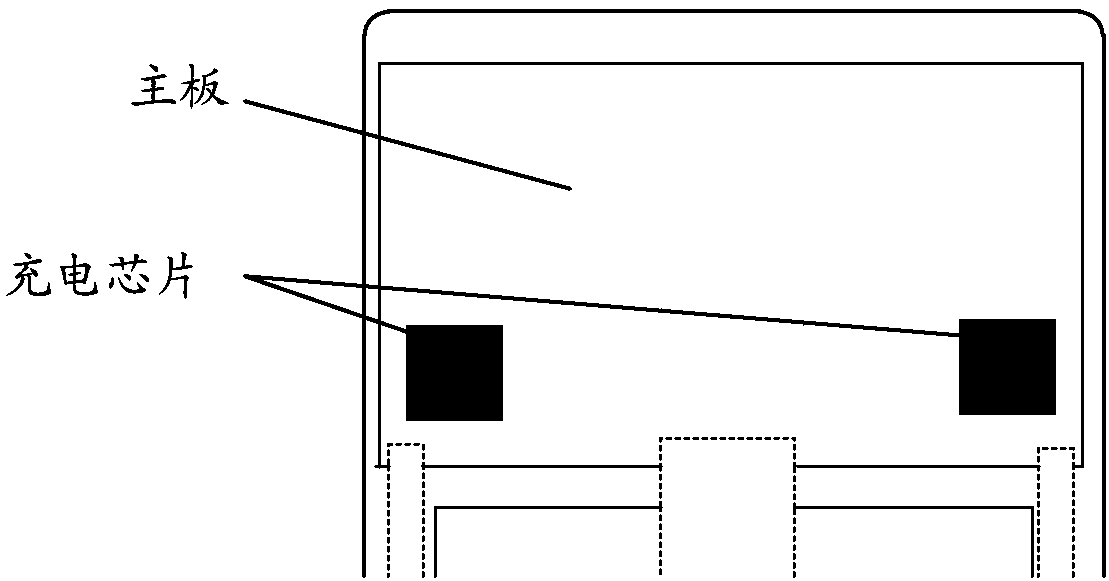

Charging circuit and charging method thereof

InactiveCN108695914AReduce dispersion densityAvoid heatingBatteries data exchangeElectric powerElectrical batteryUSB

The embodiments of the invention disclose a charging circuit. The charging circuit is characterized in that the circuit comprises a universal serial bus (USB) interface, a main board, a battery, a first charging line for transmitting current, a second charging line for transmitting current, and a signal line for transmitting data signals; the USB interface is connected with the first end of the first charging line, the first end of the second charging line, and the first end of the third signal line; the second end of the first charging line and the second end of the second charging line are connected with the battery through the main board; and the second end of the signal line is connected with the main board. The embodiments of the present invention also provide a charging method of theabove charging circuit.

Owner:ZTE CORP

Composite high-frequency substrate with characteristics of high Dk and low Df and preparation method thereof

PendingCN110662348AImprove insulation performanceHigh dimensional stabilityCircuit susbtrate materialsDielectricManufacturing technology

The invention discloses a composite high-frequency substrate with the characteristics of high Dk and low Df. The high-frequency substrate comprises a first copper foil layer and a core layer; the corelayer comprises a plurality of high-molecular polymer film layers and a plurality of dielectric adhesive layers; the dielectric adhesive layer comprises at least one of a first dielectric adhesive layer and a second dielectric adhesive layer; the first dielectric adhesive layer is an adhesive layer with a Dk value of 6-30 and a Df value of 0.002-0.020, the second dielectric adhesive layer is an adhesive layer with a Dk value of 15-100 and a Df value of 0.002-0.020, and the Dk value of the second dielectric adhesive layer is greater than the Dk value of the first dielectric adhesive layer; andthe core layer refers to a core layer with a Dk value of 6-50 and a Df value of 0.002-0.020. The laser drilling technology is better, the inward shrinkage condition is not likely to happen, the hygroscopicity is low, the insulativity is high, the size stability is high, the thermal stability is excellent, and the high Dk and low Df electrical property is better; normal press fit parameters can beused for being matched with quick press equipment or pressure transmission equipment, the cost advantage is achieved, and the thick film manufacturing technology is achieved.

