Difference etching solution for semi-additive process preparation fine line

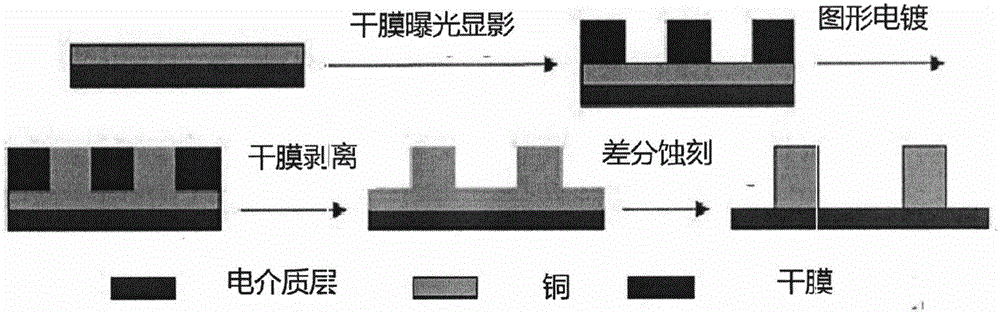

A technology of differential etching and fine lines, applied in chemical/electrolytic methods to remove conductive materials, etc., can solve problems such as difficulty in controlling high-frequency line impedance, insufficient selectivity of copper-reducing solution, and inability to maintain rectangular shape, achieving macroscopic The vision is clean and bright, the side etching effect is improved, and the effect of impedance control is beneficial.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare a differential etching solution according to the following ratio, where the solvent is deionized water, and prepare 800L of solution.

[0022]

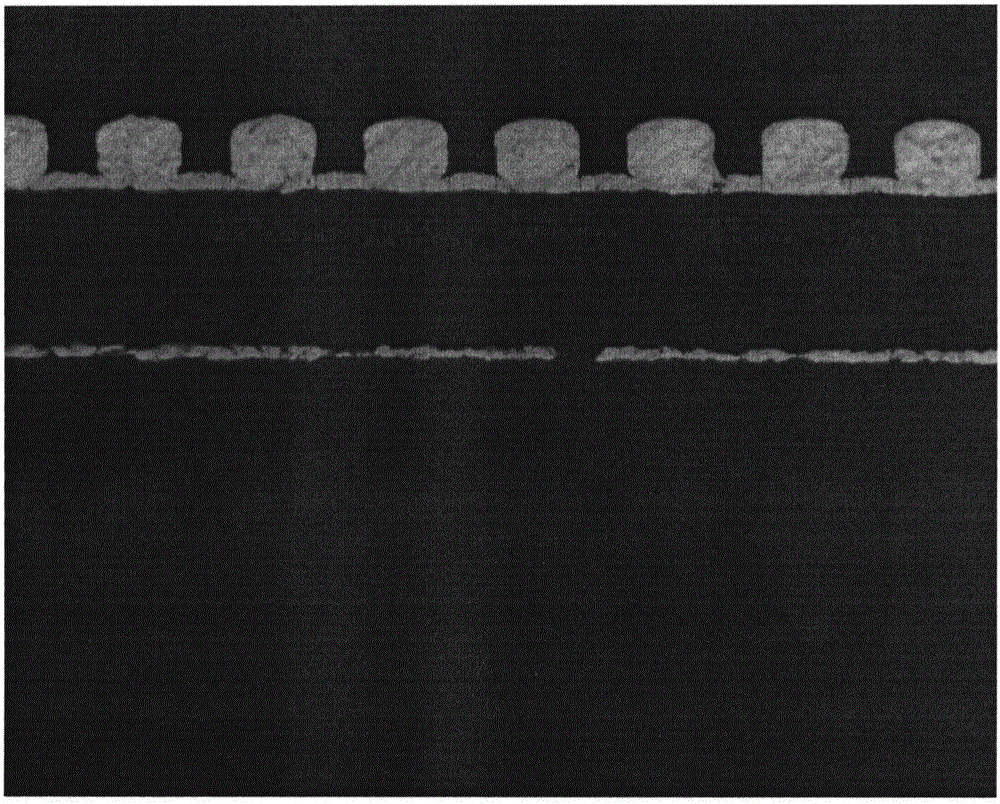

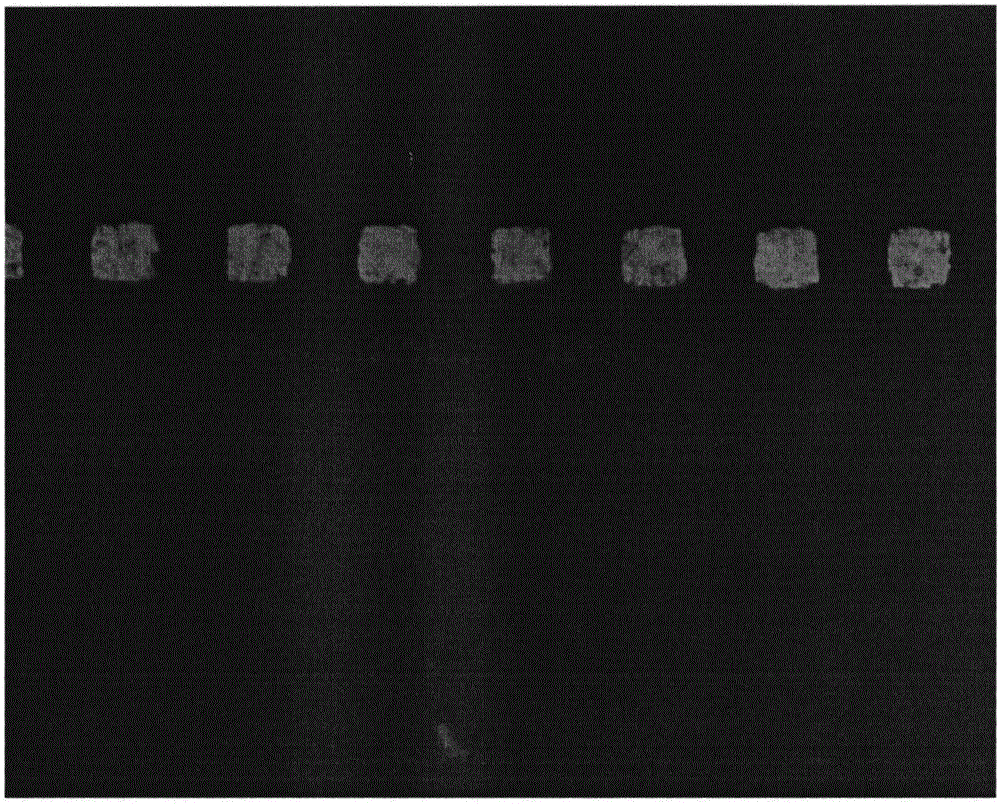

[0023] Put the prepared solution into the horizontal differential etching production equipment, set the corresponding speed according to the length of the treatment tank, check the differential etching rate, observe the line section through a metallographic microscope after differential etching, and observe whether there is side etching and bottom etching. Whether the copper is removed cleanly, whether the cross-section of the circuit remains a good rectangle, and at the same time observe the microscopic morphology of the circuit surface through the scanning electron microscope, and whether it has a certain roughness. The metallographic section pictures of the line section before and after differential etching are as follows: figure 2 and image 3 as shown, Figure 4 It is the SEM picture of the circuit topography...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com