Double-sided copper foil substrate for pi-type high-frequency and high-speed transmission and preparation method thereof

A double-sided copper foil, high-speed transmission technology, applied in circuit substrate materials, chemical instruments and methods, applications, etc., can solve problems such as poor mechanical strength, uneven film thickness, and poor electrical properties, and reduce line oxidation. risk, improve the quality of signal transmission, the effect of rapid heat dissipation and heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

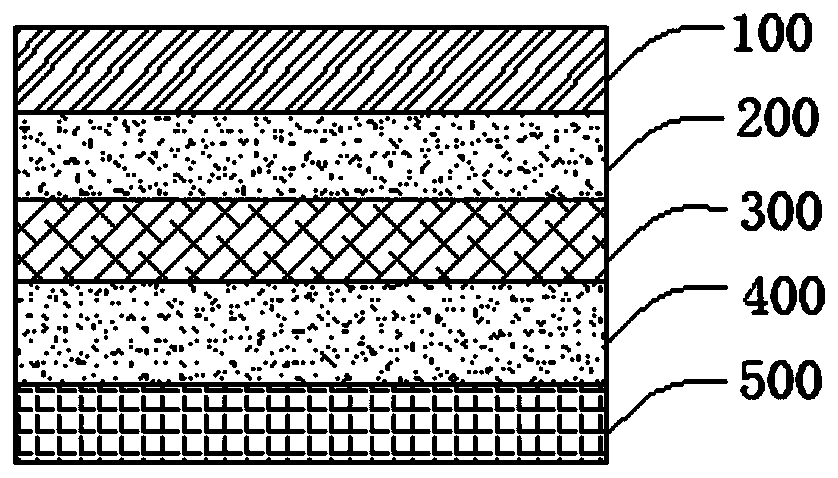

[0041] Example: a PI type double-sided copper foil substrate for high-frequency and high-speed transmission, such as figure 1 said, including

[0042] The core layer 300, the core layer is a polyimide film; the core layer has opposite upper and lower surfaces;

[0043] A very low dielectric adhesive layer, the very low dielectric adhesive layer has two layers and are respectively an upper very low dielectric adhesive layer 200 and a lower very low dielectric adhesive layer 400, and the upper very low dielectric adhesive layer 200 is formed On the upper surface of the core layer 300, the lower very low dielectric adhesive layer 400 is formed on the lower surface of the core layer 300;

[0044] A low-profile copper foil layer, the low-profile copper foil layer includes a first low-profile copper foil layer 100 and a second low-profile copper foil layer 500, and the first low-profile copper foil layer 100 is formed on the upper very low dielectric The upper surface of the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com