Owner:KUSN APLUS TEC CORP

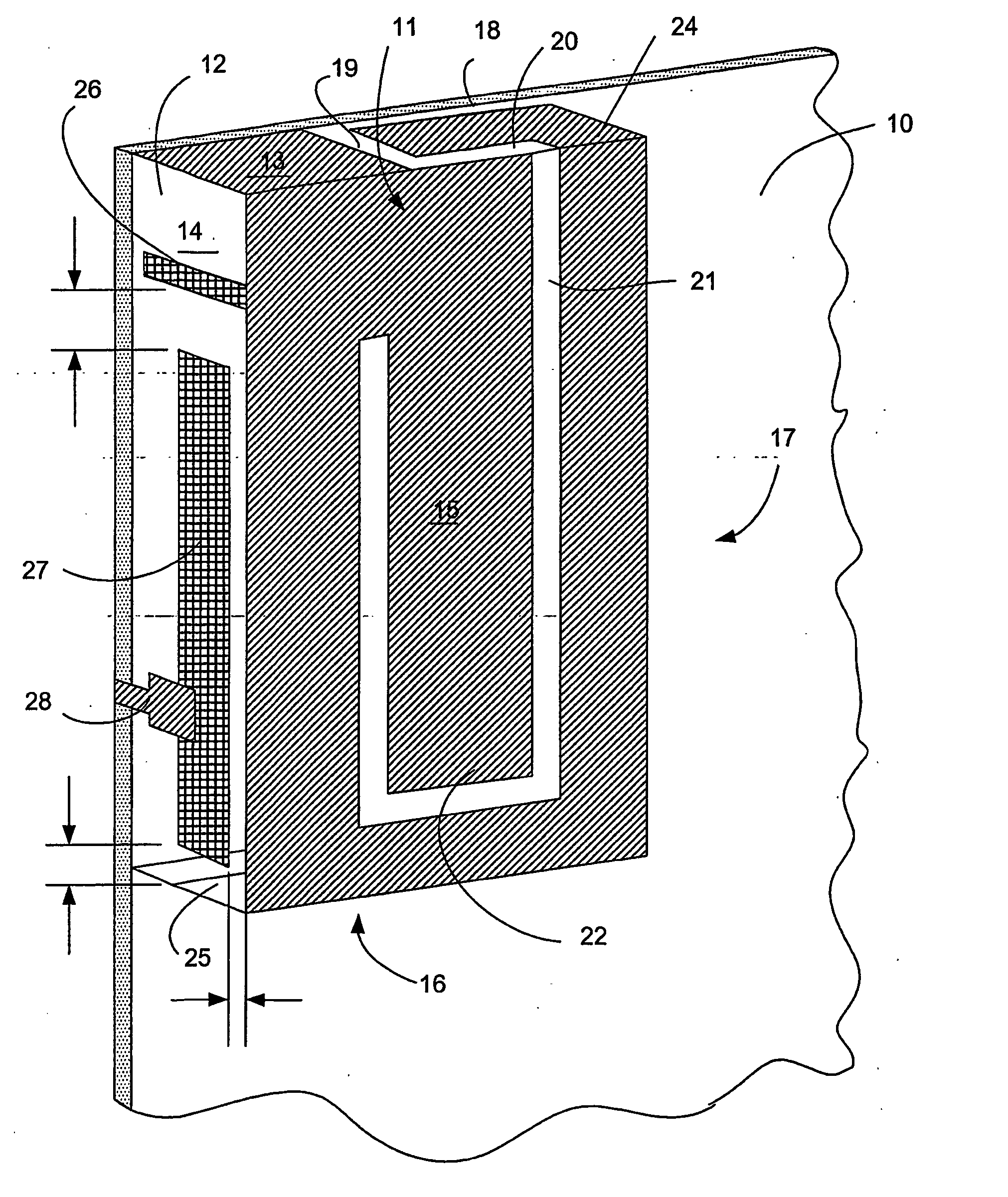

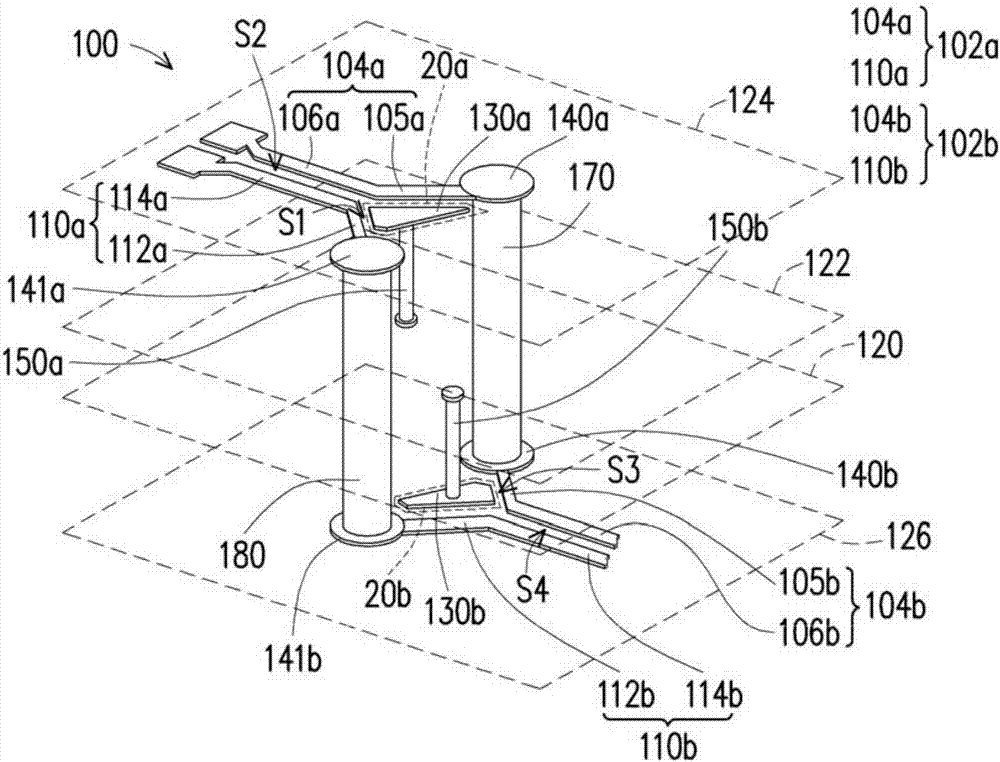

Power amplifier assembly comprising suspended strip lines

ActiveUS20140103997A1Excessive impedanceImproved Impedance ControlHigh frequency amplifiersPrinted circuit detailsAudio power amplifierElectrical conductor

It is presented a power amplifier assembly comprising; a radio frequency multi-order power amplifier comprising a circuit board; a grounding structure connected to the radio frequency multi-order power amplifier and comprising a recess; a combining network connected to a plurality of outputs of the radio frequency multi-order power amplifier. The combining network comprises: a plurality of input connection points, wherein each of the plurality of input connection points is connected to a respective output of the plurality of outputs of the radio frequency multi-order power amplifier; an output connection point; and a conductor arrangement comprising a plurality of conductive paths arranged between the plurality of input connection points and the output connection point; wherein at least one of the plurality of conductive paths is at least partly formed by a suspended conductor positioned in the recess of the grounding structure.

Owner:TELEFON AB LM ERICSSON (PUBL)

