High-density BGA printed circuit board wiring method

A technology for printed circuit boards and spherical contacts, which is used in printed circuits, printed circuit manufacturing, electrical components, etc. It can solve problems such as thin board thickness and difficulty in passing two vias through signal lines, and achieve easy-to-guaranteed yields. Conducive to impedance control and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

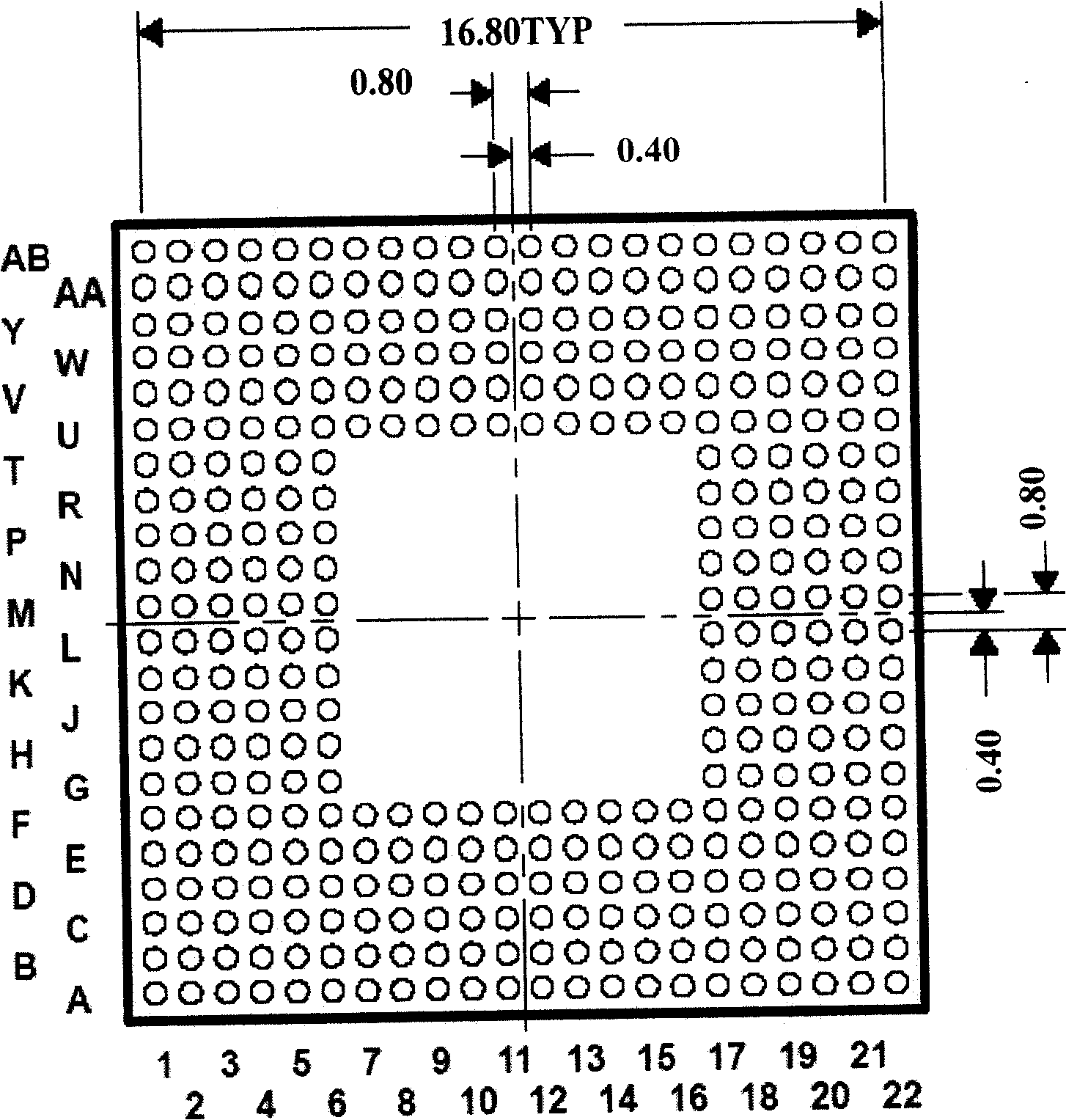

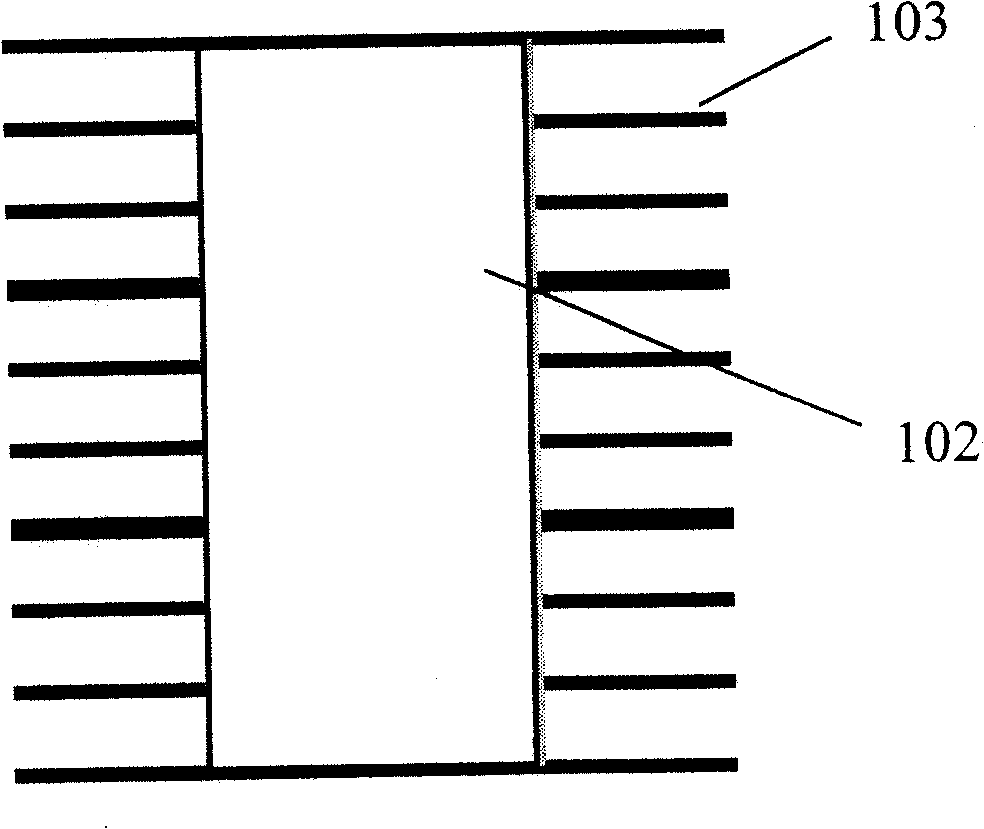

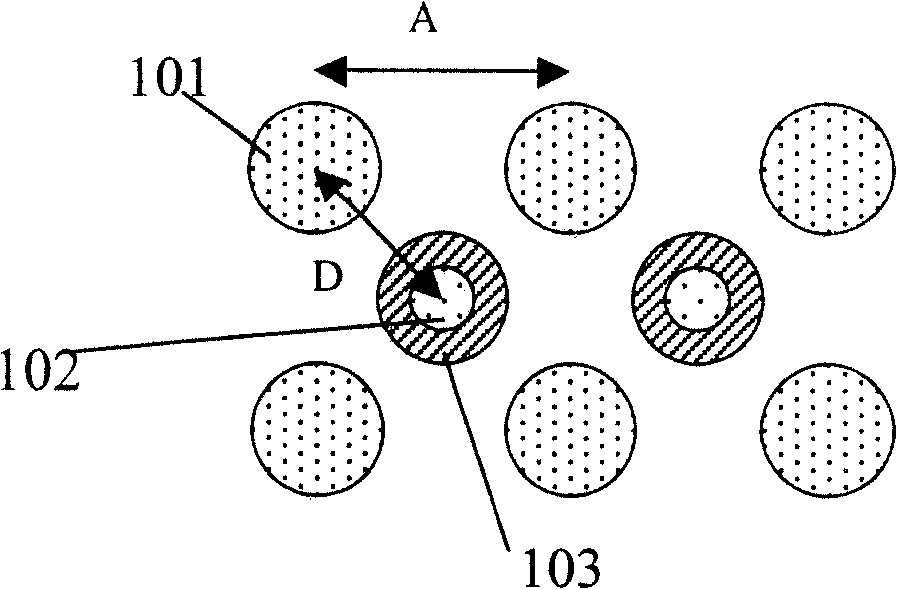

[0028] For small-pitch ball contact array printed circuit boards (that is, ball contact array printed circuit boards with a center-to-center spacing of 0.8 mm or less between adjacent ball contacts), the present invention provides a wiring method First, according to the size parameters and process requirement parameters of the small-pitch BGA pads of the printed circuit board, the maximum diameter d2 of the via top-layer pad is calculated, that is, the aforementioned distance between the device pad and the center of the via pad ( Assumed to be D), and the diameter of the device pad (assumed to be d1), the minimum spacing allowed from the device pad to the via pad (assumed to be D2) for calculation, and the calculation of the maximum diameter (d2) of the via top layer pad The formula is: d2=(D-D2-d1 / 2)*2. According to the maximum diameter of the pad on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com