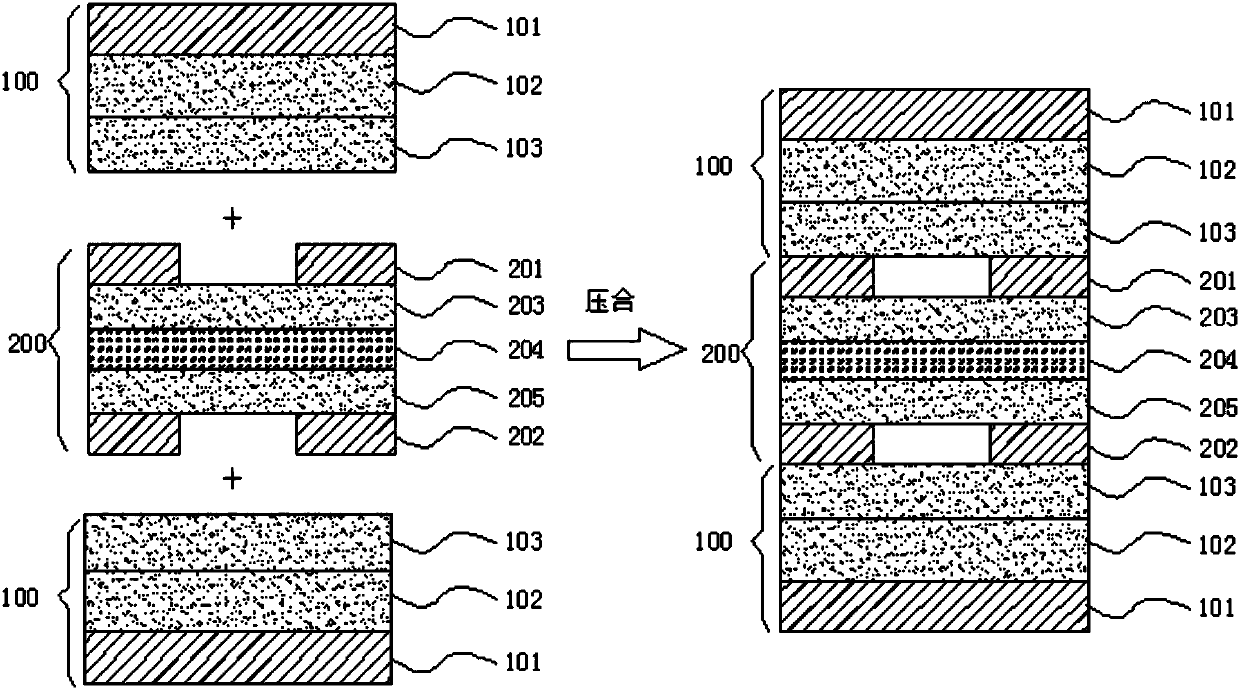

FPC based on high-frequency FRCC and FCCL single panel and manufacturing process thereof

PendingCN110366309AMaterial Interface ReductionLaser drilling process is easy to implementSynthetic resin layered productsLaminationManufacturing technologyCopper foil

The invention discloses an FPC (Flexible Printed Circuit) based on a high-frequency FRCC and an FCCL single panel. The FPC comprises at least one FRCC and at least one FCCL single panel, wherein the FRCC and the FCCL single panel are pressed together; the FRCC comprises a first copper foil layer, a first low dielectric glue layer and a second low dielectric glue layer; the FCCL single panel includes, in order, a second copper foil layer and an insulating polymer layer which is a polymer layer in a cured state. According to the invention, the FRCC without the LCP layer is matched with the high-frequency FCCL single panel to manufacture a three-layer or six-layer FPC, the process flow for manufacturing the FPC is simple, the laser drilling process is better, the situation of retraction is not easy to occur, the FPC has lower hygroscopicity and lower Dk and Df electrical properties, fast press equipment or pressure transfer equipment can be matched, the FPC has the cost advantage, the thick film manufacturing technology is provided, and meanwhile, the FRCC with the simpler interface and the lower cost is used in the FPC structure based on the high-frequency FRCC and the FCCL single panel.

Owner:KUSN APLUS TEC CORP

Double-sided copper foil substrate for pi-type high-frequency and high-speed transmission and preparation method thereof

ActiveCN108454192BLow and stable Dk/Df performanceHas skin effectLamination ancillary operationsSynthetic resin layered productsUv laserHigh density

Owner:KUSN APLUS TEC CORP

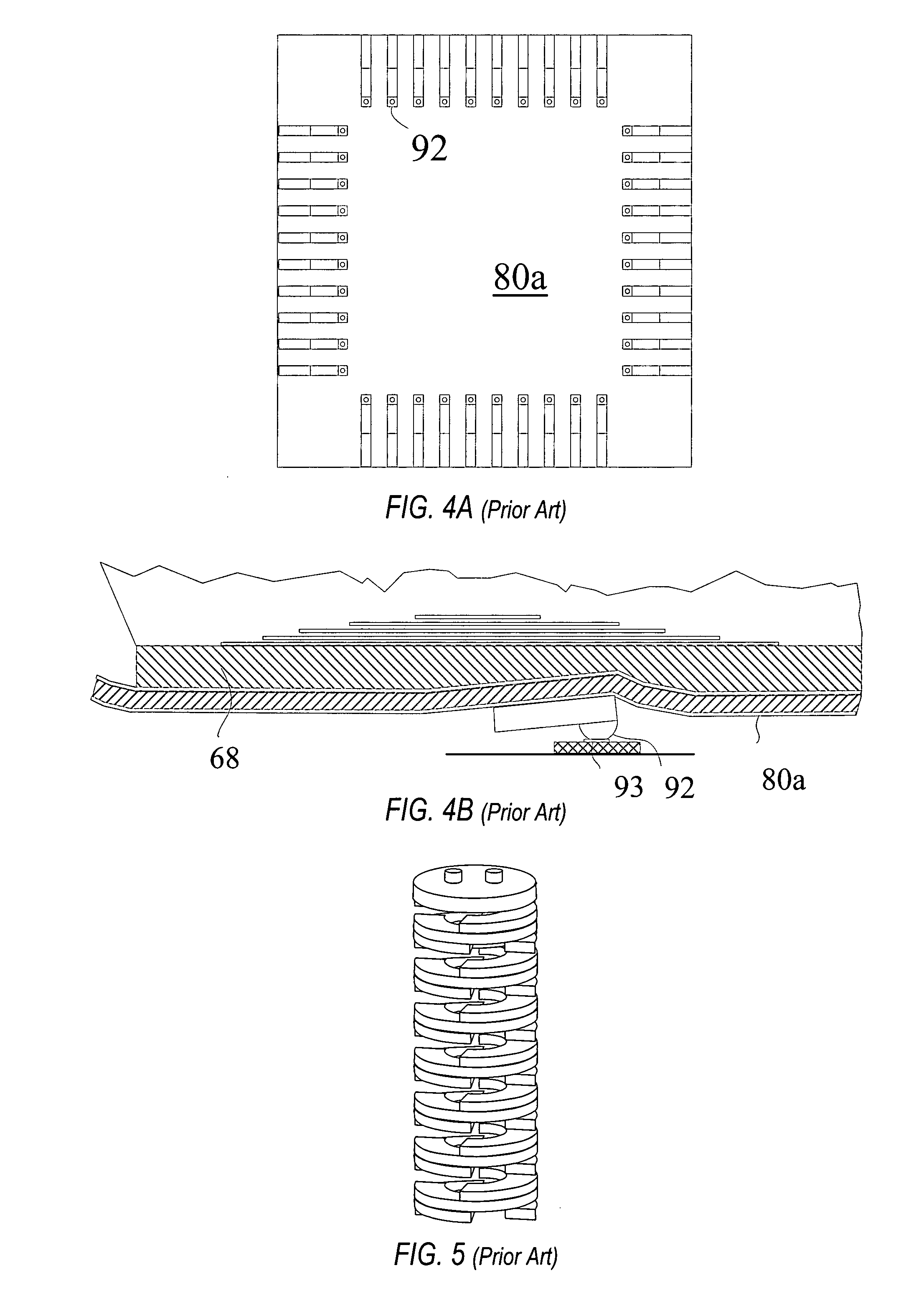

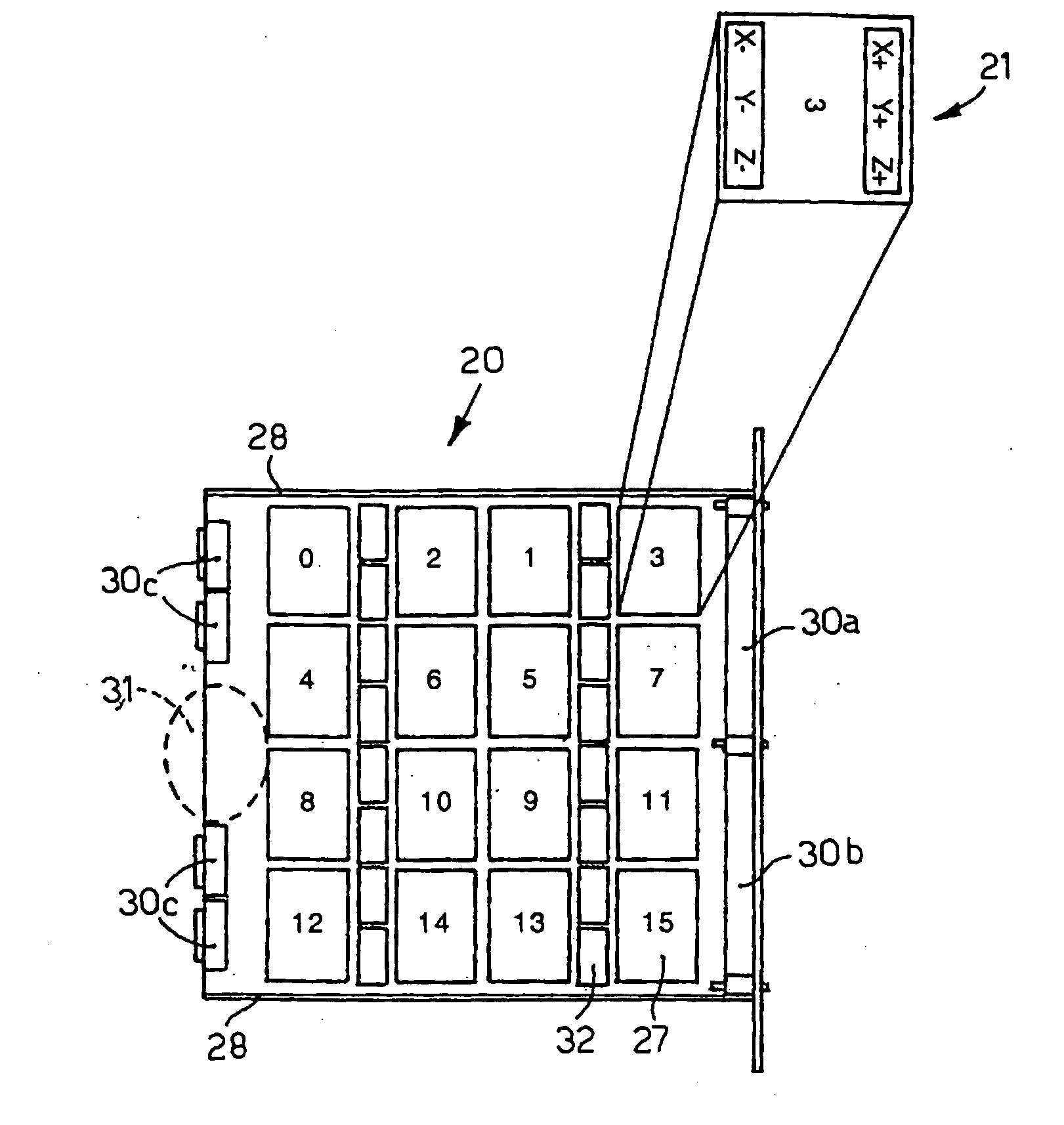

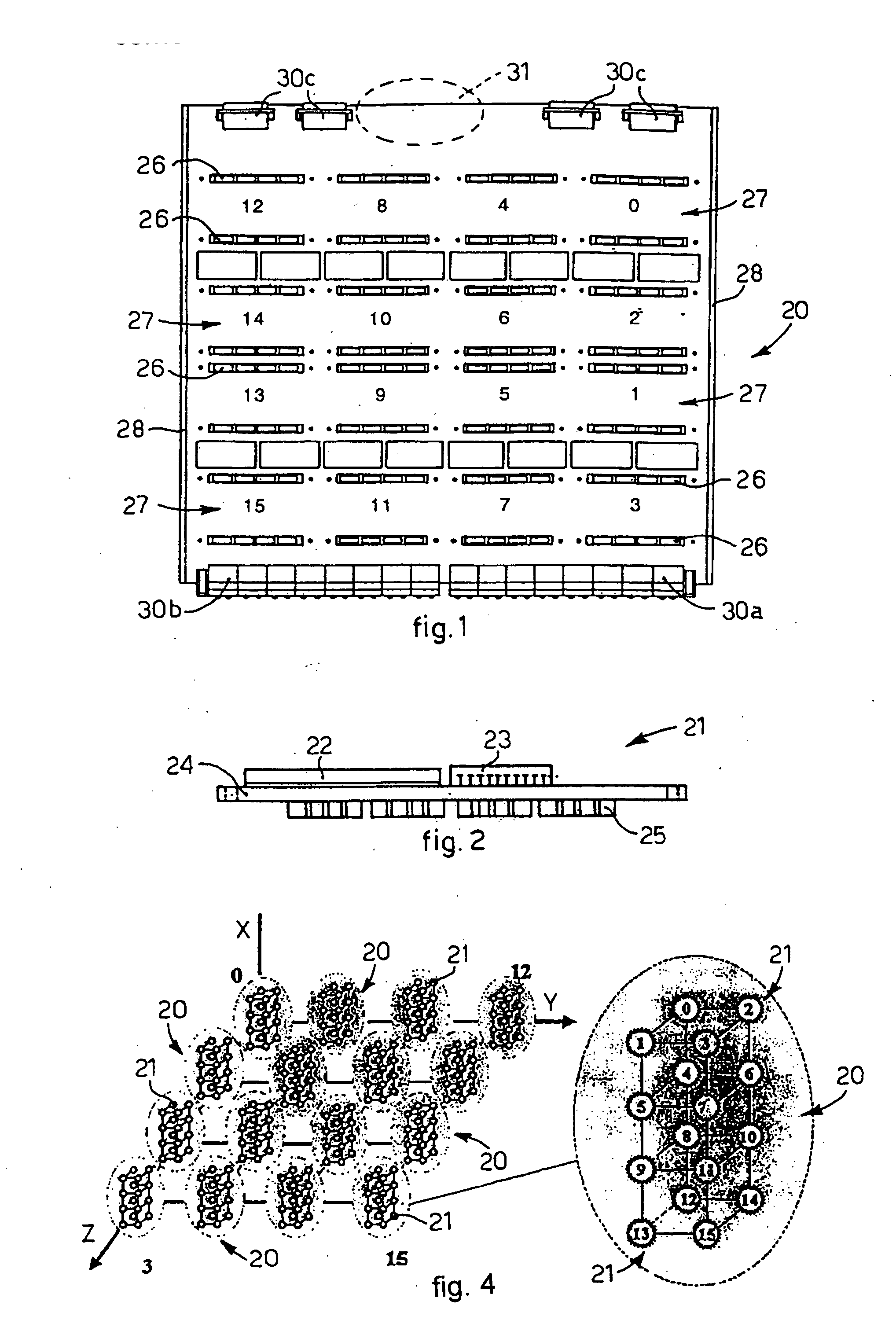

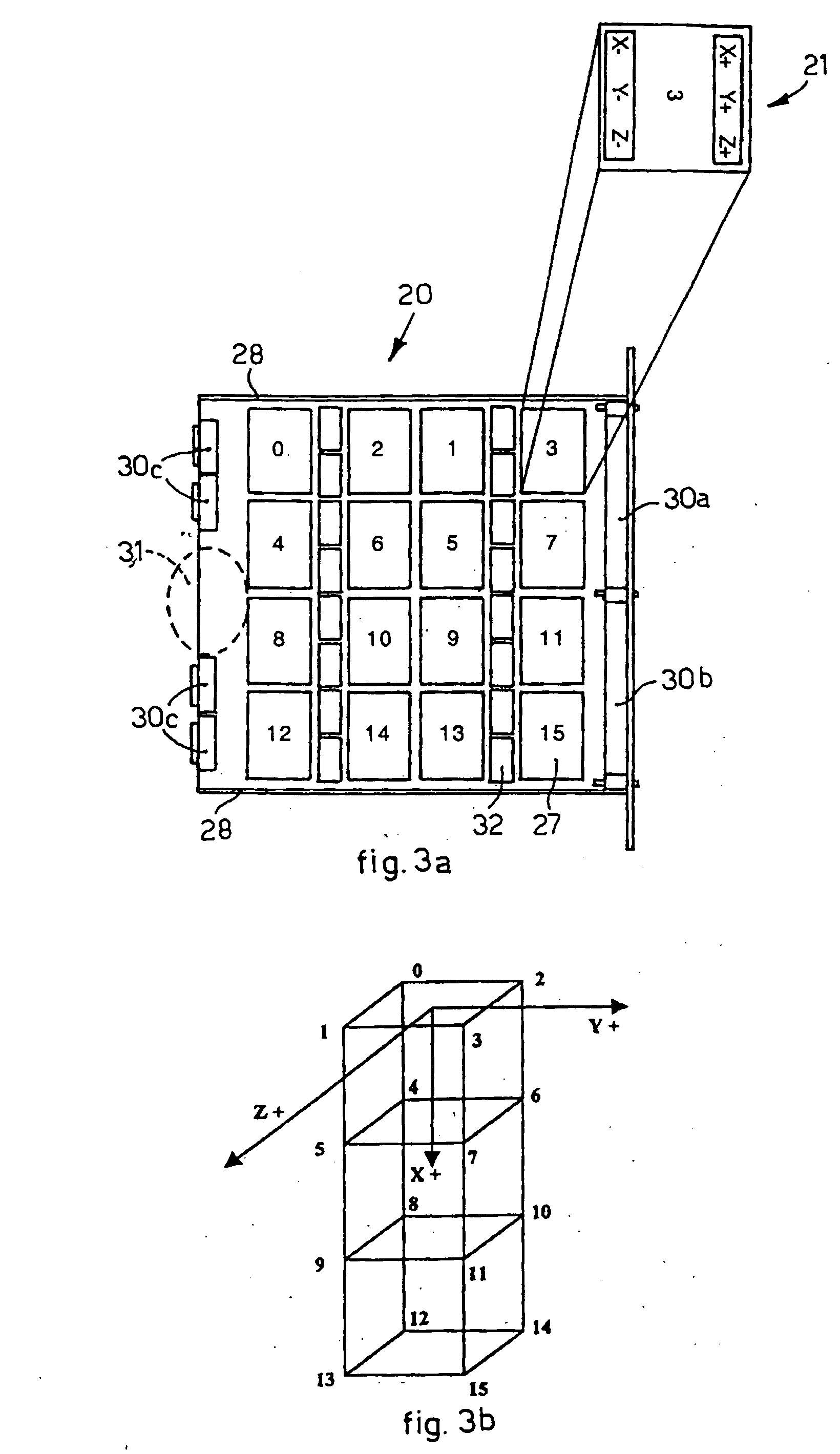

Modular electronic card for a communication network

InactiveUS20060060378A1Good homogeneity and uniformityGood impedance controlElectrical connection printed elementsElectric digital data processingIndependent groupSpatial density

Modular electronic card to support and manage a plurality of calculation nodes and their interconnections with a three-dimensional topology, wherein each node includes a card carrying at least a processing unit, a memory battery and connection members with the modular card. The modular electronic card has a spatial density of the calculation nodes equal, on the surface, to at least 0.8 nodes per square decimeter, given a node that has at least 108 differential connections divided into 12 independent groups, two for each of the fundamental directions (x, y, z) of the 3D topology.

Owner:EUROTECH

RF pcb connection structure and connection method

ActiveCN106211570BTo achieve signal connectivitySignal connectivity satisfiesStacked PCBsElectrical connection printed elementsRadio frequency circuitsEngineering

The invention discloses a radio frequency PCB connecting structure and connecting method. The radio frequency PCB connecting structure comprises a first PCB and a second PCB. The first PCB is arranged above the second PCB, a first radio-frequency circuit is arranged on the top layer of the first PCB, a first signal welding disc is arranged on the bottom layer of the first PCB, and the first radio-frequency circuit is electrically connected with the first signal welding disc through a signal through hole; a second radio-frequency circuit is arranged on the top layer of the second PCB, a second signal welding disc corresponding to the first signal welding disc is arranged on the second radio-frequency circuit, and the first signal welding disc and the second signal welding disc are welded. According to the radio frequency PCB connecting structure and connecting method, the first radio-frequency circuit is communicated with the first signal welding disc through the signal through hole, then the first signal welding disc and the second signal welding disc located on the second radio-frequency circuit are welded, and signal communication between the first radio-frequency circuit and the second radio-frequency circuit is achieved.

Owner:COMBA TELECOM SYST CHINA LTD

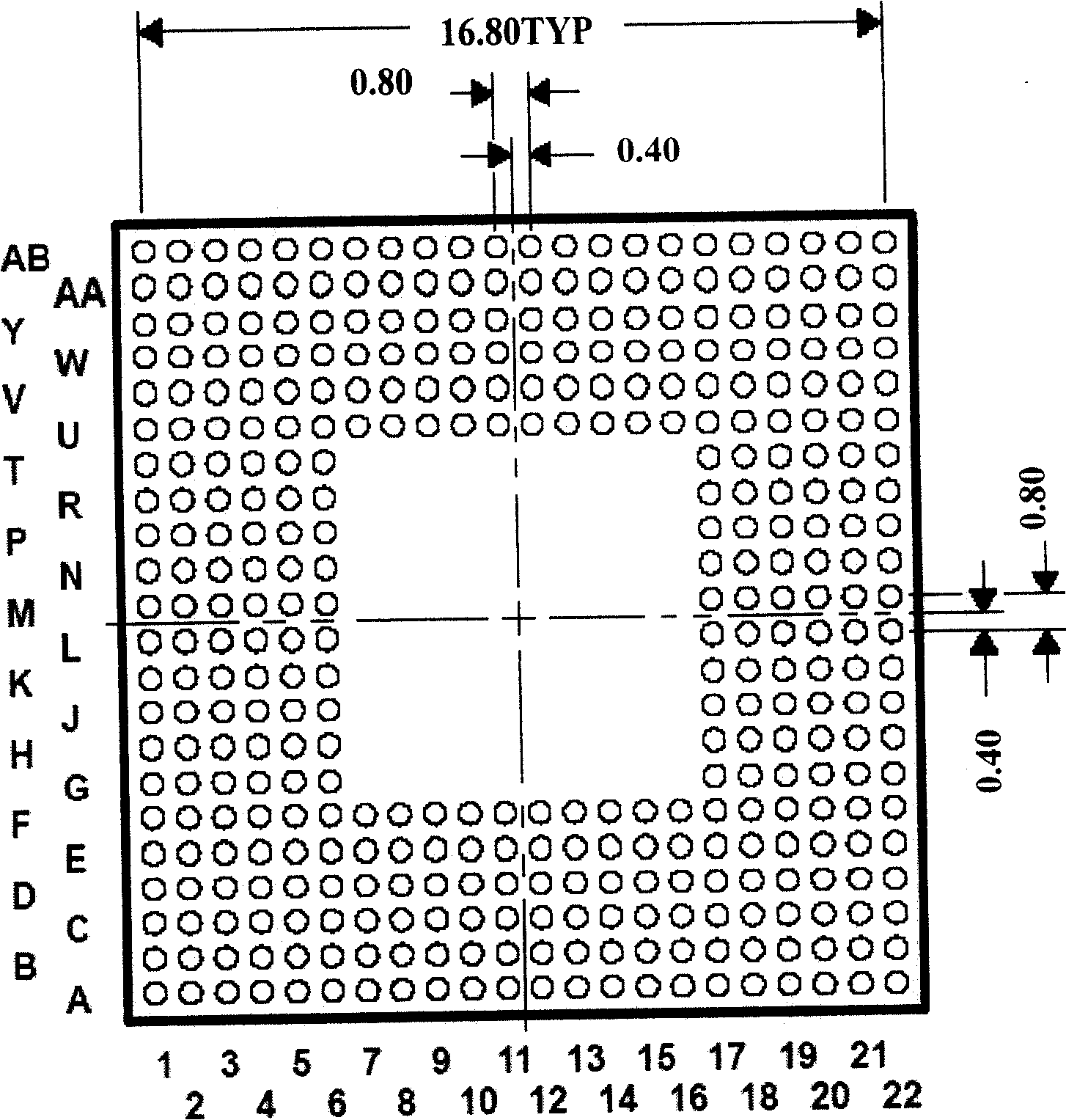

High-density BGA printed circuit board wiring method

InactiveCN100441071CYield is easy to guaranteeEasy to routePrinted element electric connection formationElectricityHigh density

The method for high-dense ball contact matrix PEB routing comprises: for said PCB with small span, according to size parameters and technical requirements of BGA bonding pad, calculating maximal diameter of past-hole top bonding pad to obtain a hole-past hole diameter larger a little than said maximal diameter for PCB; if two adjacent past-holes do not conduct electricity on the signal layer, then gets rid of said past-hole pad or decreases diameter of said common pad to cross a signal wire between two holes. This invention can increase past-hole diameter and plate thickness benefit to control impedance and solve problem hard to cross signal wire.

Owner:HUAWEI TECH CO LTD

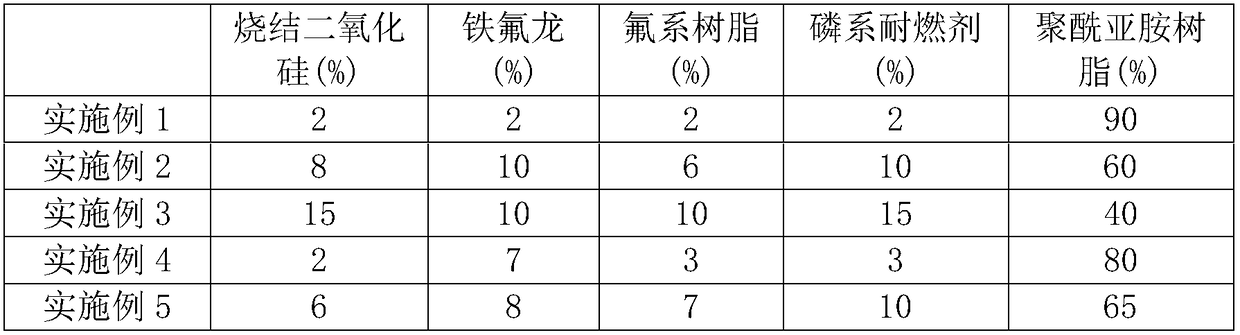

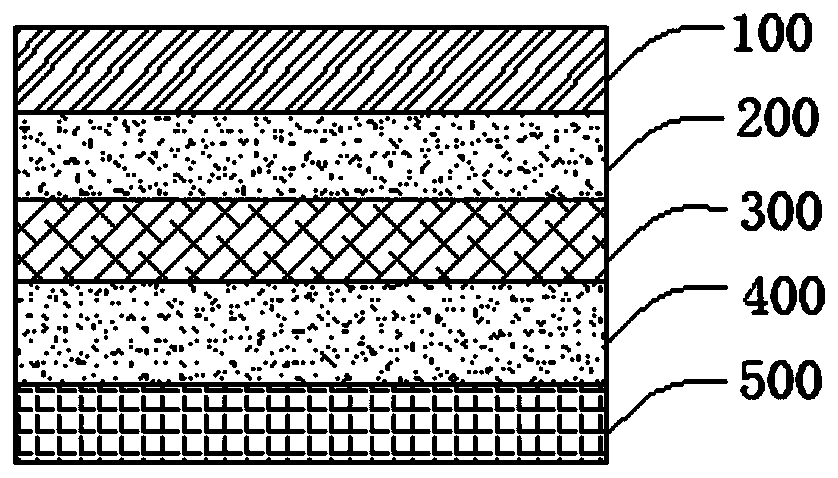

High-uniformity multi-layer impedance flexible circuit board and fabrication method thereof

InactiveCN106793481ALow dielectric constantImproved Impedance ControlCircuit susbtrate materialsMultilayer circuit manufactureFlexible circuitsImpedance control

The invention provides a high-uniformity multi-layer impedance flexible circuit board and a fabrication method thereof. By employing a base layer, a dielectric constant of the impedance flexible circuit board using the base layer can be effectively reduced, and impedance control of the impedance flexible circuit board is improved; by combining an impedance layer material provided by the invention and by means of a formulation and synergistic effect of each constituent, the impedance flexible circuit board has lower dielectric constant compared with an impedance flexible circuit board which has the same thickness structure and uses a traditional glass fabric; the fabrication method of the circuit board is simple and is easy to operate and master, accurate alignment among layers and uniform stress are achieved, plate sliding and pressure loss can be prevented, a product is high in quality, and a positioning line is arranged by an infrared positioning emitter; and the impedance flexible circuit board after lamination is high in integral uniformity, the time that resin in a prepreg is in melting flowing is prolonged, full filling among a plurality of core board layers is ensured, flowing is uniform, the efficiency is greatly improved, and a lamination parameter is optimized.

Owner:GUANGDONG KINGSHINE ELECTRONICS TECH CO LTD

Electronic apparatus equipped with flexible boards

ActiveUS11147155B2Ease of incorporating a flexible boardImproved Impedance ControlTelevision system detailsCross-talk/noise/interference reductionStructural engineeringGround line

An electronic apparatus which achieves ease of incorporating flexible boards into the electronic apparatus and ease of impedance control at the same time. A first flexible board and a second flexible board are placed along a structure having a bent portion and a flat portion. Differential signal wires are wired on one surface of the first flexible board placed between the structure and the second flexible board, and first ground wires for impedance control of the differential signal wires are wired on the other surface and on a rear side of the differential signal wires. Second ground wires for impedance control of the differential signal wires are wired on one surface of the second flexible board the one surface of the first flexible board faces. A wiring density of the first and second ground wires differs between an area along the bent portion and an area along the flat portion.

Owner:CANON KK

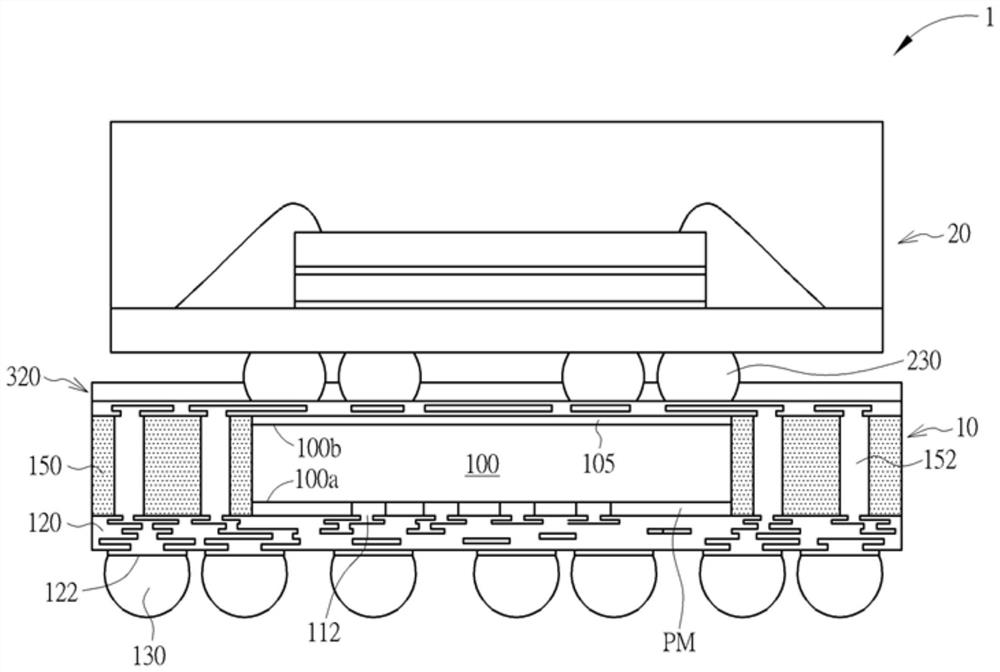

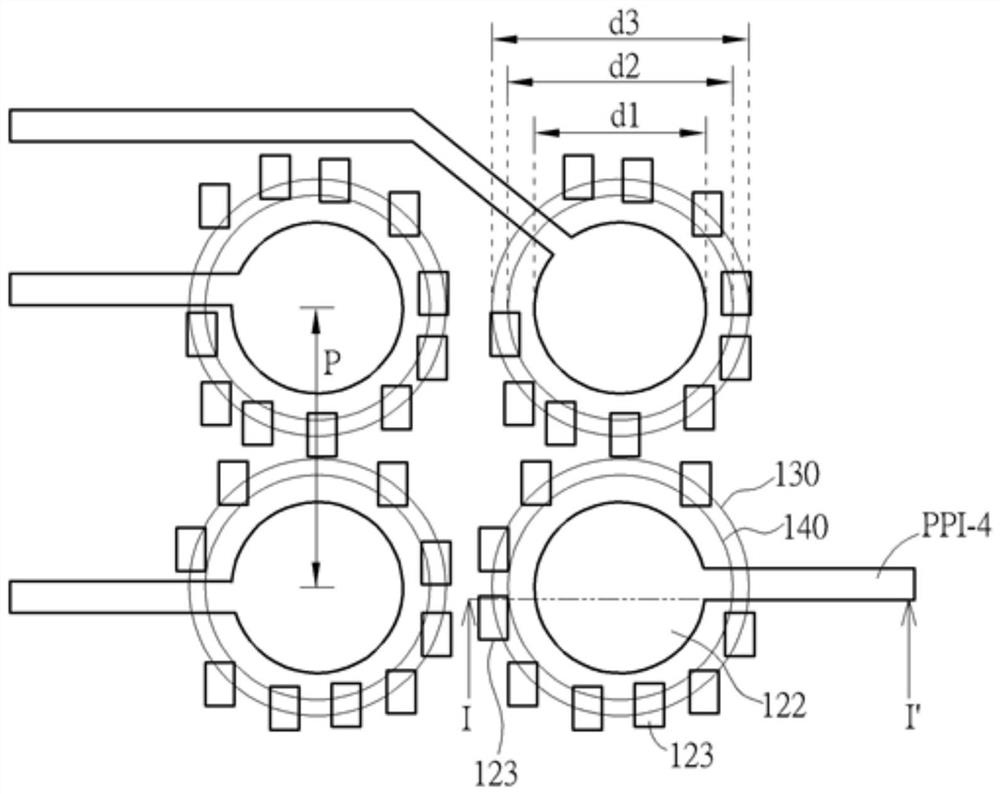

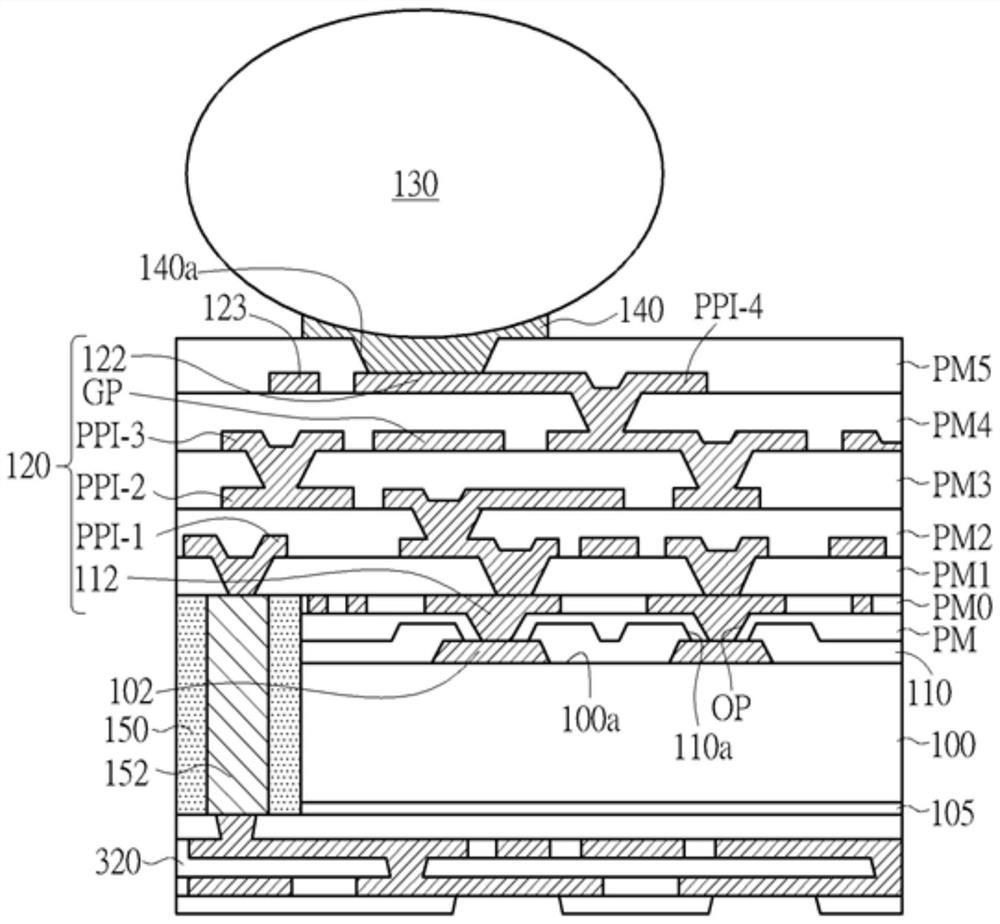

Semiconductor structure

PendingCN114823605AImproved Impedance ControlSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureSolder ball

The invention provides a semiconductor structure capable of improving impedance control. A semiconductor structure includes a semiconductor die having an active surface, a passivation layer covering the active surface of the semiconductor die, and a post-passivation interconnect (PPI) layer disposed over the passivation layer. The PPI layer includes a ball pad having a first diameter. The polymer layer covers the periphery of the ball pad. An under bump metal (UBM) layer is disposed on the ball pad. The second diameter of the UBM layer is greater than the first diameter of the ball pad. A solder ball is mounted on the UBM layer.

Owner:MEDIATEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com